Patents

Literature

51results about How to "Without reducing productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

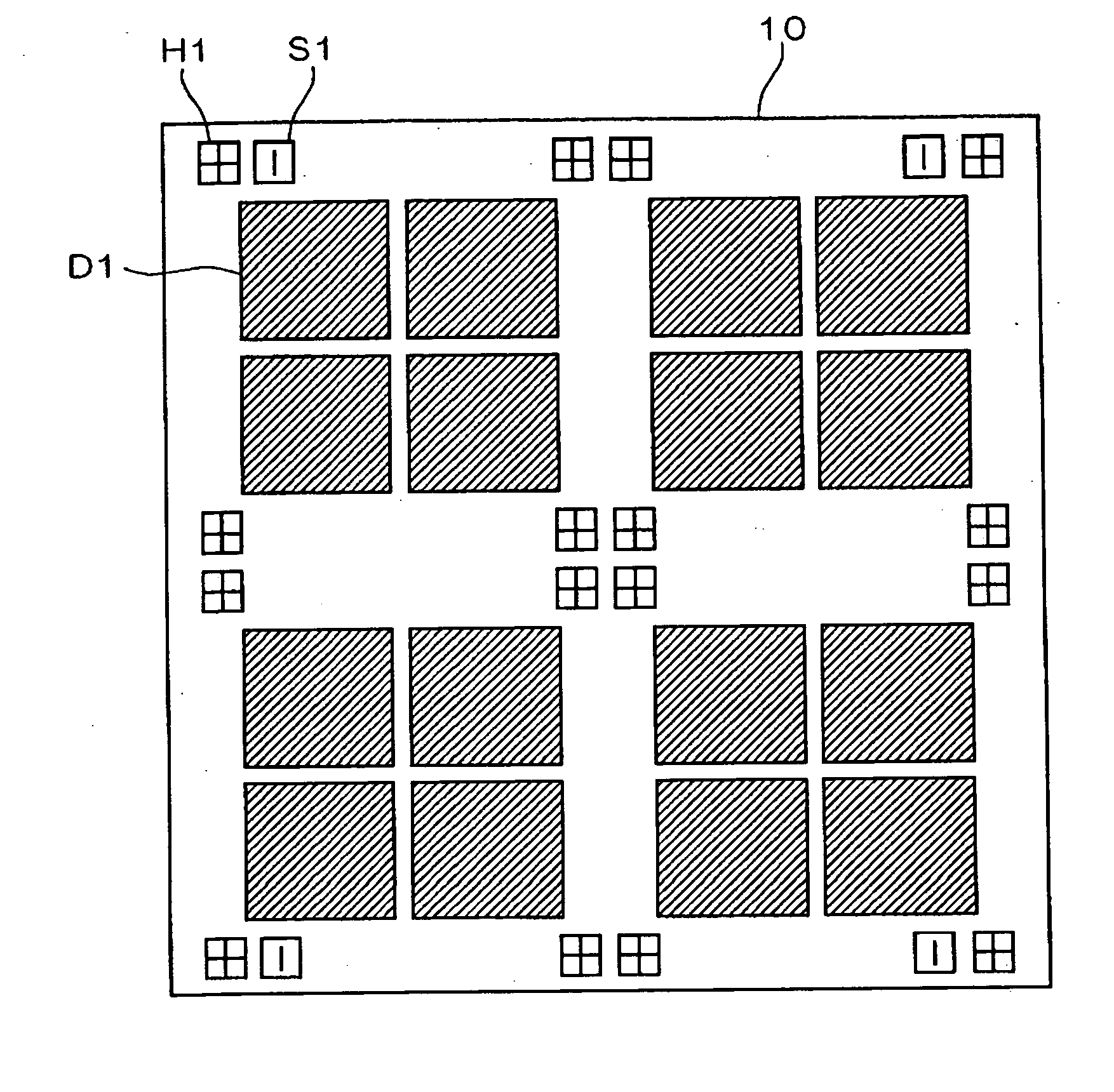

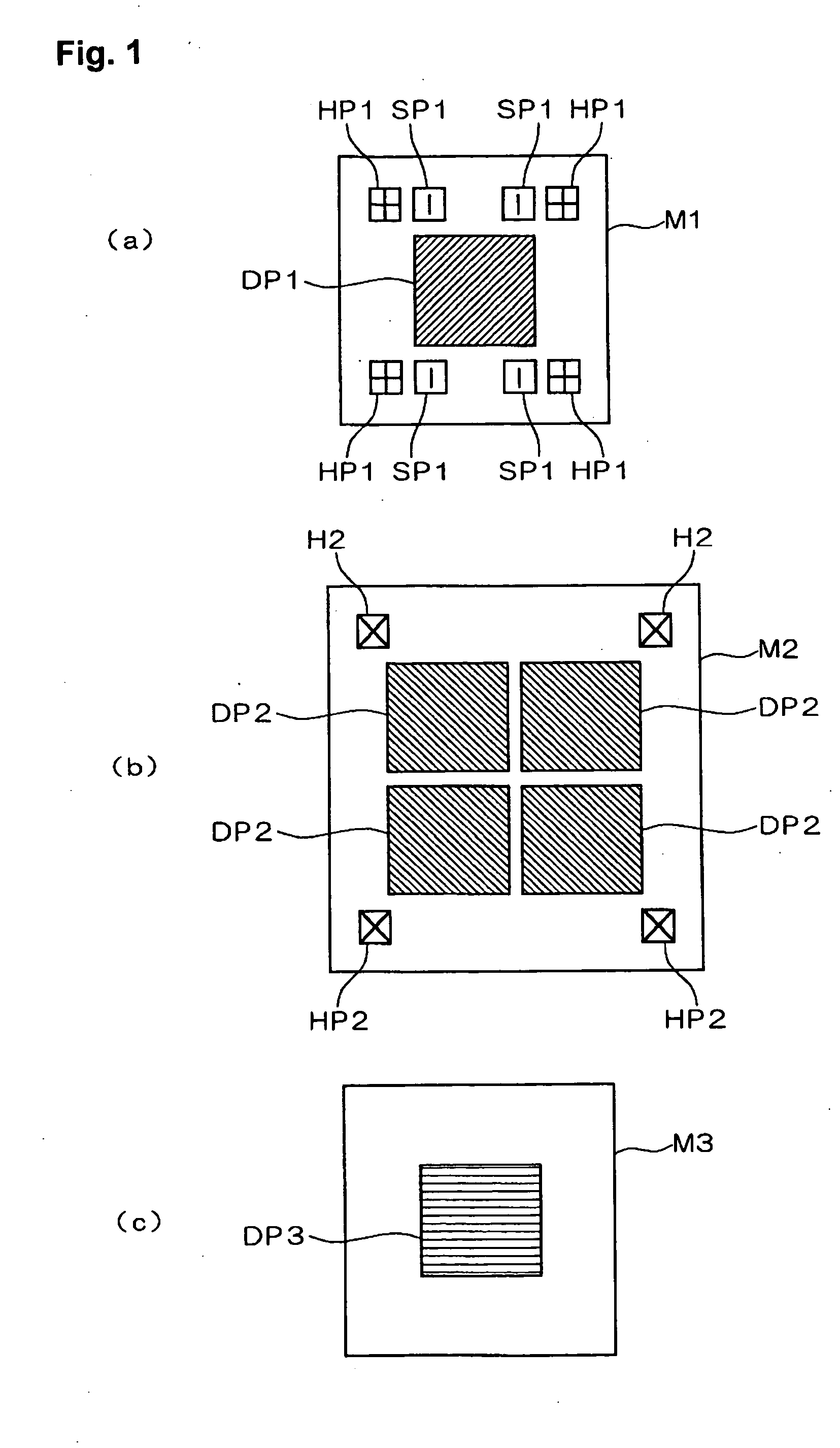

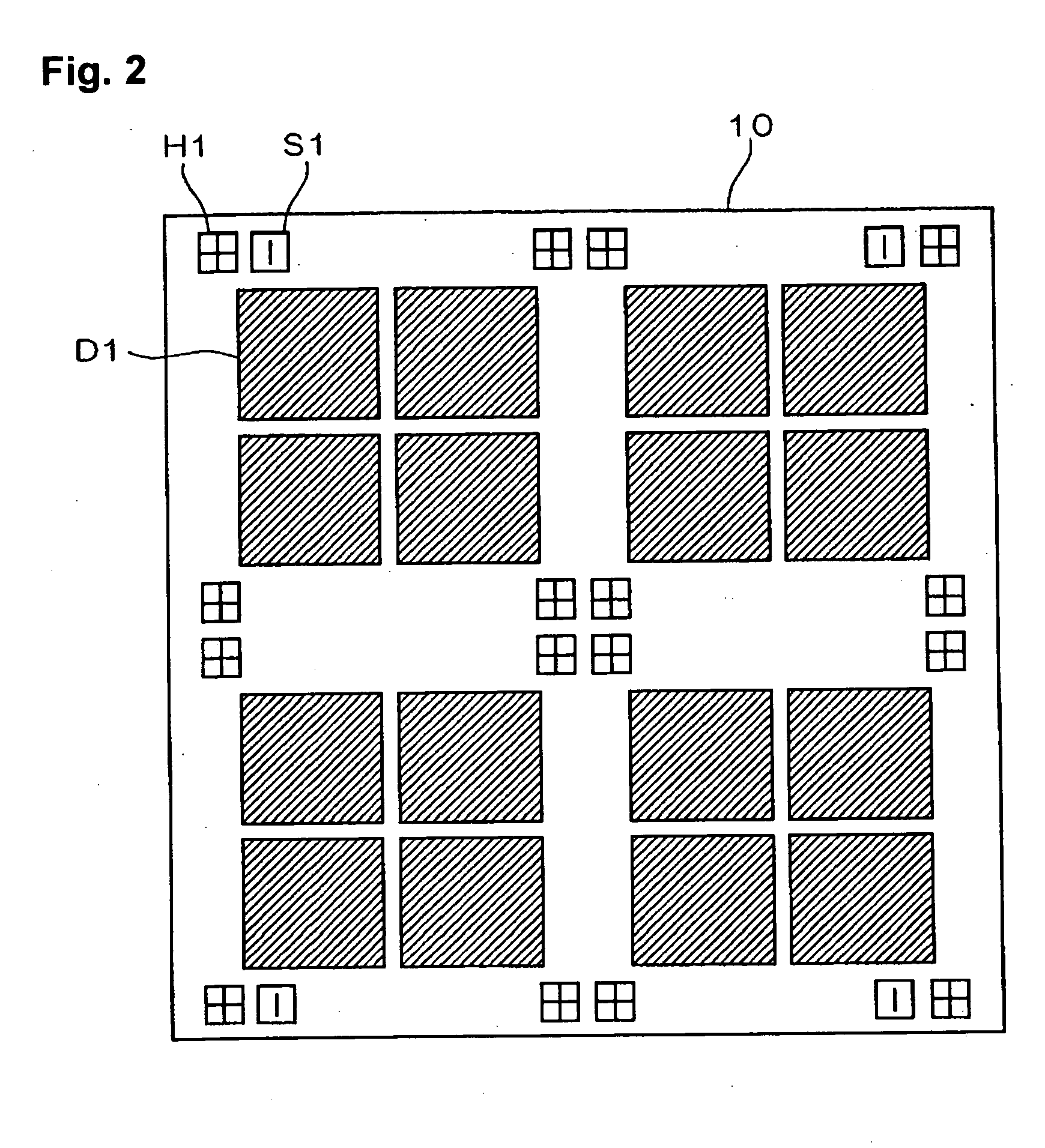

Method for fabricating semiconductor device, and electro-optical device, integrated circuit and electronic apparatus including the semiconductor device

InactiveUS7547589B2High resolutionDecrease productivityTransistorOther printing matterProduction rateEngineering

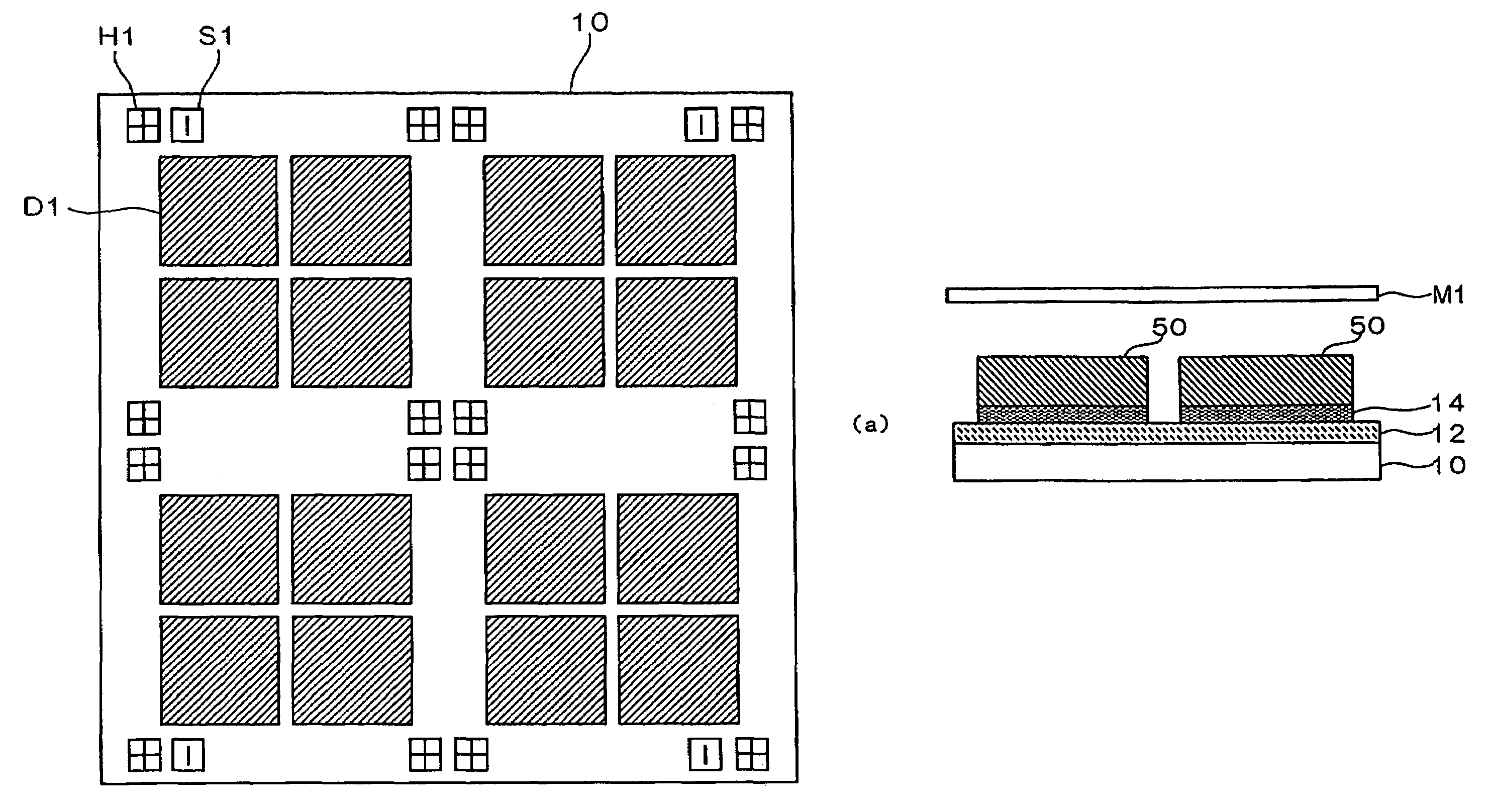

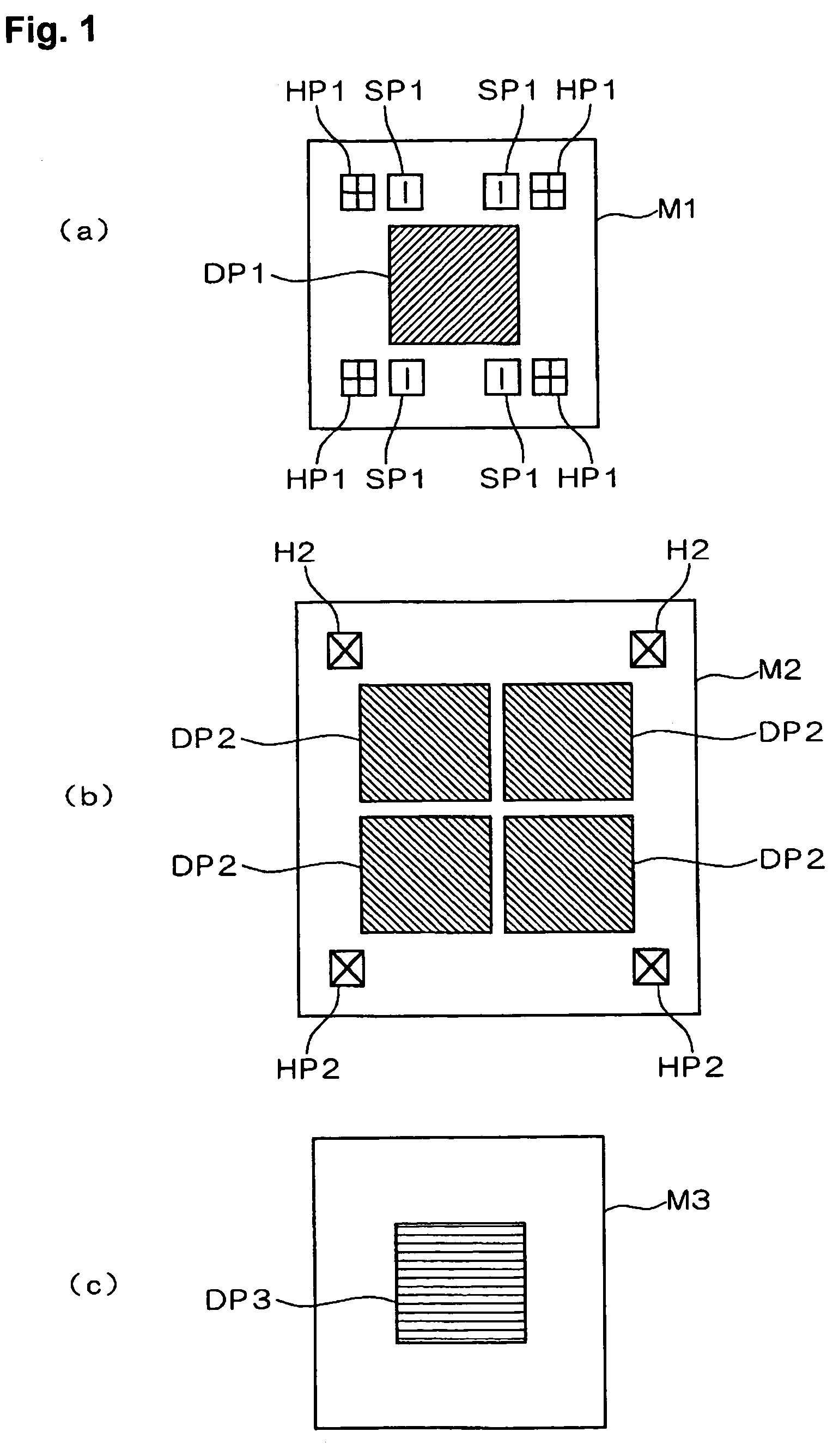

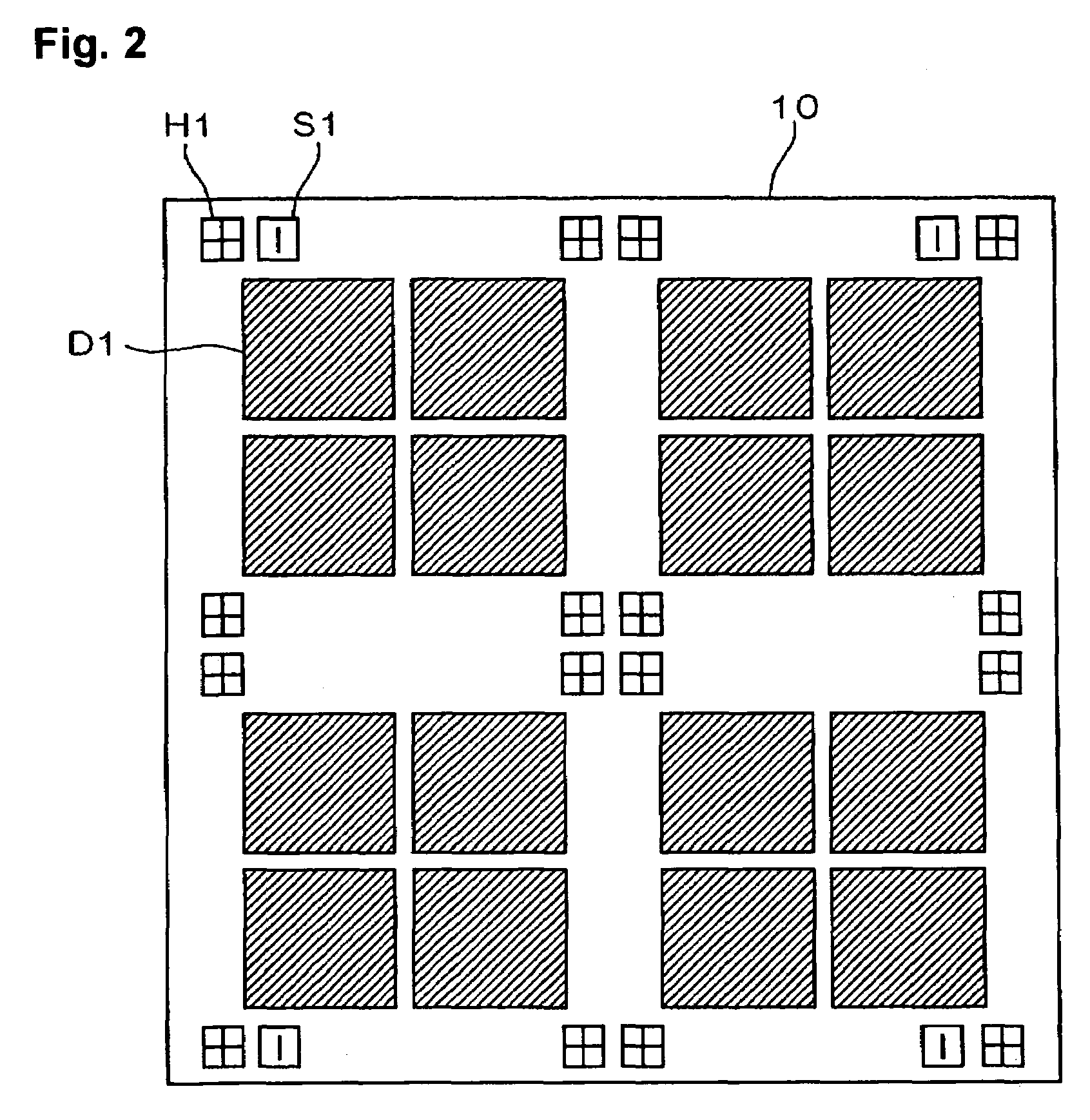

The invention provides a technique that enables formation of minute patterns on an uneven substrate in volume production without reducing productivity. The method for fabricating a semiconductor device includes: first patterning a semiconductor film on a substrate to form element regions, each of which will be provided with a source / drain region and a channel region, second forming a gate insulating film covering segments of the patterned semiconductor film in the respective element regions, third forming gate electrodes on the gate insulating film at predetermined positions, and fourth forming the source / drain region and the channel region in each element region. At least the gate electrodes are formed by a process including an exposure step through a holographic exposure mask in the third step, and by a process including an exposure step through a projection exposure mask, the element regions are formed in the first step, and the source / drain regions and the channel regions are formed in the fourth step.

Owner:SEIKO EPSON CORP

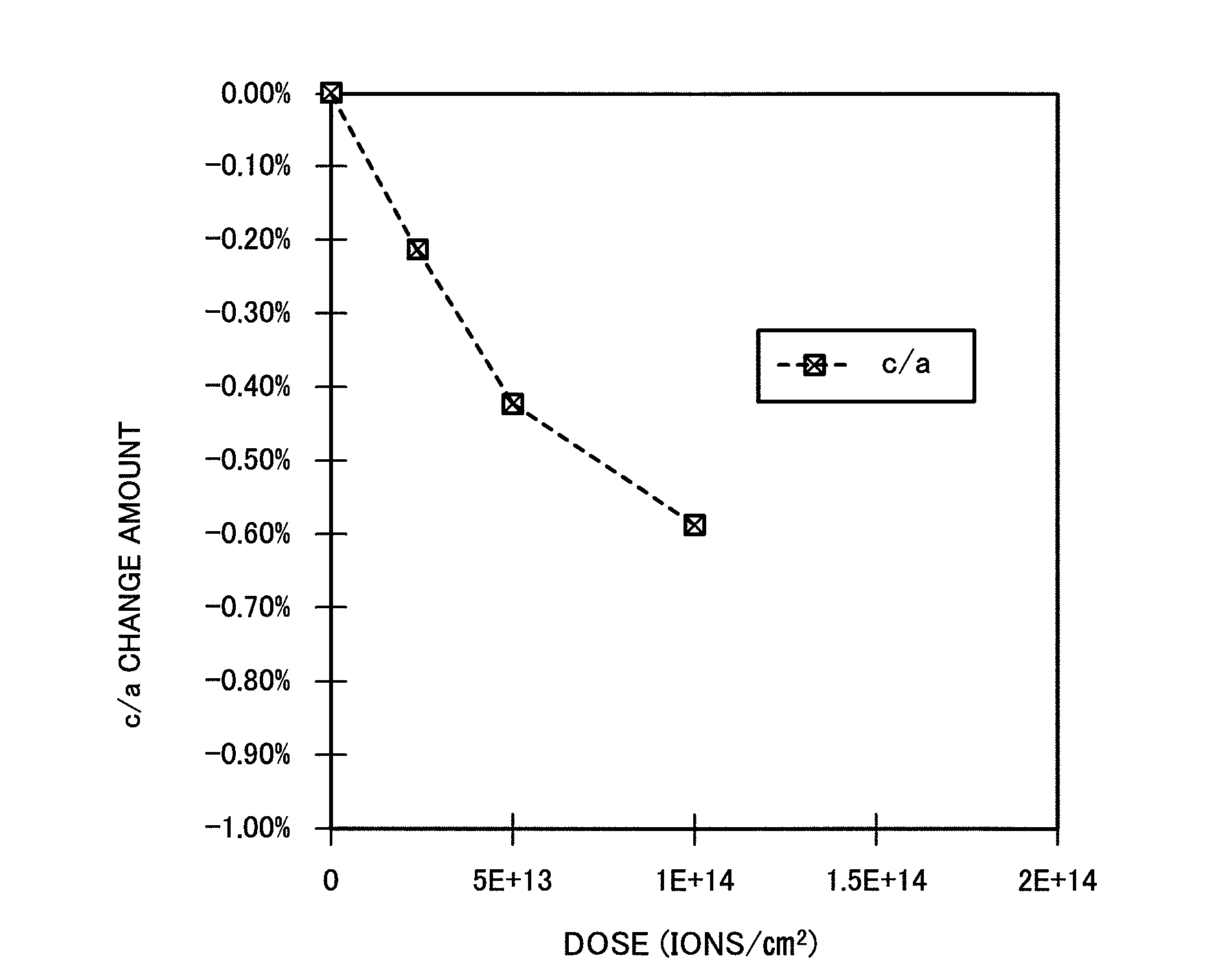

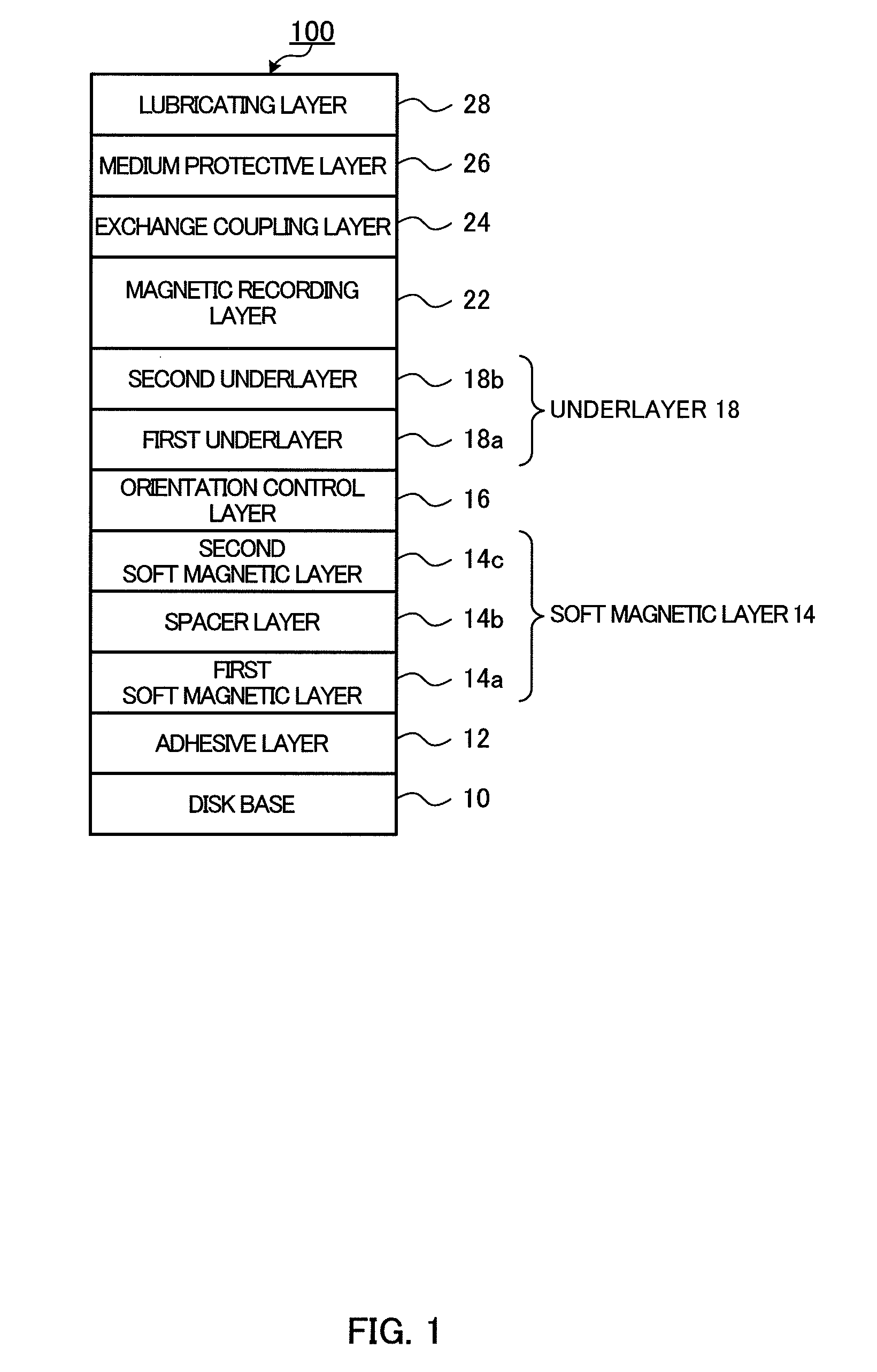

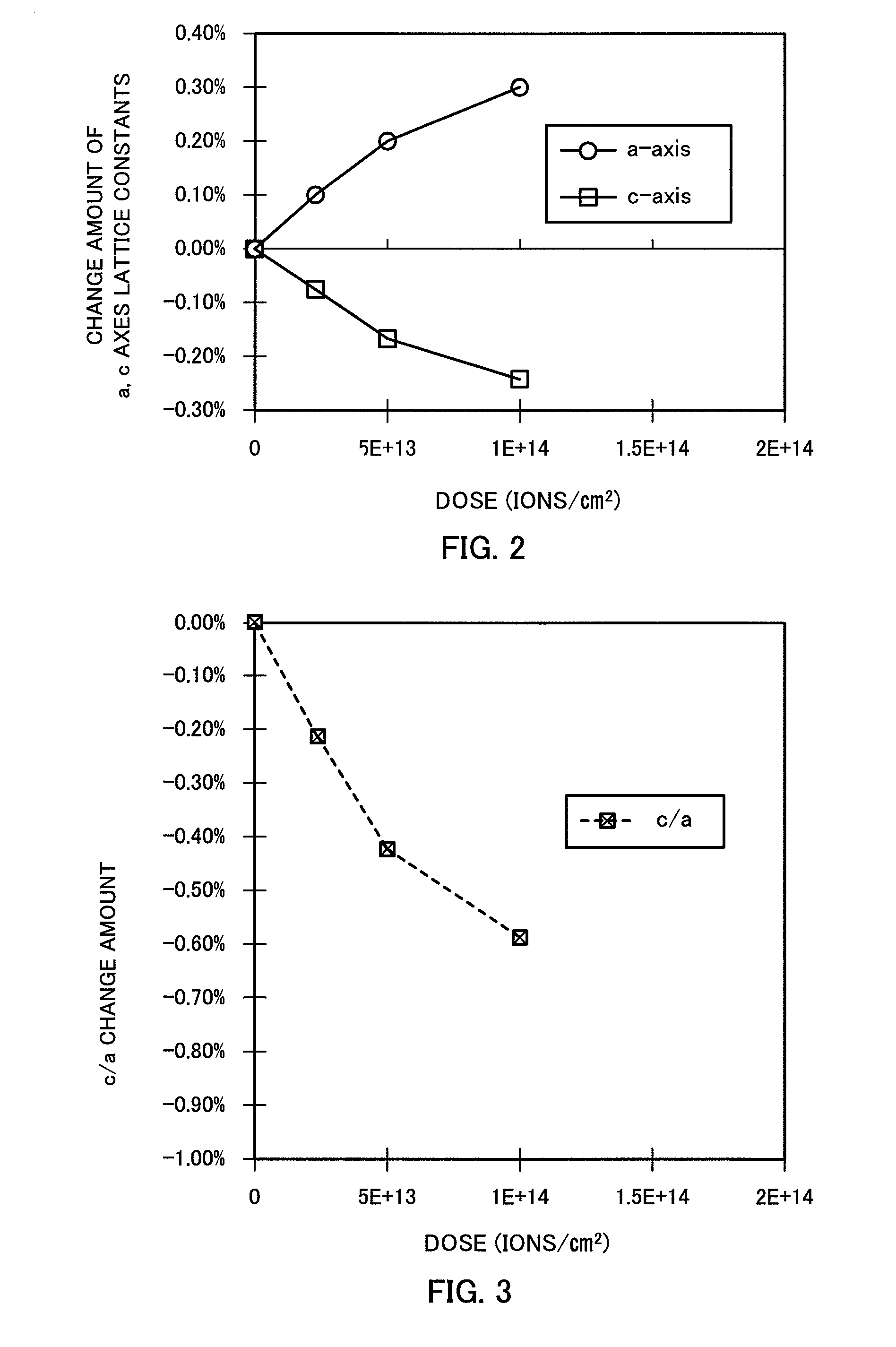

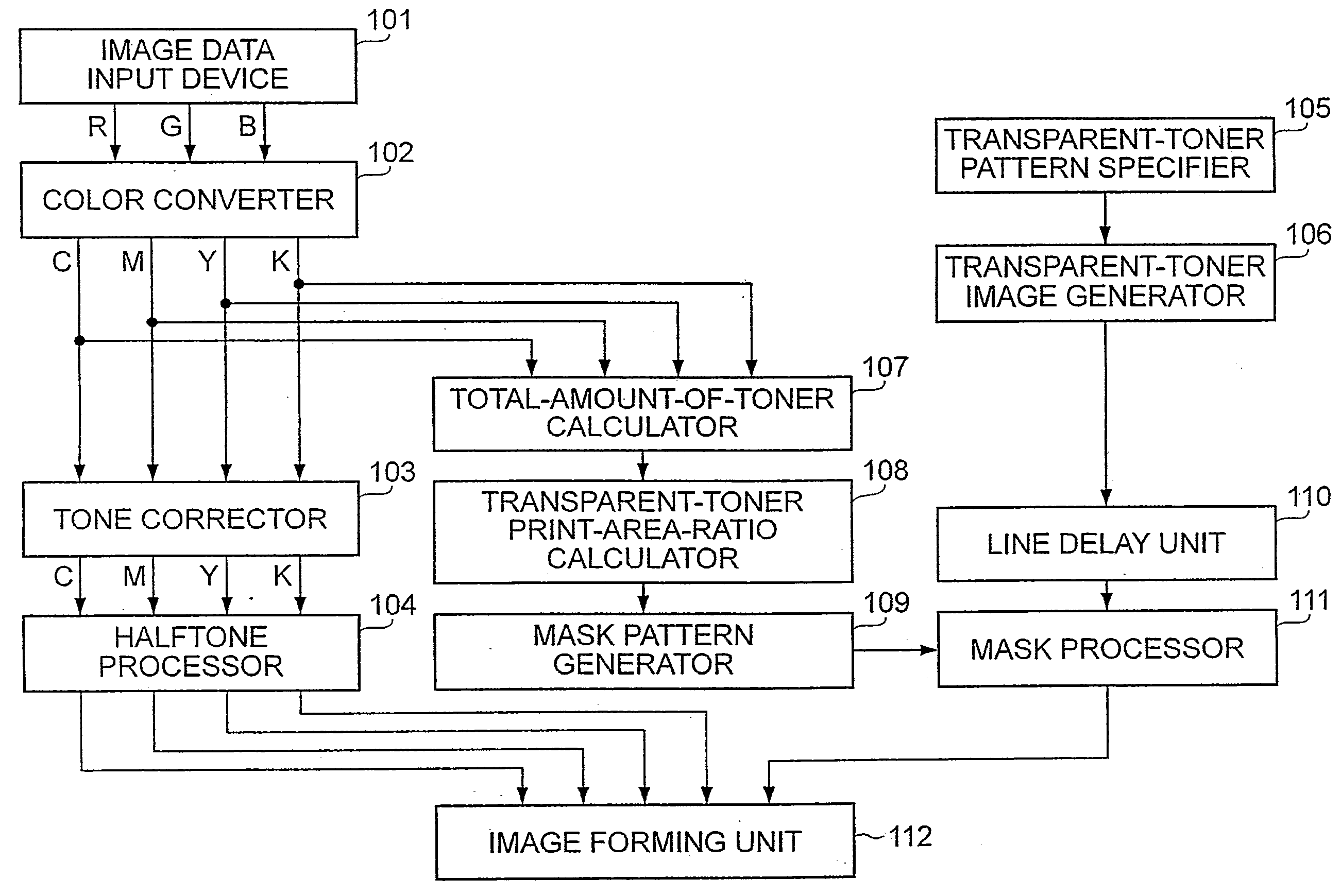

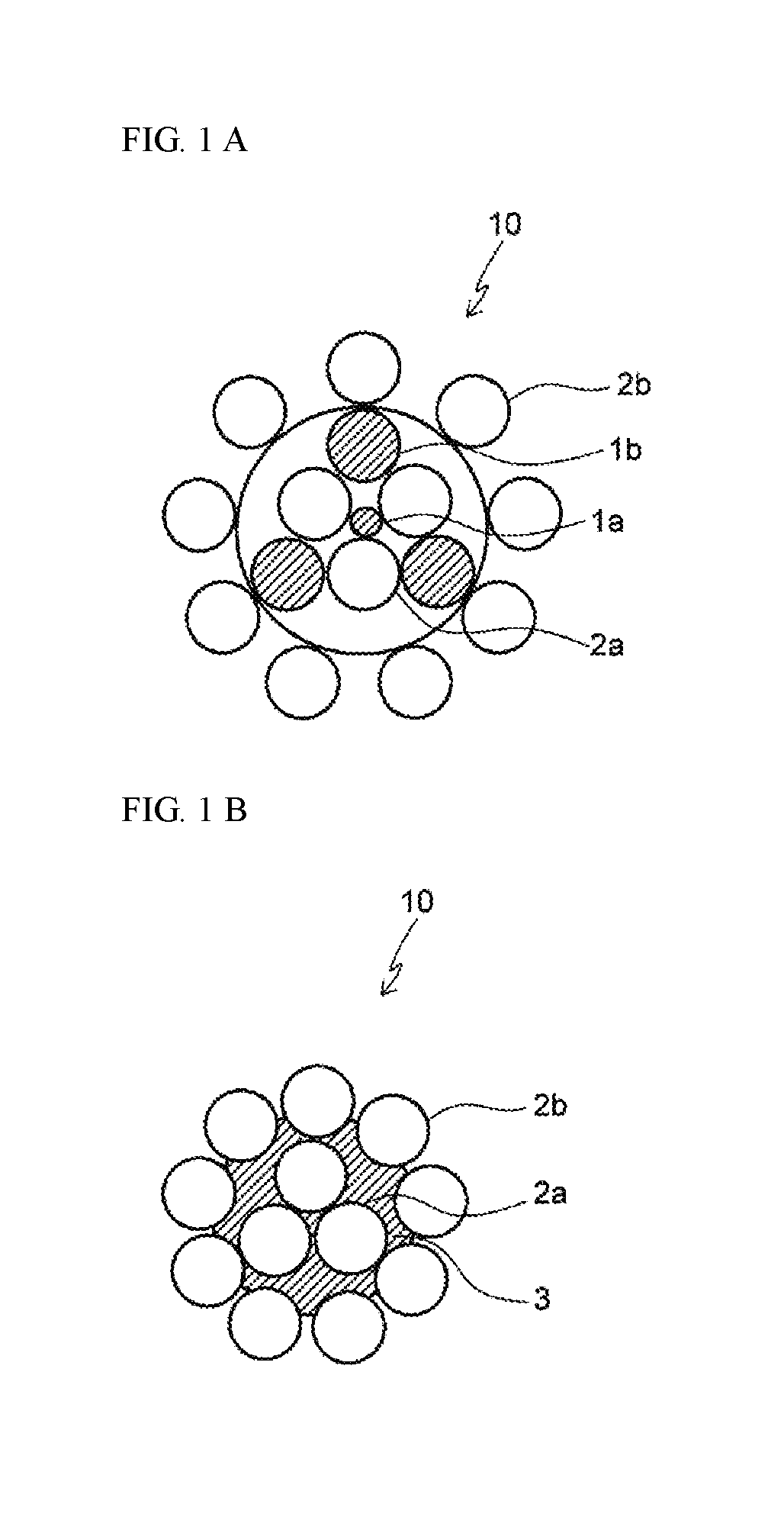

Magnetic recording medium and manufacturing method of the same

InactiveUS8414966B2Excellent magnetic recording reproduction characteristicReduce space lossVacuum evaporation coatingSputtering coatingEngineeringRecording layer

To provide a magnetic recording medium enabling excellent magnetic recording reproduction characteristics to be exhibited with the spacing loss reduced and a manufacturing method of the medium, a method of manufacturing a magnetic recording medium of the invention is to manufacture a magnetic recording medium having a magnetic recording layer of a granular structure having nonmagnetic boundary portions between pillar-shaped magnetic particles on a nonmagnetic substrate, and an exchange coupling layer provided on the magnetic recording layer to add an action of exchange coupling the magnetic particles, and is characterized by having an ion irradiation step of performing ion irradiation on the entire surface of the exchange coupling layer after layering the exchange coupling layer on the magnetic recording layer.

Owner:WESTERN DIGITAL CORP A DE CORP +1

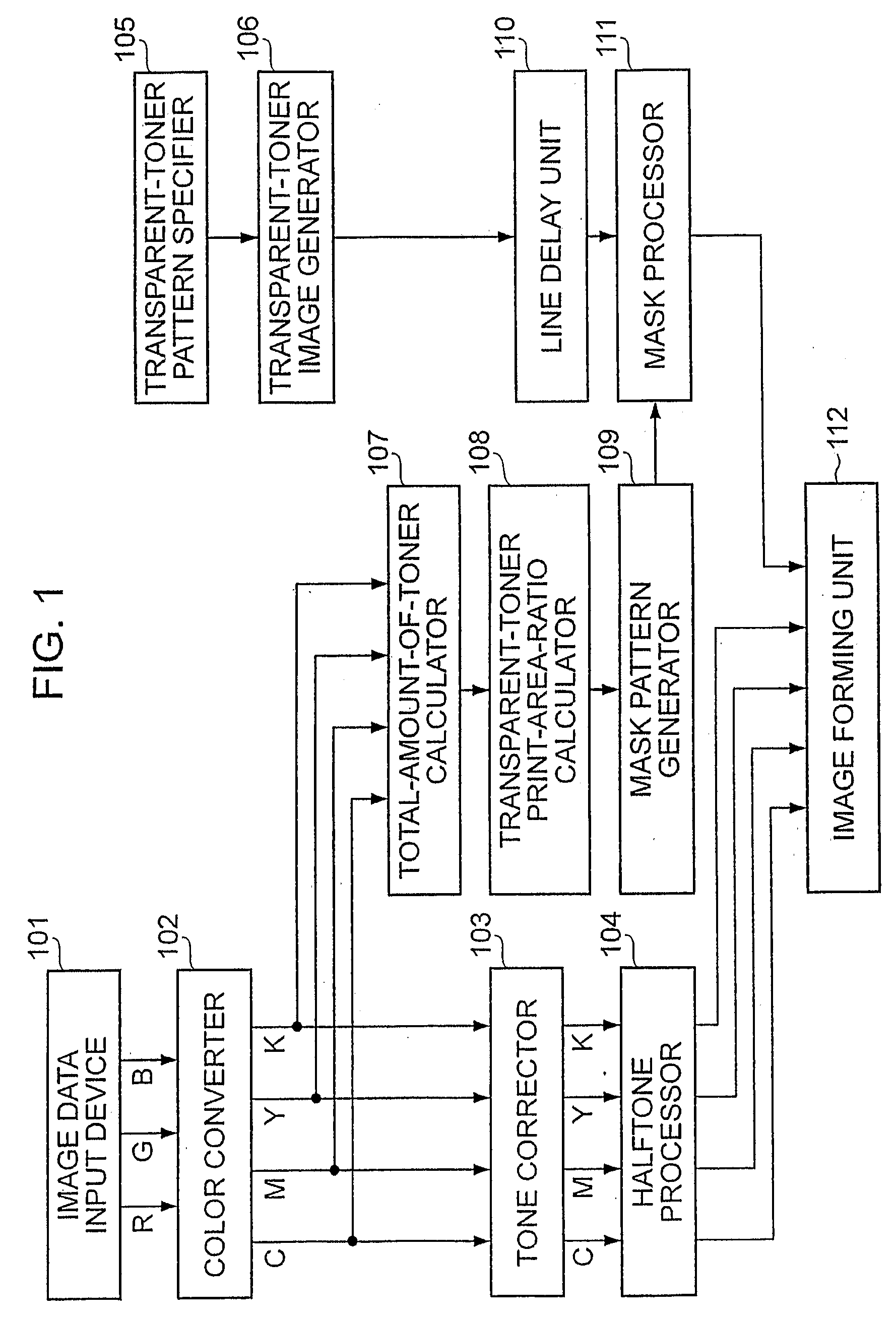

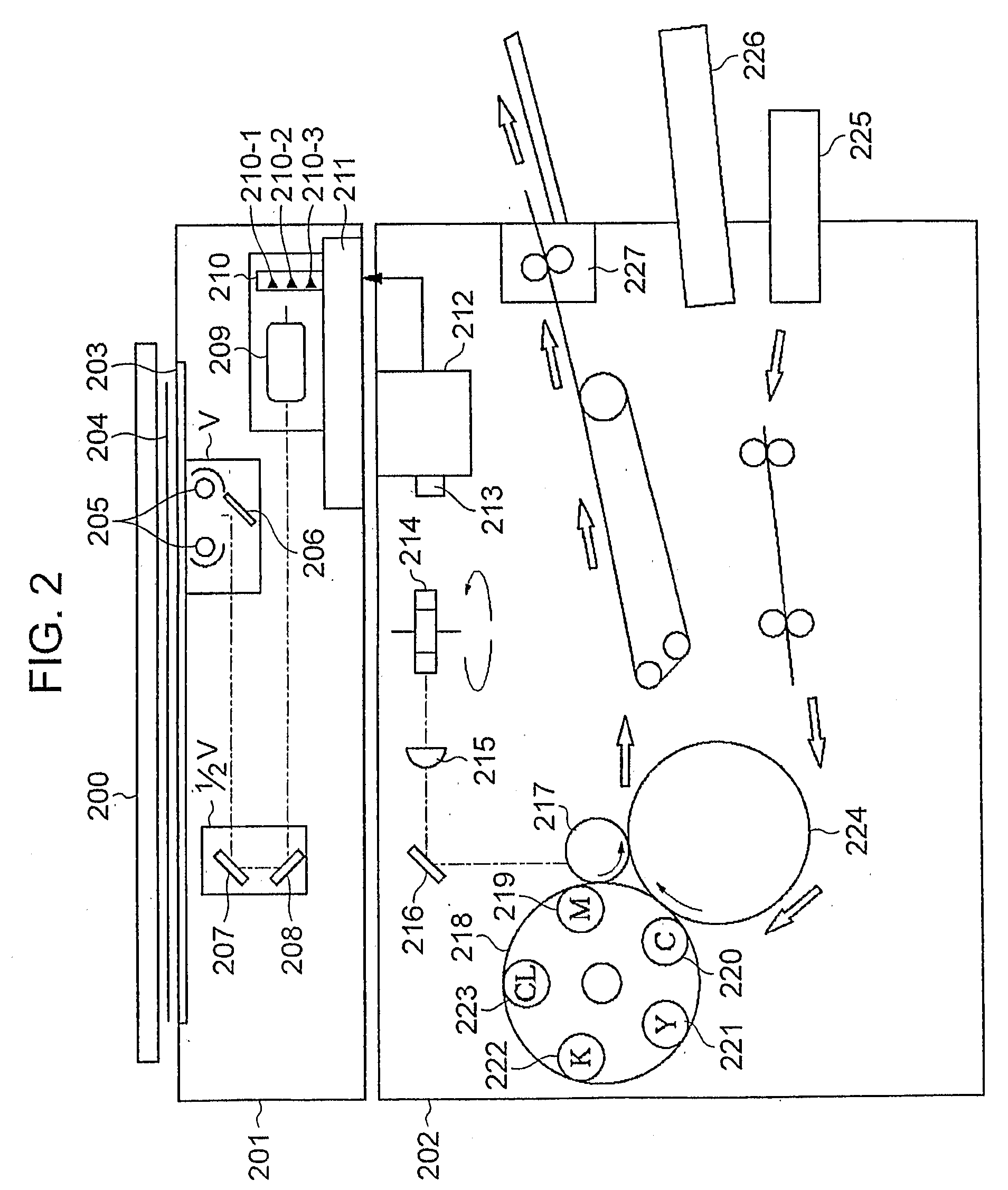

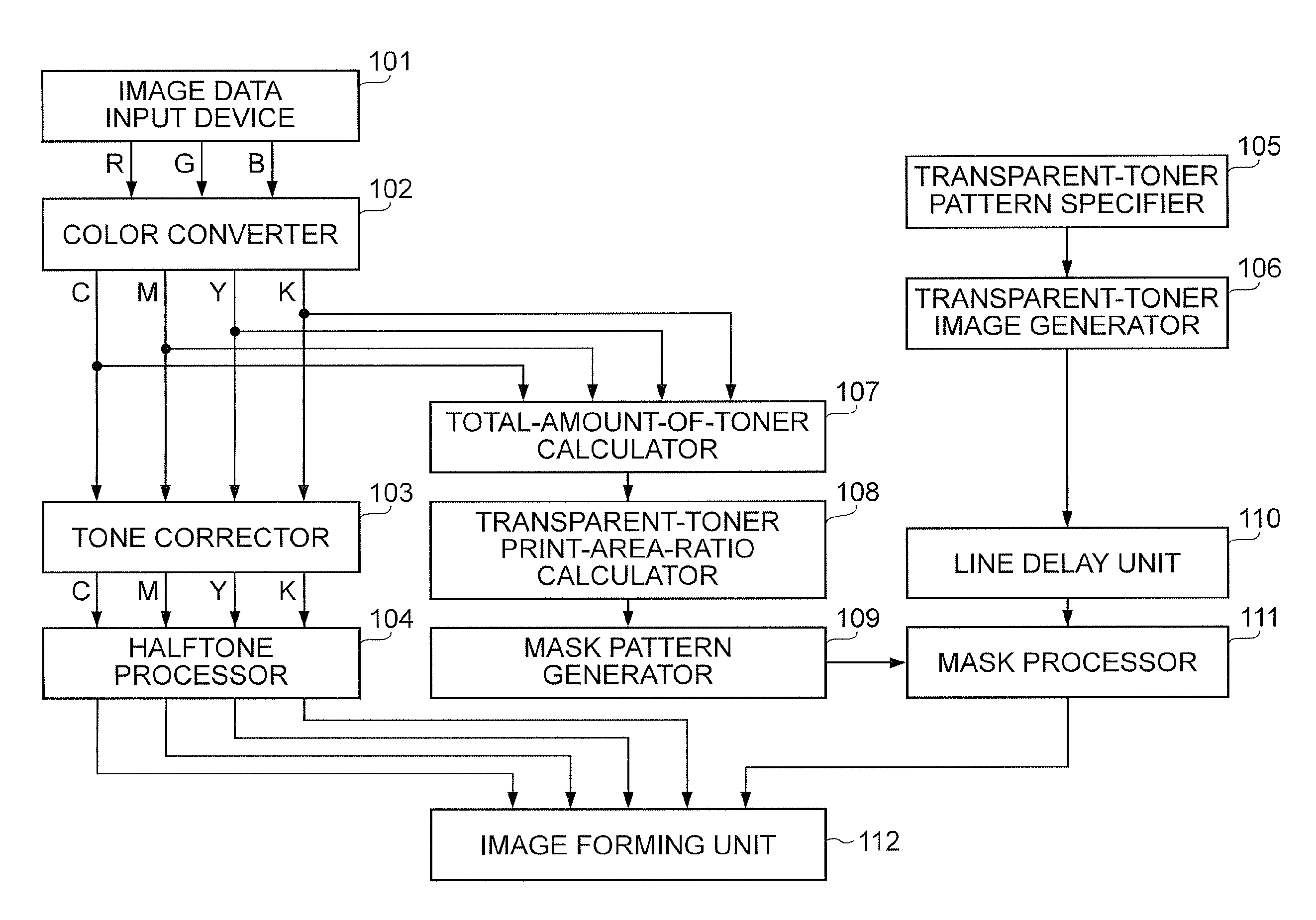

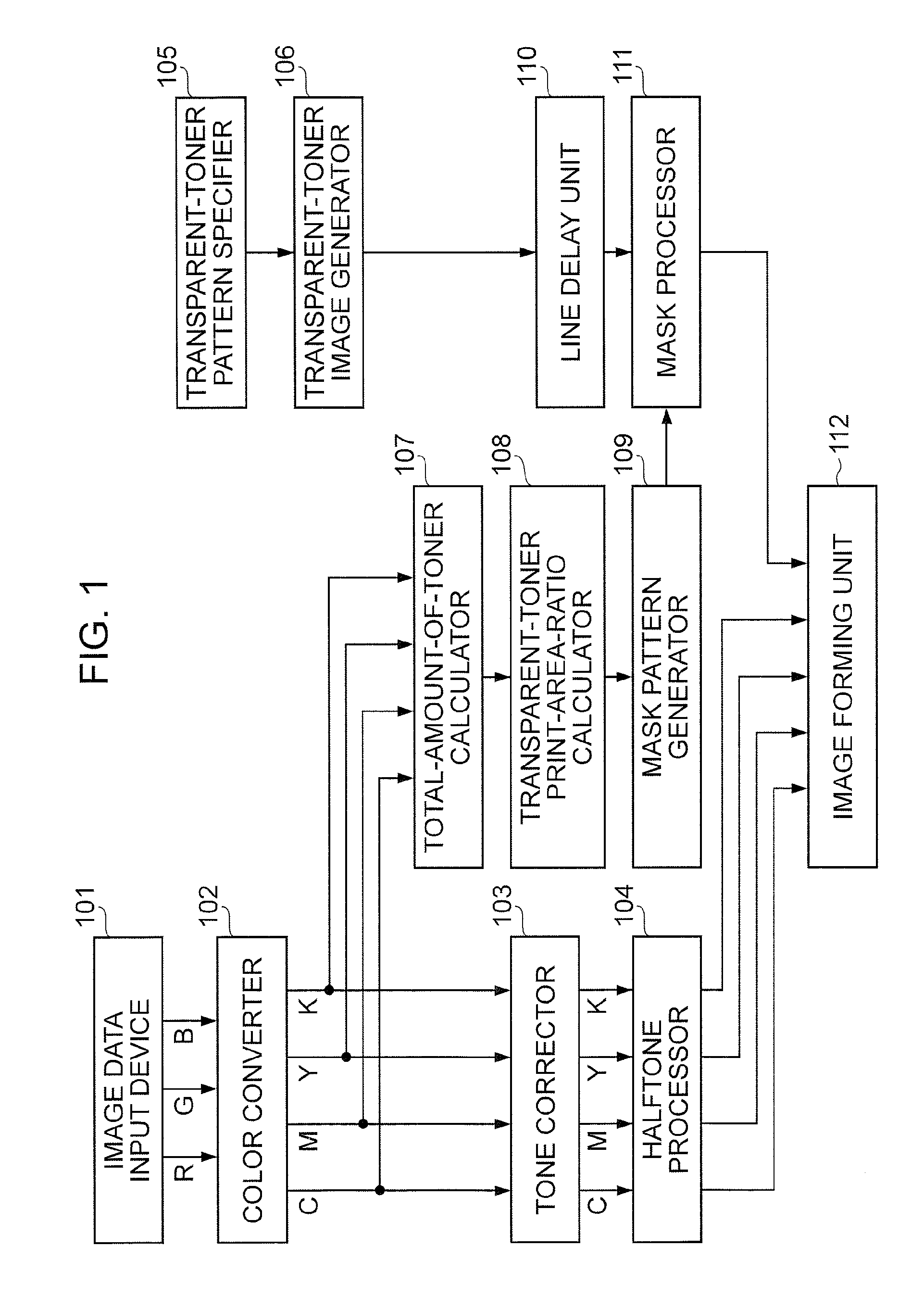

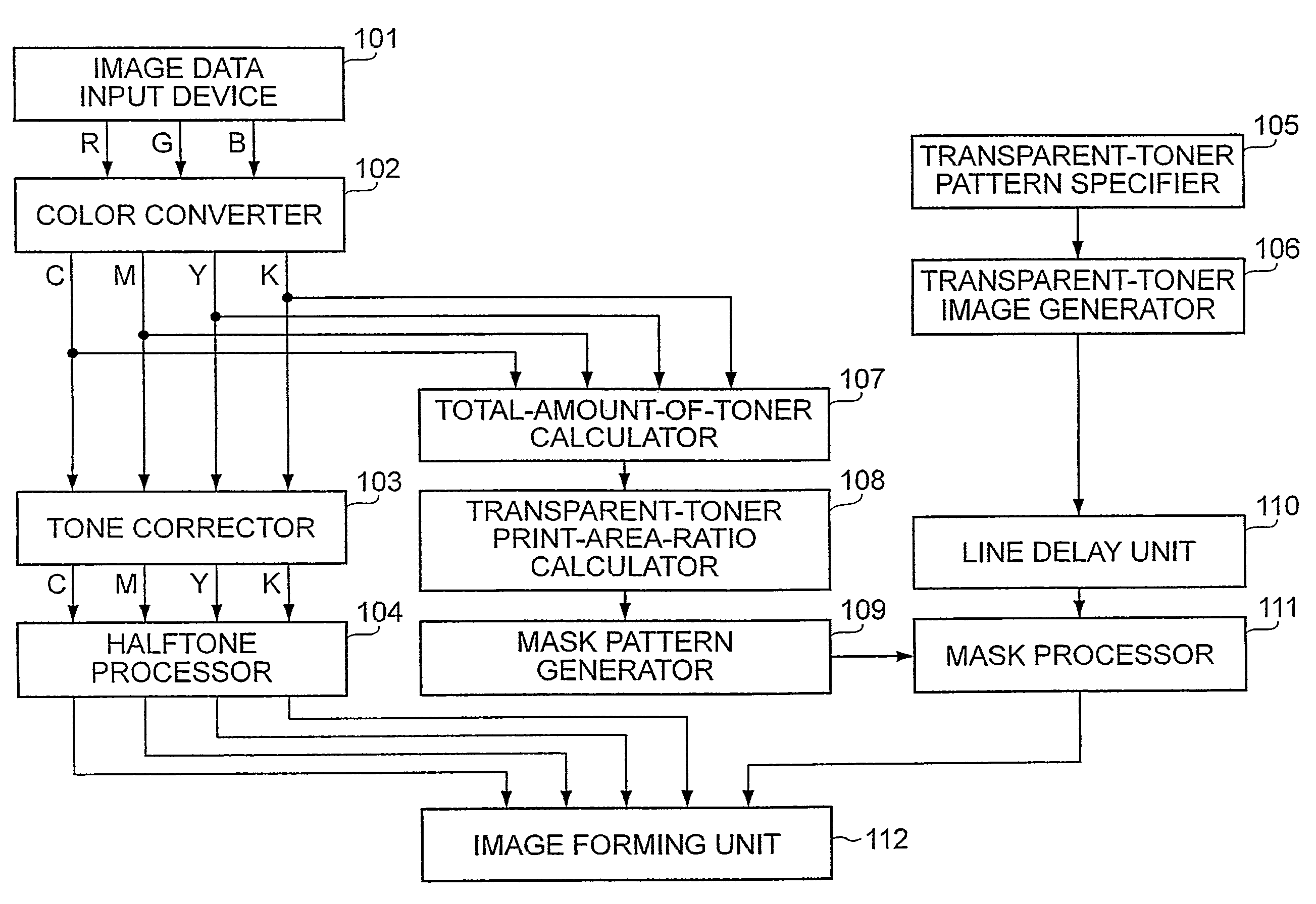

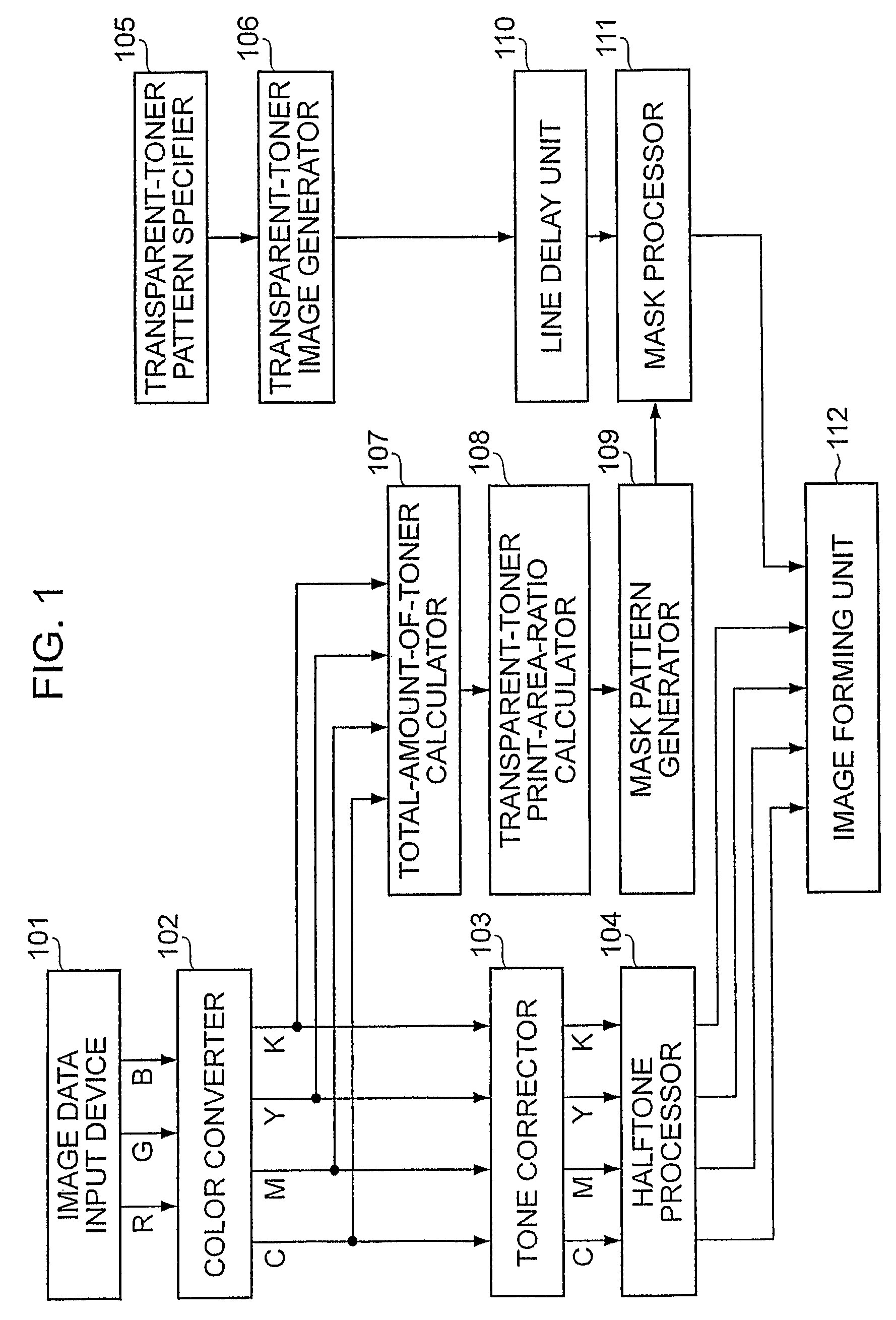

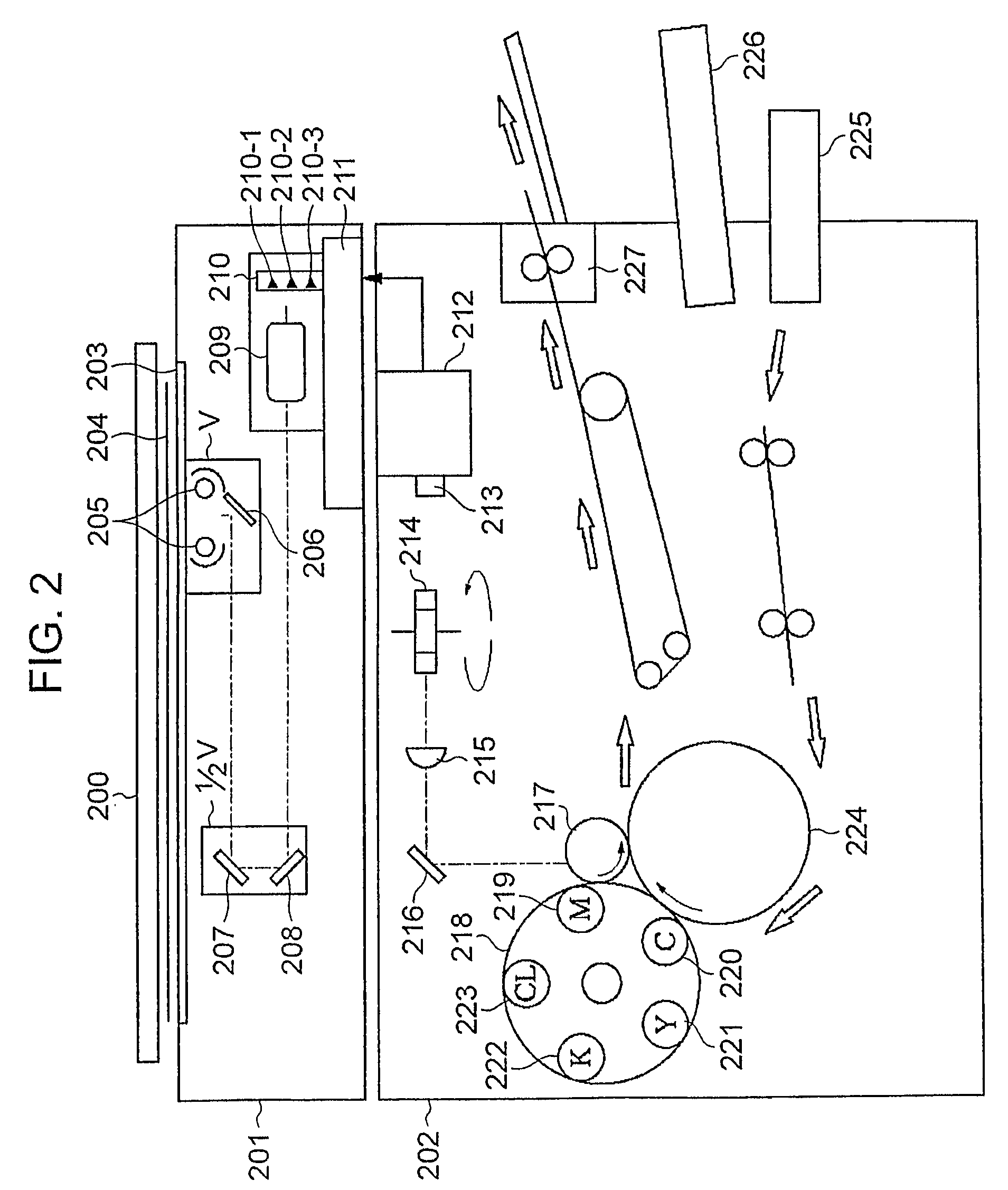

Image processing apparatus and method controlling the amount of transparent ink for recording

InactiveUS20090097046A1Without reducing productivityLimited amountDigitally marking record carriersMulticolor photographic processingImaging processingMagenta

An image processing apparatus includes a calculation unit configured to calculate an amount of a first coloring material (at least one of cyan, magenta, yellow and black) in an area including a plurality of pixels; a determination unit configured to determine an allowable amount of a second coloring material, being substantially colorless and transparent, in the area on the basis of the amount of the first coloring material, calculated by the calculation unit, and a limit of the amount of the coloring material; and a control unit configured to control an amount of the second coloring material in the area so as not to exceed the allowable amount of the second coloring material.

Owner:CANON KK

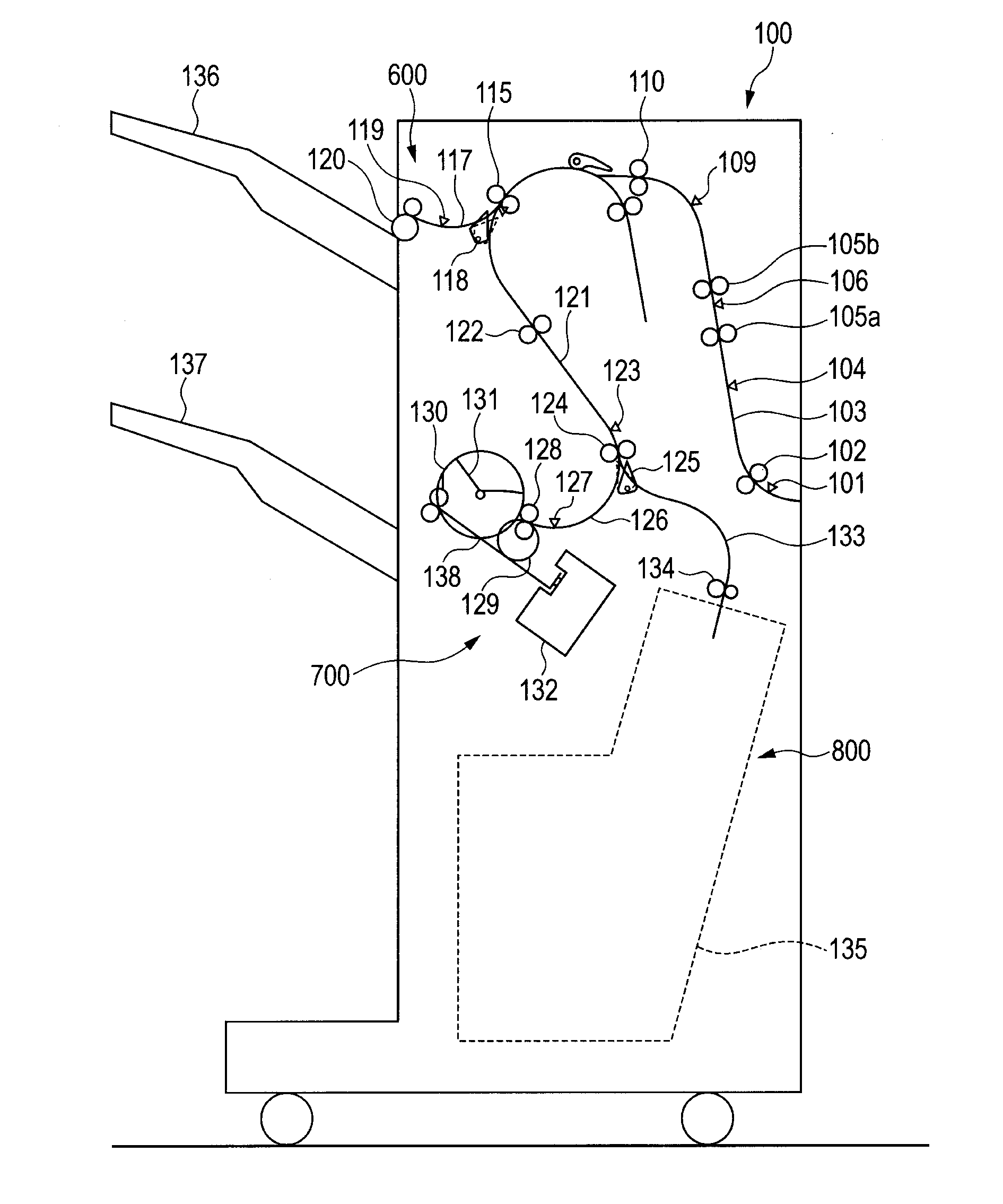

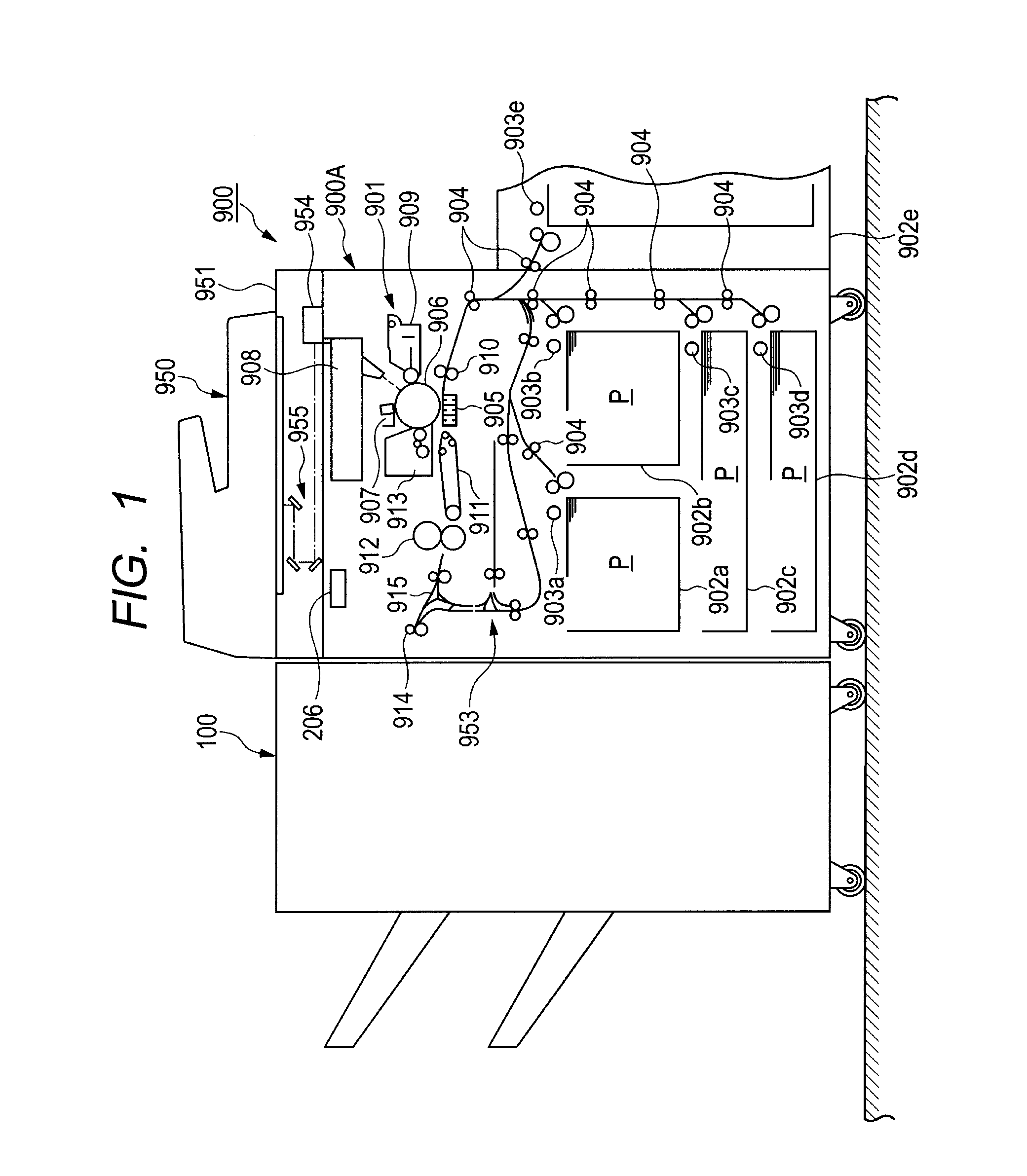

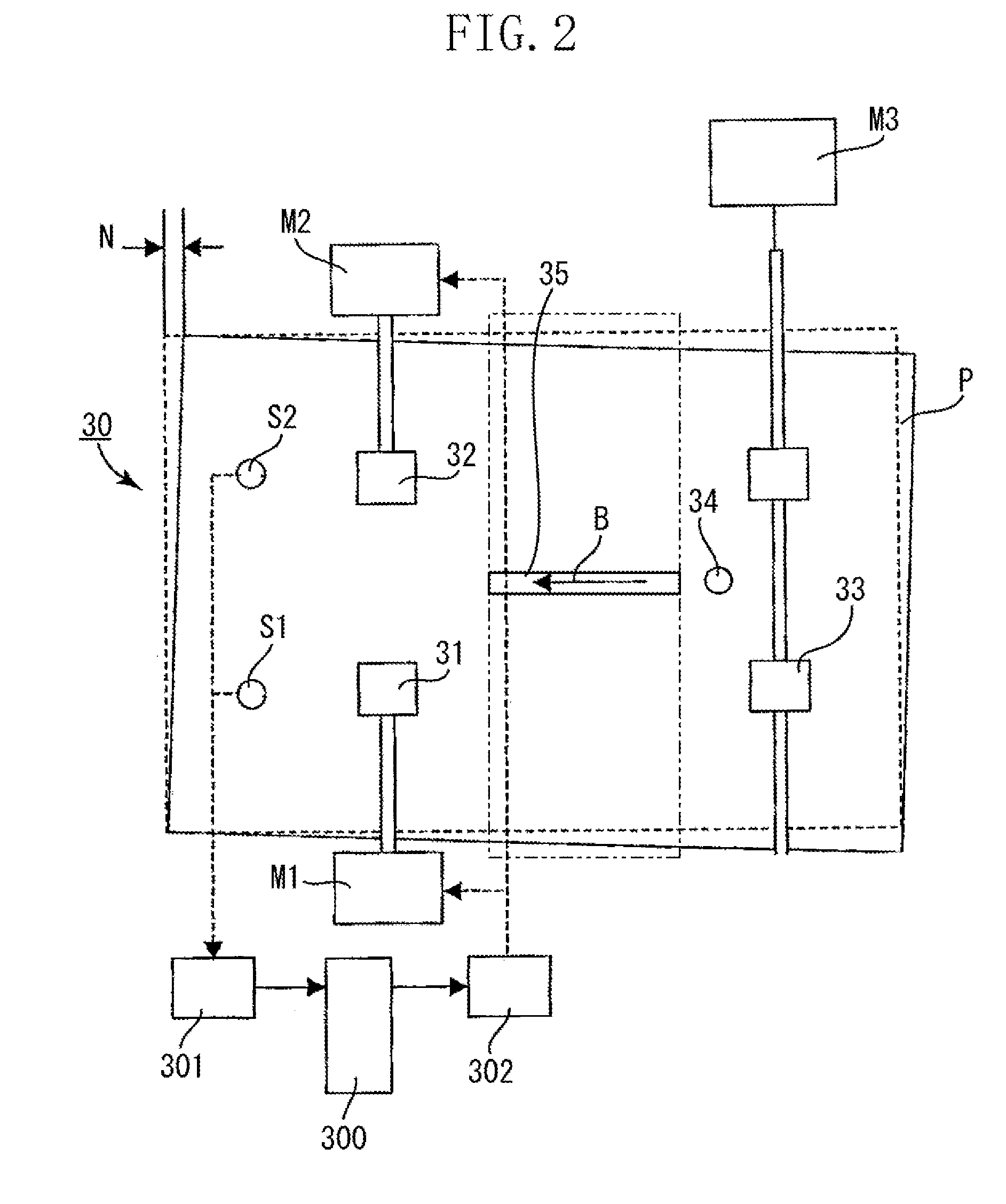

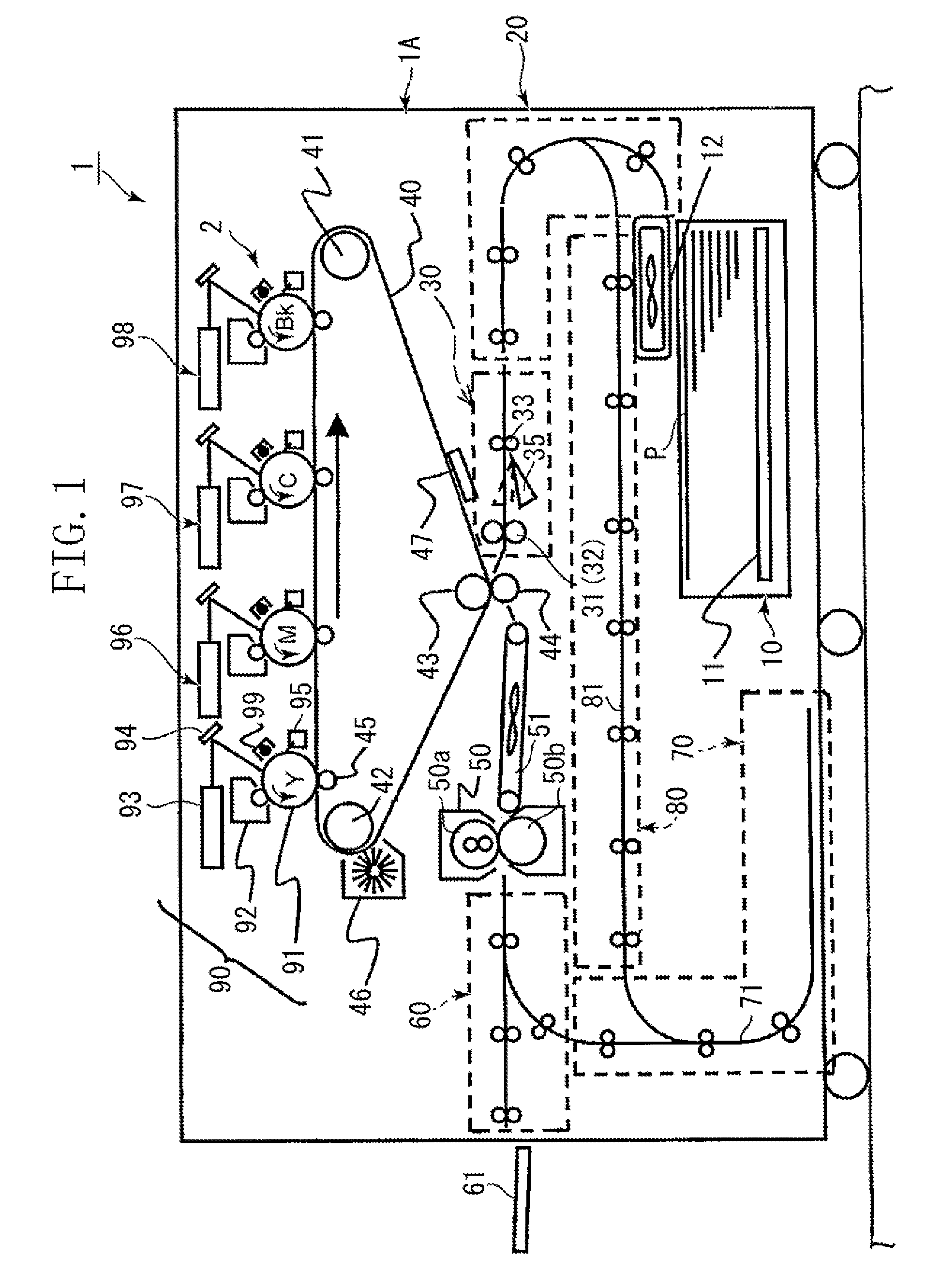

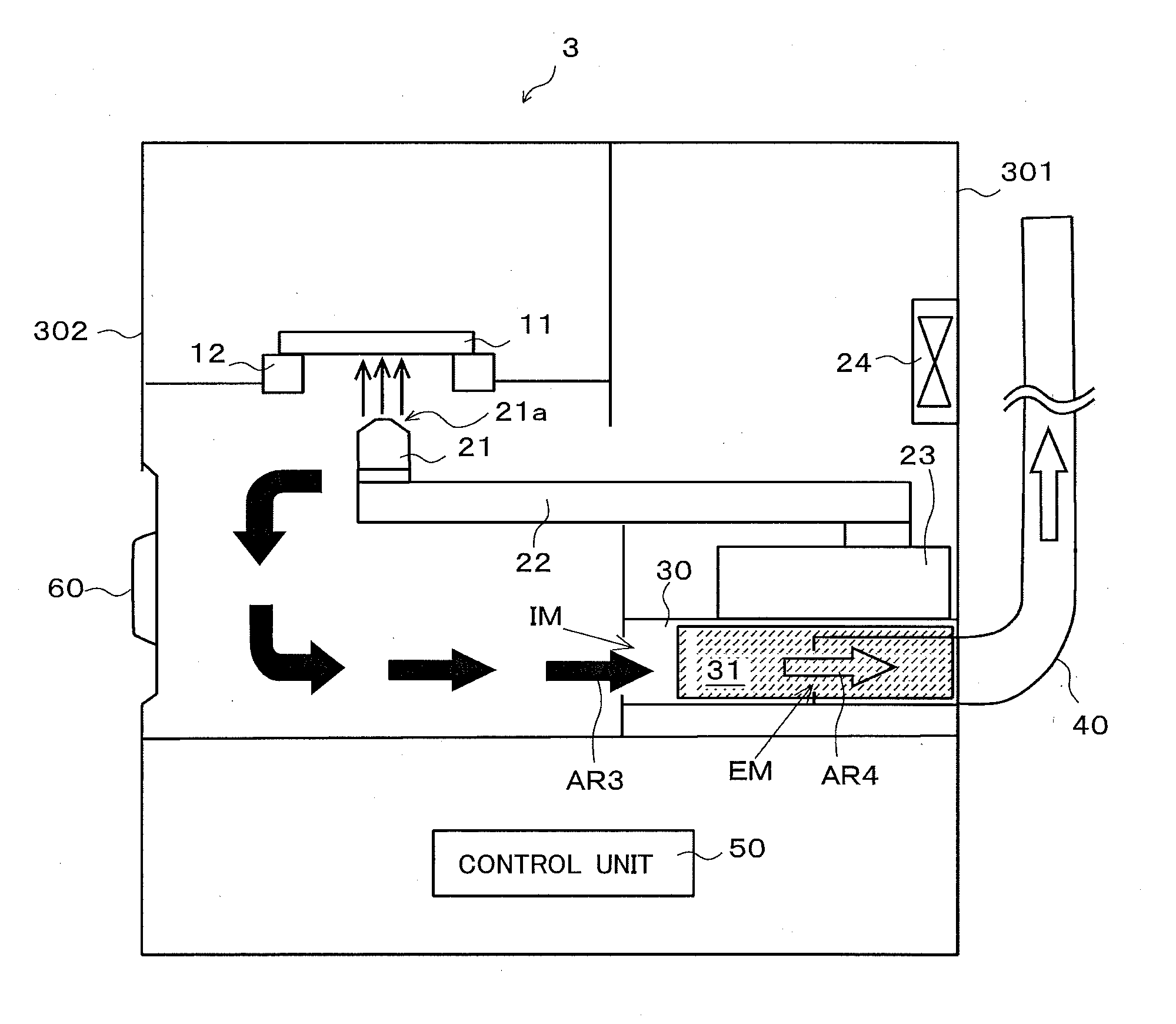

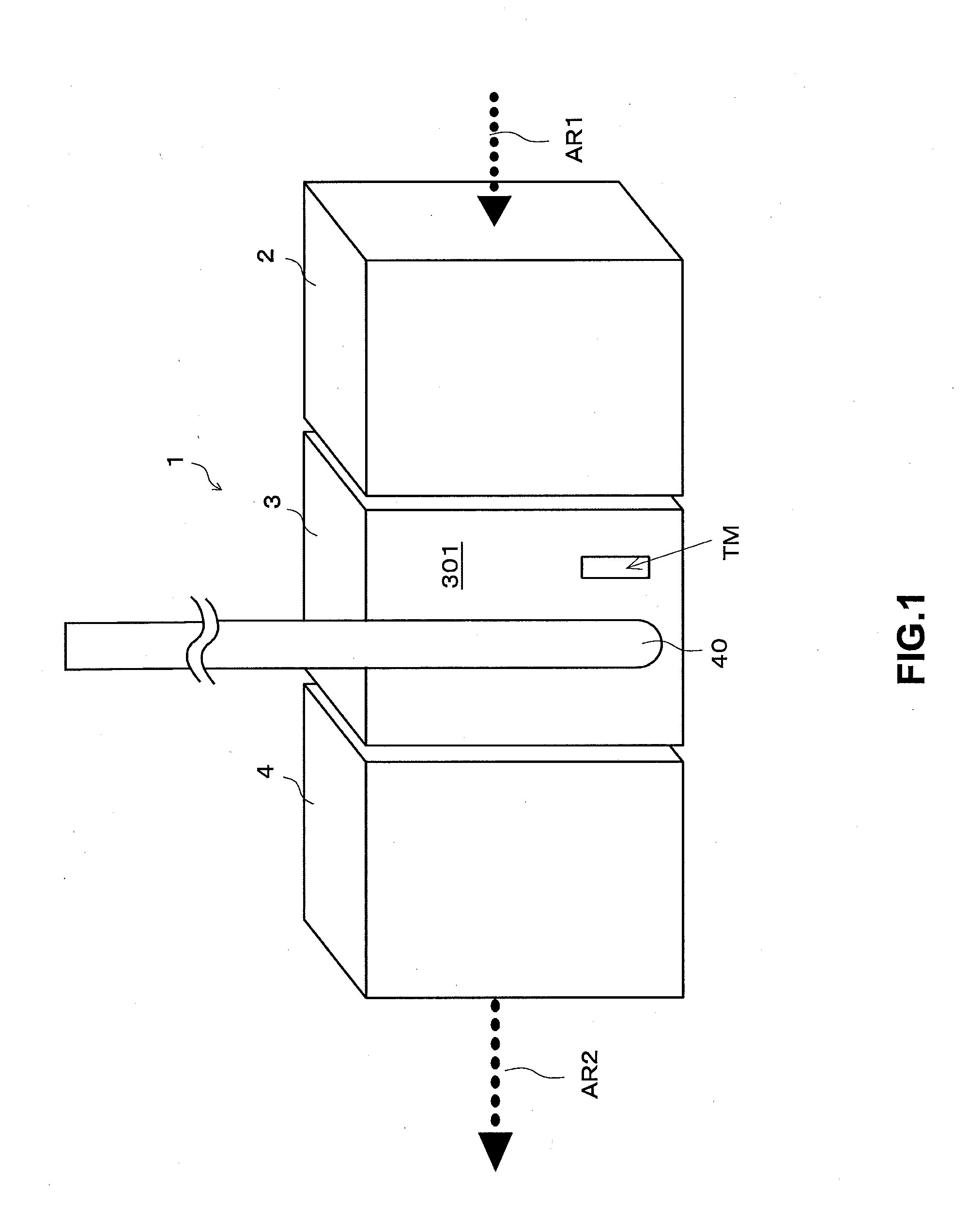

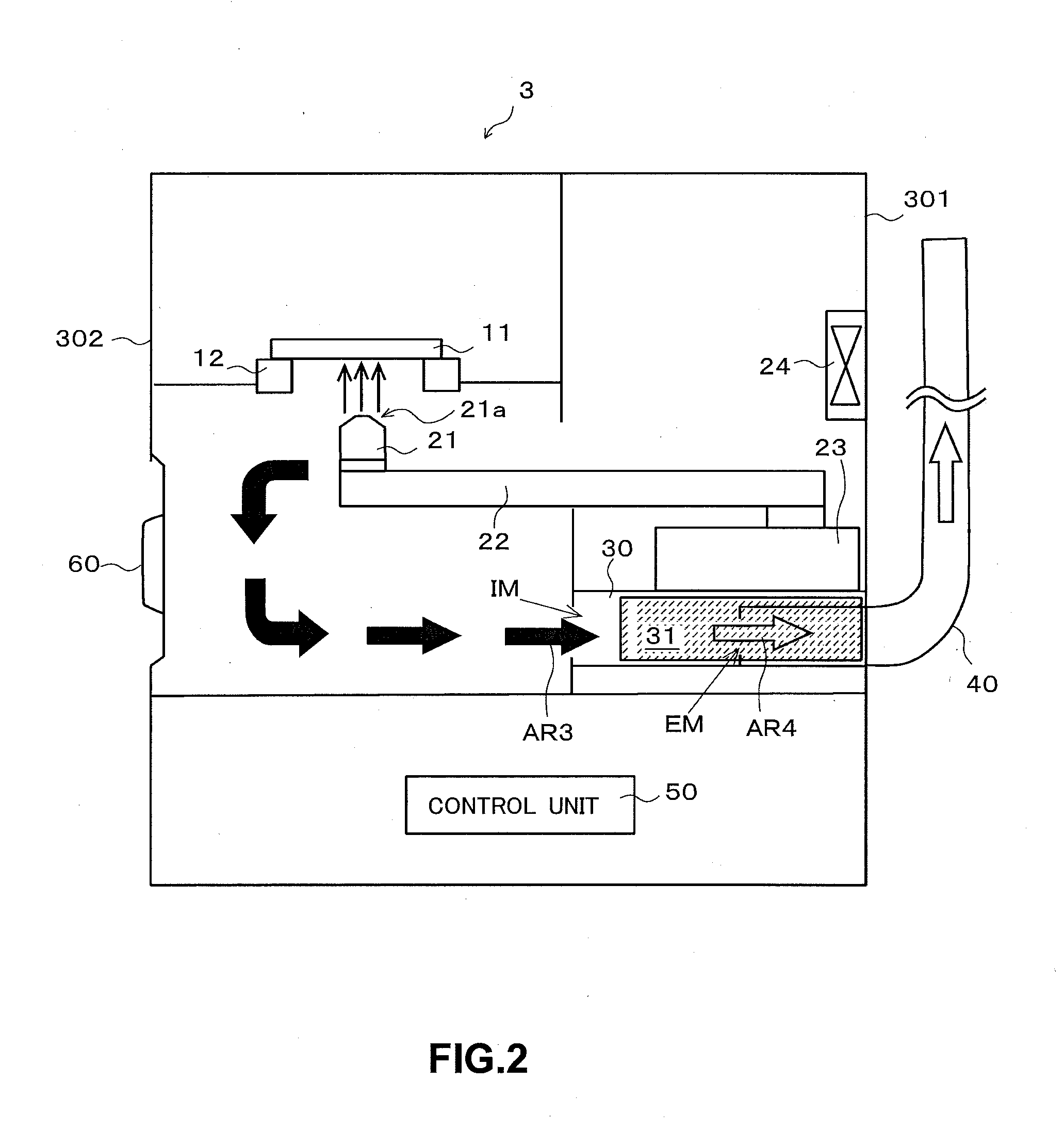

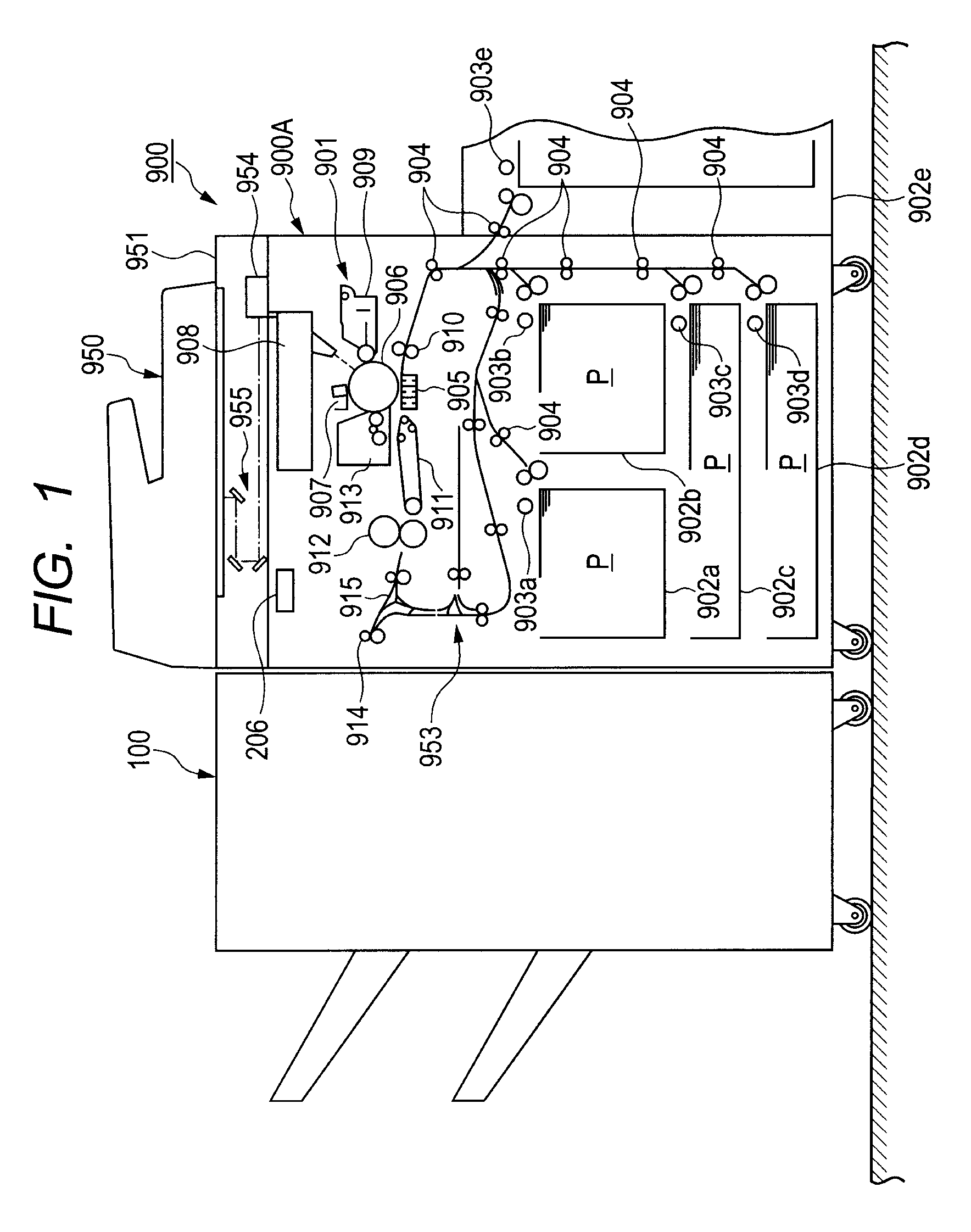

Sheet-discharge apparatus, sheet processing apparatus, and image forming apparatus

ActiveUS20120093555A1Easy alignmentReduce alignmentFunction indicatorsElectrographic process apparatusInformation controlImage formation

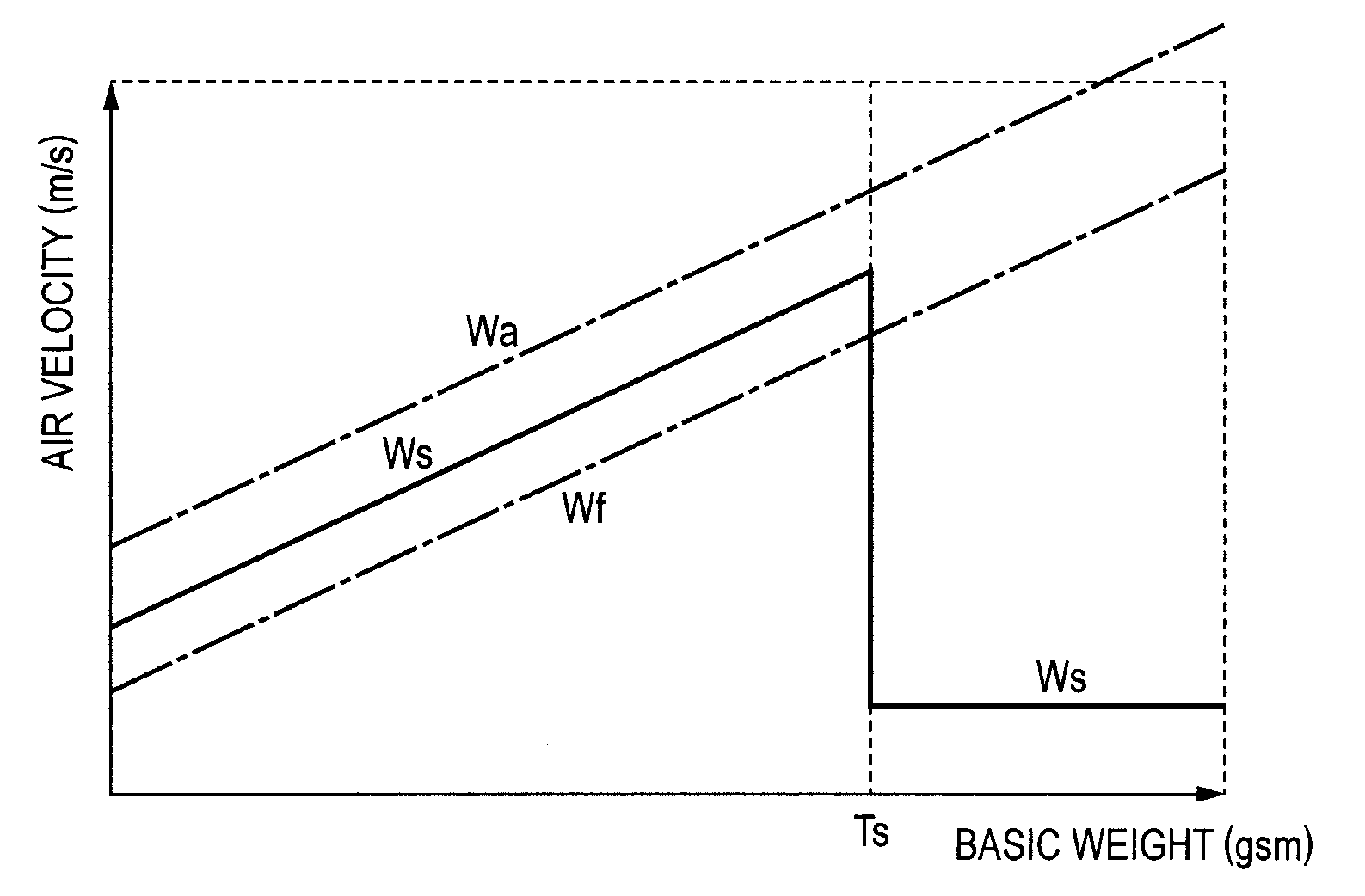

The sheet processing apparatus includes a sheet-discharge fan that blows air downward of a sheet-discharged by an upper sheet-discharge roller, and a control portion configured to control an air velocity of air blown from the sheet-discharge fan according to a basic weight of the sheet. In the case where the basic weight of the sheet is a predetermined value or less, the control portion increases the air velocity of the sheet-discharge fan according to the basic weight of the sheet based on basic weight information from an input portion for inputting the basic weight information of the sheet. The control portion also controls the air velocity of the sheet-discharge fan to be a velocity at which the sheet whose rear edge contacts the sheet-stacking wall does not move in a sheet-discharge direction in the case where the basic weight of the sheet exceeds the predetermined value.

Owner:CANON KK

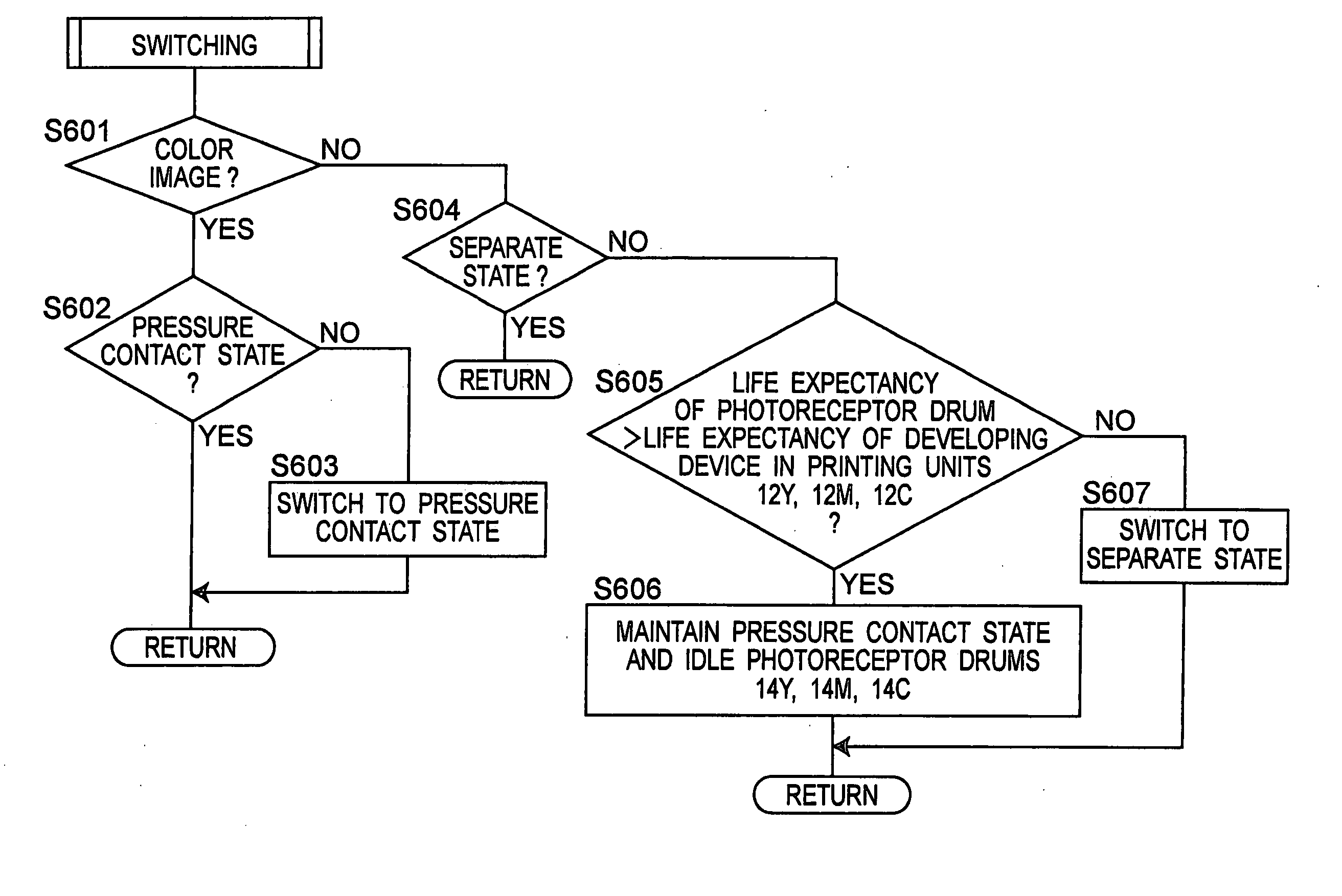

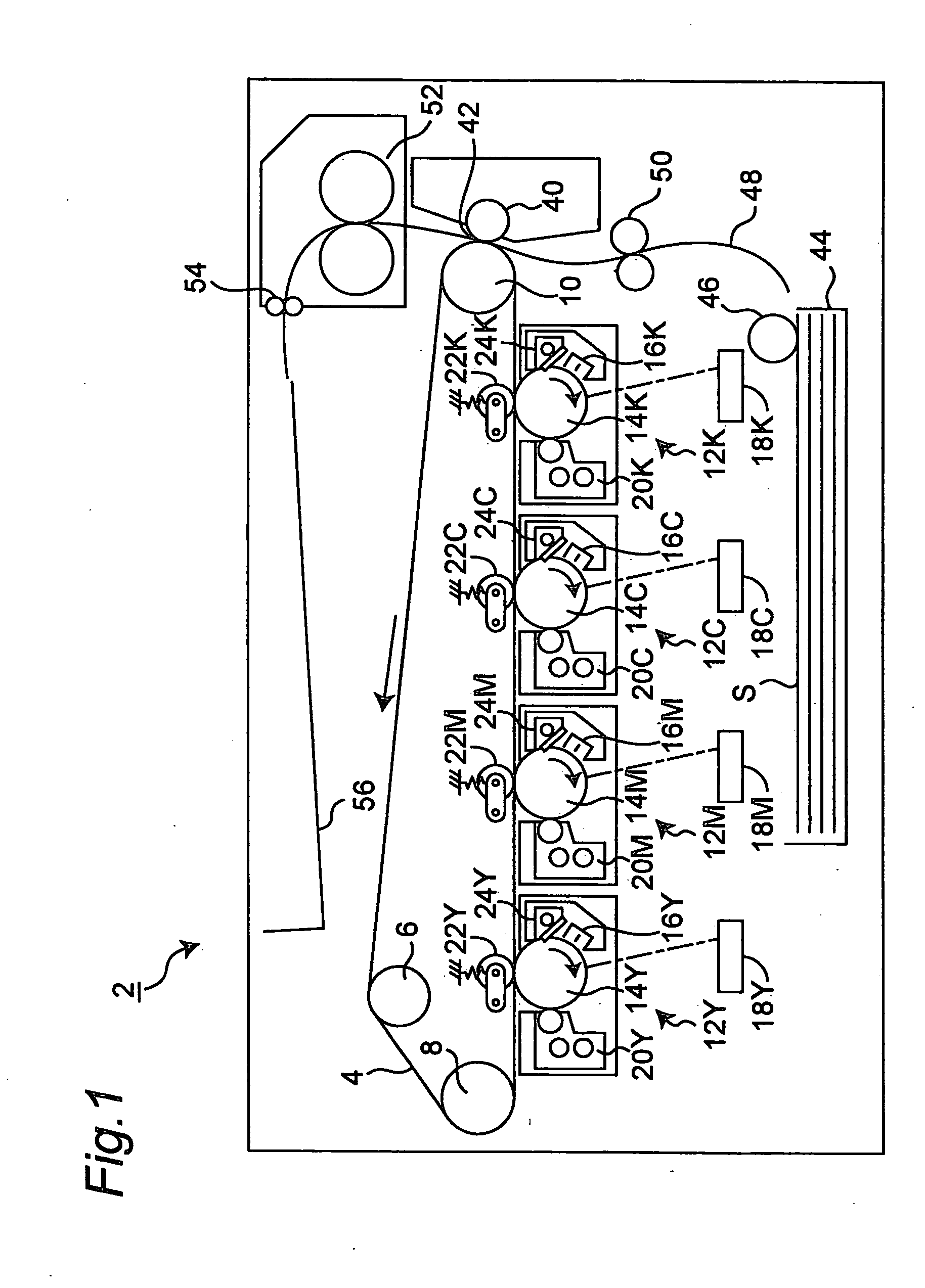

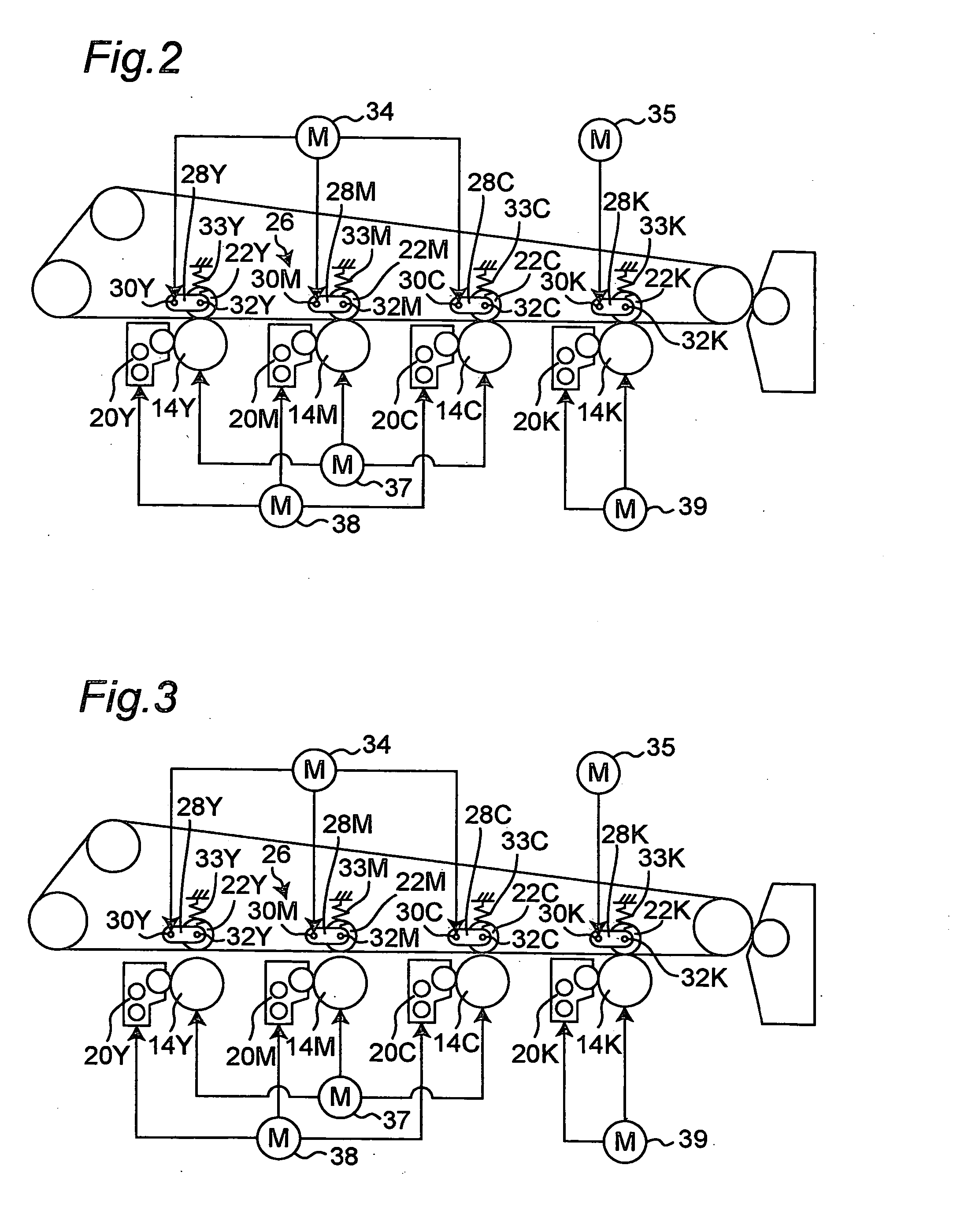

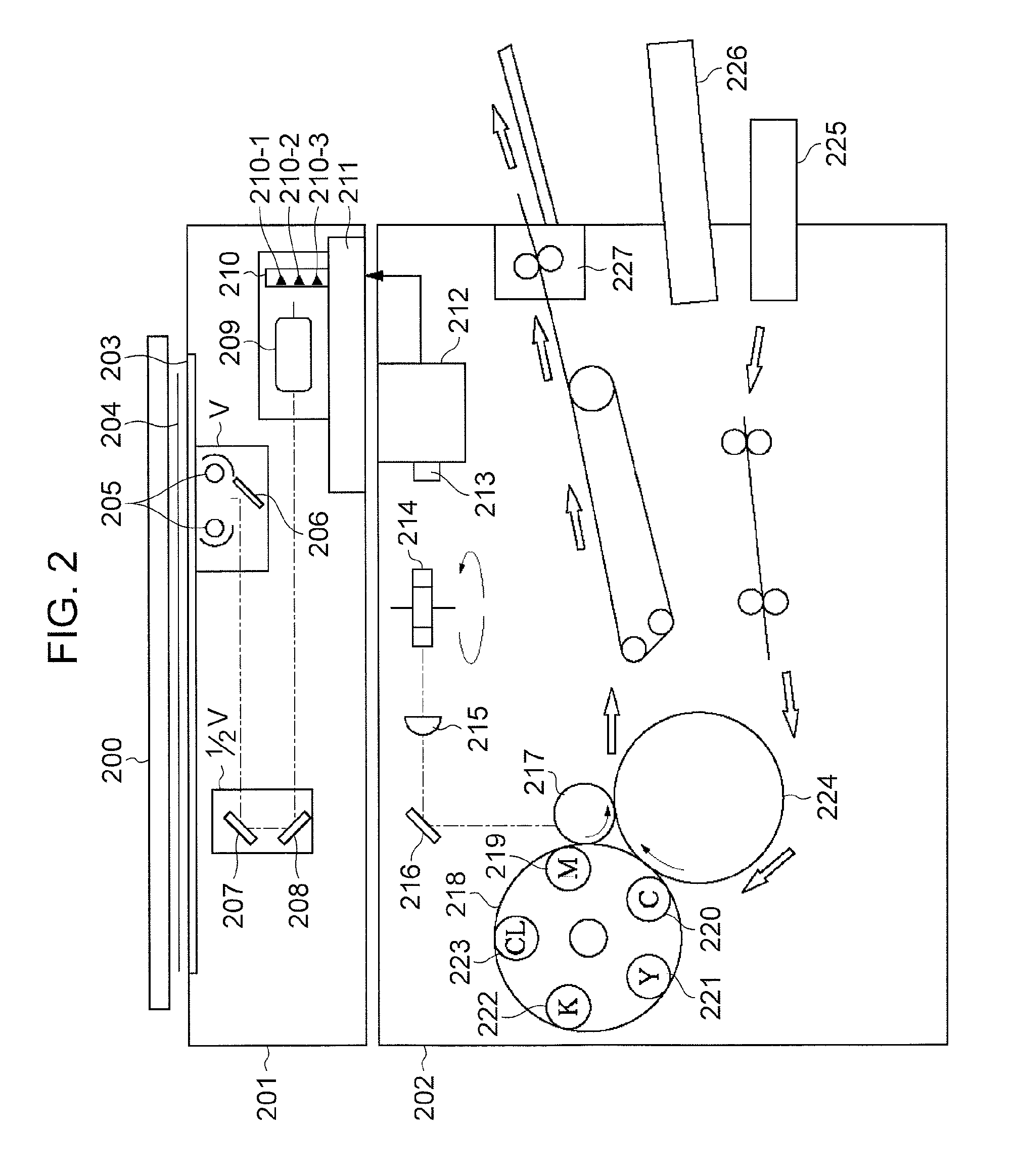

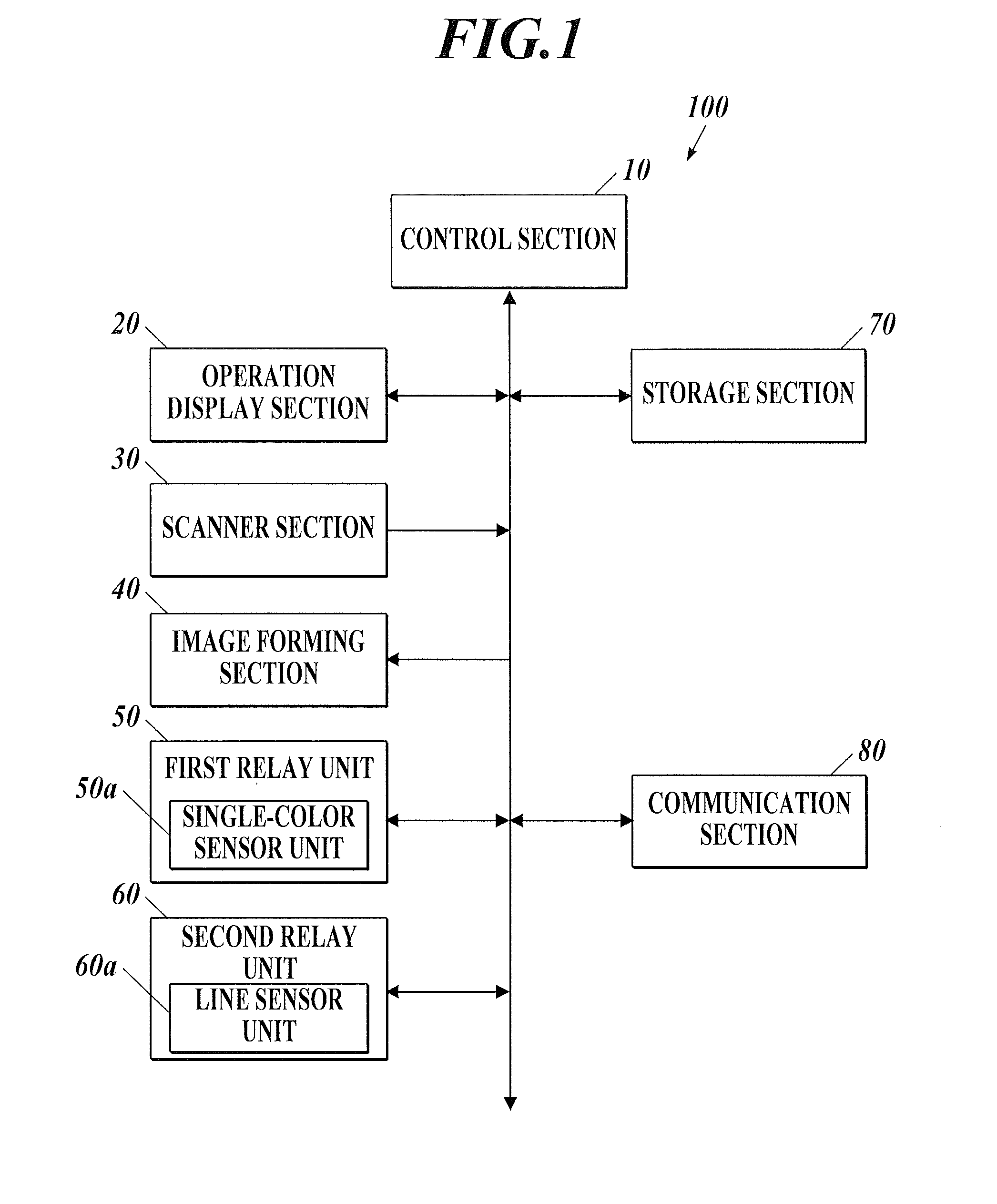

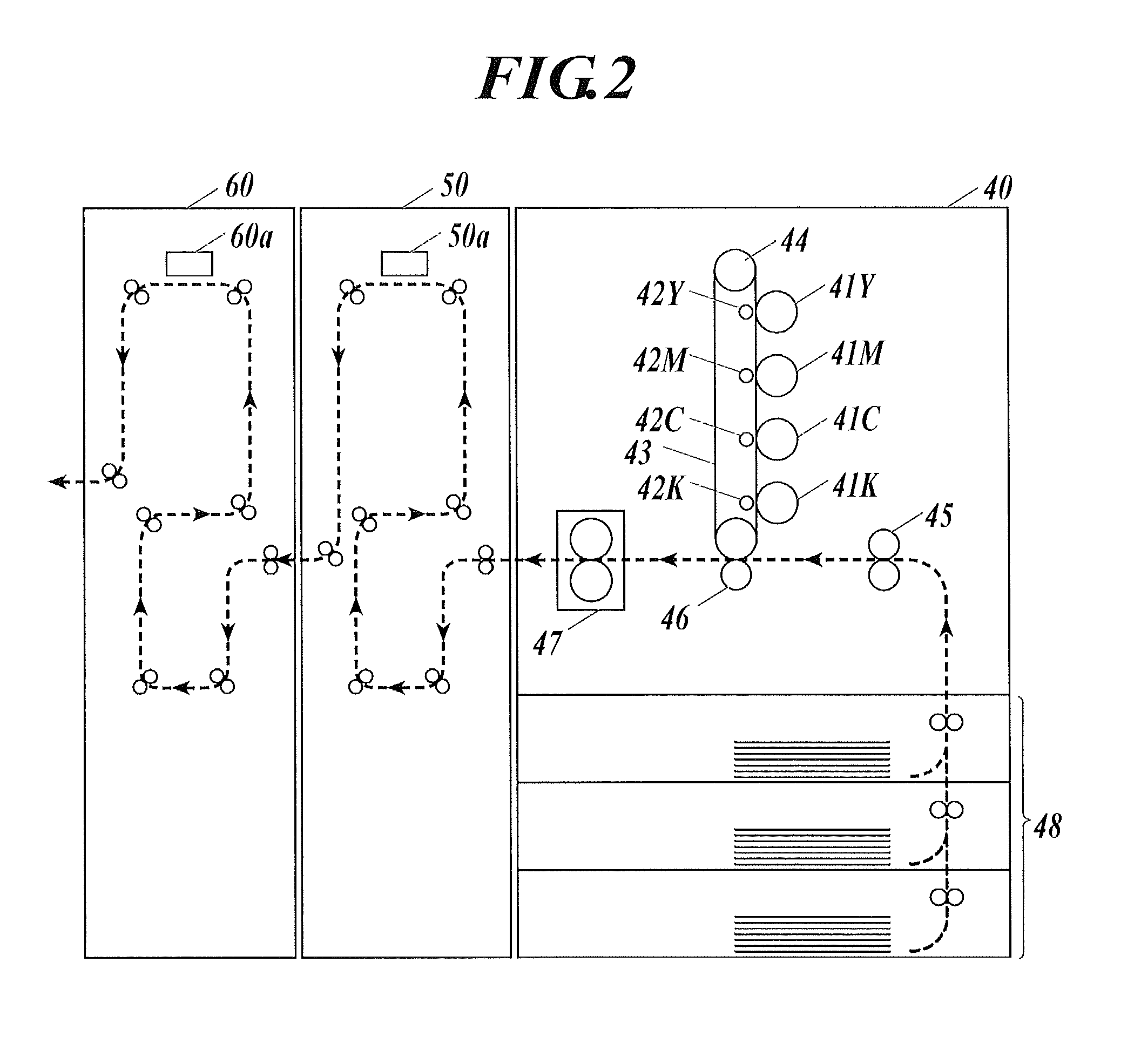

Image forming apparatus

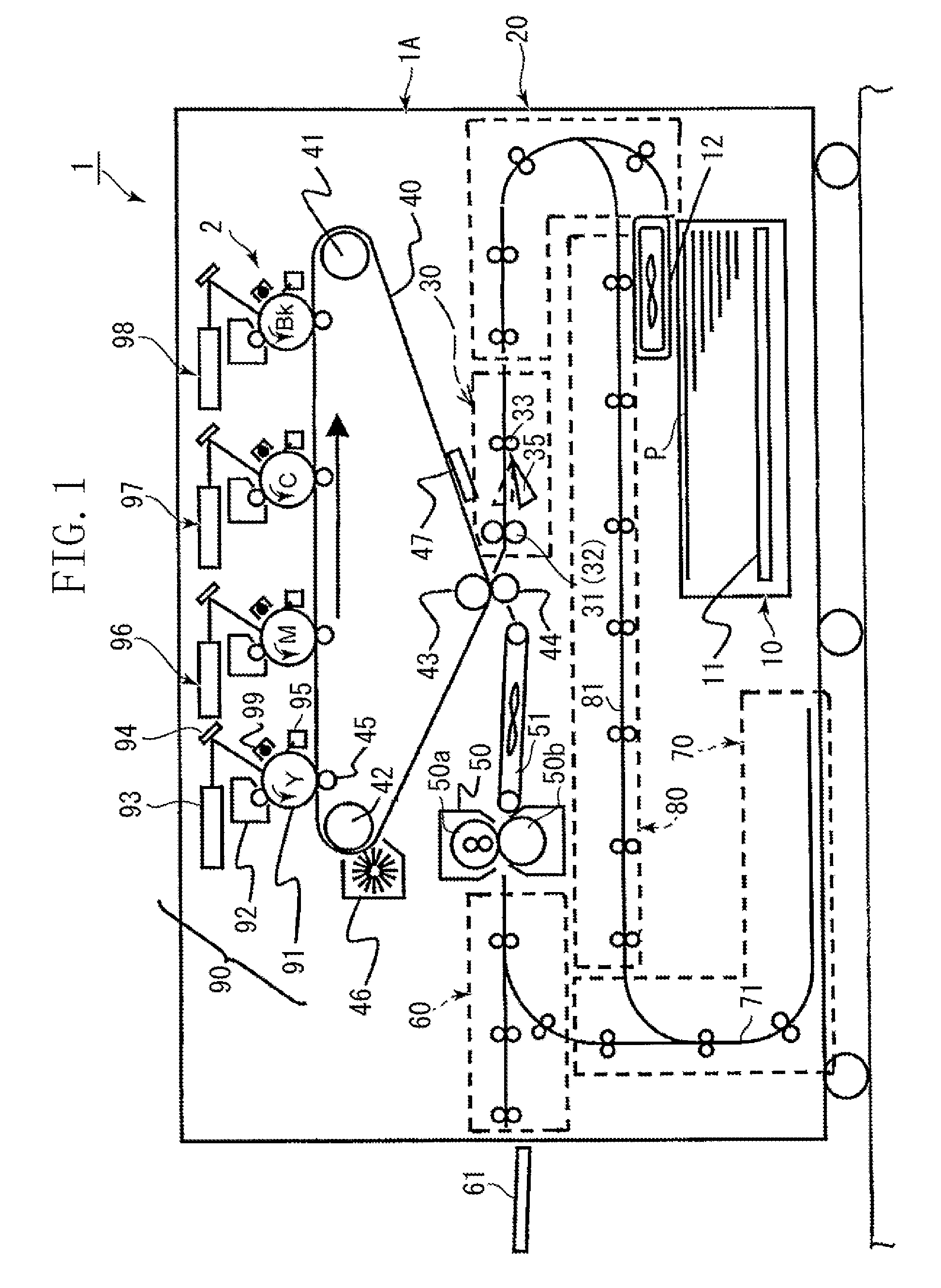

InactiveUS20050069334A1Without reducing productivityQuality improvementElectrographic process apparatusEngineeringSeparated state

Owner:KONICA MINOLTA BUSINESS TECH INC

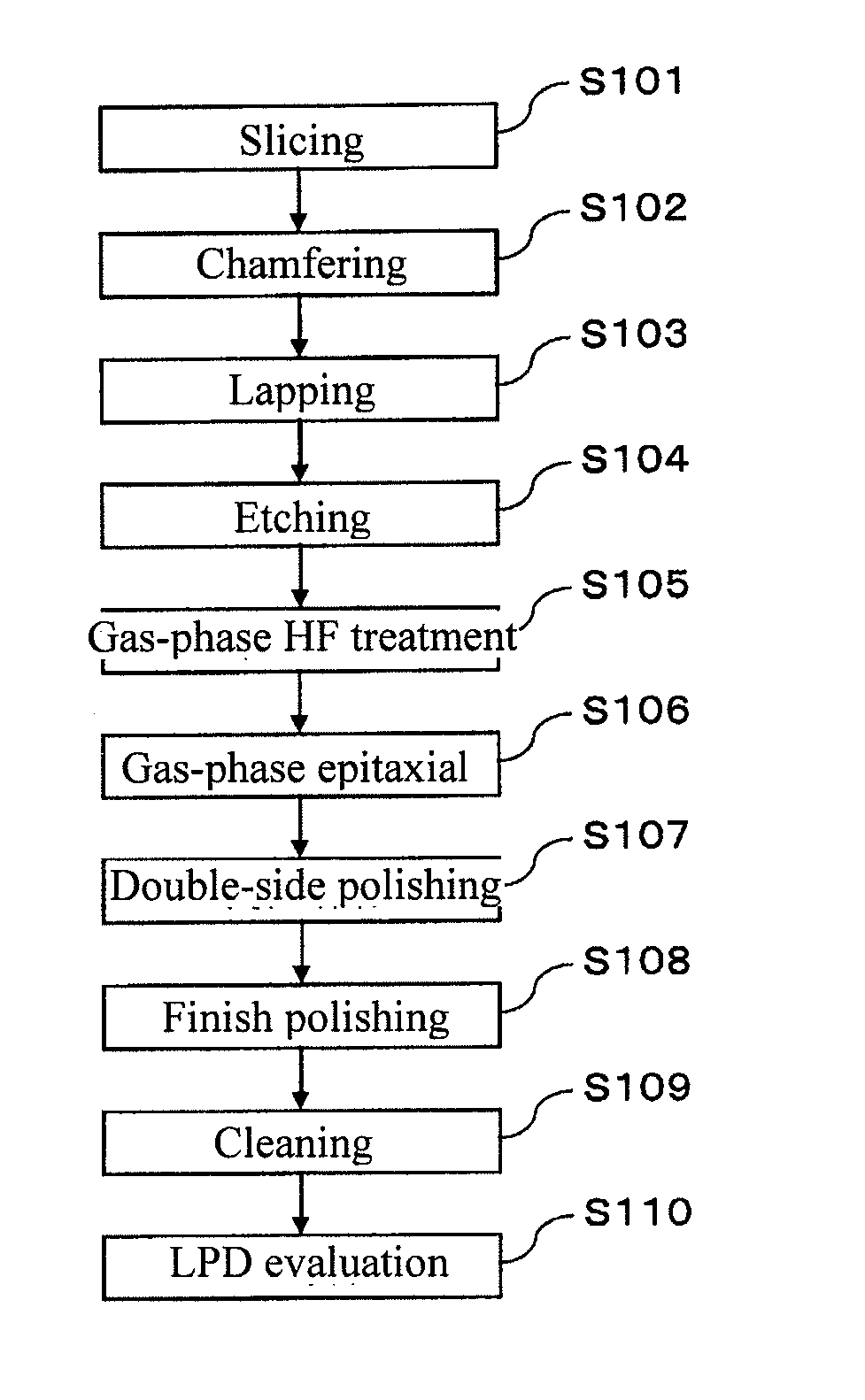

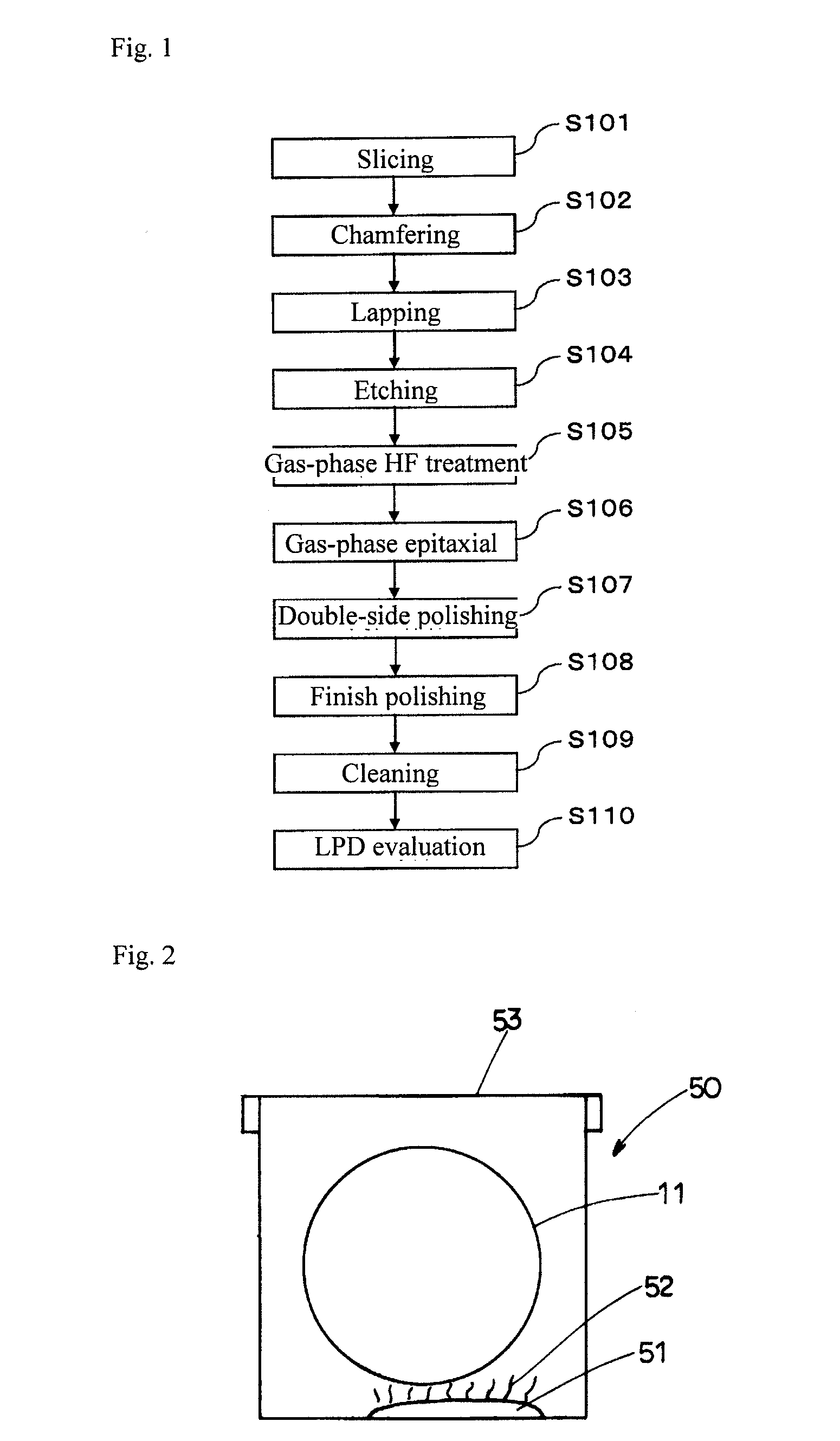

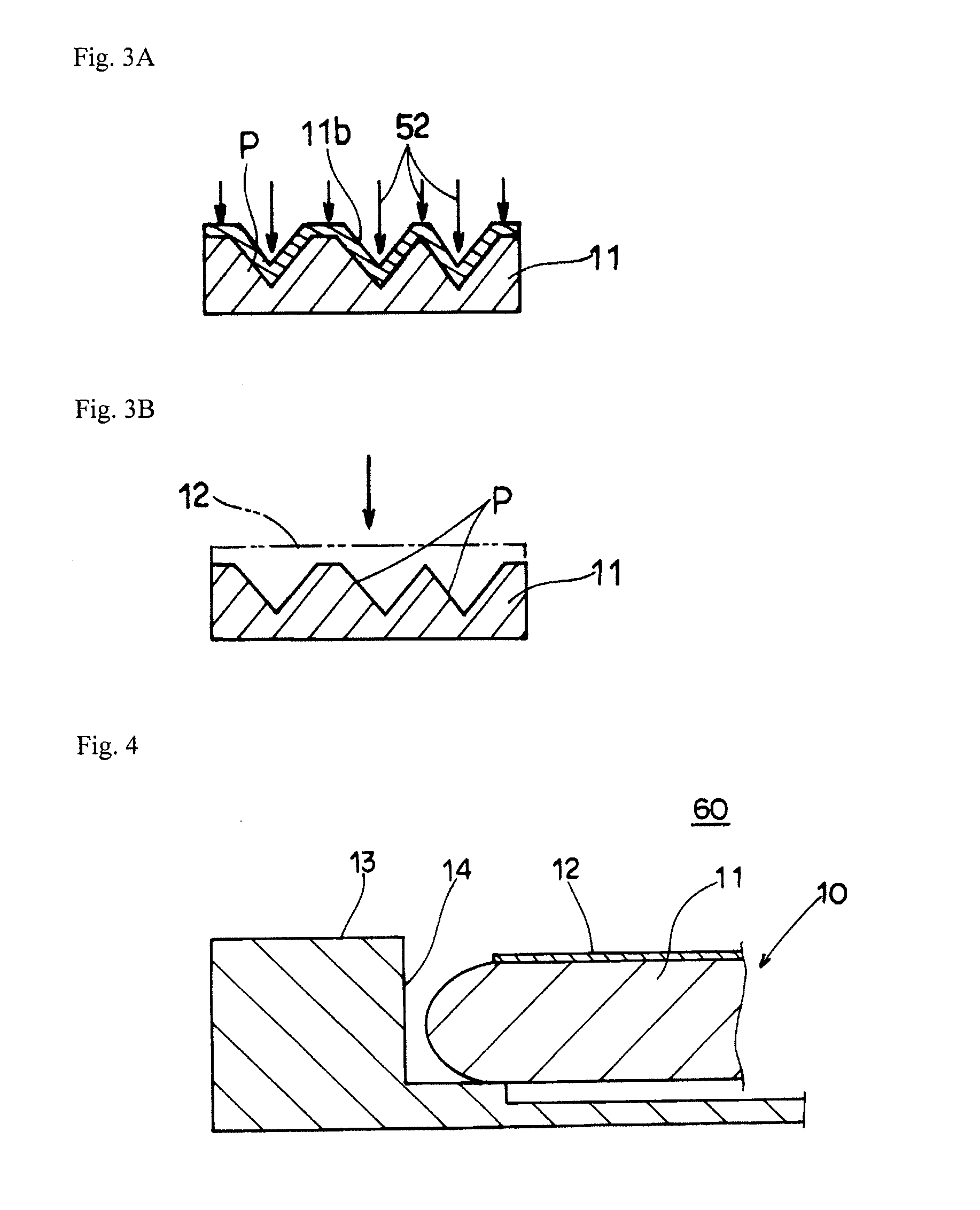

Method for manufacturing epitaxial silicon wafer

InactiveUS20100288192A1Enhancing wafer flatnessWithout reducing productivityPolycrystalline material growthAfter-treatment detailsProduction rateHydrogen fluoride

A silicon oxide film on a wafer front surface, including on internal surfaces of pits, is removed by hydrogen fluoride gas. The pits are thus completely filled with a film growth component at a time of epitaxial film growth. Thereby, productivity is not reduced; wafer flatness is enhanced; and micro-roughness of the wafer front surface is improved.

Owner:SUMCO CORP

Image processing apparatus and method controlling the amount of transparent ink for recording

InactiveUS20110090521A1Without reducing productivityLimited amountDigitally marking record carriersDigital computer detailsEngineeringImage processing

An image processing apparatus includes a calculation unit configured to calculate an amount of a first coloring material in an area including a plurality of pixels; a determination unit configured to determine an allowable amount of a second coloring material in the area on the basis of the amount of the first coloring material, calculated by the calculation unit, and a limit of the amount of the coloring material; and a control unit configured to control an amount of the second coloring material in the area so as not to exceed the allowable amount of the second coloring material.

Owner:CANON KK

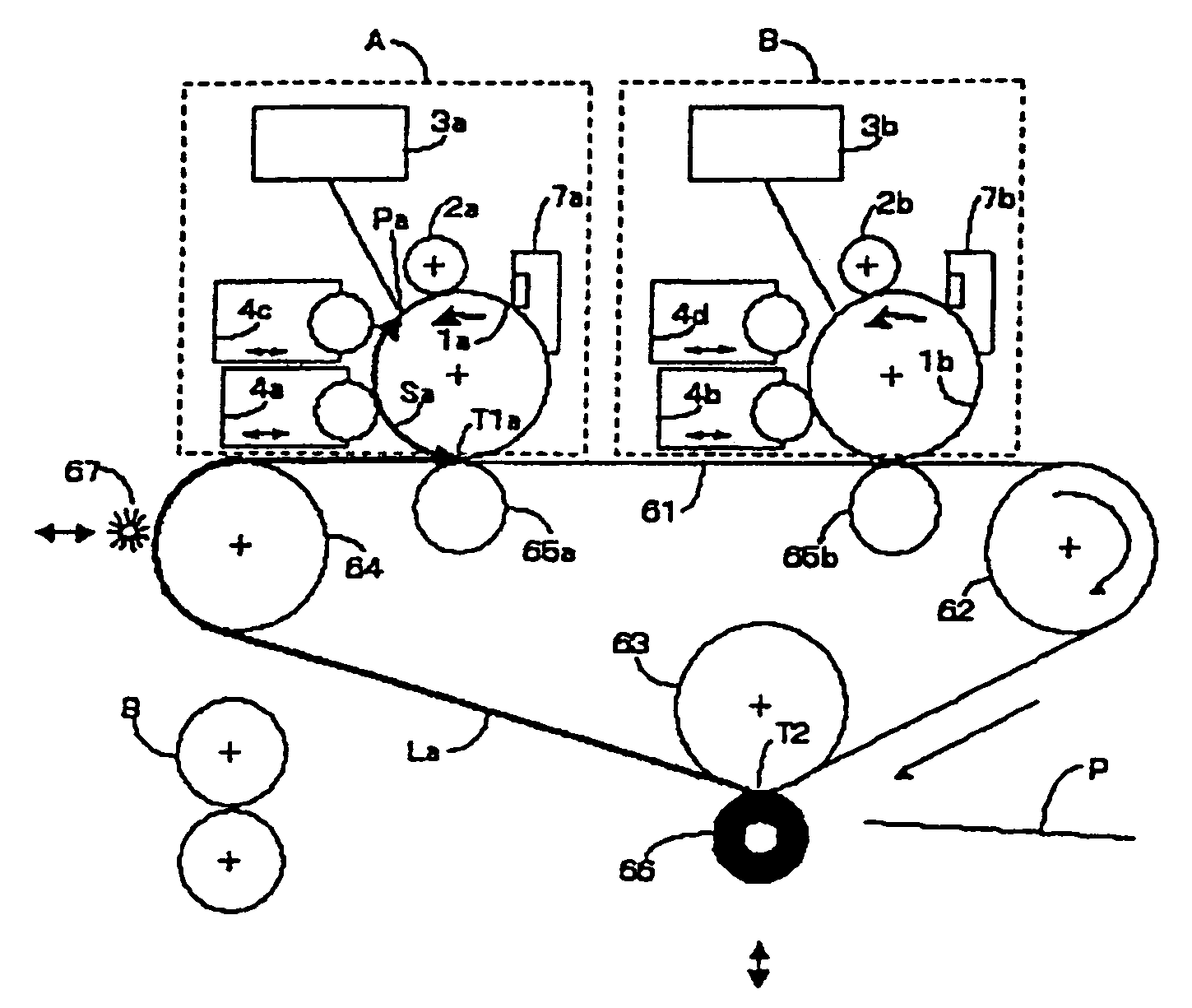

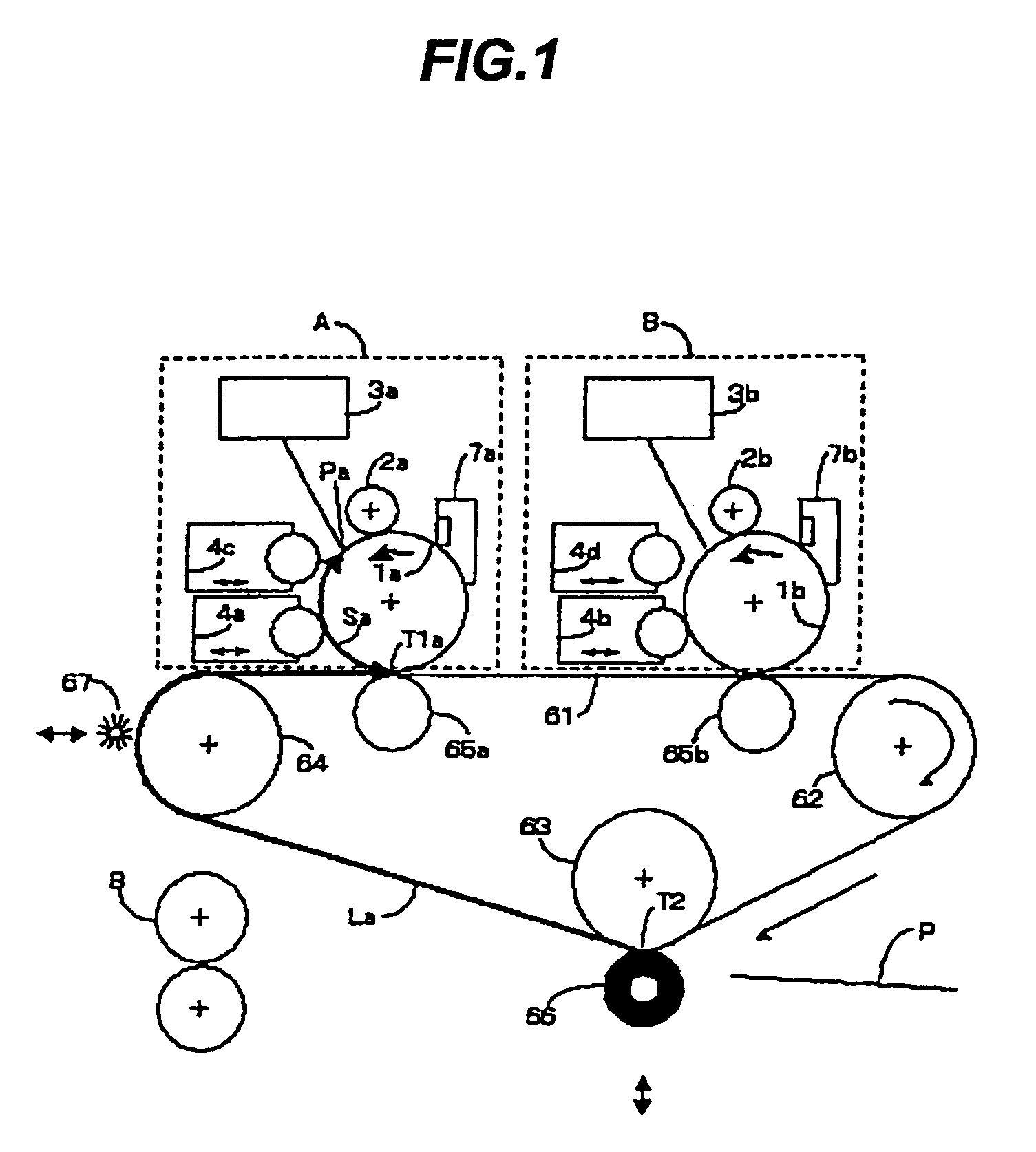

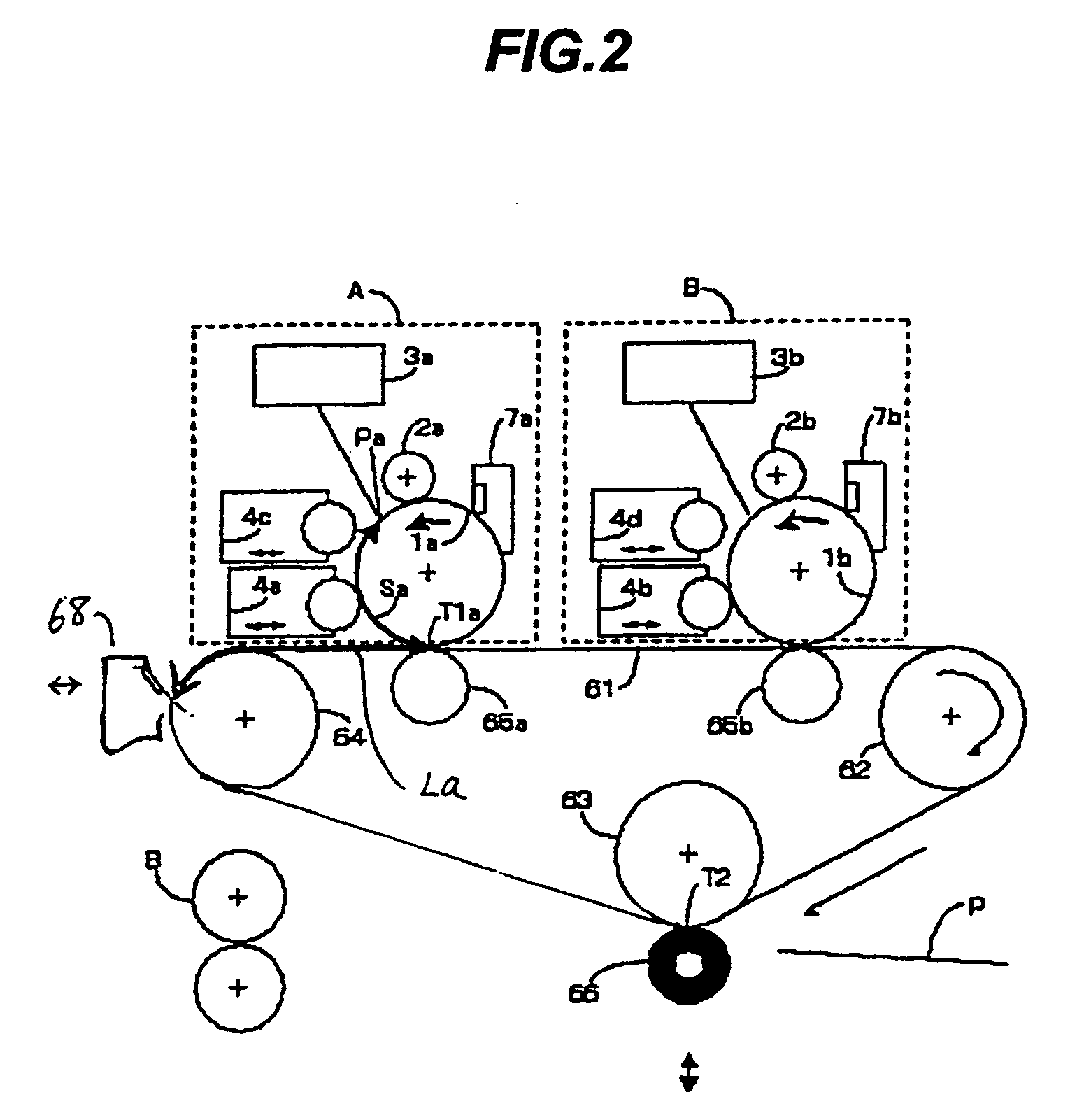

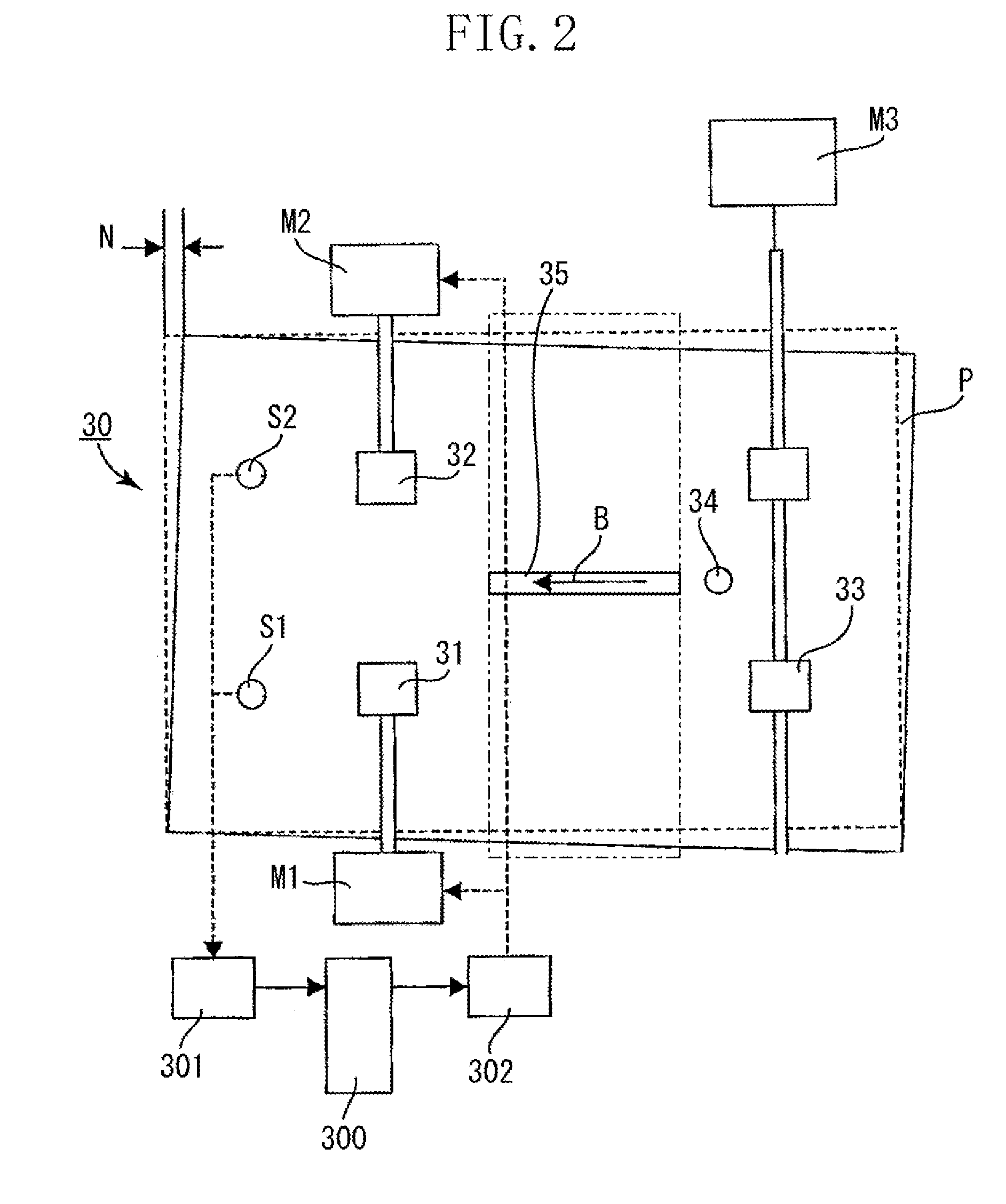

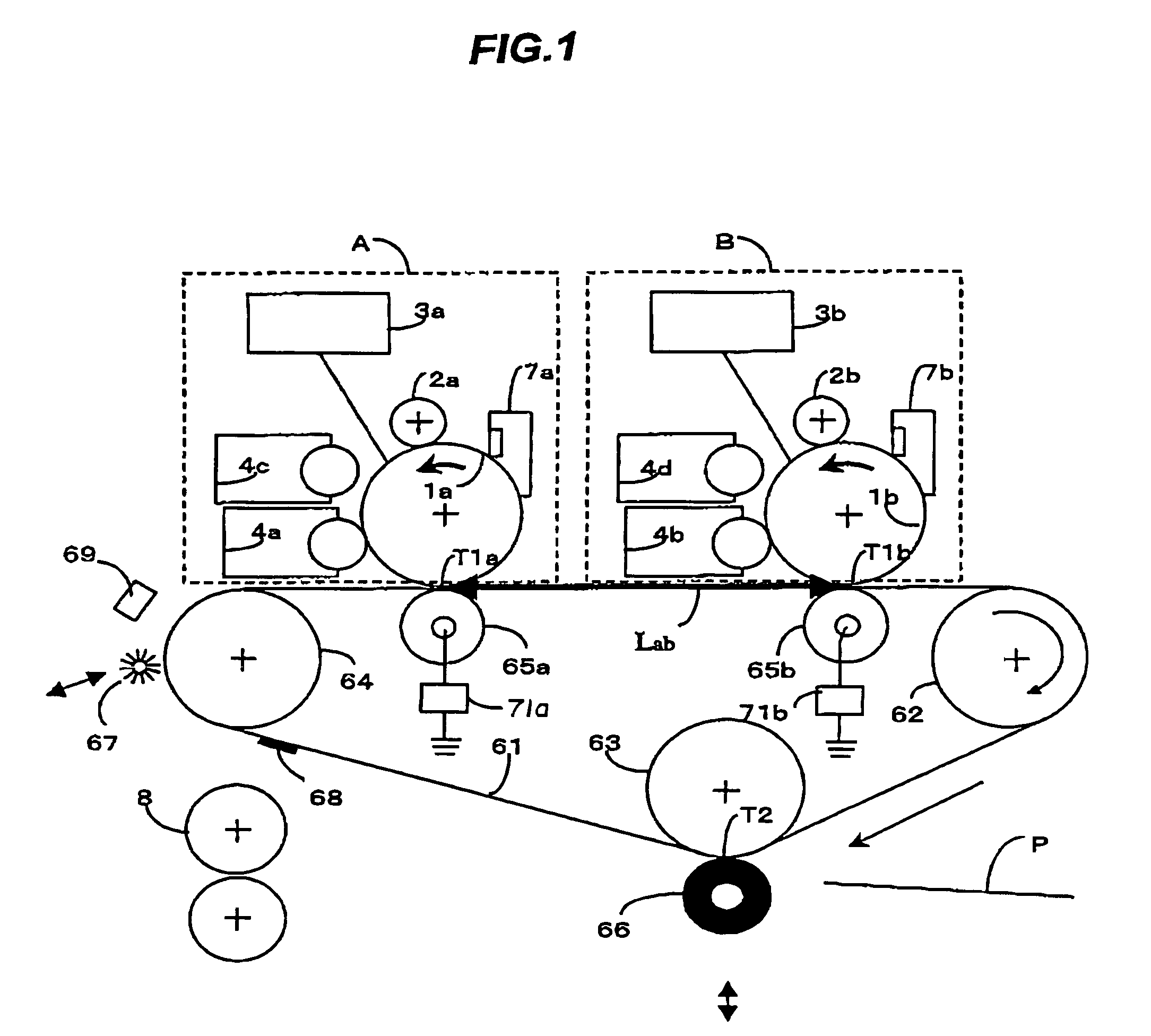

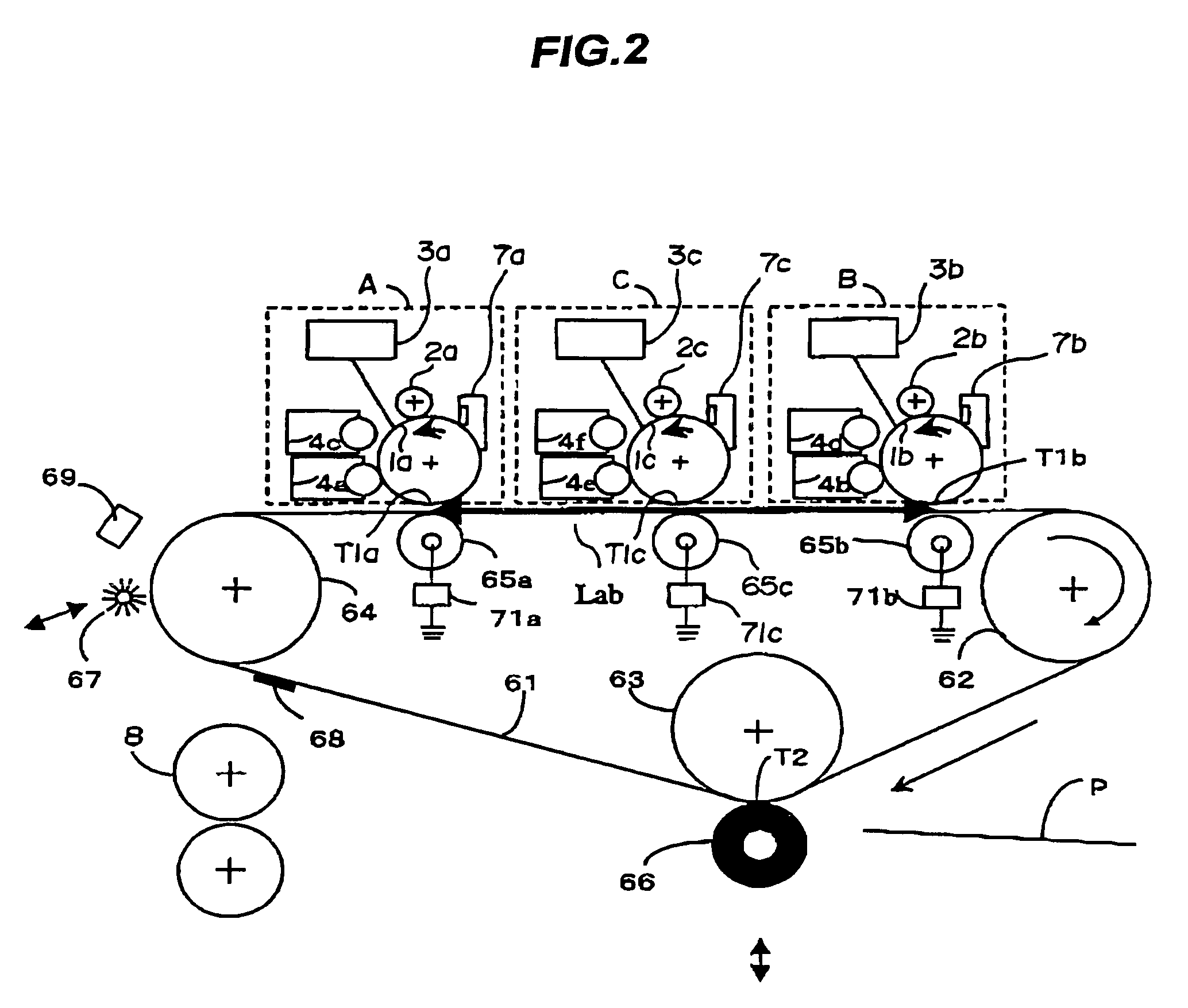

Image forming apparatus

InactiveUS7106981B2Without reducing productivityQuality improvementElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

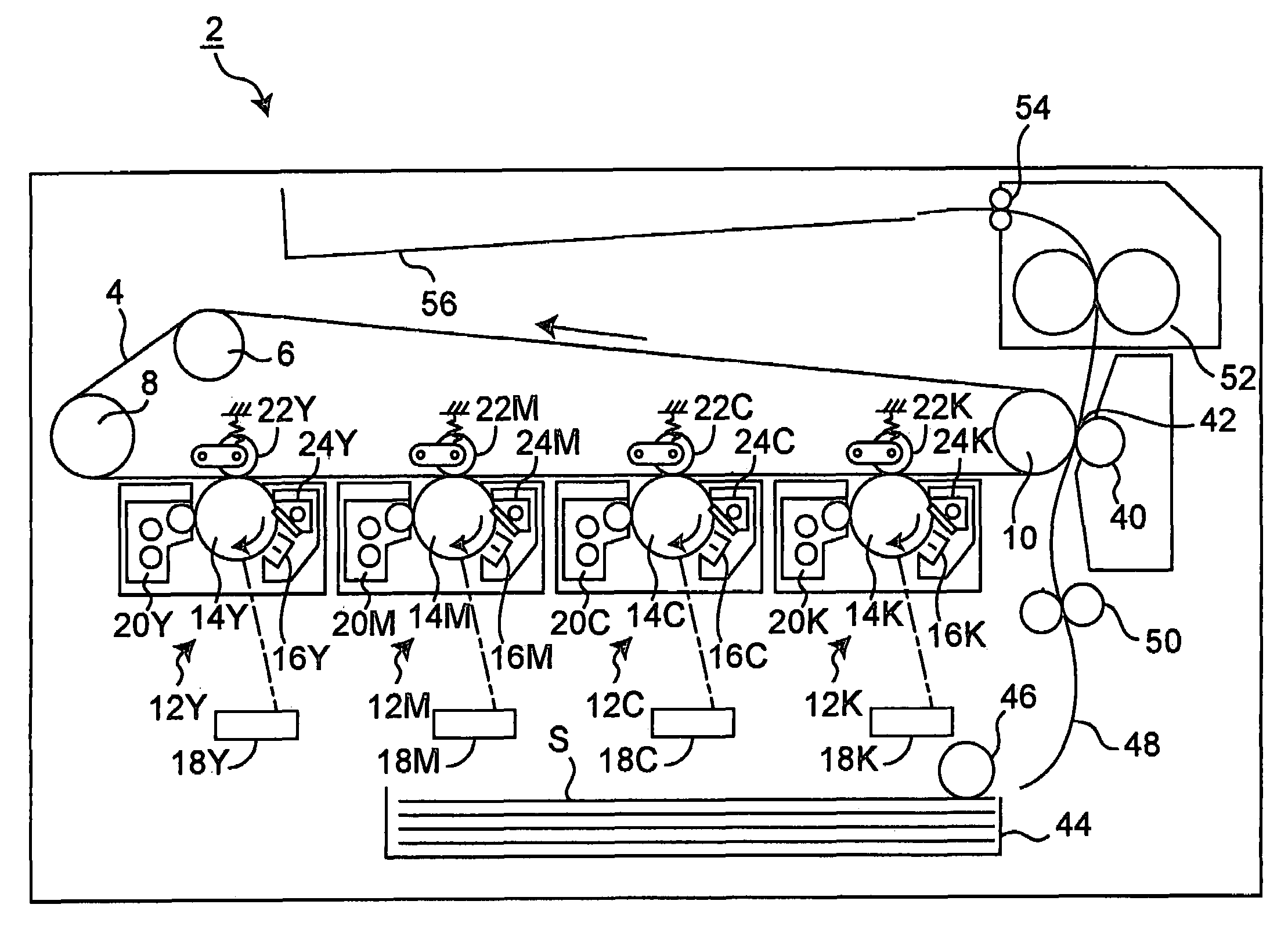

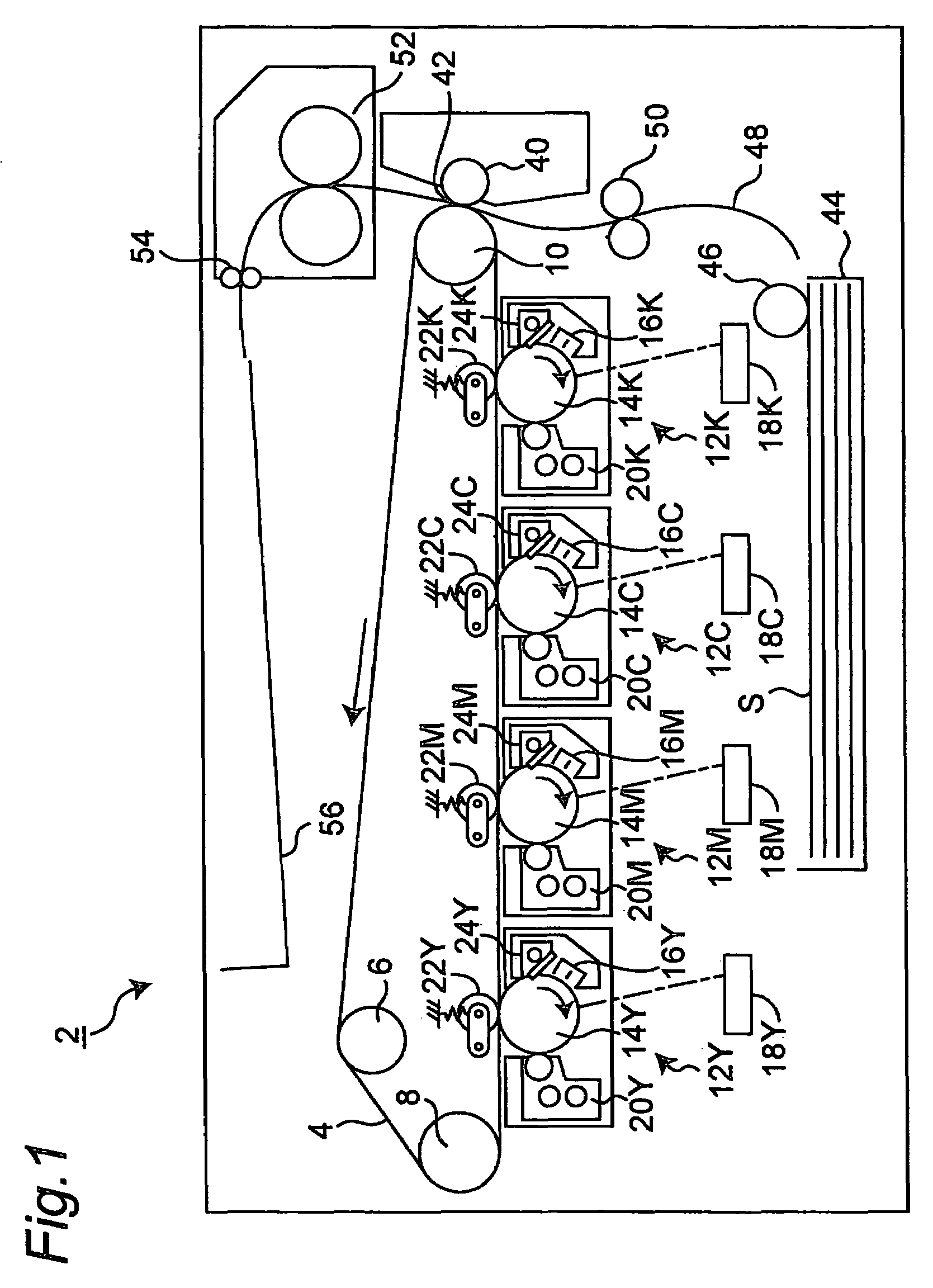

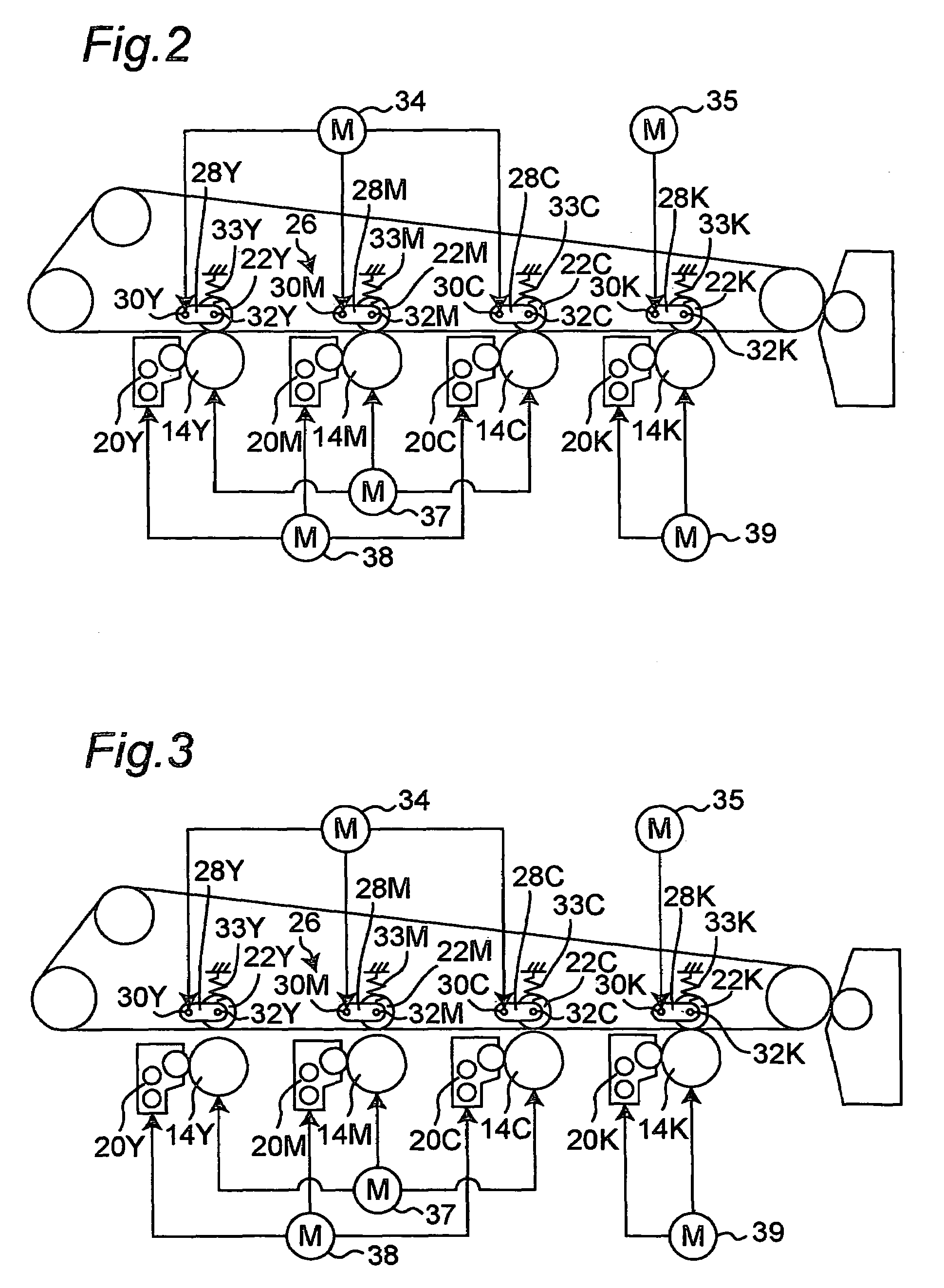

Image forming apparatus

InactiveUS7085524B2Without reducing productivityAvoid formingElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes a plurality of movable image carriers, a movable intermediate transfer body, and a contacting member separably contacting to the intermediate transfer body at a contacting position. A position for transfer between a first image carrier and the intermediate transfer body defines a first transfer position. A position for transfer between a second image carrier and the intermediate transfer body defines a second transfer position. A toner image formed on said intermediate transfer body is again transferred onto a transfer material after passing through said first transfer position and said second transfer position. The latent image formation on the first image carrier is done at a time different from a contacting operation of the contacting member.

Owner:CANON KK

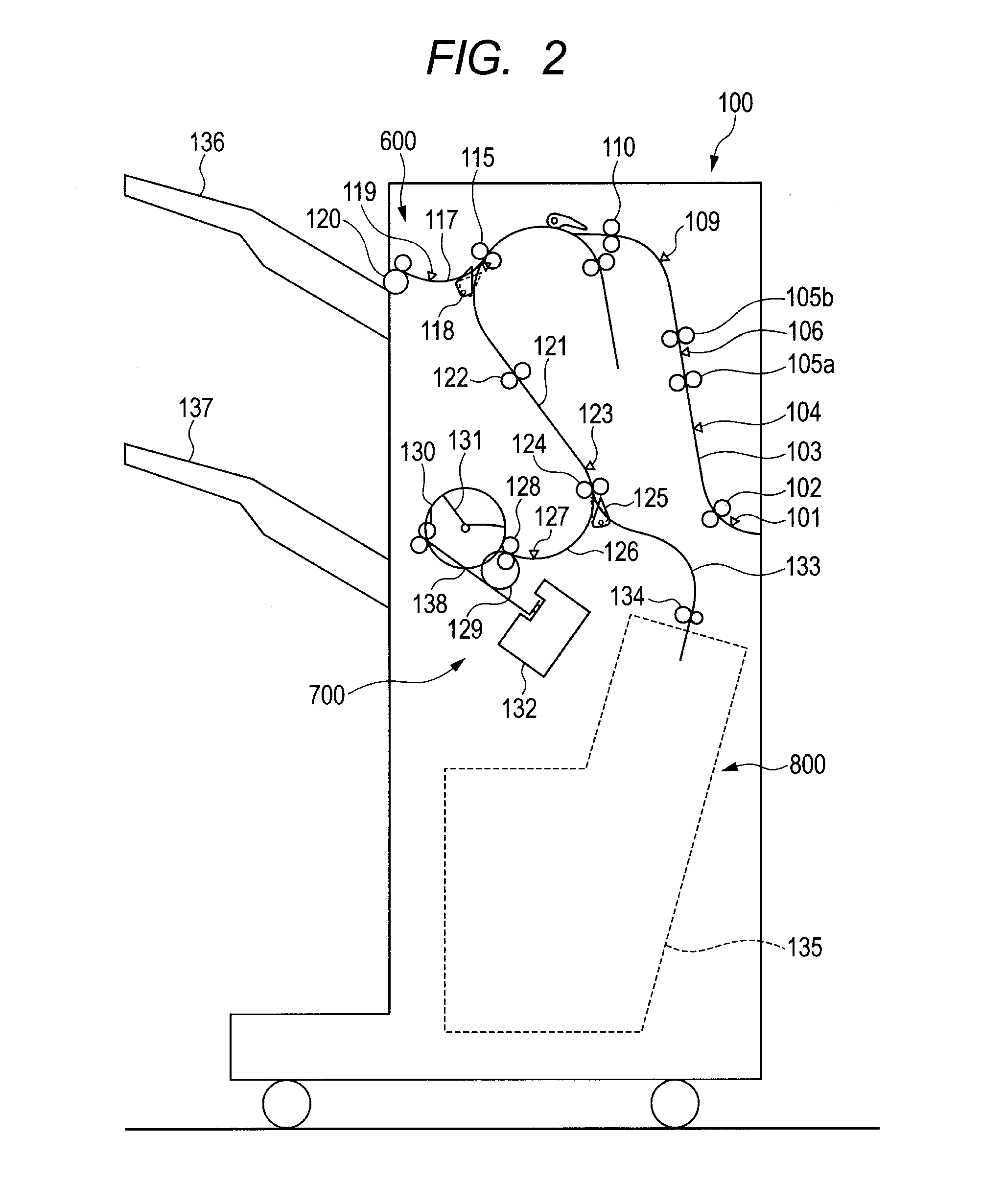

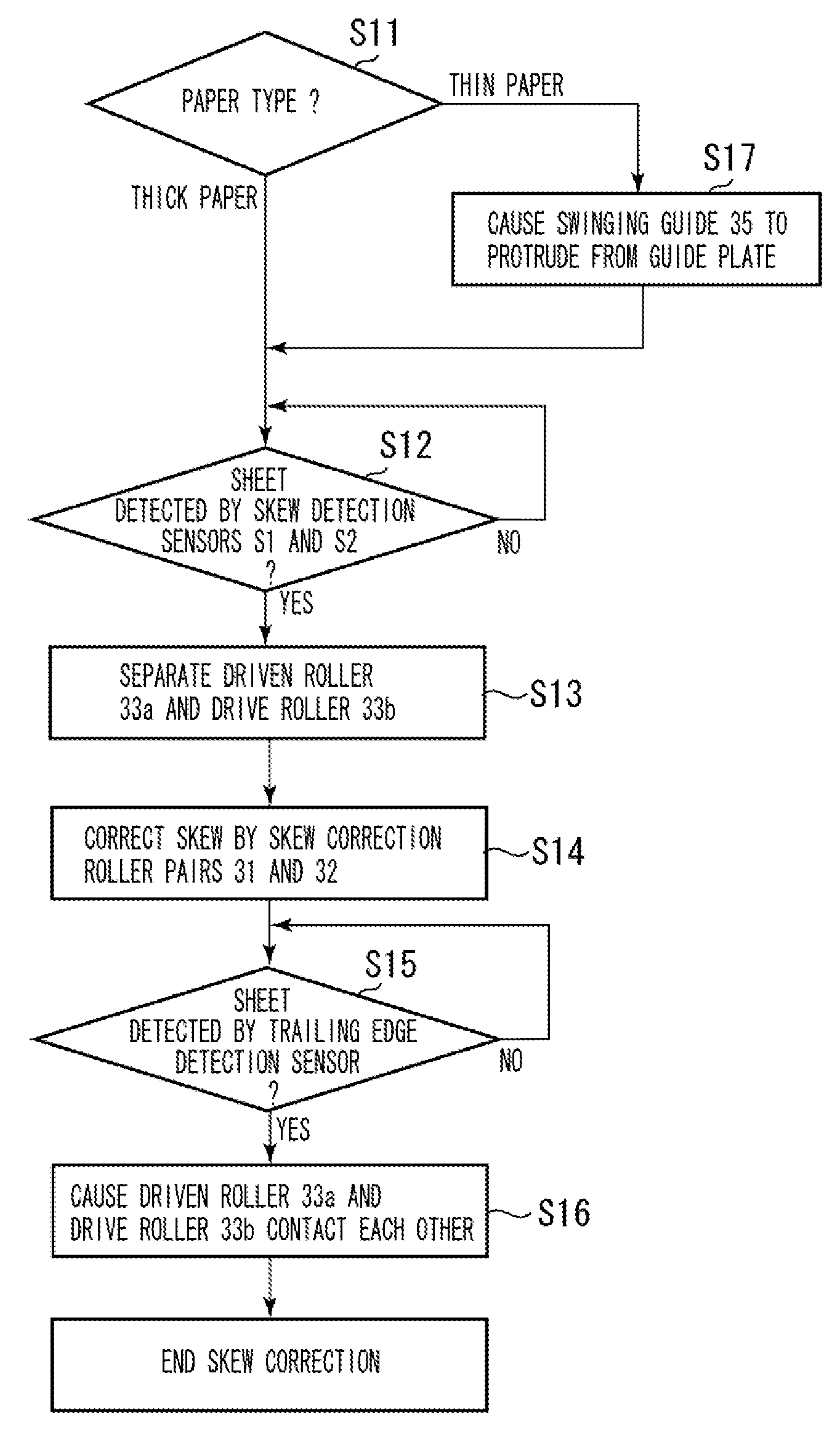

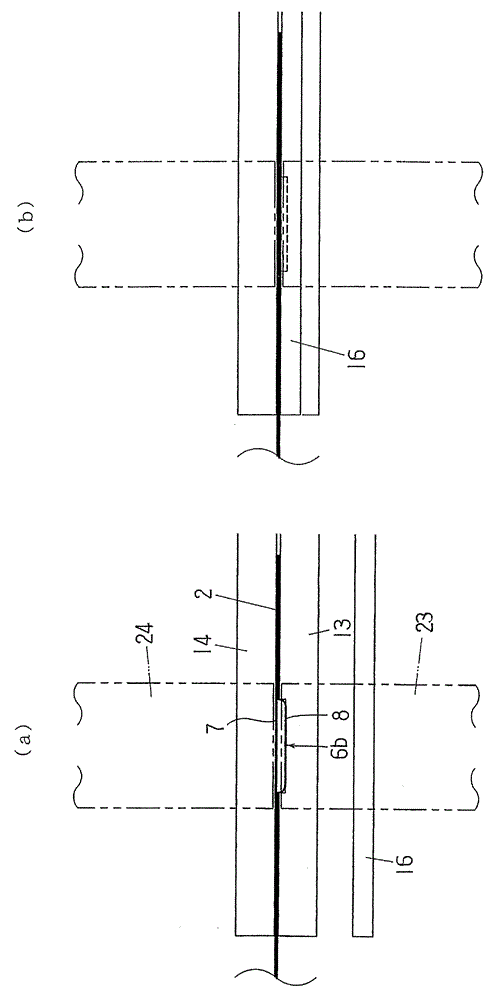

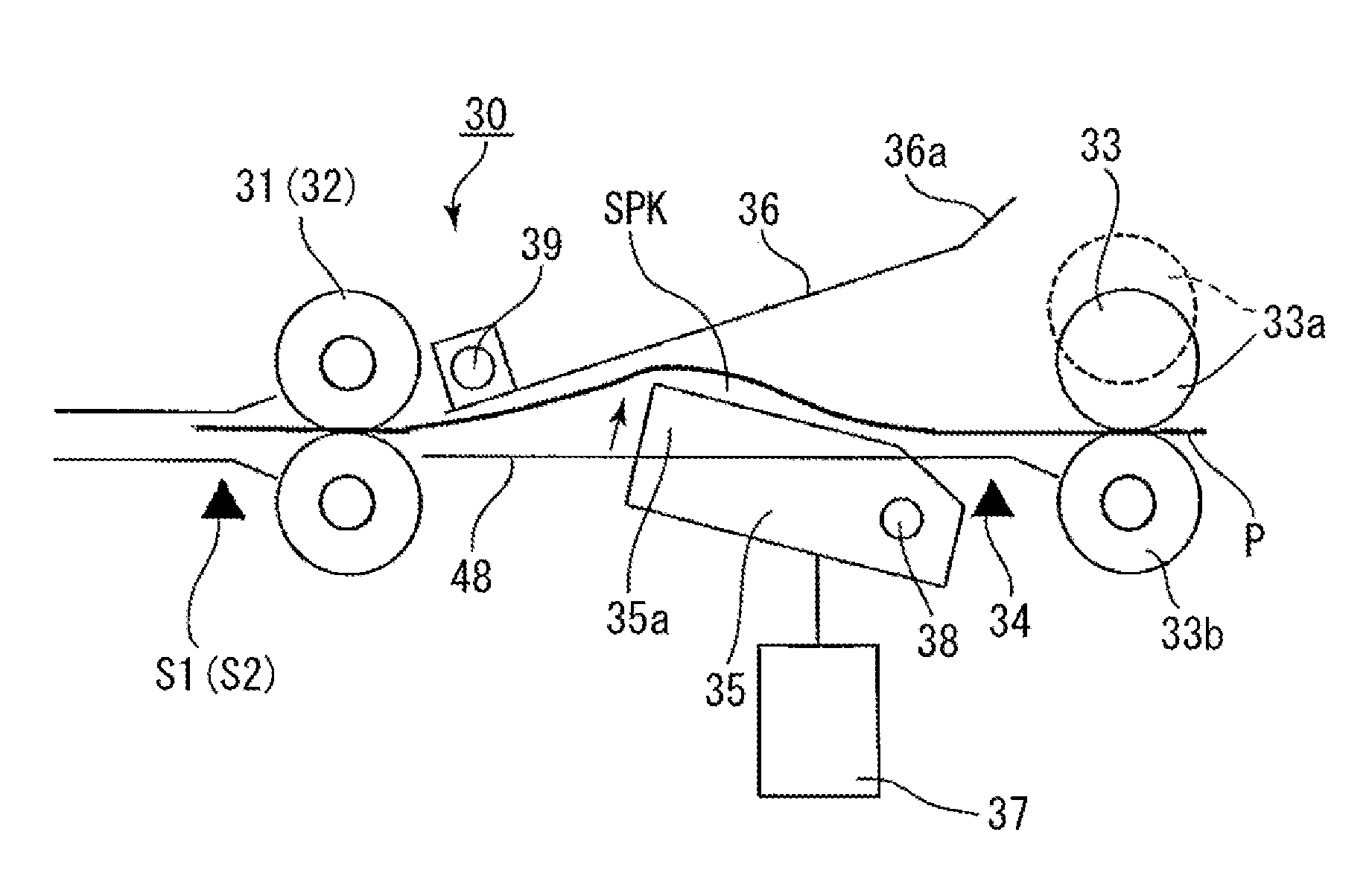

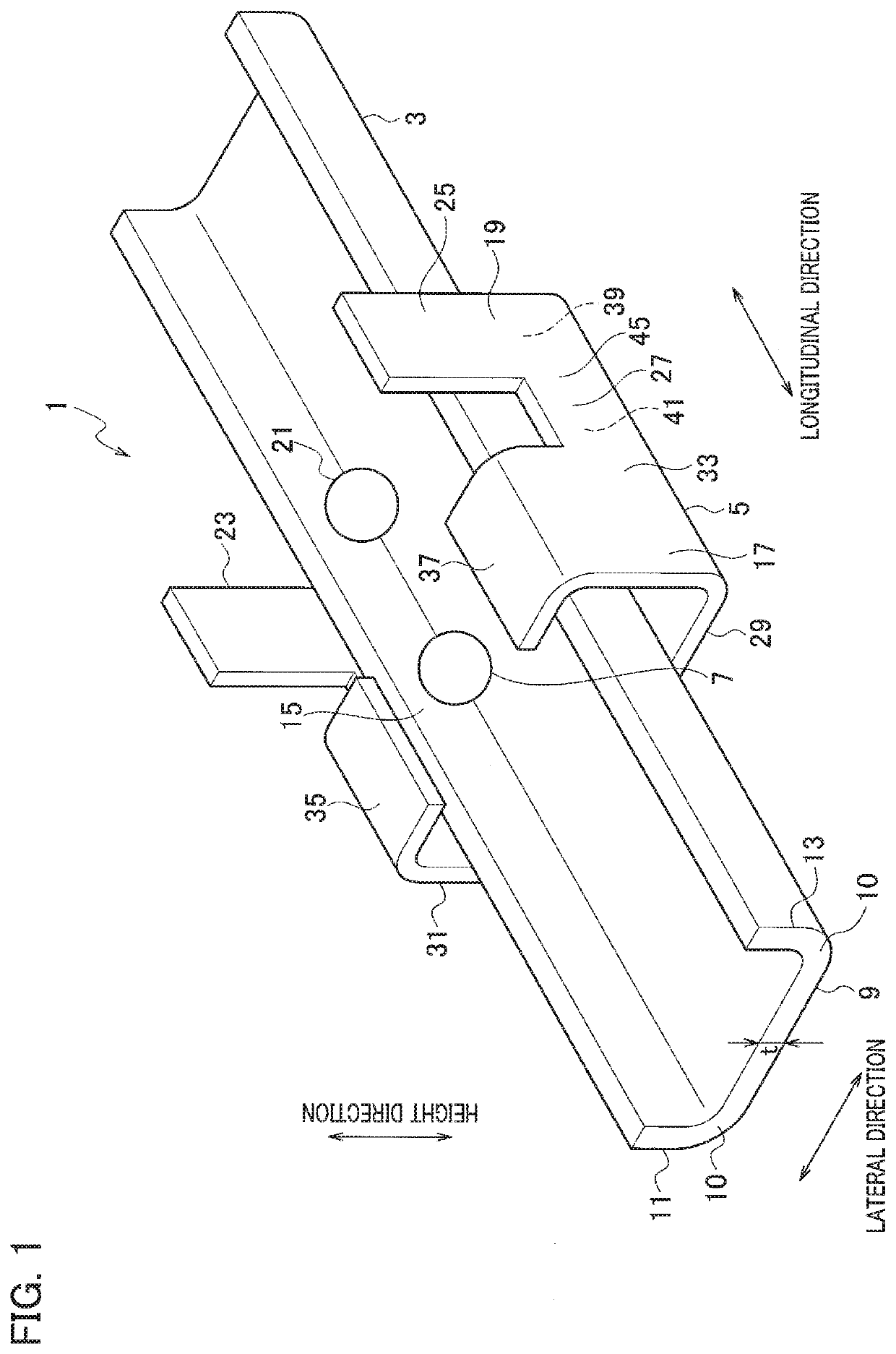

Sheet conveying apparatus and image forming apparatus

InactiveUS20080036137A1Without reducing productivityRegistering devicesFunction indicatorsMechanical engineering

A registration unit includes a skew correction roller pair configured to rotate a sheet conveyed from a conveyance roller pair and to correct skew of the sheet. The registration unit sheet further includes a projectable swinging guide arranged between the conveyance roller pair and the skew correction roller pair to deflect the sheet. The skew correction roller pair corrects the skew of the sheet deflected by the swinging guide.

Owner:CANON KK

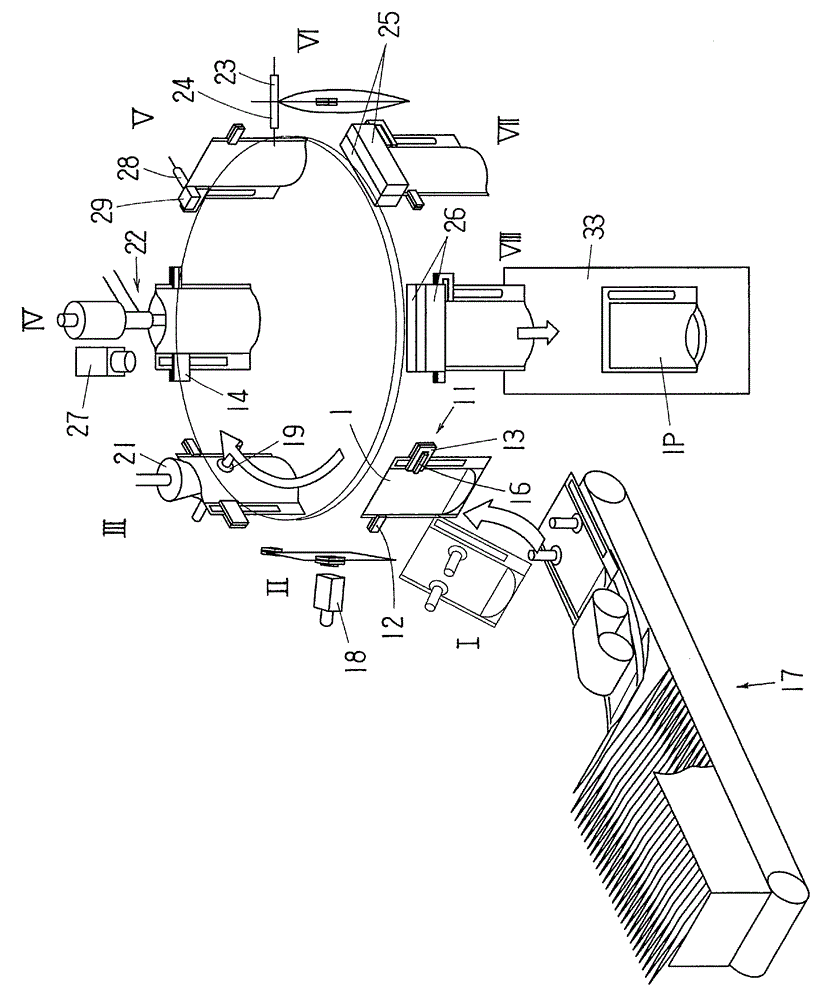

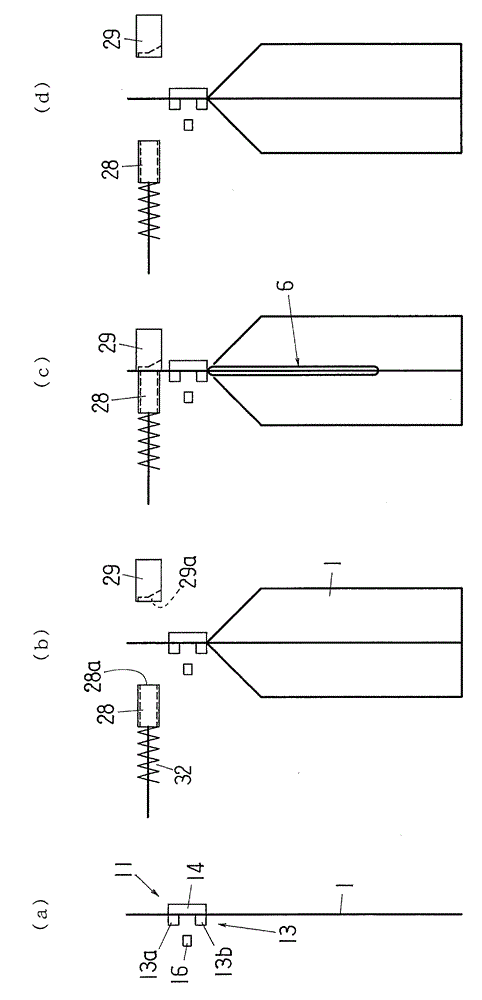

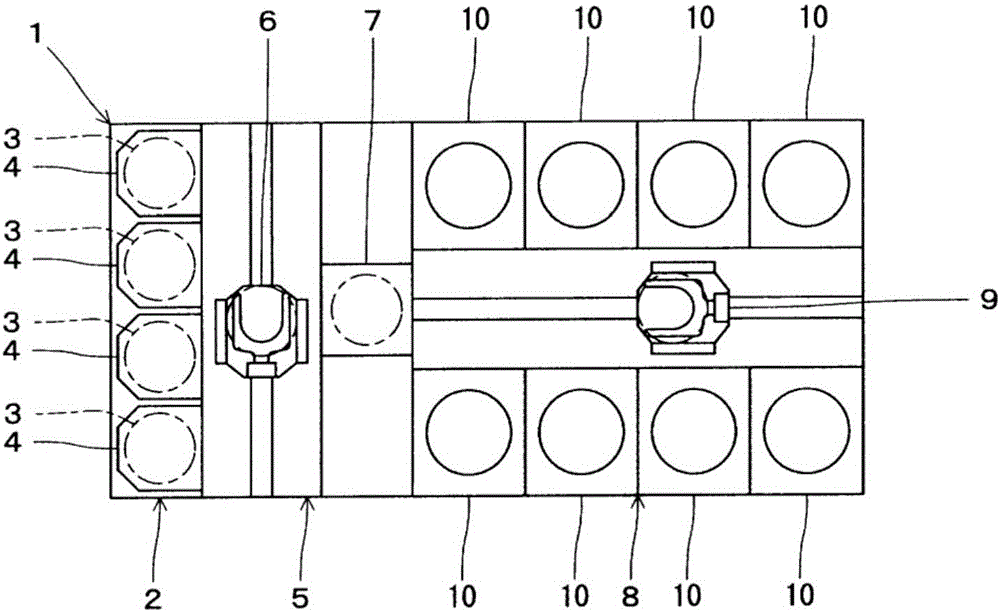

Gas Charging Method And Gas Charging Apparatus For Bag Equipped With Gas Compartment Portion

ActiveCN104029861AEvenly filledWithout reducing productivityPackaging by pressurising/gasifyingWrapper twisting/gatheringProduction rateEngineering

The invention relates to a gas charging method and a gas charging apparatus for a bag equipped with a gas compartment portion. Even in a circumstance that the front and rear film sheets (7, 8) of the gas compartment portion are adhered firmly due to static electricity, the production rate is not reduced and filling to the gas compartment portion (6) can be performed successfully. In a stop position (IV), a pre-heating step of the gas compartment portion (6) of the bag (1) is performed by a heated gas-blowing nozzle (27). A preliminary gas injection step for injecting gas into the gas compartment portion is performed by a gas blowing nozzle (28) and a receiving member (29) in stop position (V). Then, a gas filling step is carried out in stop position (VI) by gas injection nozzles (23, 24), and the incision (9) in the gas compartment portion is sealed in the stop position (VII). In the following pre-heating step, the front and rear film sheets (7, 8) of the gas compartment portion (6) are softened, and in the preliminary gas injection step, the film sheets (7, 8) are separated and their adhesion is eliminated.

Owner:TOYO JIDOKI CO LTD

Image processing apparatus and method controlling the amount of transparent ink for recording

InactiveUS7940425B2Without reducing productivityLimited amountDigitally marking record carriersDigital computer detailsImaging processingMagenta

An image processing apparatus includes a calculation unit configured to calculate an amount of a first coloring material (at least one of cyan, magenta, yellow and black) in an area including a plurality of pixels; a determination unit configured to determine an allowable amount of a second coloring material, being substantially colorless and transparent, in the area on the basis of the amount of the first coloring material, calculated by the calculation unit, and a limit of the amount of the coloring material; and a control unit configured to control an amount of the second coloring material in the area so as not to exceed the allowable amount of the second coloring material.

Owner:CANON KK

Sheet conveying apparatus and image forming apparatus

InactiveUS7798491B2Without reducing productivityRegistering devicesFunction indicatorsEngineeringMechanical engineering

A registration unit includes a skew correction roller pair configured to rotate a sheet conveyed from a conveyance roller pair and to correct skew of the sheet. The registration unit sheet further includes a projectable swinging guide arranged between the conveyance roller pair and the skew correction roller pair to deflect the sheet. The skew correction roller pair corrects the skew of the sheet deflected by the swinging guide.

Owner:CANON KK

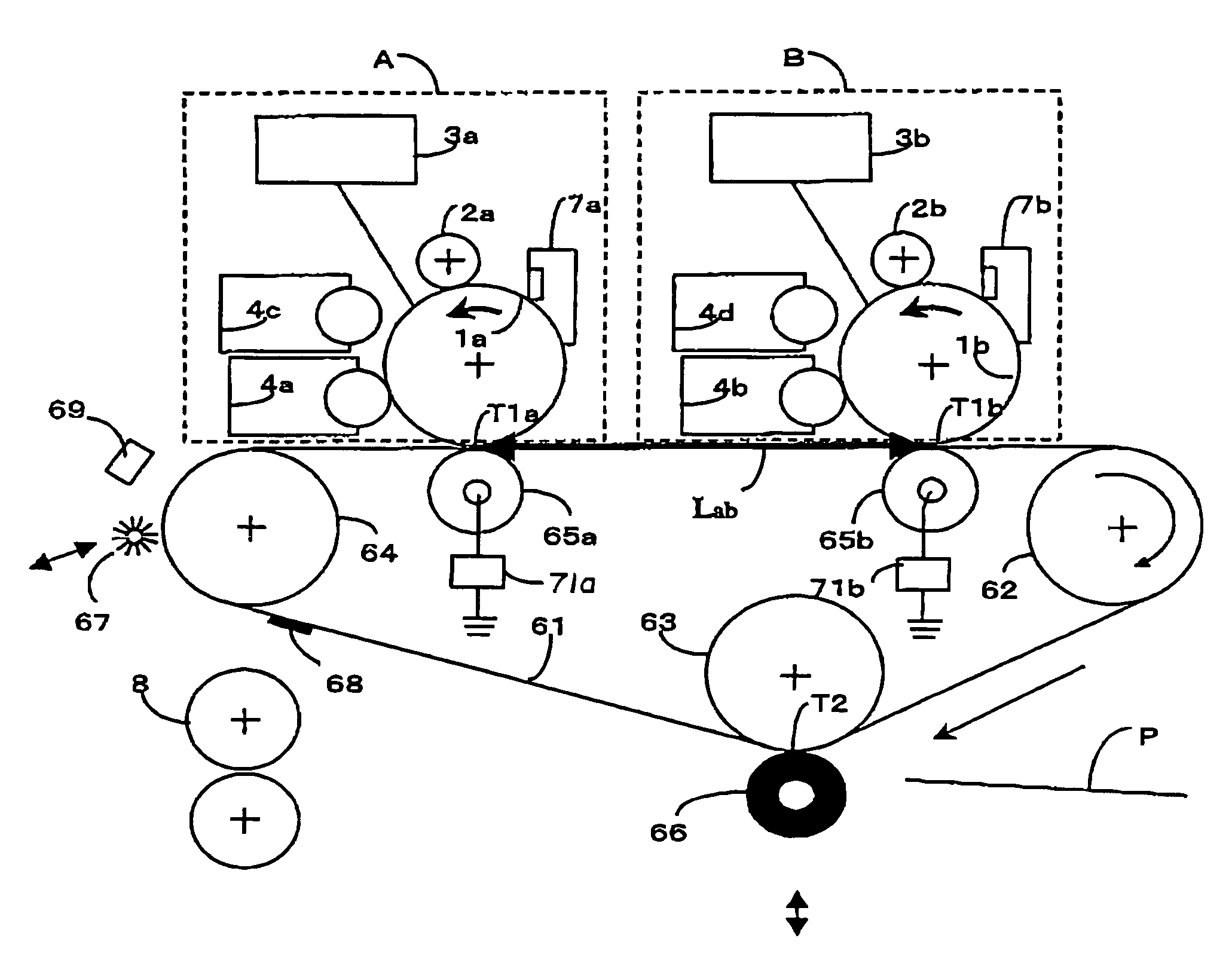

Imaging forming apparatus

InactiveUS7010254B2Avoid interferenceWithout reducing productivityElectrographic process apparatusImage formationEngineering

Owner:CANON KK

Method for fabricating semiconductor device, and electro-optical device, integrated circuit and electronic apparatus including the semiconductor device

InactiveUS20050026340A1Enhance the imageReduce throughputTransistorOther printing matterProduction rateDevice material

The invention provides a technique that enables formation of minute patterns on an uneven substrate in volume production without reducing productivity. The method for fabricating a semiconductor device includes: first patterning a semiconductor film on a substrate to form element regions, each of which will be provided with a source / drain region and a channel region, second forming a gate insulating film covering segments of the patterned semiconductor film in the respective element regions, third forming gate electrodes on the gate insulating film at predetermined positions, and fourth forming the source / drain region and the channel region in each element region. At least the gate electrodes are formed by a process including an exposure step through a holographic exposure mask in the third step, and by a process including an exposure step through a projection exposure mask, the element regions are formed in the first step, and the source / drain regions and the channel regions are formed in the fourth step.

Owner:SEIKO EPSON CORP

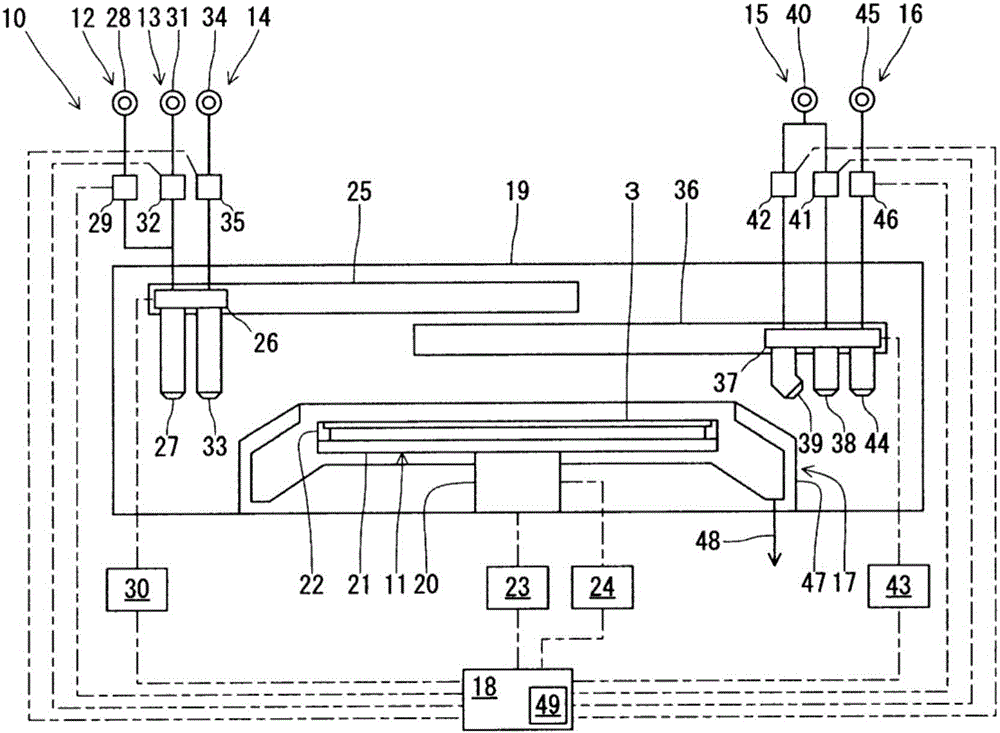

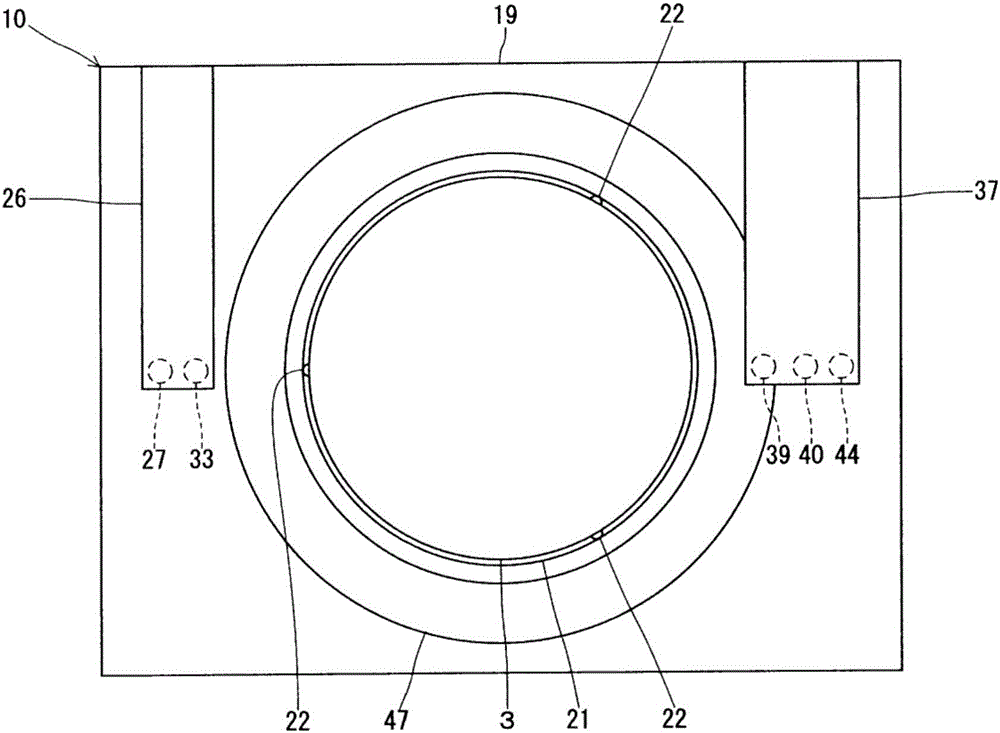

Substrate-processing device, substrate-processing method, and computer-readable recording medium on which substrate-processing program has been recorded

ActiveCN106463377AEasy to handleInhibitionDrying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate-processing device is provided with: a substrate rotation unit (11) for causing a substrate (3) to turn while the substrate (3) is held; a processing liquid feeding unit (13) for feeding a processing liquid to the substrate; and a substitution liquid feeding unit for feeding a substitution liquid, which is substituted for the processing liquid fed from the processing liquid feeding unit, to the substrate. When the substitution liquid feeding unit (14) is feeding the substitution liquid to the substrate, the processing liquid feeding unit (13) feeds the processing liquid to a position further on the outer periphery side of the substrate than the position at which the substitution liquid fed from the substitution liquid feed unit is fed onto the substrate, and a liquid film of the processing liquid is formed. The entirety of the surface of the substrate can be kept covered by a liquid film without increasing the amount of the substitution liquid consumed.

Owner:TOKYO ELECTRON LTD

Applying apparatus

ActiveUS20160059170A1Increase flow rateEffective exhaustCombination devicesPrinted circuit assemblingEngineeringNozzle

An applying apparatus that applies a flux liquid includes: a nozzle from which the flux liquid is injected; and an intake and exhaust unit that sucks the flux liquid injected from the nozzle through an intake port and exhausts a gas through an exhaust port. The intake and exhaust unit has a filtering unit that filters the flux liquid sucked through the intake port and through which the gas passes before the gas reaches the exhaust port. The filtering unit is movably provided within the intake and exhaust unit so that when installing / removing the filtering unit with respect to the intake and exhaust unit, the filtering unit moves in a direction substantially parallel to a direction in which the flux liquid is sucked through the intake port and in which the gas is exhausted through the exhaust port.

Owner:FUJITSU GENERAL LTD

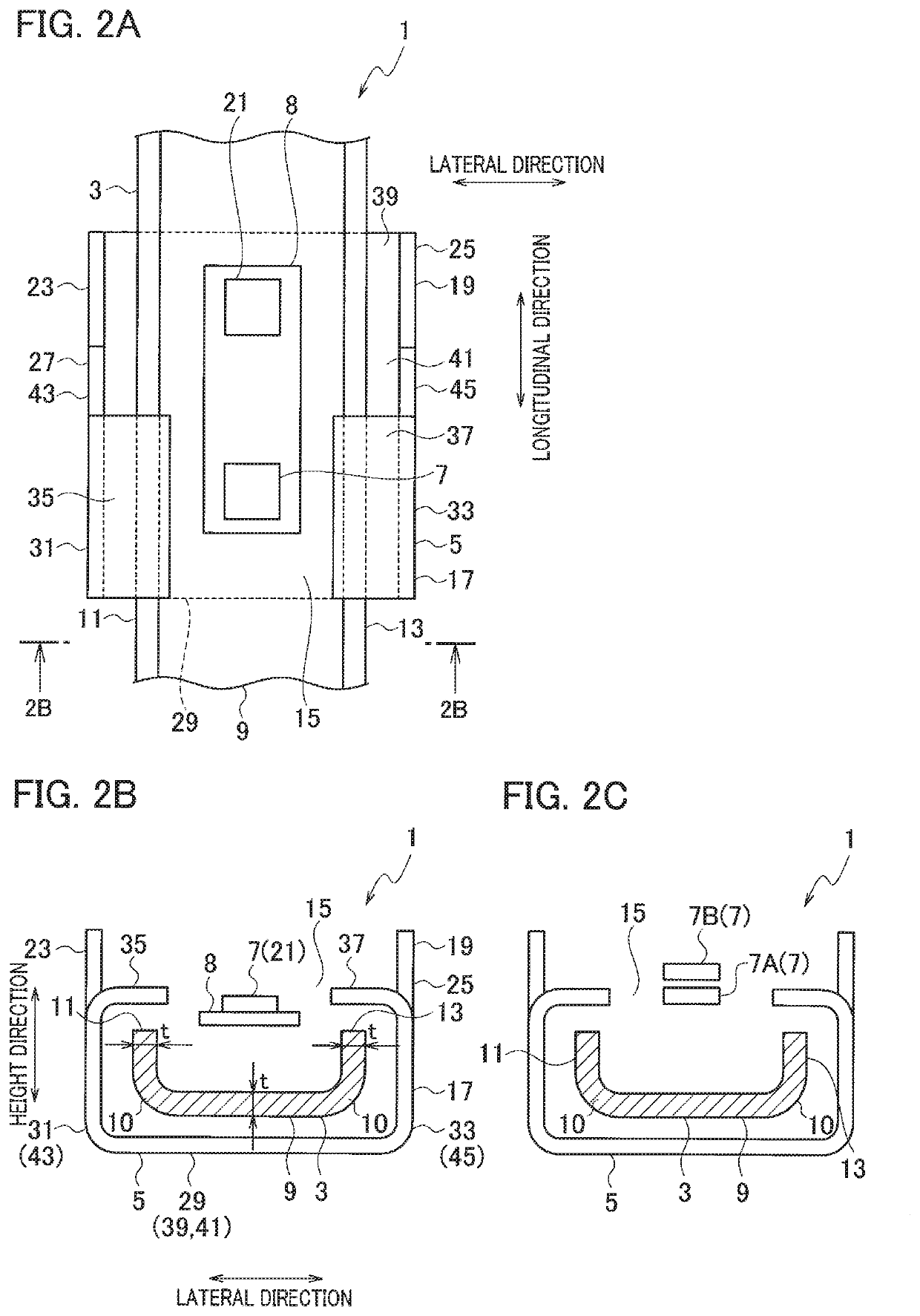

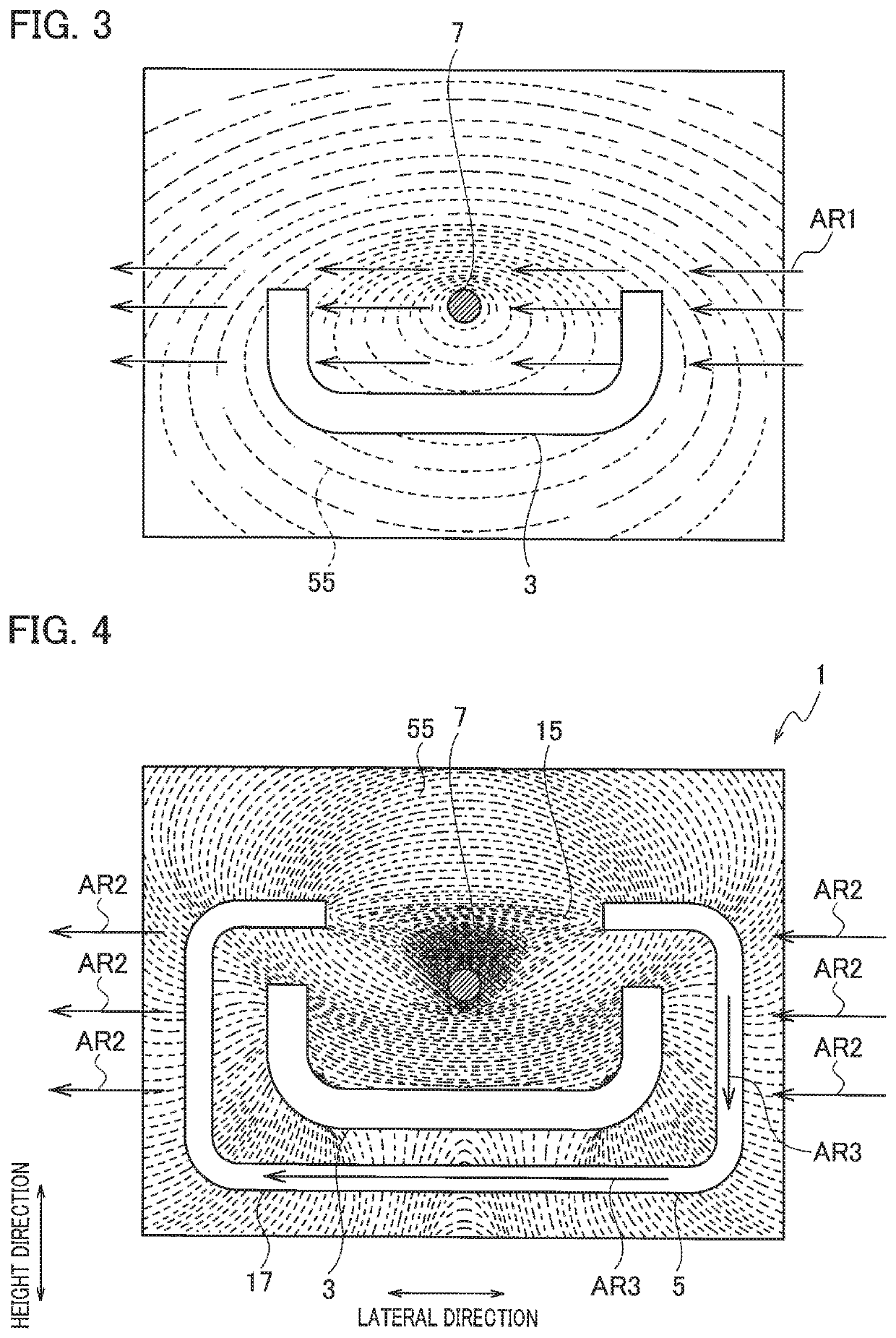

Current detection device

ActiveUS20200158760A1Without reducing productivityInstrument screening arrangementsCurrent measurements onlyCurrent transducerBusbar

In a current detection device, a busbar extends through the interior of a shield member. The busbar is thin in thickness and yet is bent, when viewed in a direction of extension. A current sensor detects a magnetic field generated by an electric current flowing in the busbar.

Owner:YAZAKI CORP

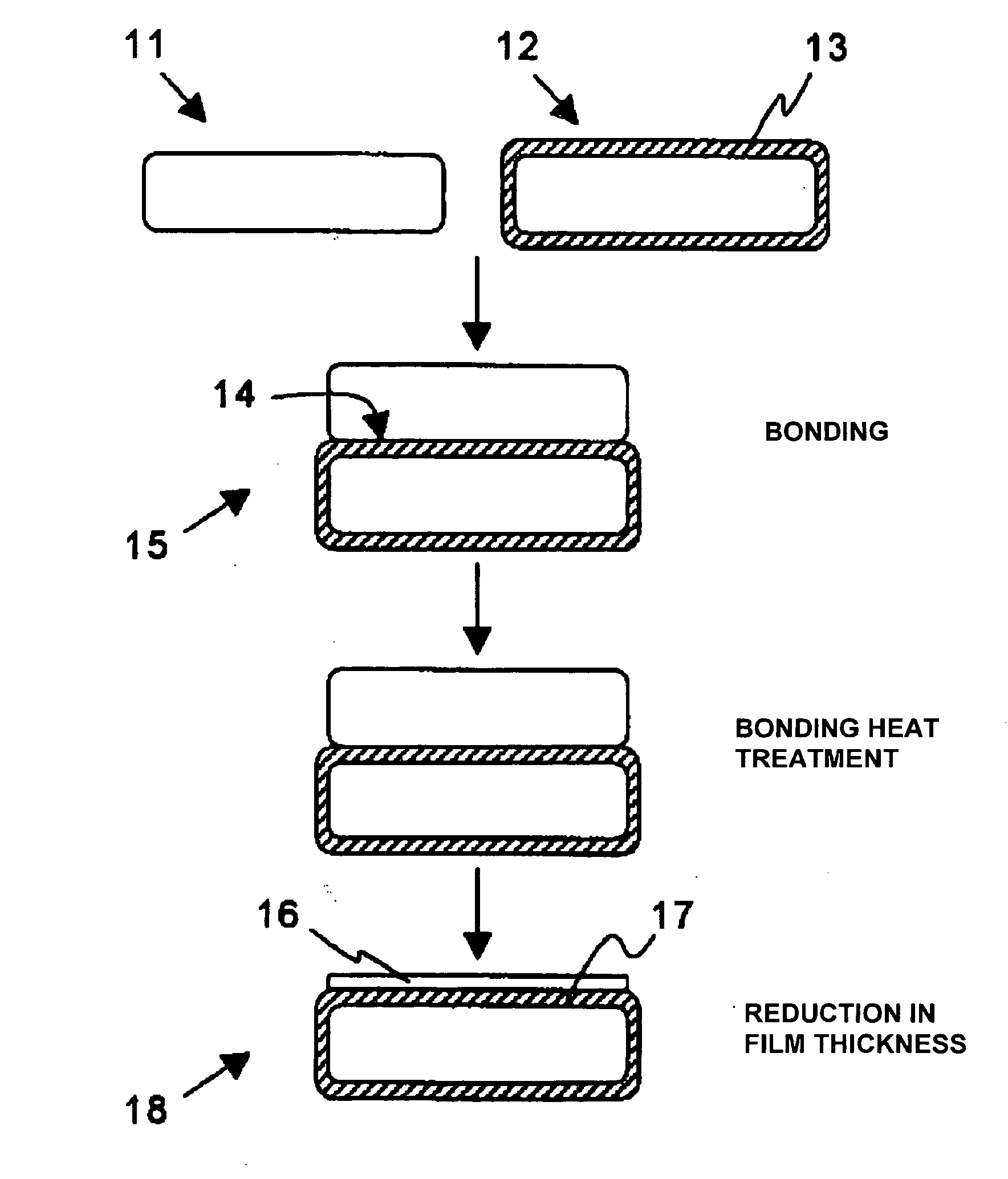

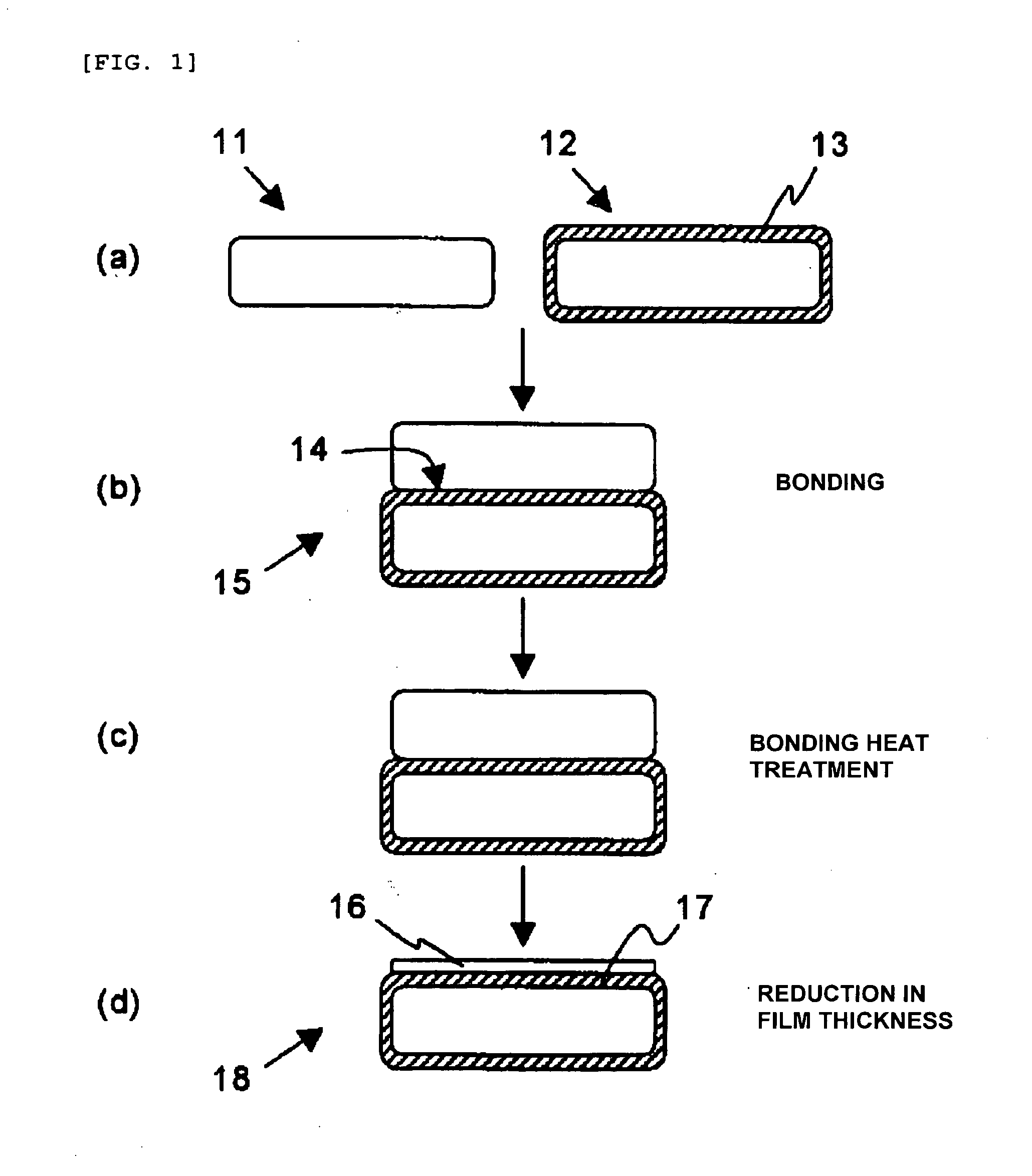

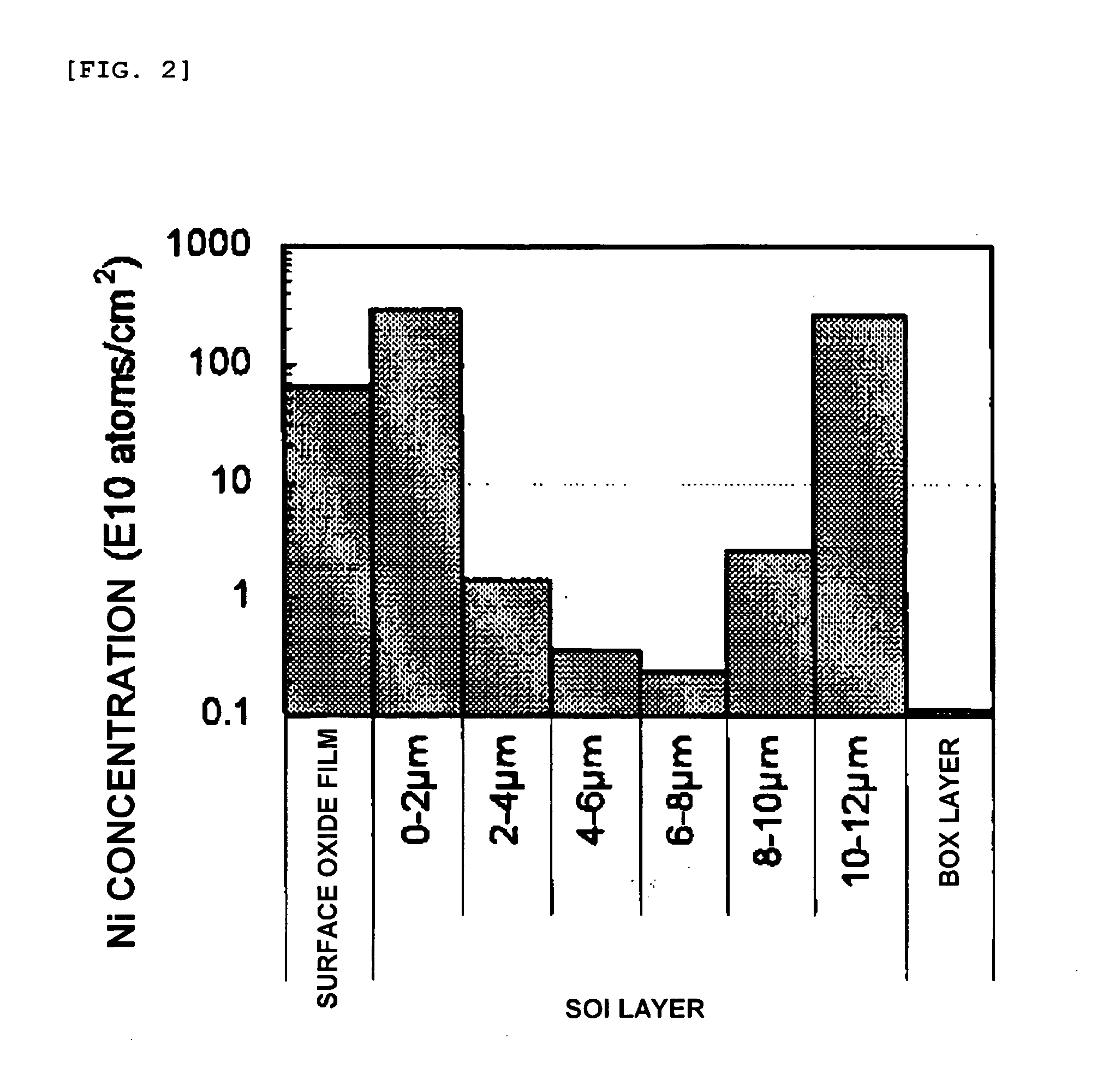

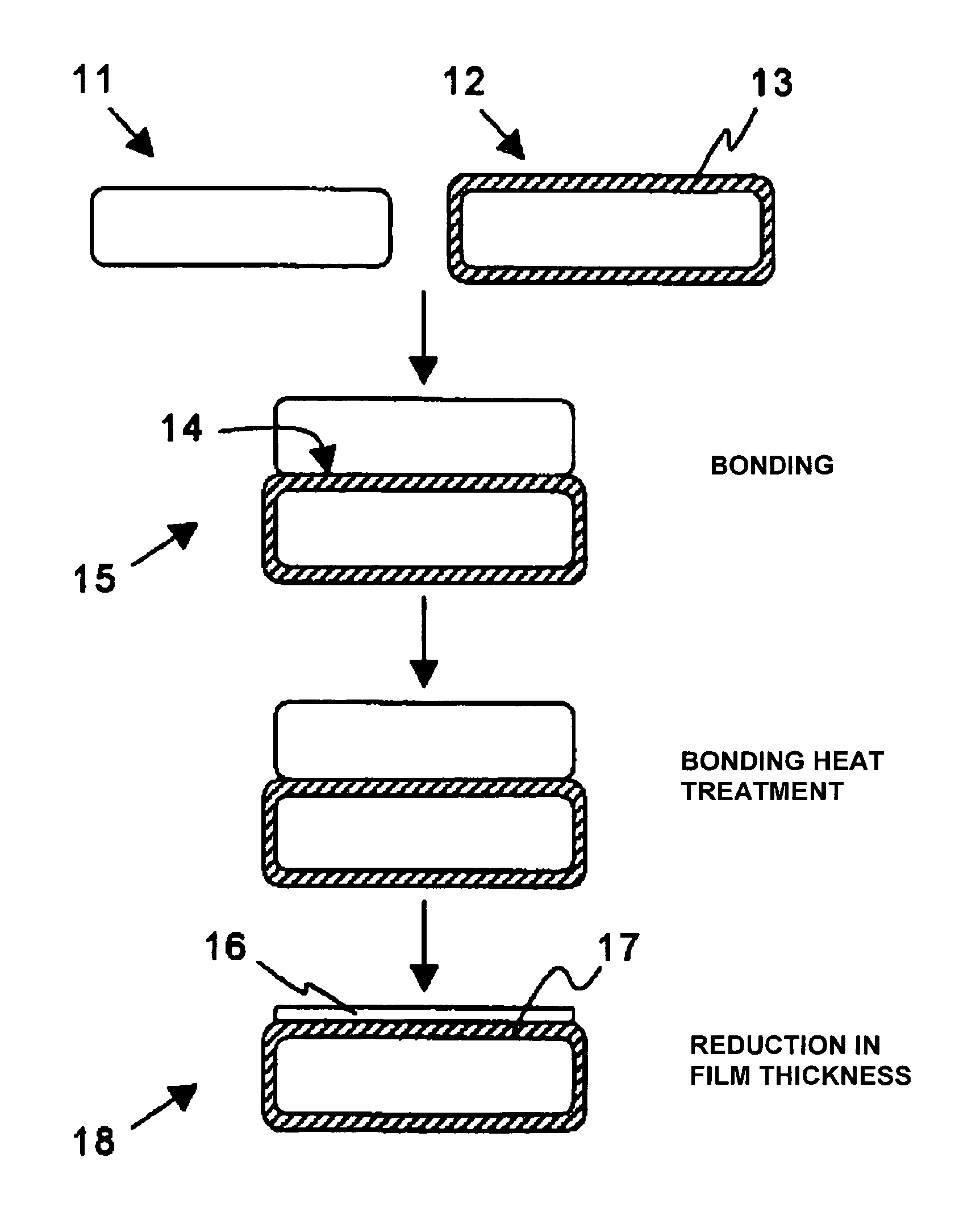

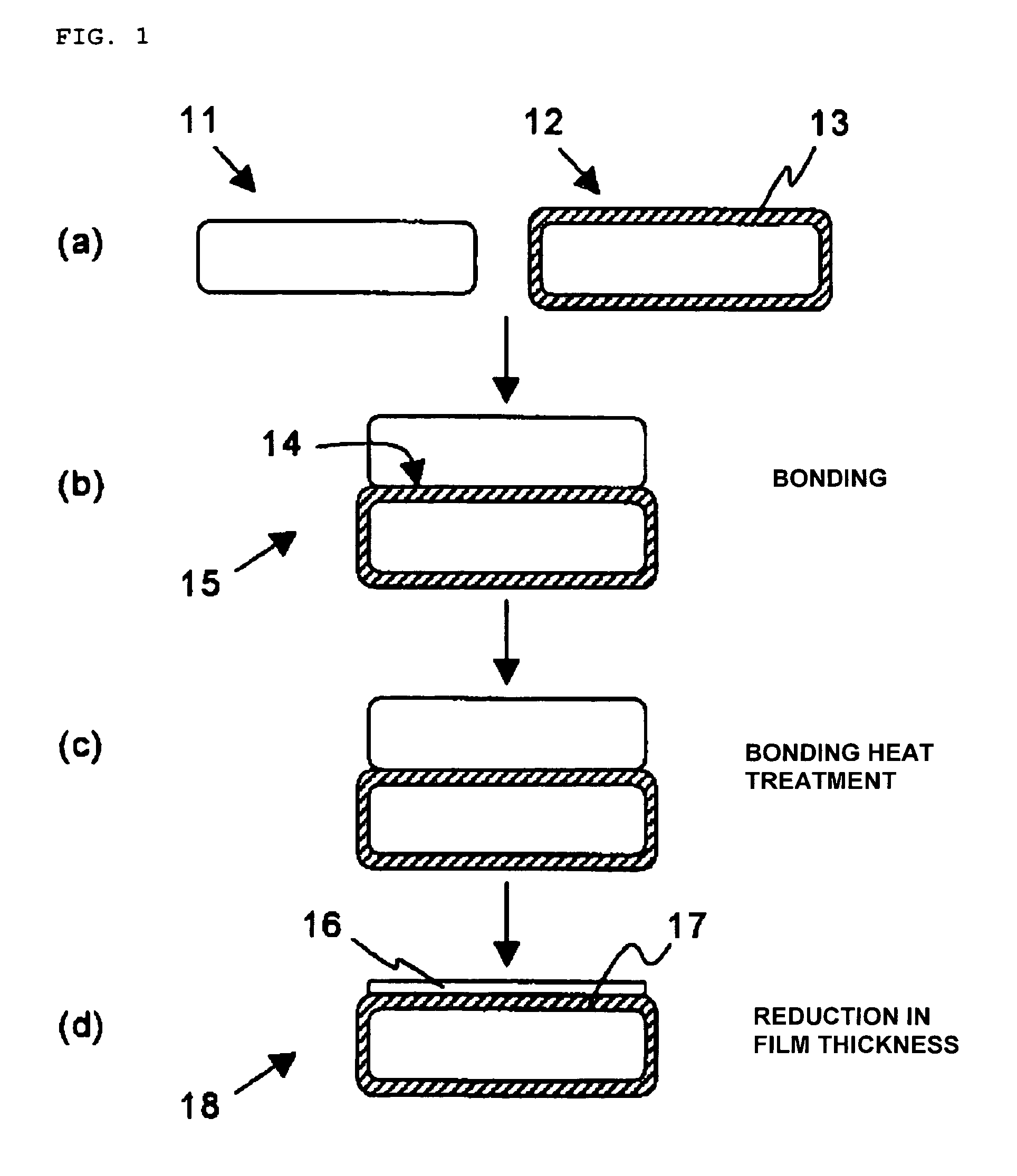

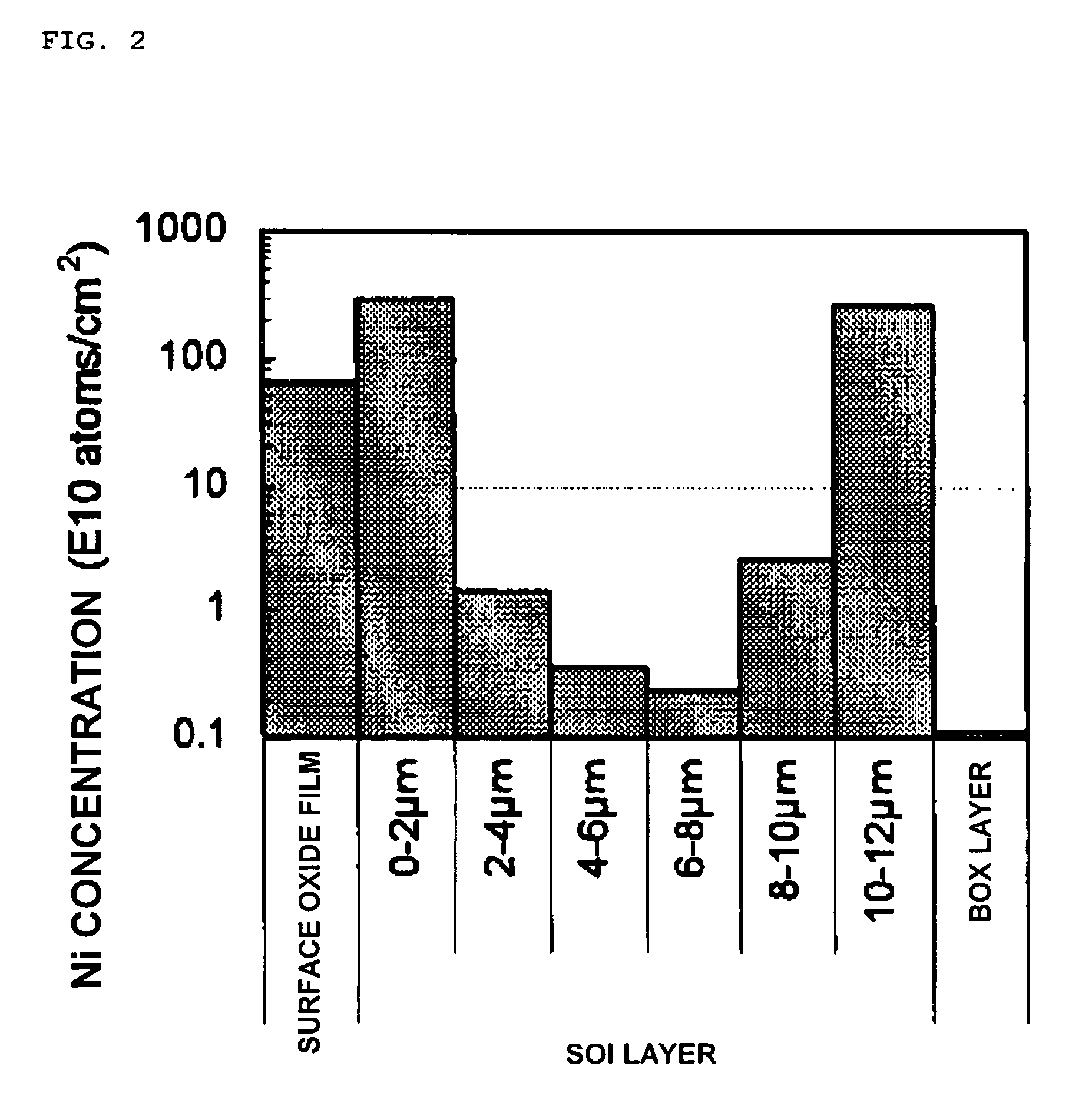

Method for Manufacturing SOI Substrate and SOI Substrate

ActiveUS20090042361A1Prevent degradationEfficient preparationSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideSoi substrate

According to the present invention, there is provided a method for manufacturing an SOI substrate based on a bonding method, comprising at least: forming a silicon oxide film on a surface of at least one of a single-crystal silicon substrate that becomes an SOI layer and a single-crystal silicon substrate that becomes a support substrate; bonding the single-crystal silicon substrate that becomes the SOI layer to the single-crystal silicon substrate that becomes the support substrate through the silicon oxide film; and performing a heat treatment for holding at a temperature falling within the range of at least 950° C. to 1100° C. and then carrying out a heat treatment at a temperature higher than 1100° C. when effecting a bonding heat treatment for increasing bonding strength. As a result, there are provided the method for manufacturing an SOI substrate that can efficiently manufacture an SOI substrate having an excellent gettering ability with respect to metal contamination in an SOI layer, and the SOI substrate.

Owner:SHIN-ETSU HANDOTAI CO LTD

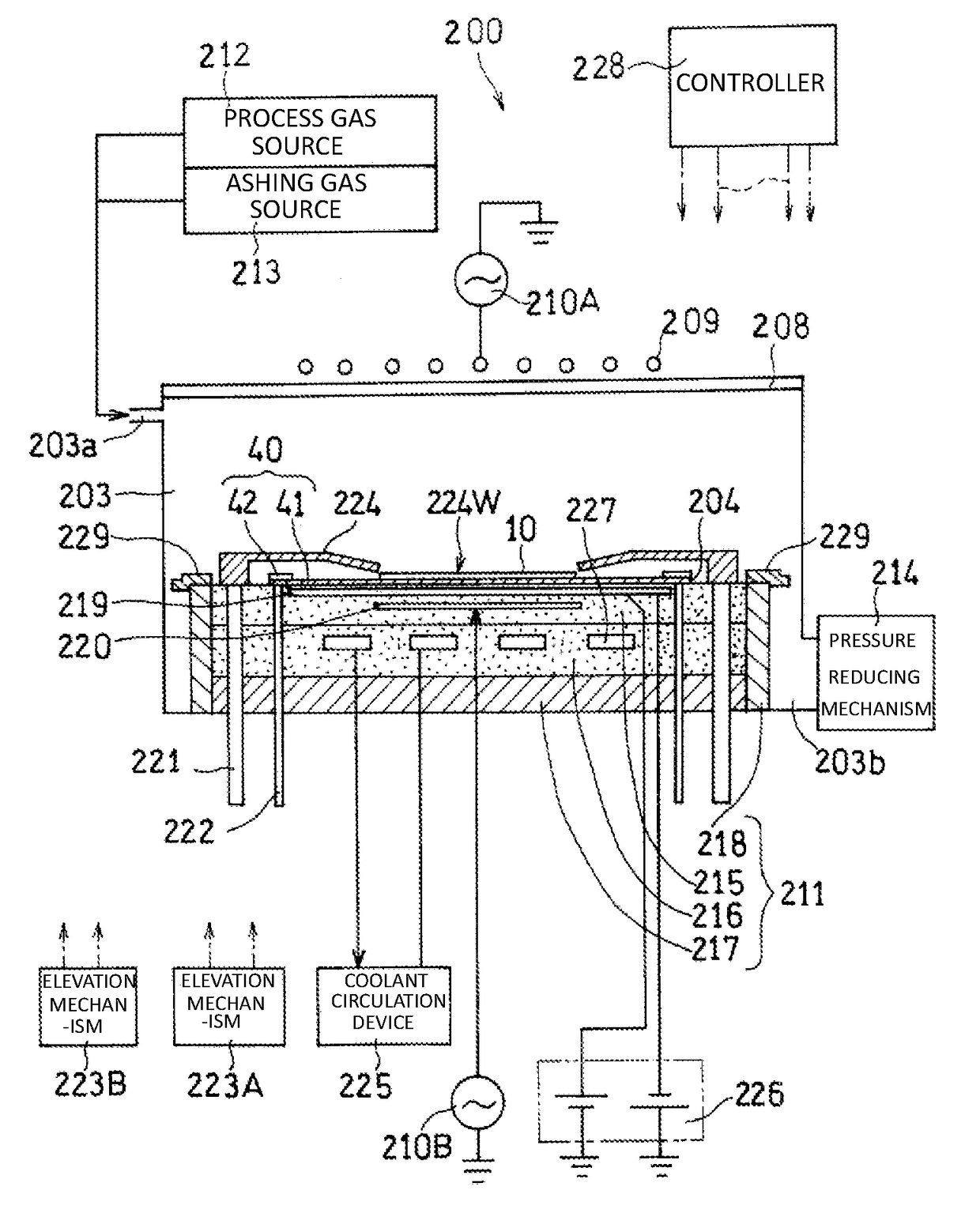

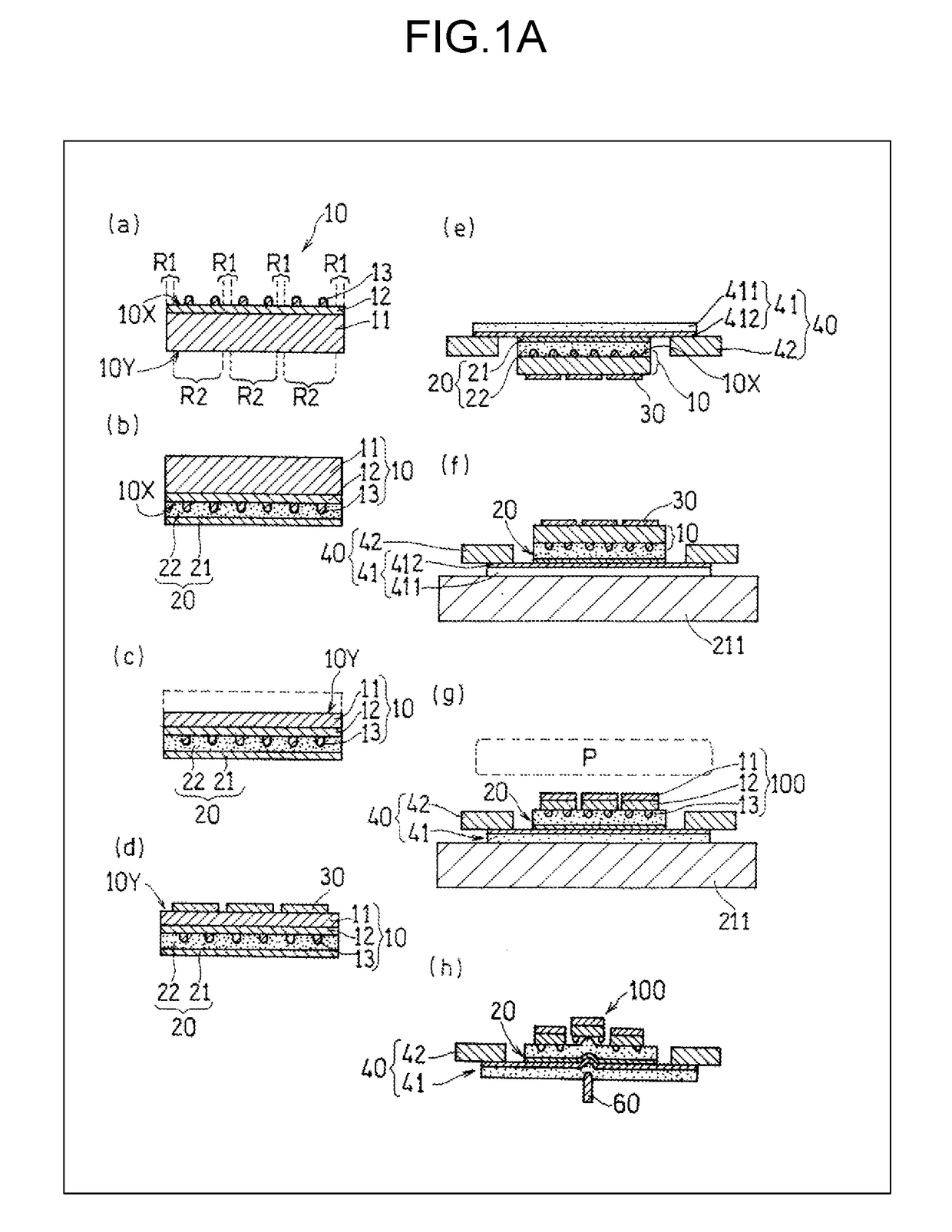

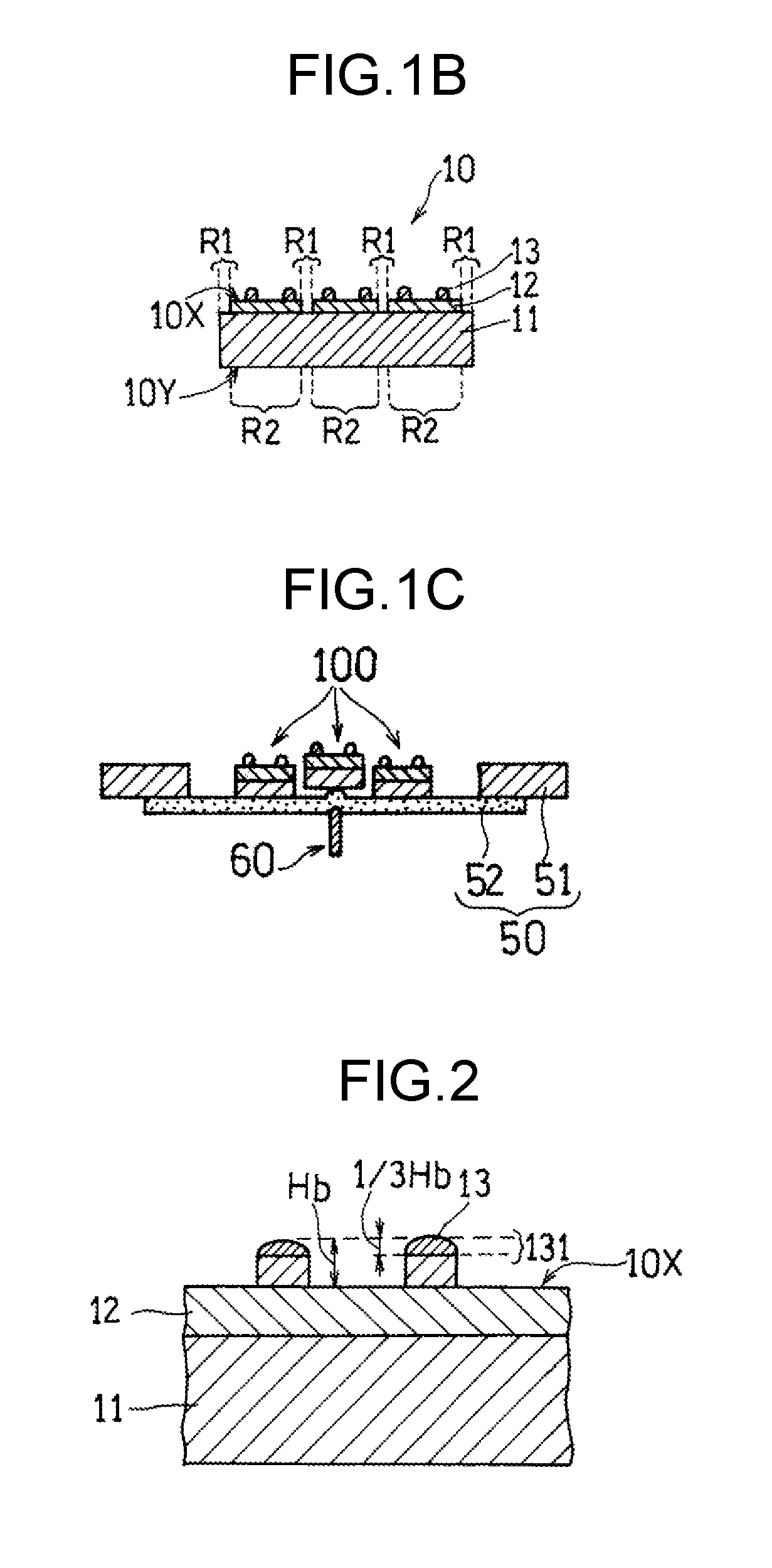

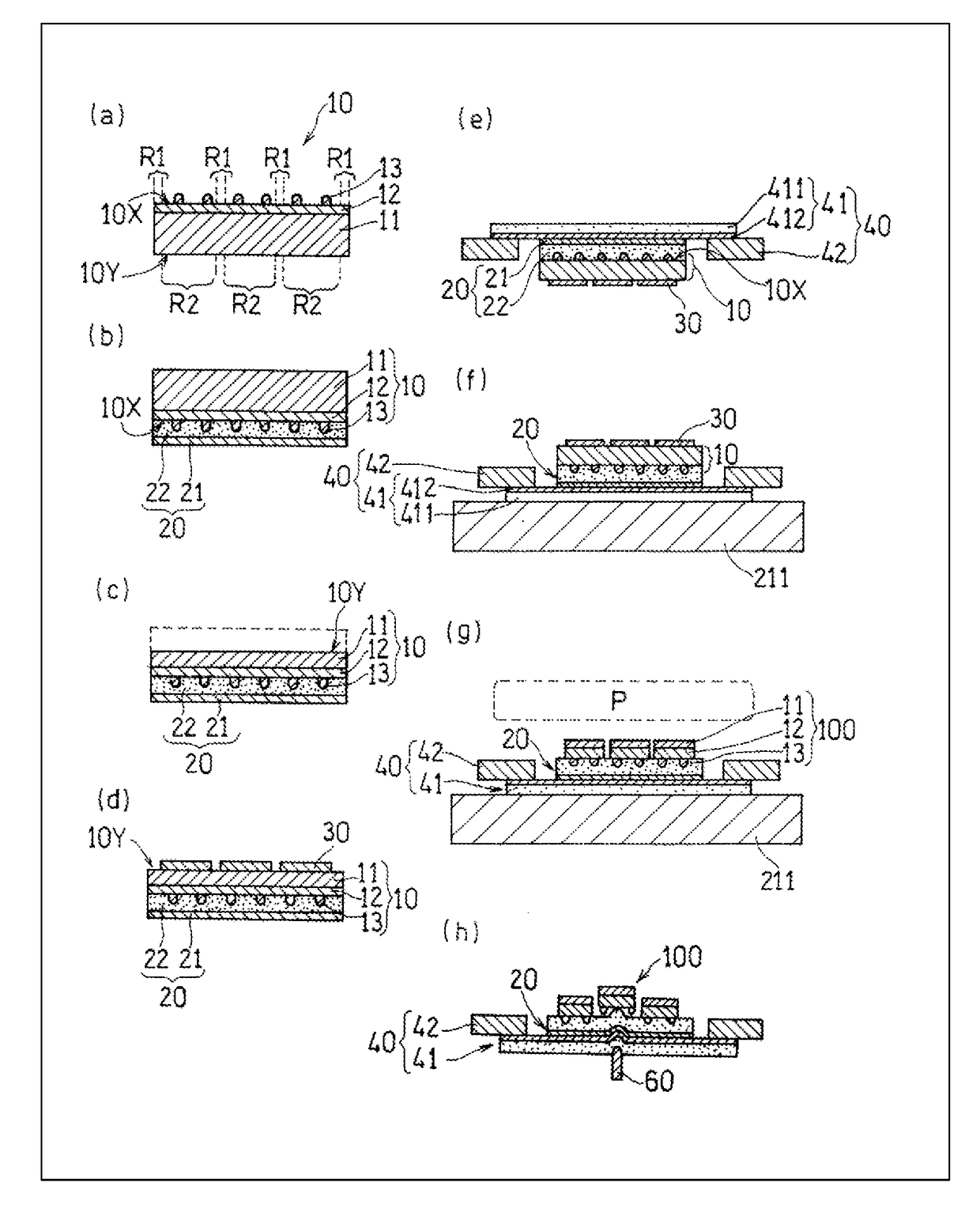

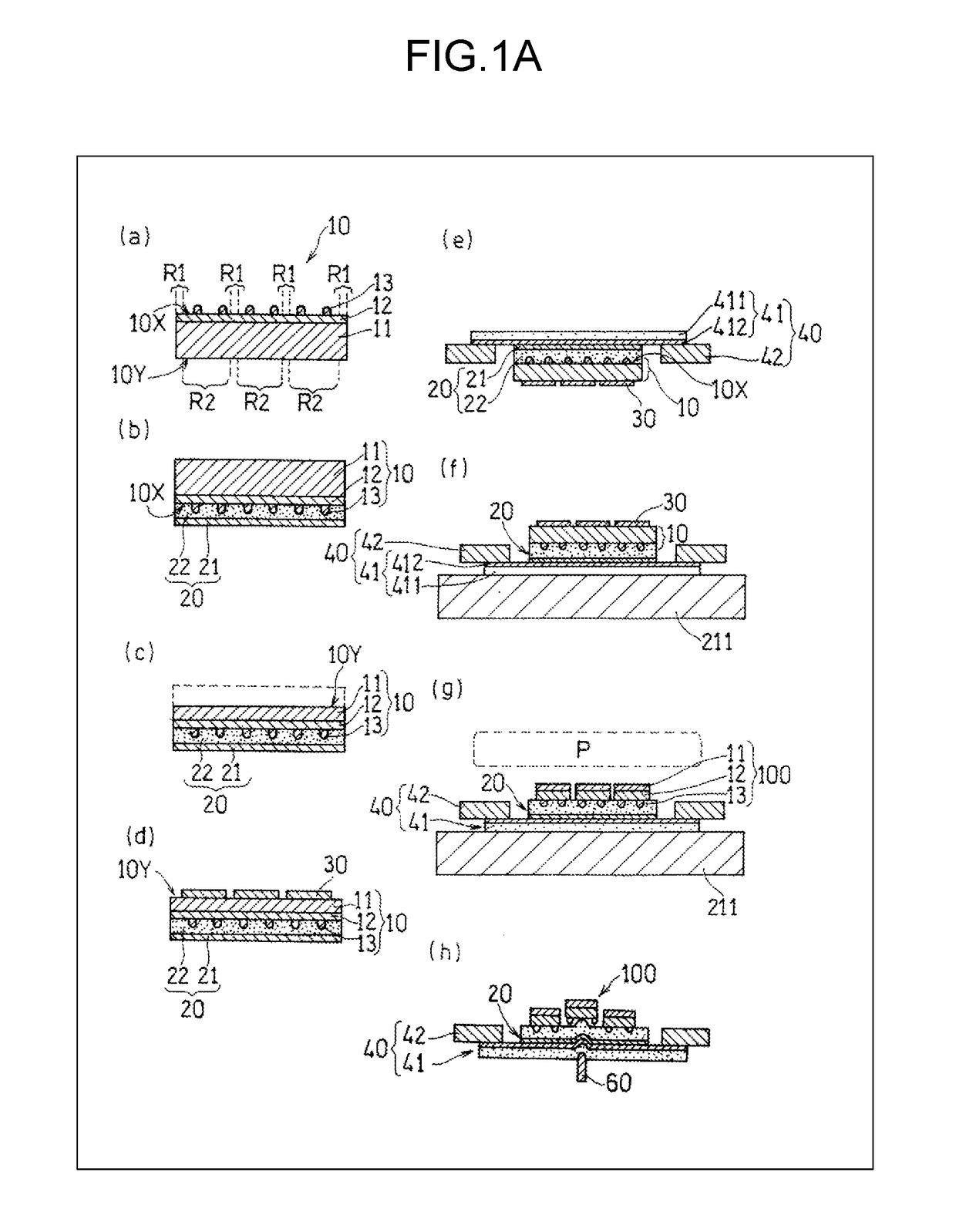

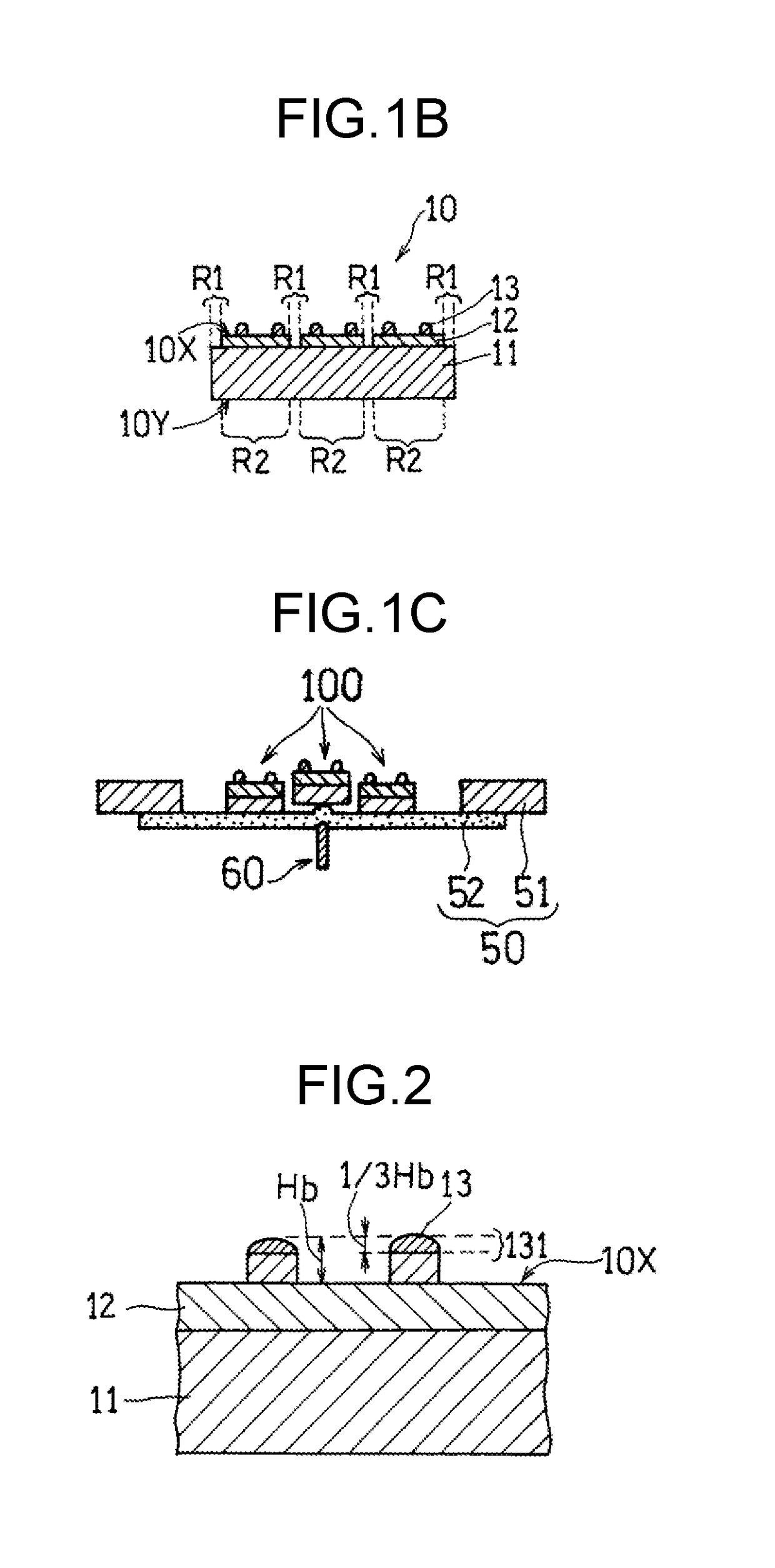

Element chip manufacturing method

ActiveUS20170345781A1Without reduce productivitySuppress degradation and damageDecorative surface effectsSemiconductor/solid-state device detailsPlasma processingEngineering

An element chip manufacturing method includes a preparation process of preparing a substrate which includes a first surface having an exposed bump and a second surface opposite to the first surface and includes a plurality of element regions defined by dividing regions, a bump embedding process of embedding at least a head top part of the bump into the adhesive layer, a mask forming process of forming a mask in the second surface. The method for manufacturing the element chip includes a holding process of arranging the first surface to oppose a holding tape supported on a frame and holding the substrate on the holding tape, a placement process of placing the substrate on a stage provided inside of a plasma processing apparatus through the holding tape, after the mask forming process and the holding process.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

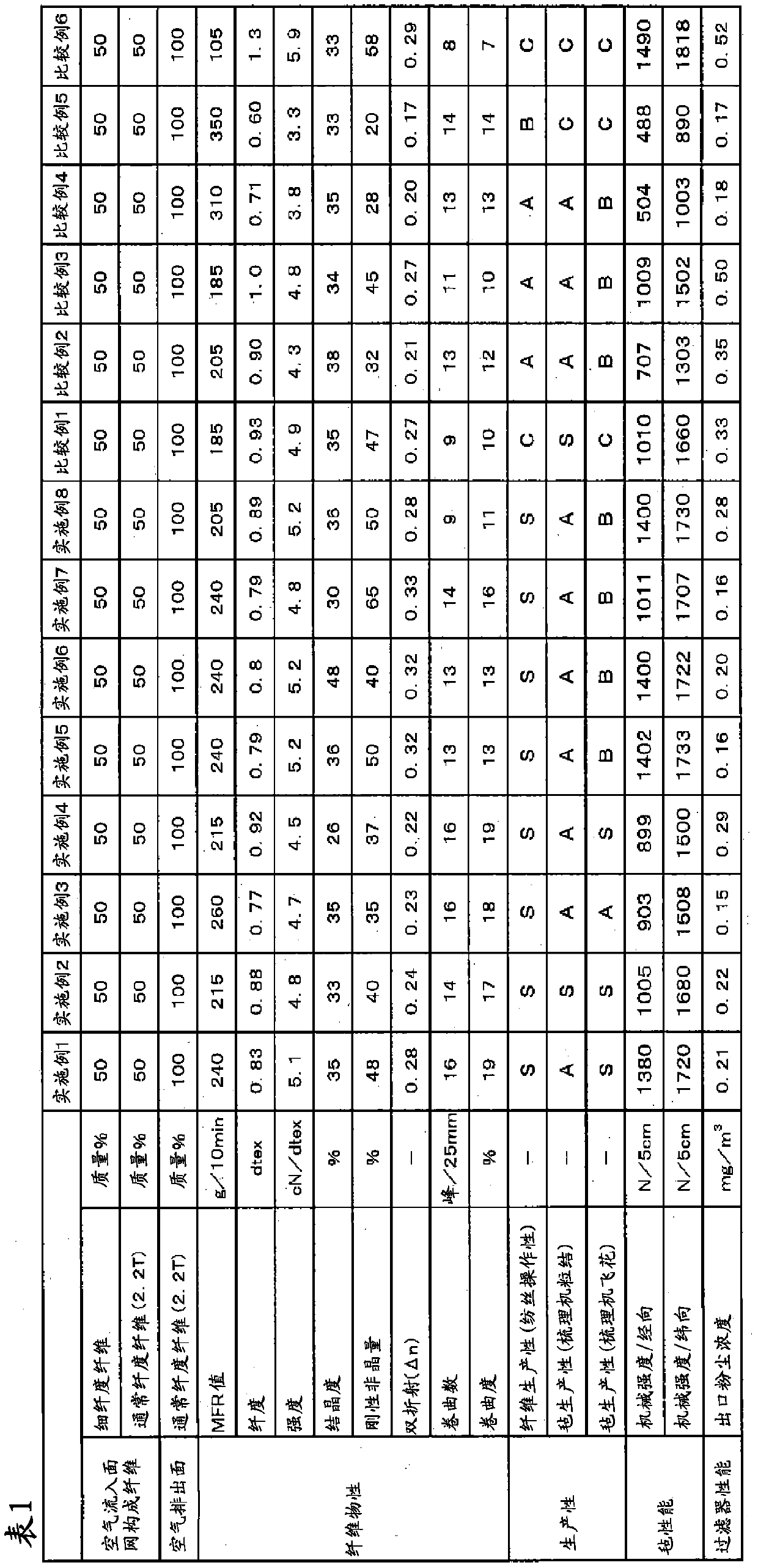

Polyphenylene sulfide short fiber, fibrous structure, filter felt, and bag filter

ActiveCN111433395AWithout reducing productivityImprove the capture effectDispersed particle filtrationLaminationPolymer scienceSingle fibre

Provided is a polyphenylene sulfide short fiber having a monofilament fineness of 0.70 to 0.95 dtex, a strength of 4.5 to 5.5 cN / dtex, a fiber length of 20 to 100 mm, and a melt flow rate (MFR) valueof 200 to 295 g / 10 min. This polyphenylene sulfide short fiber enables improvements to be made in the dust collection performance and mechanical strength without impairing the fiber productivity or felt productivity.

Owner:TORAY IND INC

Element chip manufacturing method

ActiveUS20170345715A1Without reducing productivitySuppressing degradationSemiconductor/solid-state device detailsSolid-state devicesEngineeringEmbedding process

An element chip manufacturing method includes a preparation process of preparing a substrate which includes a first surface provided with a bump and a second surface and includes a plurality of element regions defined by dividing regions, a bump embedding process of adhering a protection tape having an adhesive layer to the first surface and embedding. The element chip manufacturing method includes a thinning process of grinding the second surface in a state where the protection tape is adhered to the first surface and thinning the substrate, after the bump embedding process, a mask forming process of forming a mask in the second surface and exposes the dividing regions, after the thinning process, a holding process of arranging the first surface to oppose a holding tape supported on a frame and holding the substrate on the holding tape.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

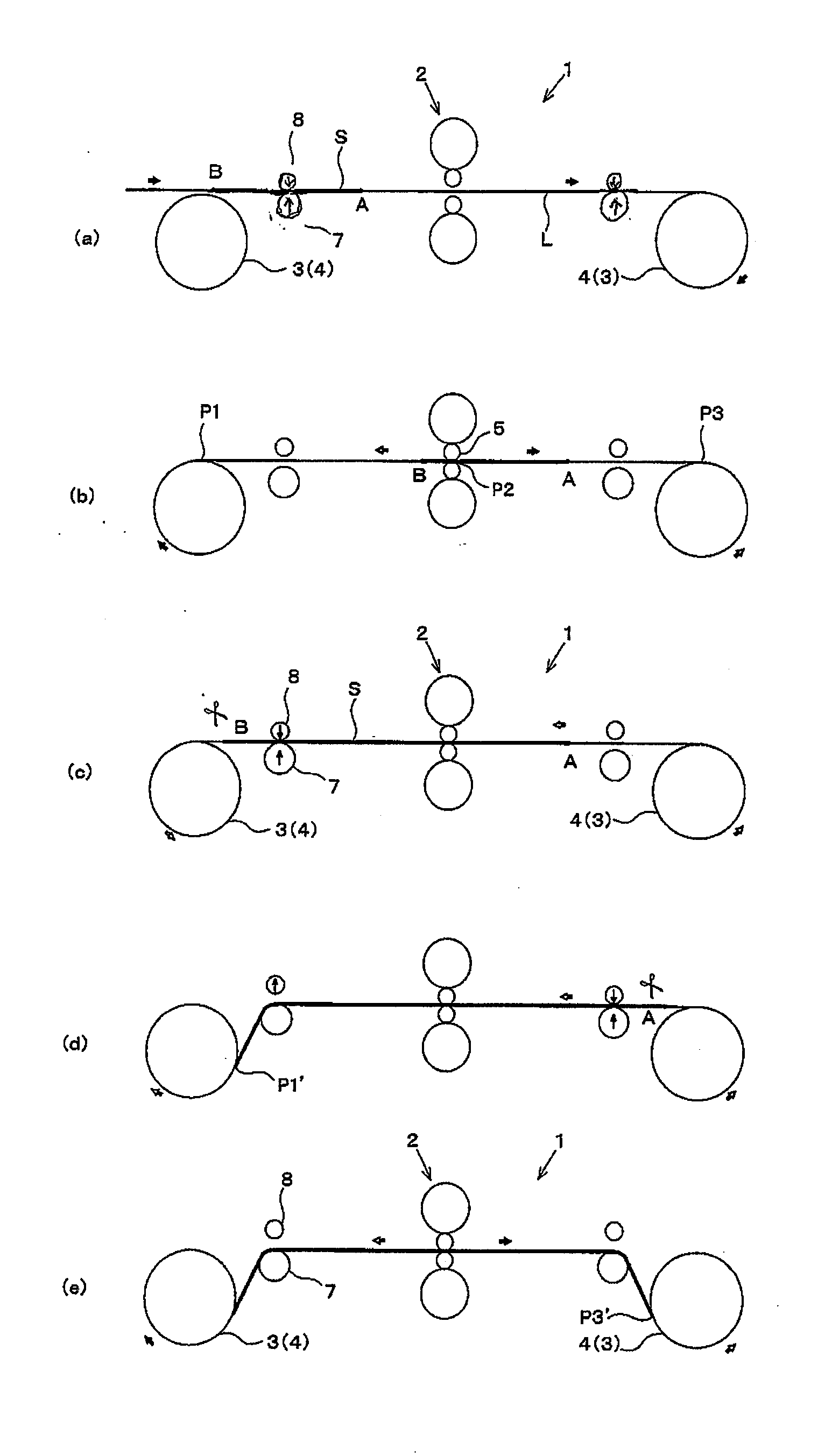

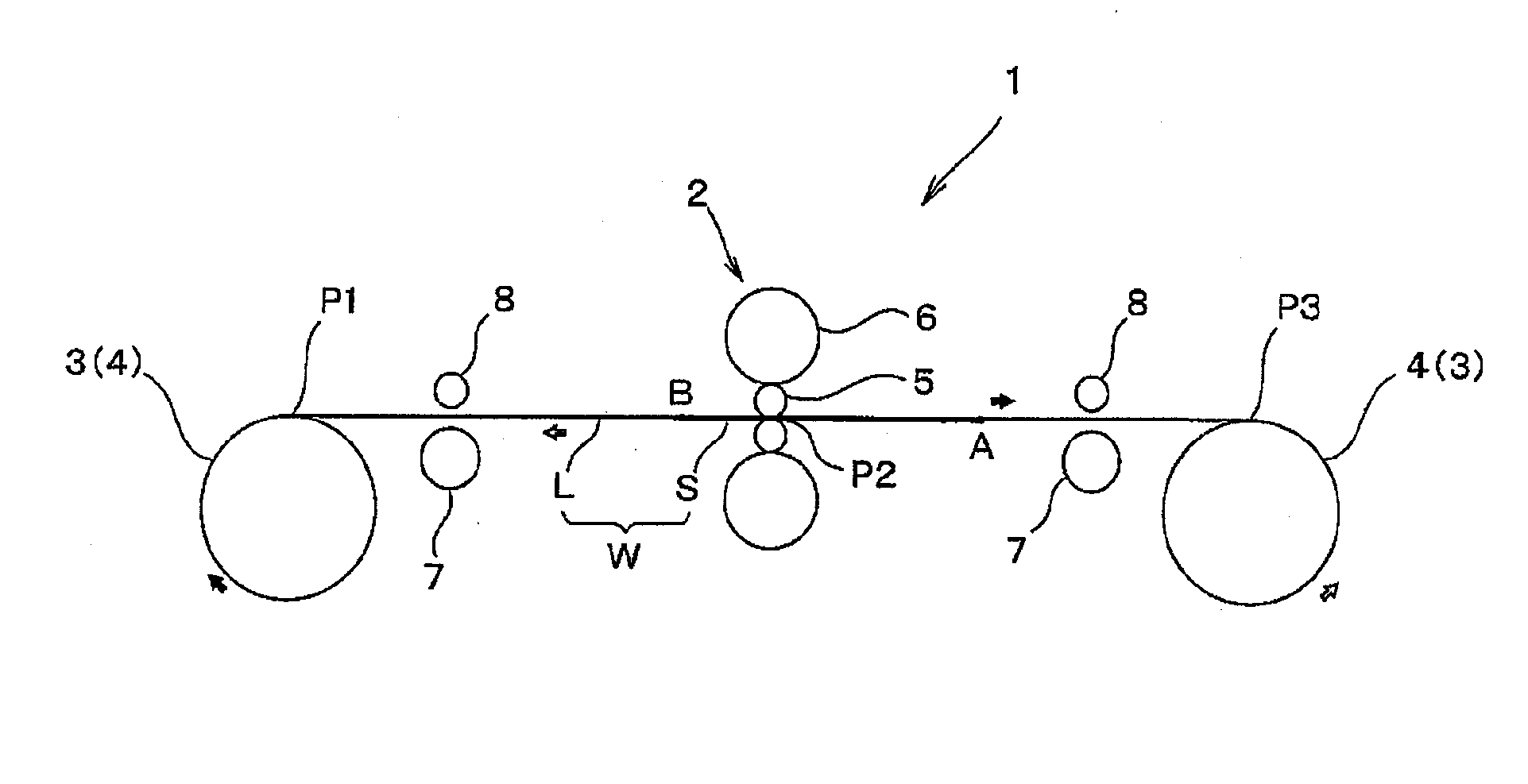

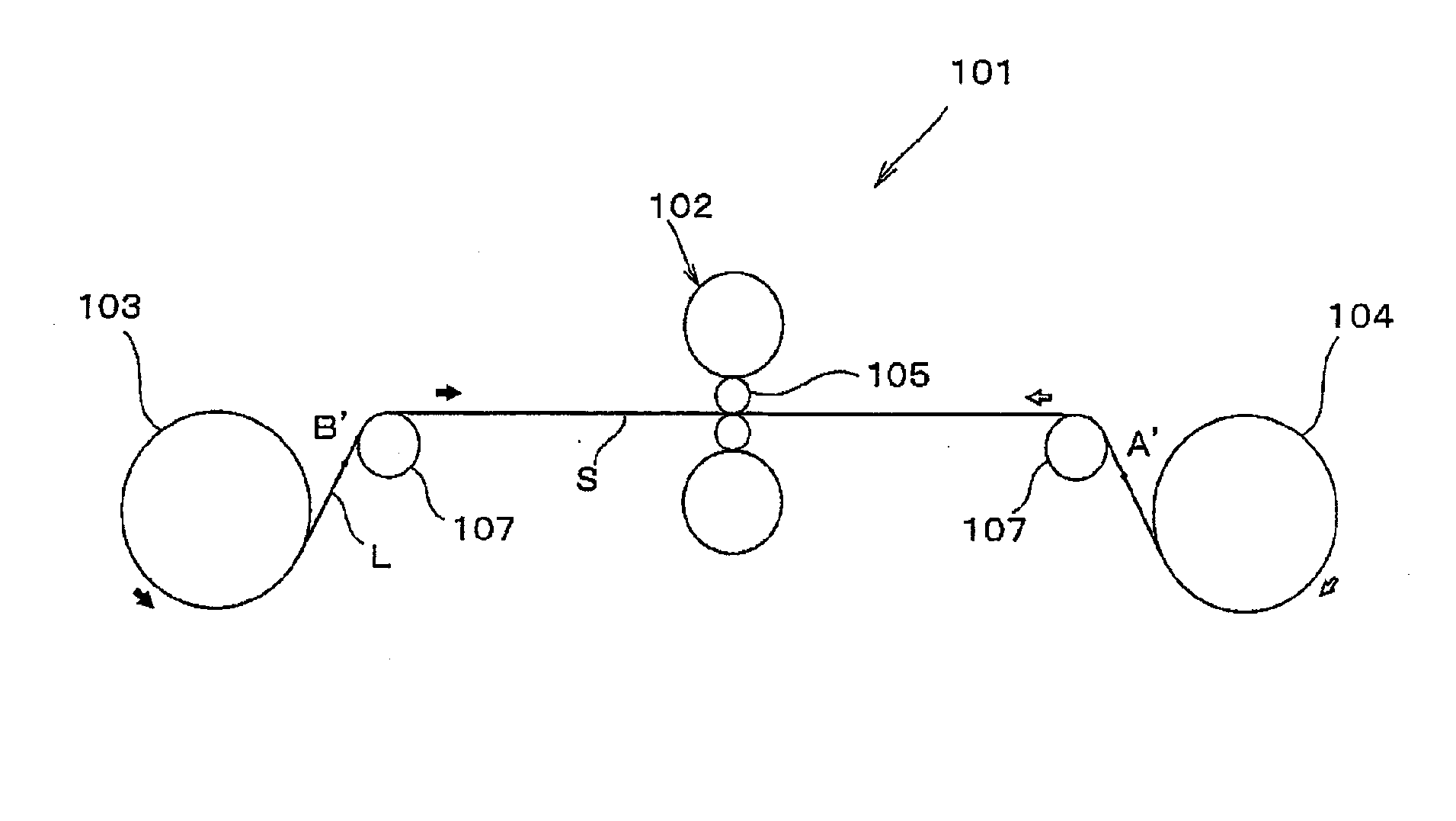

Rolling device and rolling method of short stacking material

InactiveCN102836874AInhibitionWithout reducing productivityMetal rolling arrangementsProduction rateEngineering

The invention provides a rolling device and rolling method of a short stacking material. The rolling of the short stacking material can be reliably carried out in order to prevent the reduction of the production efficiency and to prevent the damage caused by the deflector roller of the rolling mill. A front end reel of the mill bar provided with a connection part used to connect a pre-guiding material and a short stacking material is hung on the reeling scroll from the rolling road side, and a rear end reel of the above mentioned mill bar is hung on the above mentioned unreeling scroll from the rolling road side. When the length of the above mentioned of the short stacking material is shorter than the interval of the above mentioned unreeling scroll and the above mentioned reeling scroll, the rolling of the short stacking material can be carried out under the condition of the contact between the working roller and the short stacking material. When the length of the above mentioned short stacking material is longer than the interval of the above mentioned unreeling scroll and the above mentioned reeling scroll, the front end of the above mentioned rolling material is hung on the reeling scroll. After the rear end of the above mentioned rolling material is hung on the unreeling scroll, on one side, the above mentioned deflector roller can be used to support the rolling material, on the other side, the working roller can be used to roll the short stacking material.

Owner:KOBE STEEL LTD

Method for manufacturing SOI substrate and SOI substrate

ActiveUS7749861B2Efficient preparationImprove inhalation effectSemiconductor/solid-state device manufacturingSemiconductor devicesSoi substrateOptoelectronics

According to the present invention, there is provided a method for manufacturing an SOI substrate based on a bonding method, comprising at least: forming a silicon oxide film on a surface of at least one of a single-crystal silicon substrate that becomes an SOI layer and a single-crystal silicon substrate that becomes a support substrate; bonding the single-crystal silicon substrate that becomes the SOI layer to the single-crystal silicon substrate that becomes the support substrate through the silicon oxide film; and performing a heat treatment for holding at a temperature falling within the range of at least 950° C. to 1100° C. and then carrying out a heat treatment at a temperature higher than 1100° C. when effecting a bonding heat treatment for increasing bonding strength. As a result, there are provided the method for manufacturing an SOI substrate that can efficiently manufacture an SOI substrate having an excellent gettering ability with respect to metal contamination in an SOI layer, and the SOI substrate.

Owner:SHIN-ETSU HANDOTAI CO LTD

Process for producing graft copolymer latex

There is provided a process for producing graft copolymer latex. In case of removing non-reacted monomer from a rubber latex before graft polymerization, non-reacted monomer is removed in a short time by adding an electrolyte to control foaming of a rubber latex, and a graft copolymer latex is prepared without decreasing productivity.

Owner:KANEKA CORP

Sheet-discharge apparatus, sheet processing apparatus, and image forming apparatus

ActiveUS8960668B2Easy alignmentReduce alignmentFunction indicatorsElectrographic process apparatusAir velocityMechanical engineering

The sheet processing apparatus includes a sheet-discharge fan that blows air downward of a sheet-discharged by an upper sheet-discharge roller, and a control portion configured to control an air velocity of air blown from the sheet-discharge fan according to a basis weight of the sheet. In the case where the basis weight of the sheet is a predetermined value or less, the control portion increases the air velocity of the sheet-discharge fan according to the basis weight of the sheet based on basis weight information from an input portion for inputting the basis weight information of the sheet. The control portion also controls the air velocity of the sheet-discharge fan to be a velocity at which the sheet whose rear edge contacts the sheet-stacking wall does not move in a sheet-discharge direction in the case where the basis weight of the sheet exceeds the predetermined value.

Owner:CANON KK

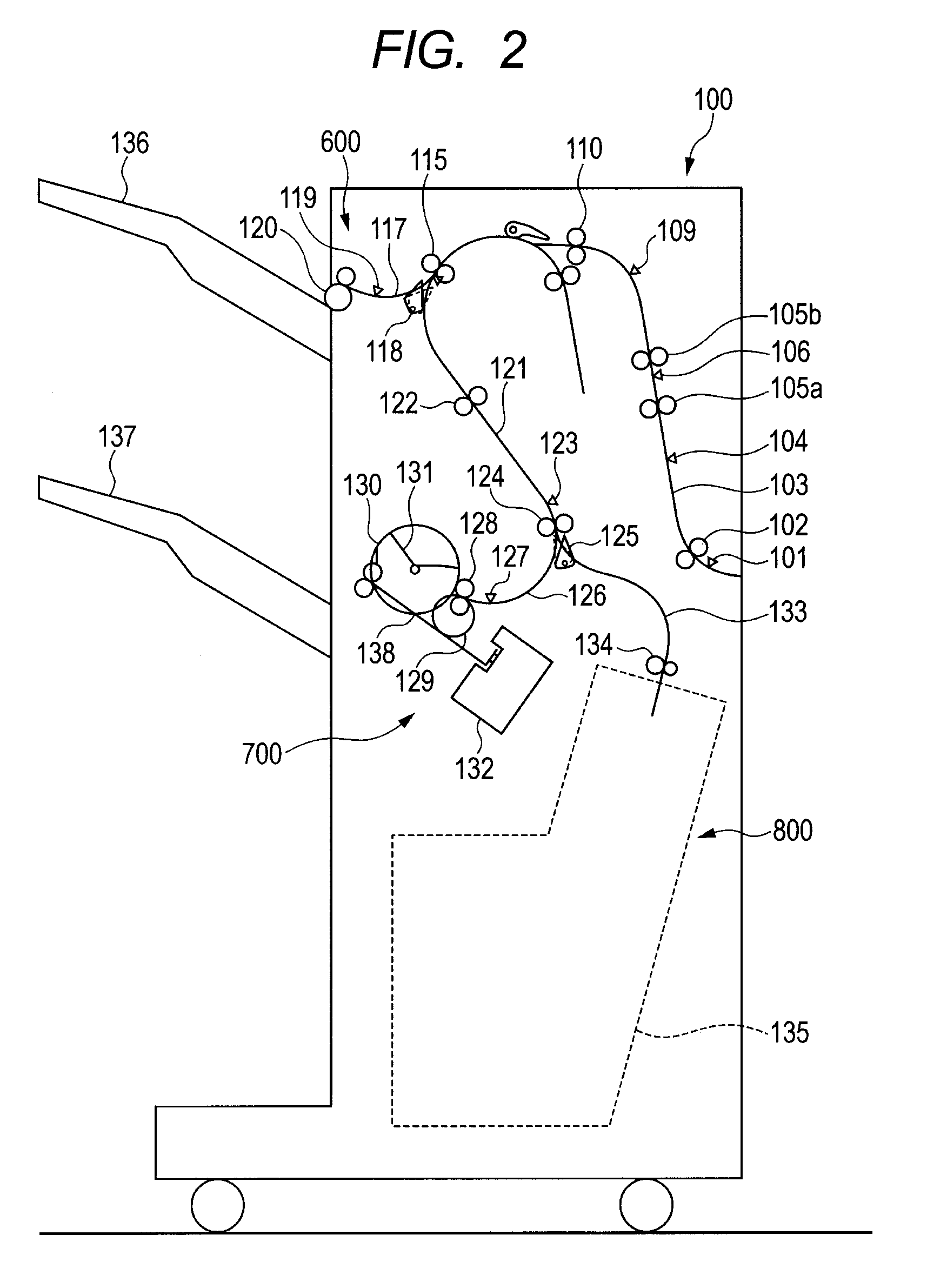

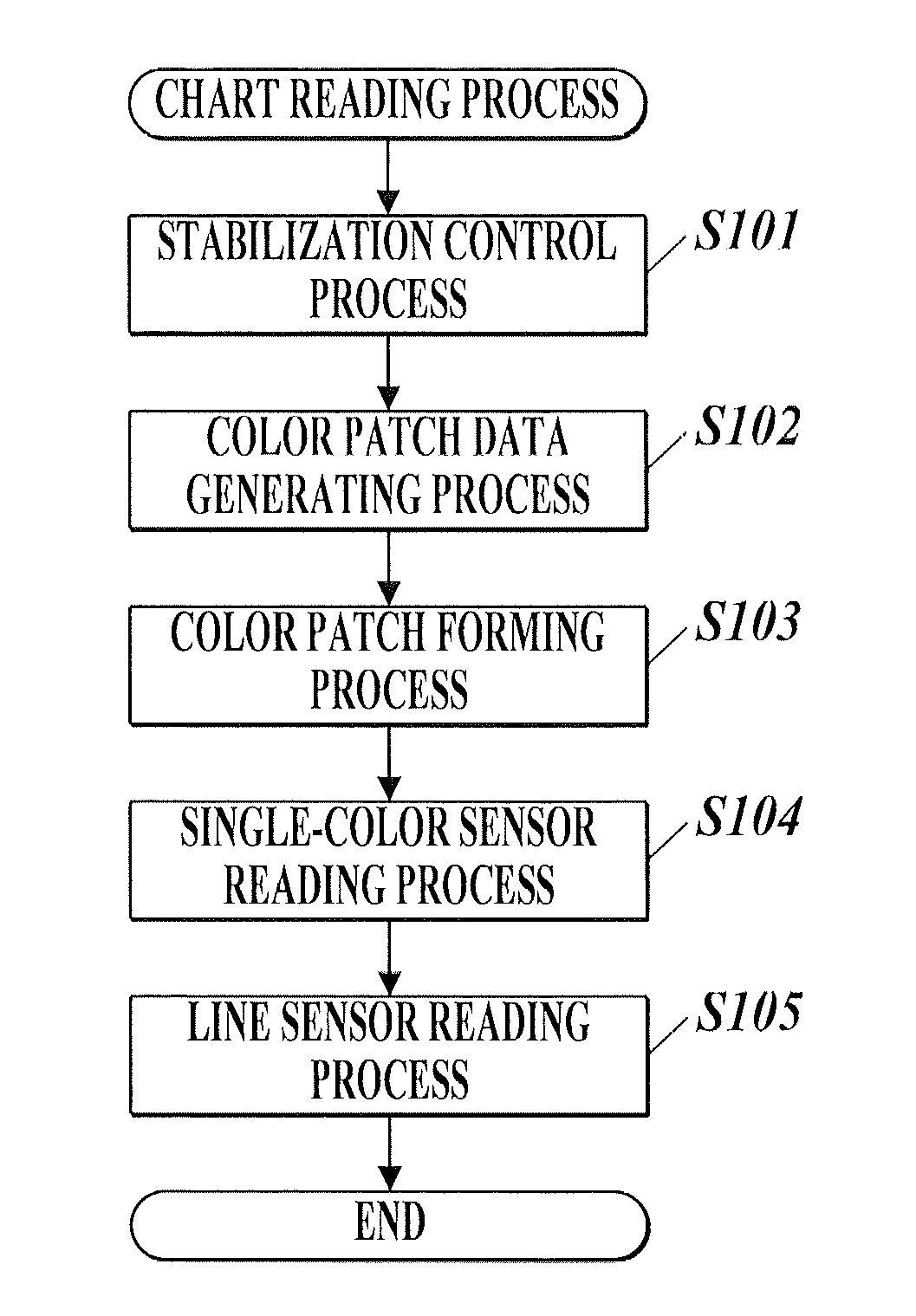

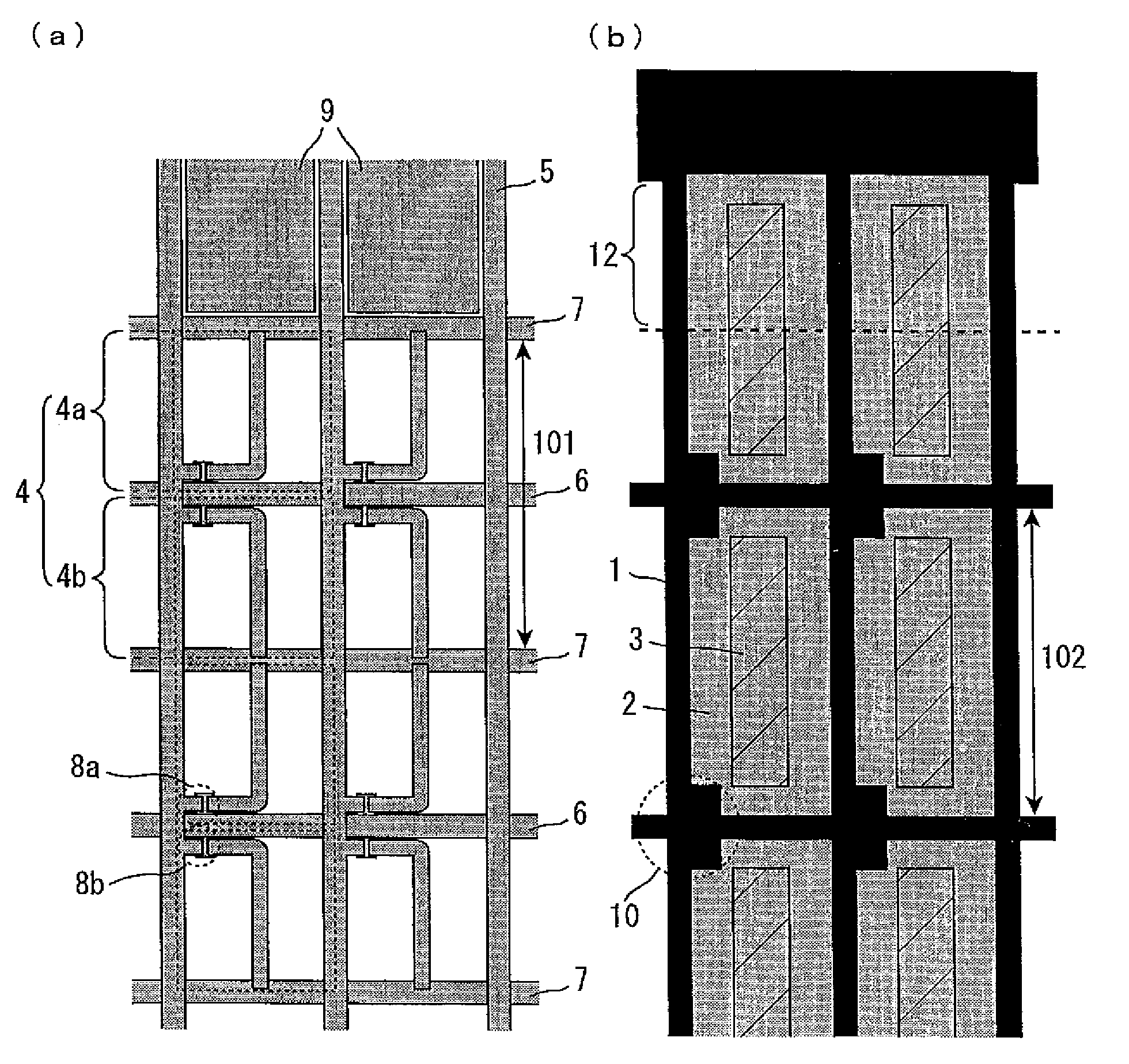

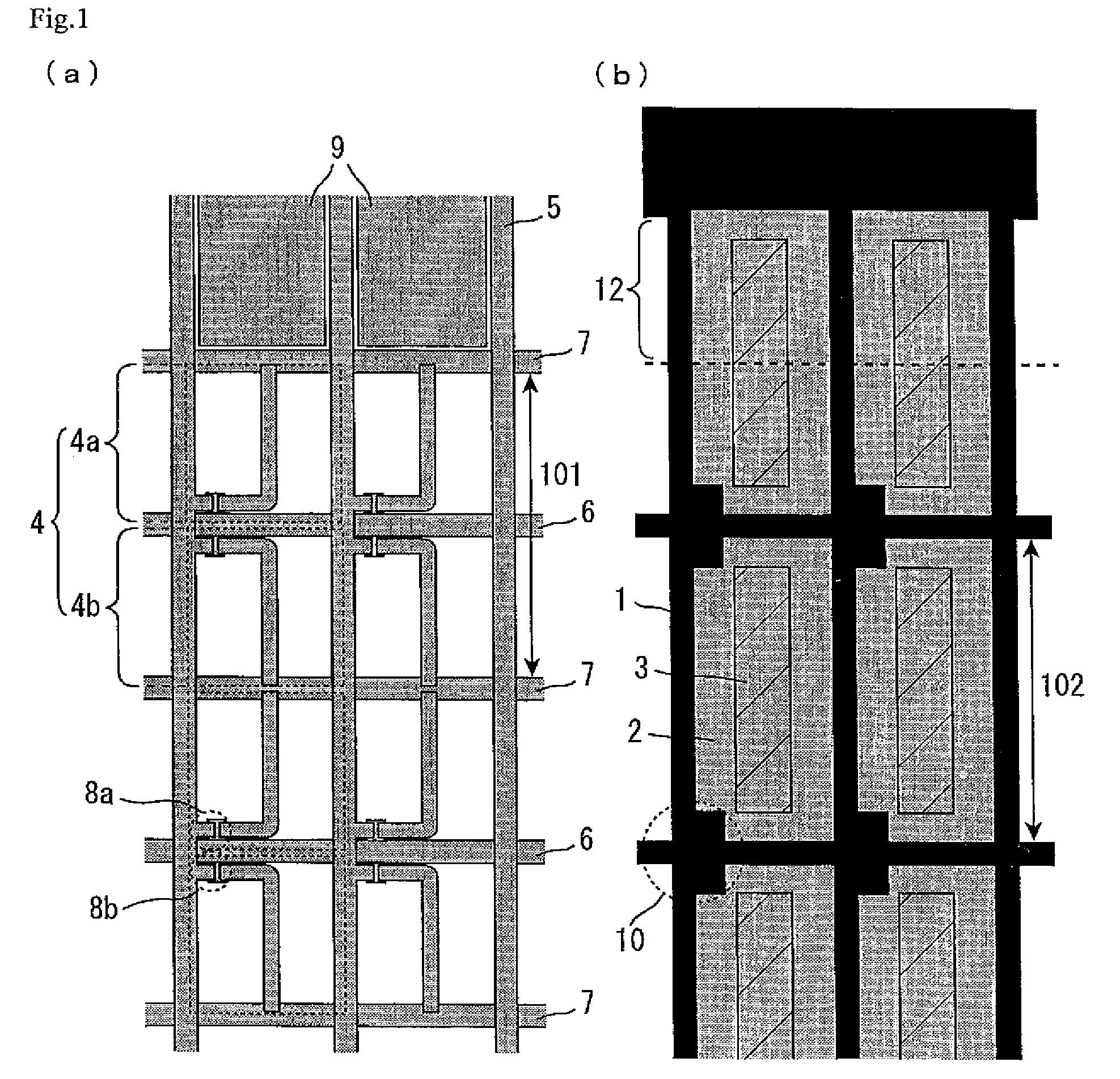

Calibration apparatus and method for calibrating image reading apparatus

ActiveUS20150201110A1Without reduce productivityWithout reducing productivityPictoral communicationSignal transitionImage formation

A calibration apparatus includes a calibration section and a conversion section. The calibration section performs calibration with first and second image reading apparatuses which read in-line a color patch formed on paper by an image forming apparatus. The first image reading apparatus includes a first device which reads the color patch and outputs the reading result as a first signal. The second image reading apparatus includes a second device which reads the color patch and outputs the reading result as a second signal having a format different from a format of the first signal. The conversion section converts the first signal into an after-conversion first signal having the format of the second signal. The calibration section performs the calibration in such a way that an output value of the second signal is adjusted to an output value of the after-conversion first signal.

Owner:KONICA MINOLTA INC

Display device and production method thereof

InactiveUS8144291B2Without reducing productivityUniform thickness distributionNon-linear opticsOptical elementsActive matrixDisplay device

A display device includes an active matrix substrate and a color filter substrate facing each other, wherein the active matrix substrate includes a scanning line, a signal line, and a switching element, and has a pixel, the switching element being arranged at an intersection of the scanning line and the signal line, the pixel including two sub-pixels, the two sub-pixels being arranged with the scanning line or the signal line therebetween, the color filter substrate includes a bank and a plurality of colored layers surrounded by the bank, the bank being arranged in regions overlapping with the signal line, and the switching element, and the plurality of colored layers include the first colored layer and the second colored layer, the first colored layer overlapping with one sub-pixel positioned at an end and a region outside a sub-pixel-arranged region, and the second colored layer overlapping with two sub-pixels.

Owner:SHARP KK

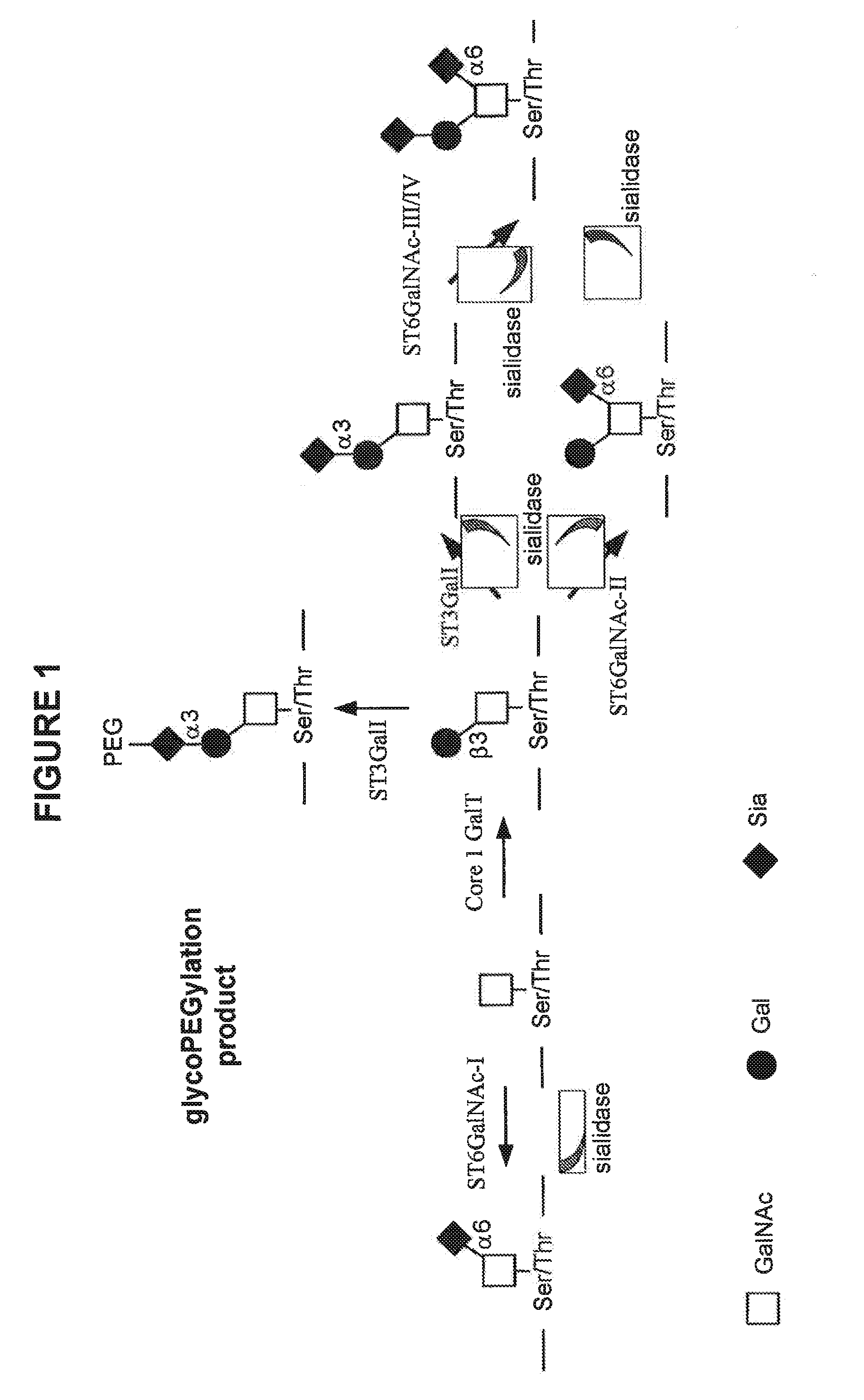

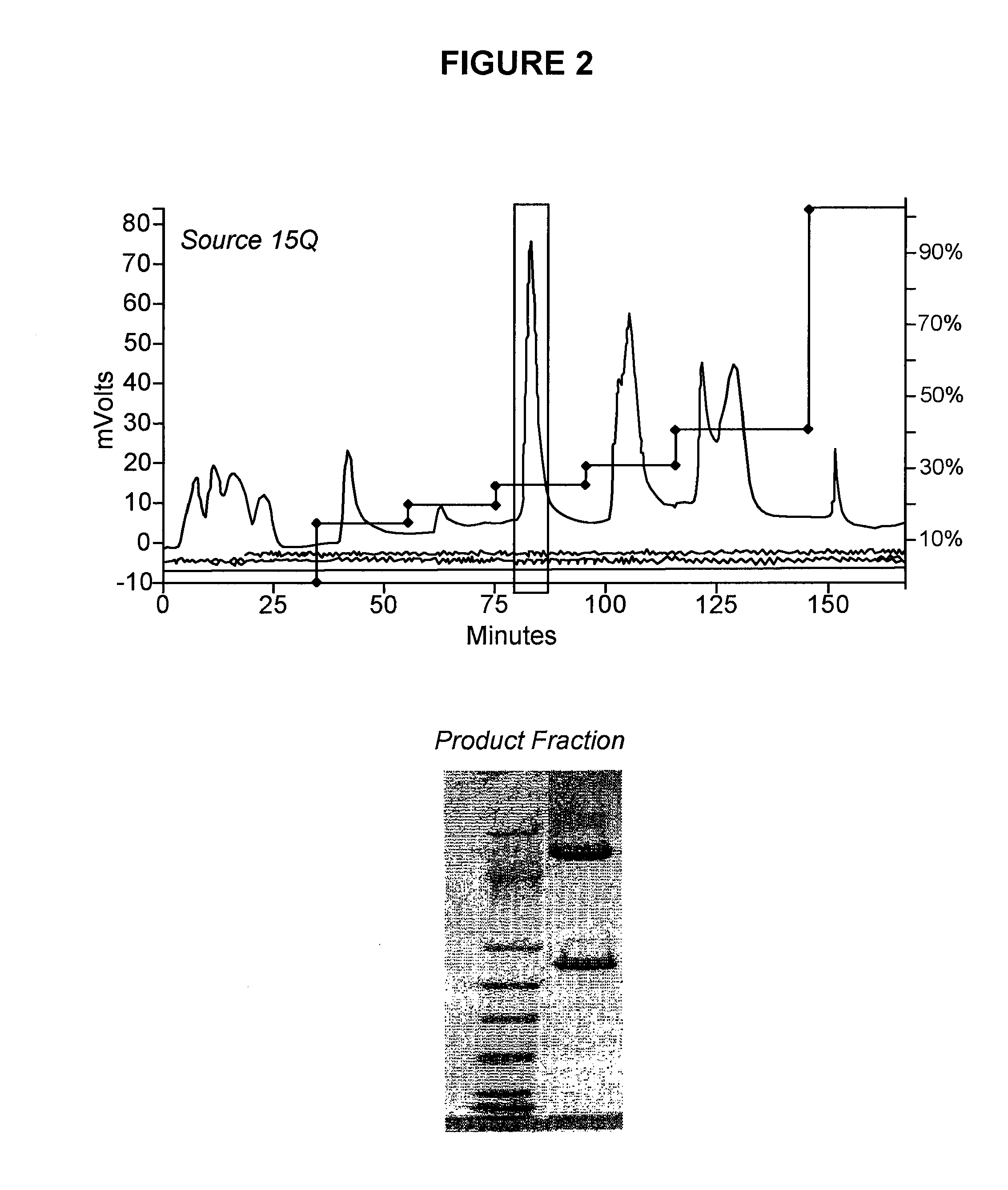

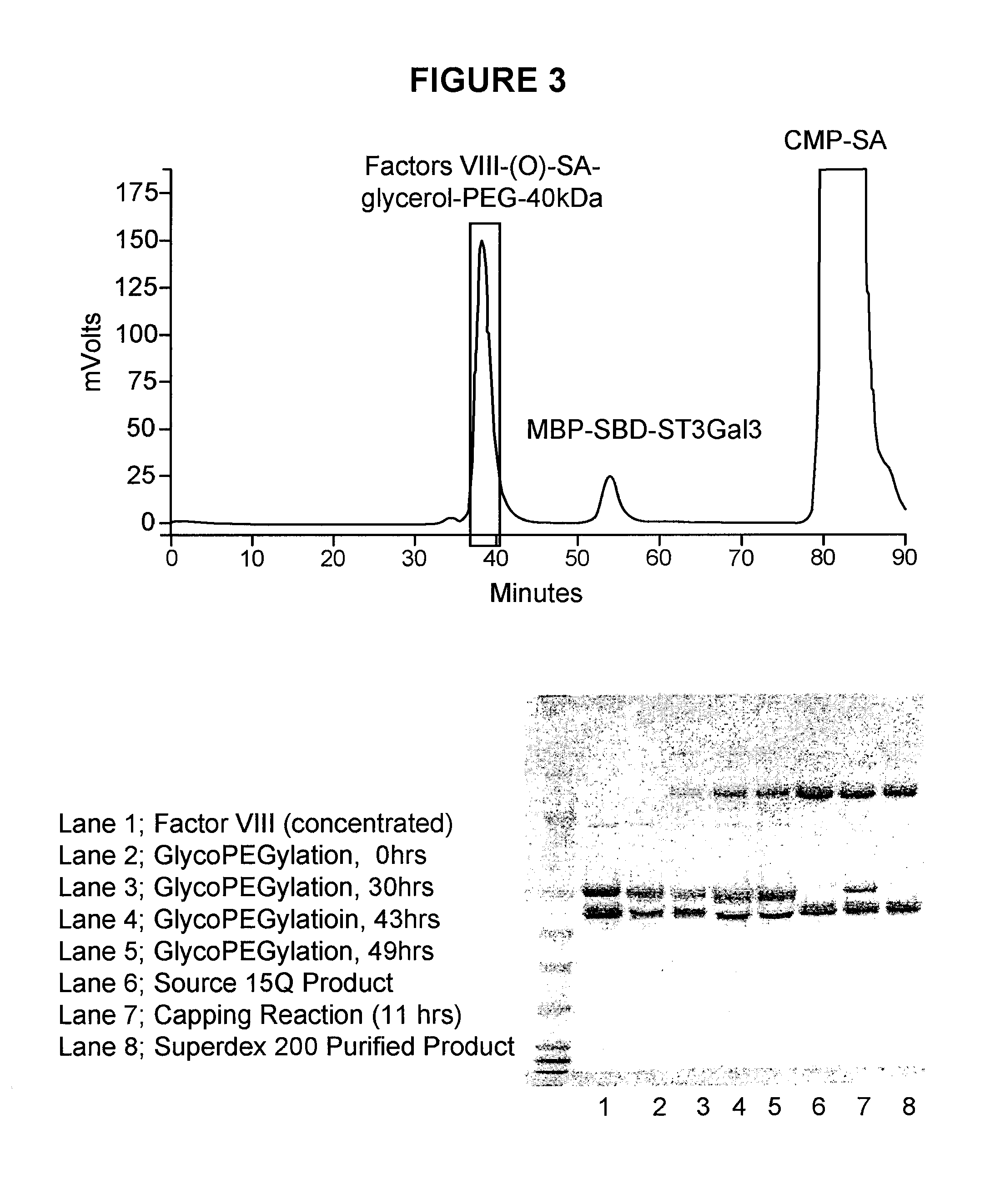

Conjugated factor viii molecules

ActiveUS20130137638A1Improve securityEasy to getFactor VIIPeptide/protein ingredientsHalf-lifeOrganic chemistry

Owner:NOVO NORDISK AS

Method for manufacturing tire

InactiveUS20190329593A1Without reducing productivityHinders its propagationHeavy duty tyresHeavy duty vehicleProduction rateIonomer

Provided is a method for manufacturing a tire using a steel cord which can be manufactured without reducing productivity and can prevent propagation of moisture inside. The method for manufacturing a tire includes a vulcanization step of vulcanizing a green tire provided with a belt having at least one belt layer, in which the belt layer includes a steel cord 10 formed by twisting a steel filament 2 together with a resin filament 1 having a softening point of 125° C. or lower, and the resin filament 1 includes at least an ionomer.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com