Polyphenylene sulfide short fiber, fibrous structure, filter felt, and bag filter

A bag filter, polyphenylene sulfide technology, applied in the direction of membrane filter, short fiber formation, filtration separation, etc., can solve the problem of not being able to function as a bag filter, filter cloth breakage, and insufficient dimensional stability of the filter cloth and other problems, to achieve the effect of improving dust collection performance and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

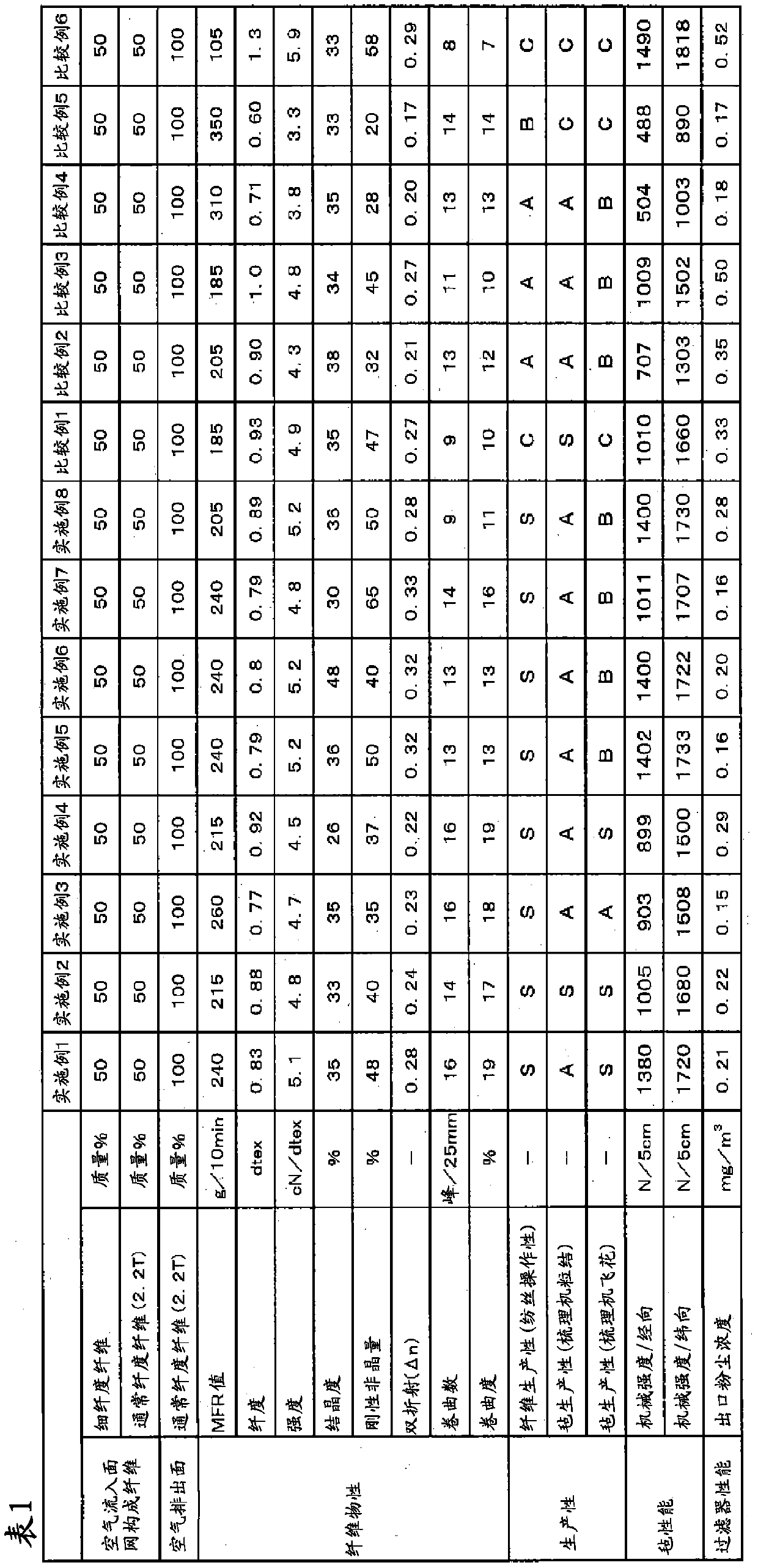

[0137] First, fine fineness fibers were produced by the method described below.

[0138] PPS pellets manufactured by Toray Co., Ltd. with an MFR value of 240 g / 10 minutes were vacuum-dried at a temperature of 160° C. for 5 hours, and then supplied to a pressure-melt type melt spinning machine at a spinning temperature of 320° C., Melt spinning with a discharge rate of 400g / min, cooling and solidification by cooling air at room temperature, applying a usual spinning oil for PPS as a sizing agent, and pulling at a pulling speed of 1,200m / min to obtain an undrawn yarn .

[0139] The obtained undrawn yarn was stretched in warm water at 95°C to a draw ratio of 3.3 times for the first step, and then the second step was drawn in steam so that the total draw ratio became 3.5 times, and then further drawn in steam. The fixed-length heat treatment was performed at a magnification of 1.10 times while being connected to a heat drum at 230°C. Next, crimping was applied with a stuffer typ...

Embodiment 2

[0143] In Example 1, when making fine-fiber fibers, the PPS pellets manufactured by Toray Co., Ltd. with an MFR value of 215 g / 10 minutes were used to make the first-stage draw ratio 3.2 times and the total draw ratio to 3.4 times. Except for this, it carried out similarly to Example 1, and obtained the fine fineness / high-strength PPS short fiber. The fineness is 0.88dtex, and the strength is 4.8cN / dtex, which is fineness / high strength.

[0144] A filter material was obtained by the same method as in Example 1 using the obtained fine fineness / high-strength PPS short fibers. Productivity and felt properties / filter properties are shown in Table 1. Spinning workability and felt productivity were good. In addition, the mechanical strength of the felt was good at warp: 1005 N / 5 cm and weft: 1680 N / 5 cm, and improvement in mechanical strength was confirmed. The outlet dust concentration, which is an index of dust collection performance, is 0.22 mg / m 3 , is good, and the improvem...

Embodiment 3

[0146] In Example 1, when making fine fineness fibers, the PPS granules manufactured by Toray Co., Ltd. with an MFR value of 260 g / 10 minutes were used to make the first-stage draw ratio 3.5 times and the total draw ratio 3.7 times. Except for this, it carried out similarly to Example 1, and obtained the fine fineness / high-strength PPS short fiber. The fineness is 0.77dtex, and the strength is 4.7cN / dtex, which is fineness / high strength.

[0147] A filter material was obtained by the same method as in Example 1 using the obtained fine fineness / high-strength PPS short fibers. Productivity and felt properties / filter properties are shown in Table 1. Spinning workability and felt productivity were good. In addition, the mechanical strength of the felt was good at warp: 903 N / 5 cm and weft: 1508 N / 5 cm, and improvement in mechanical strength was confirmed. The outlet dust concentration, which is an index of dust collection performance, is 0.15 mg / m 3 , is good, and the improvem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com