Gas Charging Method And Gas Charging Apparatus For Bag Equipped With Gas Compartment Portion

A gas and bag technology, applied in gas/liquid distribution and storage, packaging objects under special gas conditions, container filling methods, etc., can solve problems such as separation, difficult productivity, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

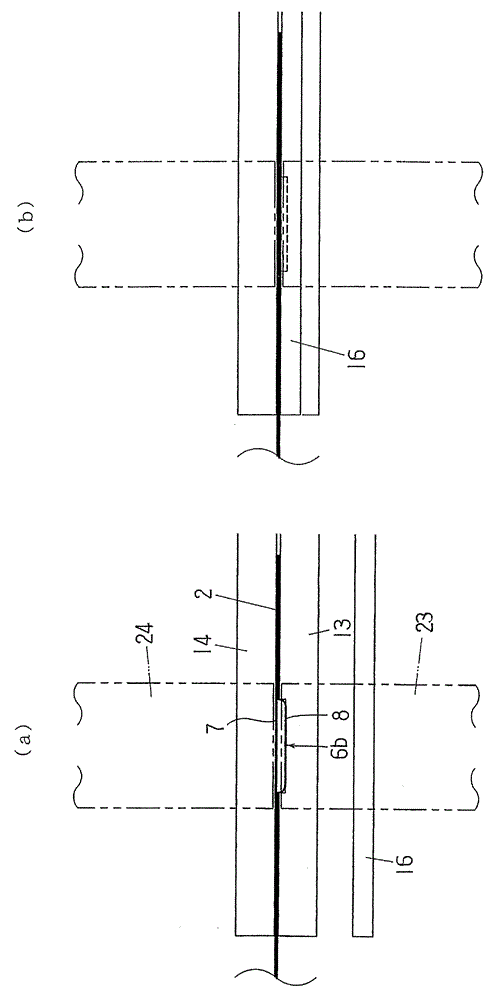

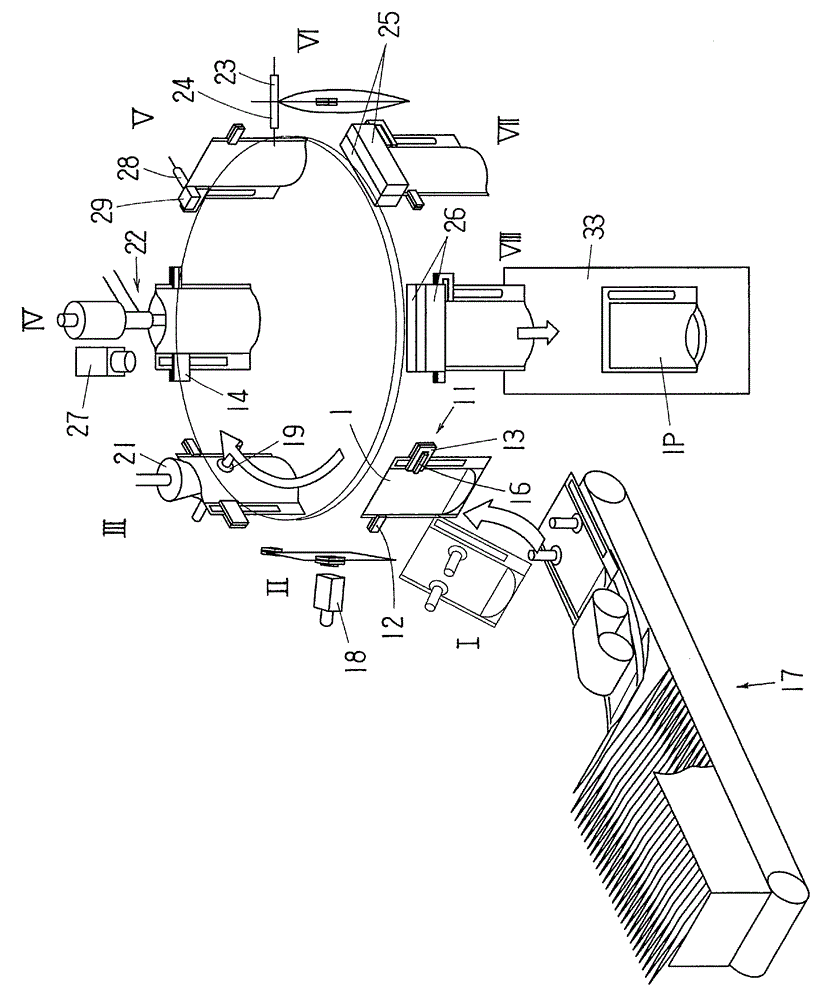

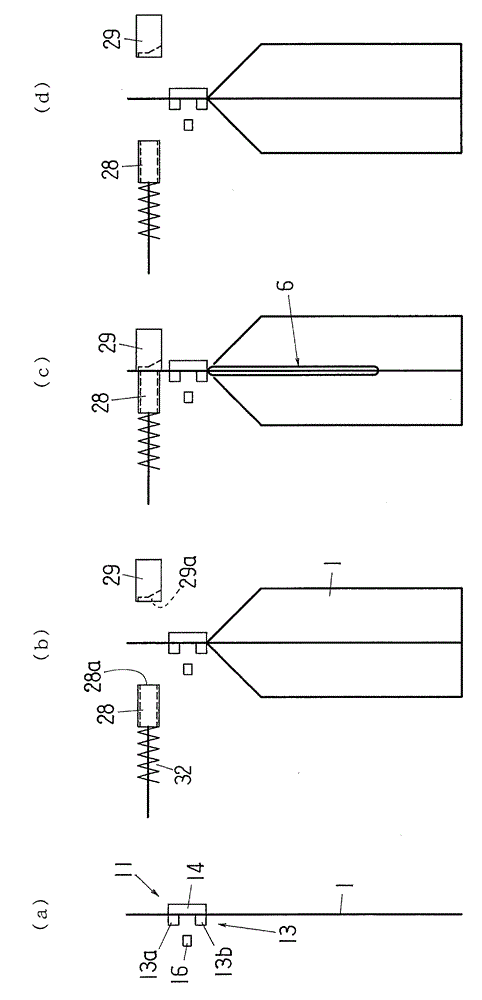

[0036] Below, refer to Figure 1 to Figure 9 , the gas filling method and apparatus according to the present invention will be described in detail.

[0037] exist Figure 5 Shown in is bag 1 with air bag attached. The bag 1 is a self-supporting bag with a gusseted bottom, and is composed of films on both the front and back sides and a folded bottom film. In the upper region X of the bag 1 , at the two side edges, the films on both the front and back sides of the bag 1 are bonded to each other, forming seals 2 , 3 . At the upper edge, the films on both sides of the front and the back are not bonded, forming an open bag mouth 4 . In the lower region Y of the bag 1, at the two side edges, the films on both the front and back sides are bonded with the bottom film sandwiched between them, and the bottom film itself is also bonded inside the folded-in side, and in the center, the surface The films on both sides of the film and the back are respectively bonded to the films on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com