Rolling device and rolling method of short stacking material

A technology for rolling materials and short yards, which is applied to the rolling field of rolling devices and short yards, can solve the problems of reduced productivity, unpredictable reliability, and growth, and achieves the effect of inhibiting damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the rolling apparatus and the rolling method according to the present invention will be described based on the drawings.

[0029] In addition, in the following description, the same code|symbol is attached|subjected to the same component. Their names and functions are also the same. Therefore, their detailed descriptions are not repeated.

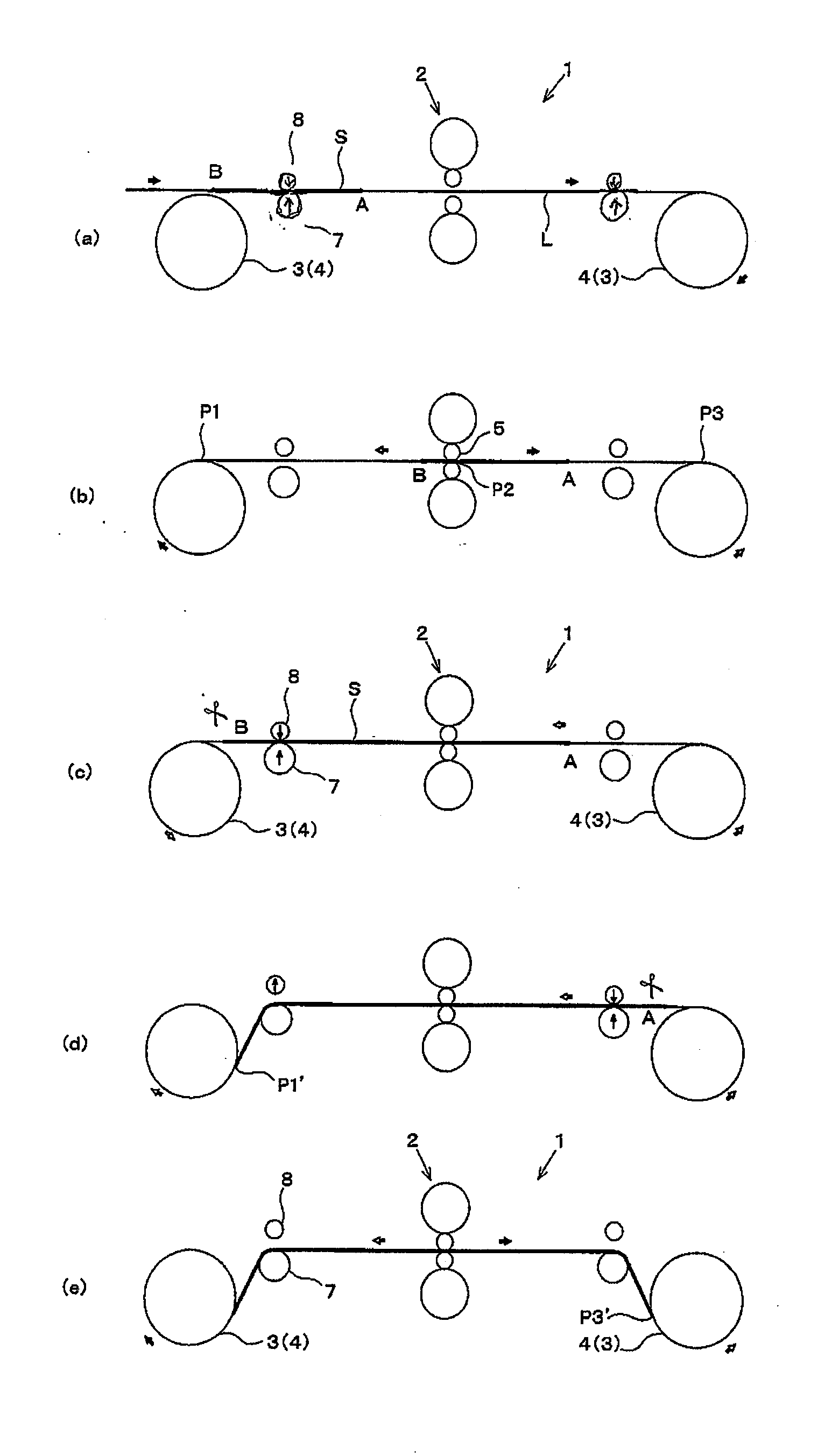

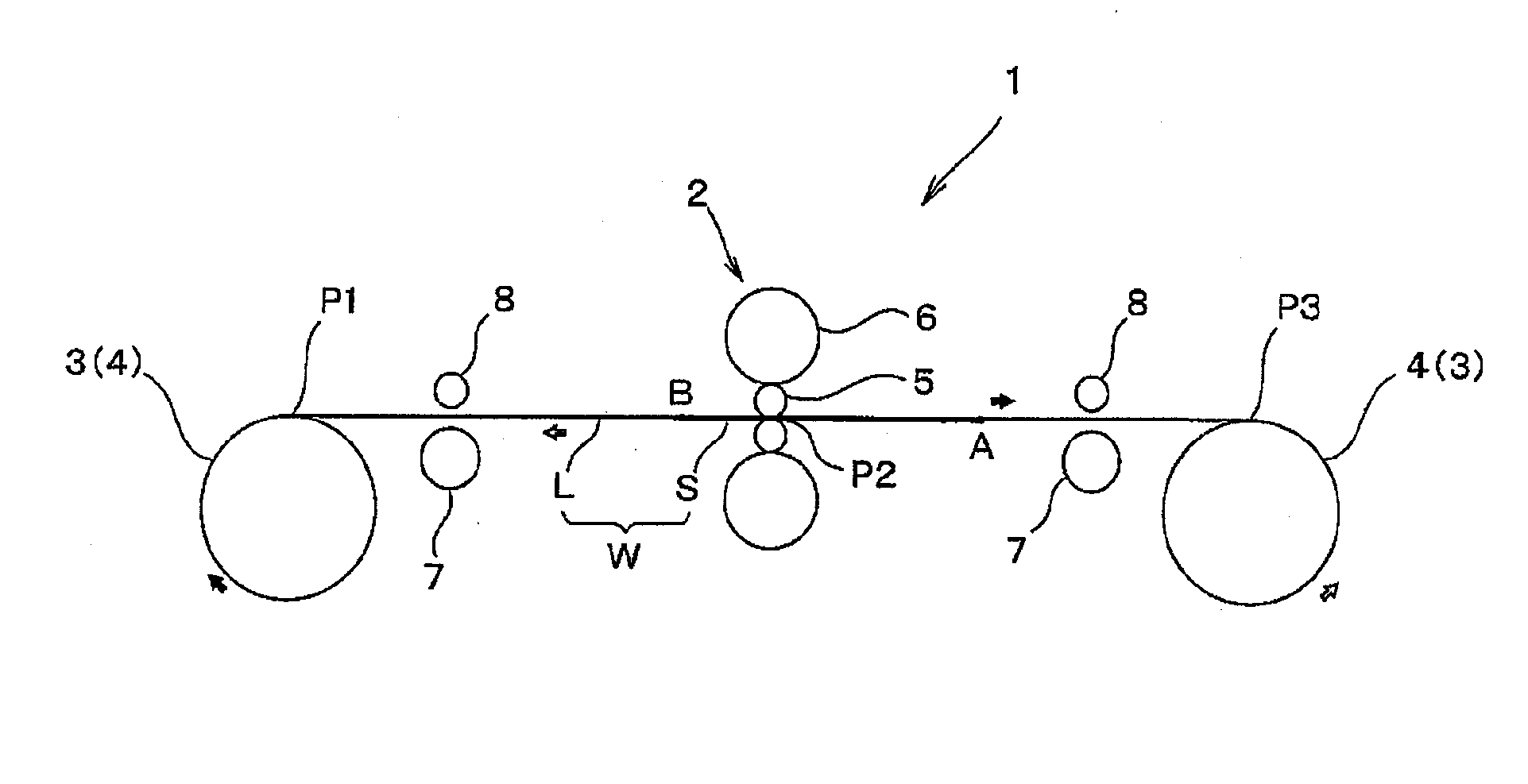

[0030] figure 1 It is a figure which shows the rolling apparatus 1 concerning this invention.

[0031] The rolling apparatus 1 includes a rolling mill 2 (4-stage rolling mill), a delivery reel 3 for sending a rolling material W to the rolling mill 2 , and a coiling reel 4 for coiling the rolling material W rolled by the rolling mill 2 .

[0032] Rolling mill 2 is a reverse rolling mill, when rolling in the right row ( figure 1 black arrow), the reel equipped on the left side of the rolling mill 2 is the sending reel 3, and the reel equipped on the right side of the rolling mill 2 is the take-up reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com