An environmentally friendly surface treatment process for non-stick pans

A surface treatment and non-stick pan technology, which is applied in the direction of manufacturing tools, metal processing equipment, and the structure of cooking utensils, etc., can solve the problems of coating peeling off, not being environmentally friendly, and increasing production costs, so as to improve adhesion and save production costs , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0030] An environment-friendly non-stick surface treatment process, comprising the steps of:

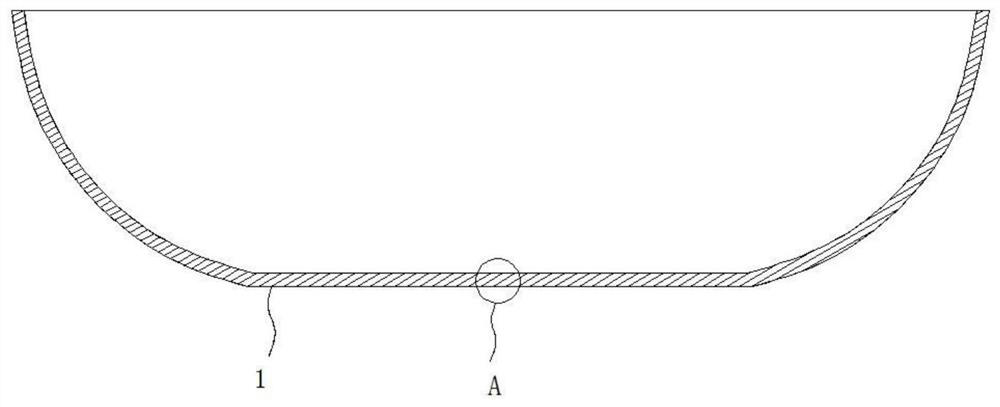

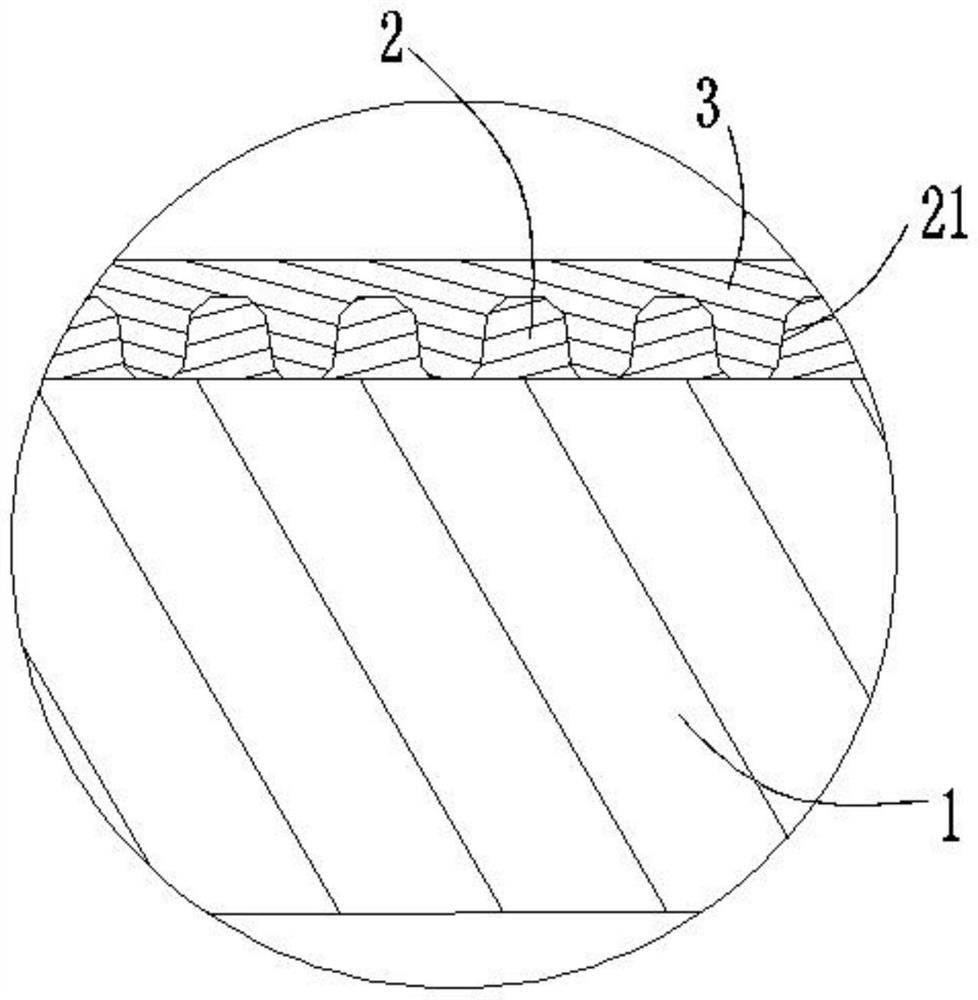

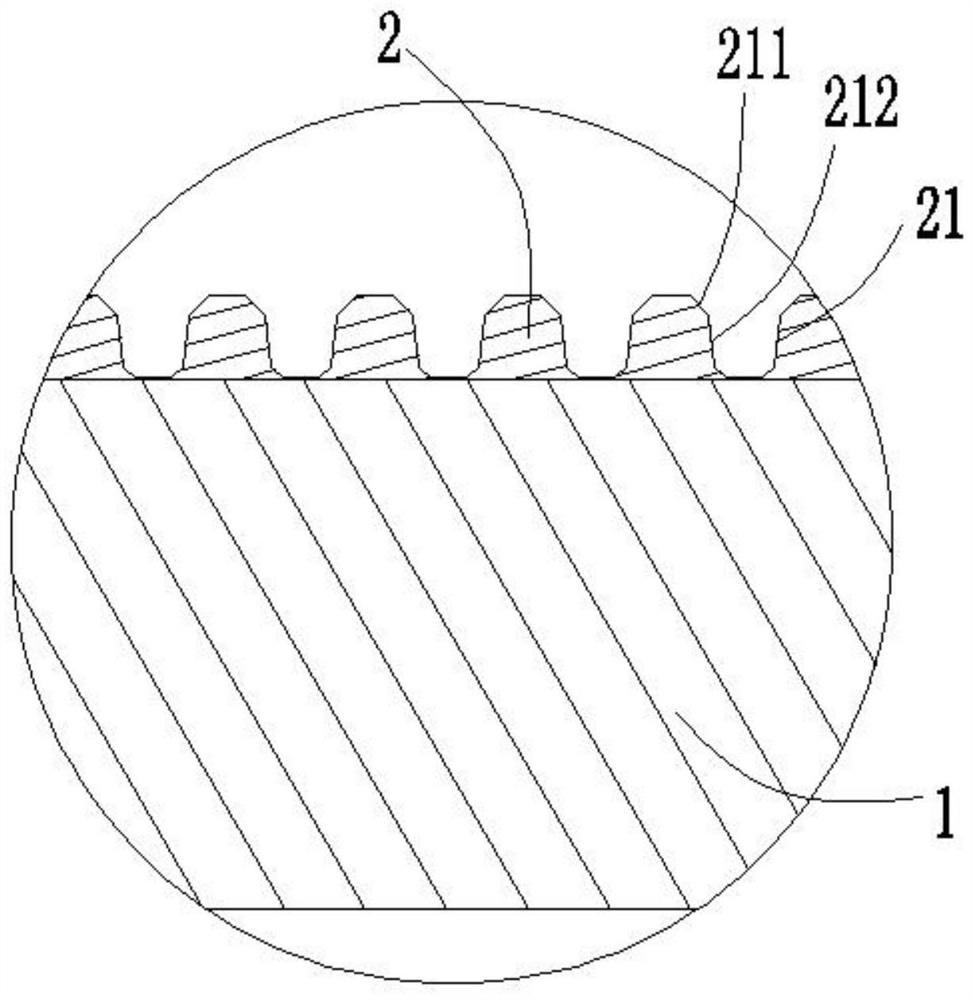

[0031]1) Pot blank forming: 2) Forming microporous layer: using laser to scan the surface of the pan blank to form multiple microporous structures, thereby forming the microporous layer; 3) Spraying non-stick coating on the surface of the microporous layer: the A non-stick coating is filled within the microporous structure. Due to the use of lasers in the present invention, microporous structures can be drilled on the surface of the pot embryo. These microporous structures can achieve small diameters and long hole depths. The micropores of these elongated structures can be distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com