Preparation method of phosphatized polyaniline-silicon dioxide graft modified graphene/waterborne epoxy-group-containing silicon resin composite coating

A technology of silica and graft modification, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of high production cost, unsatisfactory dispersion improvement effect, complicated preparation process, etc., and achieve the effect of increasing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

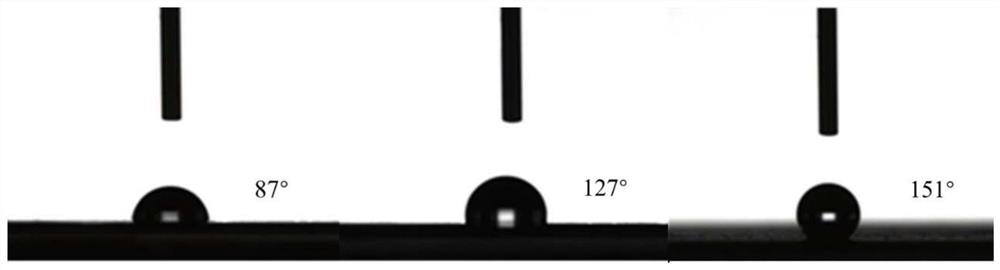

[0070] Specific embodiment one: the preparation method of phosphating polyaniline-silicon dioxide graft modified graphene / water-based epoxy-containing silicone resin composite coating in this embodiment is carried out according to the following steps:

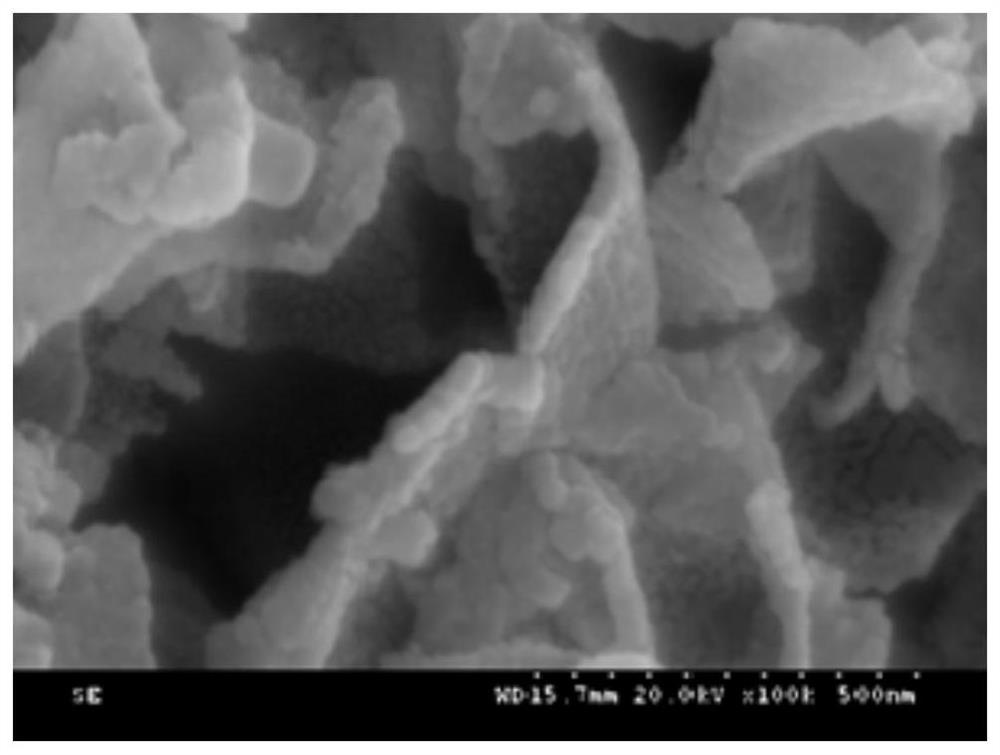

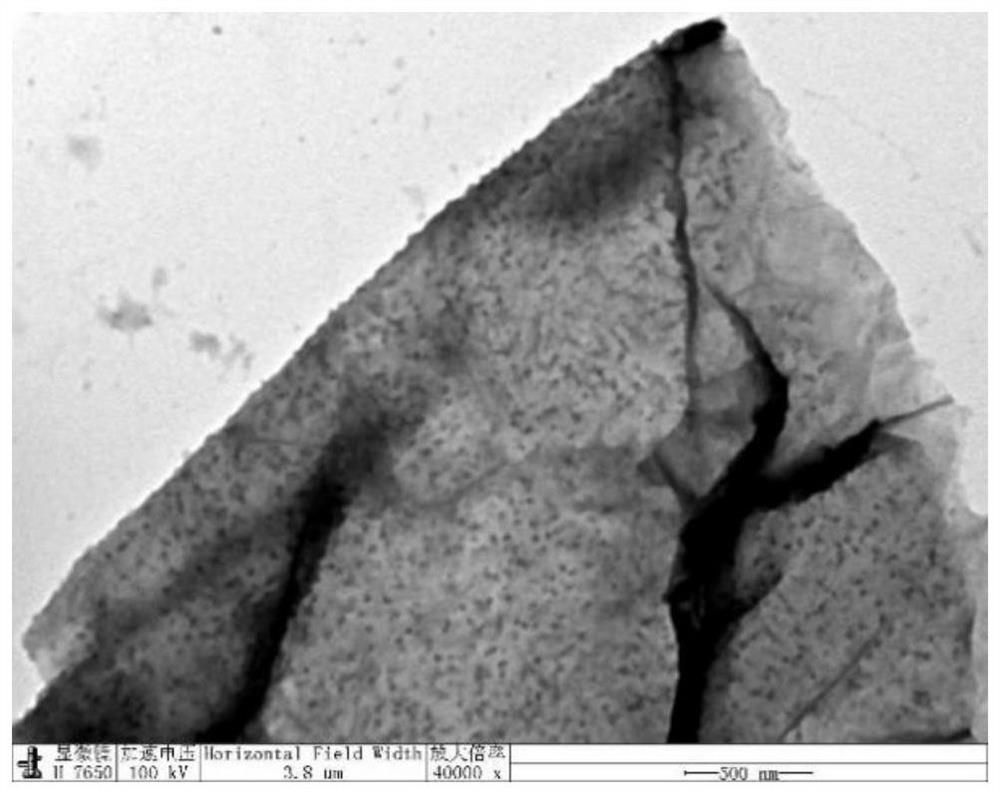

[0071] 1. Preparation of graphene oxide-silica composites

[0072] Add graphene oxide into deionized water, ultrasonically disperse for 3 to 4 hours to obtain a graphene oxide dispersion, then add ammonia water, and magnetically stir for 15 minutes to obtain an alkaline graphene oxide dispersion, then add absolute ethanol, deionized water and orthosilicon The mixed solution of ethyl acetate was stirred and reacted at 60° C. for 6 h, filtered and washed until the solid product became neutral, and a graphene oxide-silicon dioxide composite material was obtained;

[0073] The concentration of the graphene oxide dispersion is 1-1.5 mg / mL;

[0074] The ratio of the volume of tetraethyl orthosilicate to the mass of graphene oxide is...

specific Embodiment approach 2

[0100] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal in step 4 is steel.

specific Embodiment approach 3

[0101] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the alloy in step 4 is aluminum alloy or magnesium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com