Mulberry silk blended quick-drying fabric and preparation method thereof

A technology of mulberry silk and fabrics, applied in the field of textile fabrics, can solve the problems of poor blending uniformity of mulberry silk fibers, high cost of mulberry silk, and poor quick-drying performance, and achieve good quick-drying performance, reduce production costs, and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

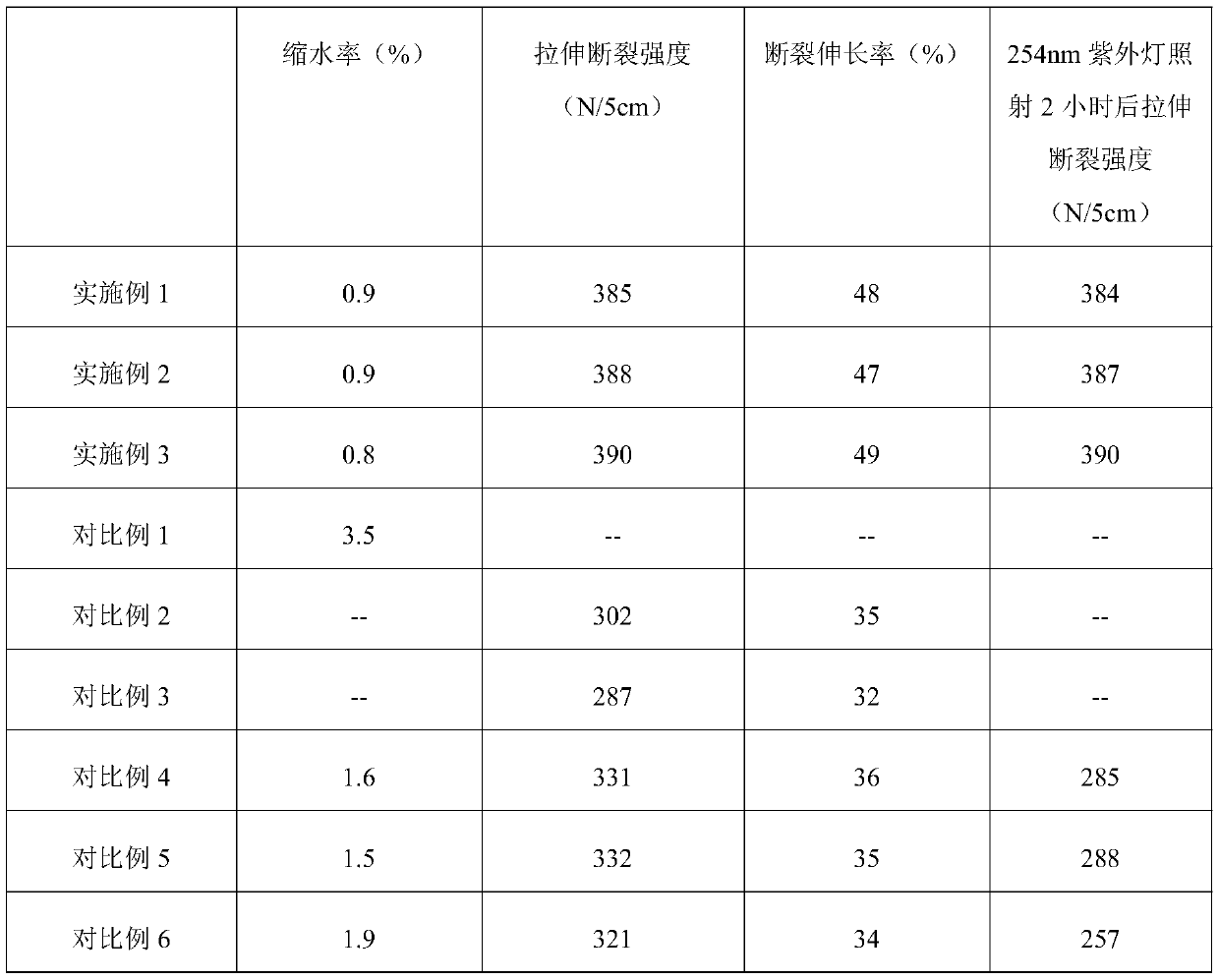

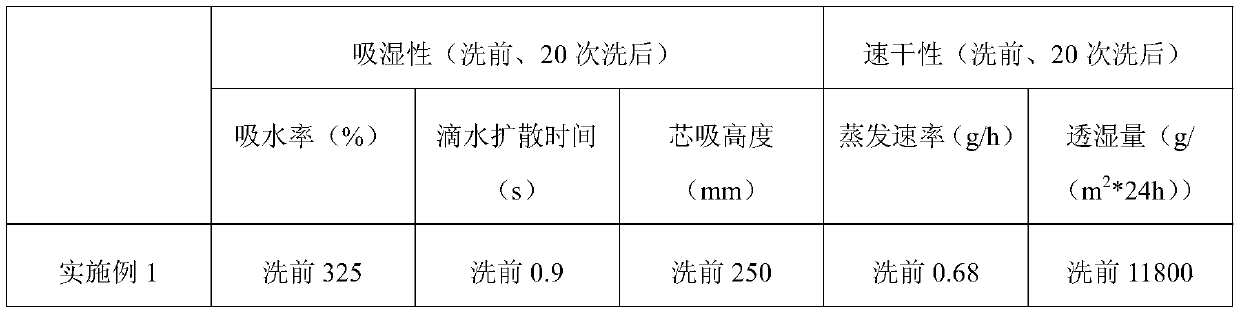

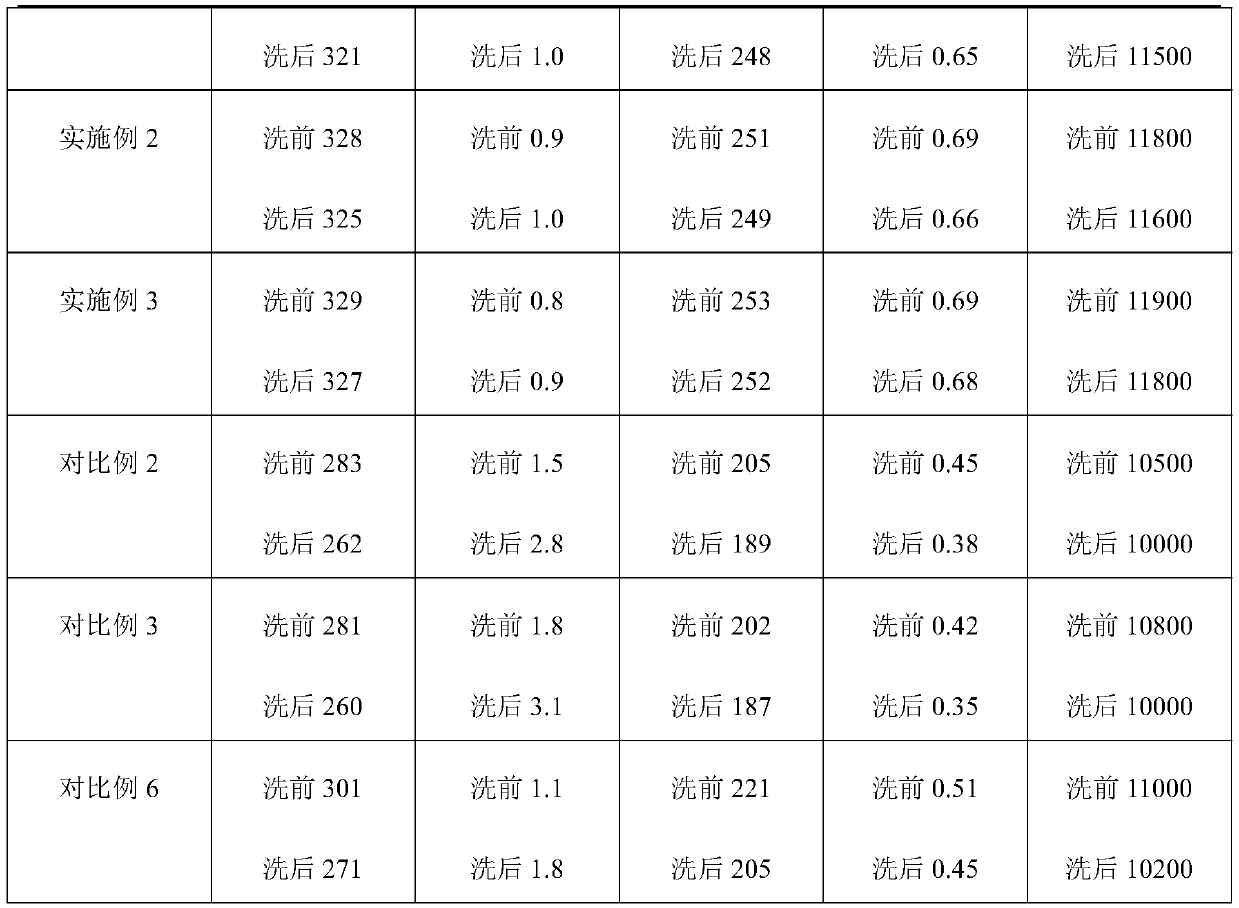

Examples

Embodiment 1

[0033] A preparation method of mulberry silk blended quick-drying fabric, in parts by weight, 10 parts of mulberry silk, 6 parts of wool fiber and 3 parts of water-soluble vinylon fiber are blended into the first yarn, and the inner surface layer and the outer surface layer are formed by machine weaving. 3 parts of cotton fiber and 8 parts of bamboo fiber are blended into the second yarn, and the middle layer is formed by upper machine weaving, so as to obtain the fabric blank, and the finishing liquid is used for ultrasonic heating and finishing, and soaked in clear water for 5 minutes after being pulled out (removing unreacted borax etc.), drying to obtain the described a kind of mulberry silk blended quick-drying fabric; wherein, the preparation method of the first yarn is: first processing mulberry silk into mulberry silk drawing, and then mixing wool fiber and water-soluble vinylon fiber Blending is processed into wool-water-soluble vinylon blended raw sliver, and then the...

Embodiment 2

[0048] A preparation method of mulberry silk blended quick-drying fabric, in parts by weight, 10 parts of mulberry silk, 9 parts of wool fiber and 2 parts of water-soluble vinylon fiber are blended into the first yarn, and the inner surface layer and the outer surface layer are formed by machine weaving. 4 parts of cotton fiber and 5 parts of bamboo fiber are blended into the second yarn, and the middle layer is formed by upper machine weaving, so as to obtain the fabric blank, and the finishing liquid is used for ultrasonic heating and finishing, and soaked in clear water for 10 minutes after being pulled out (removing unreacted borax etc.), drying to obtain the described a kind of mulberry silk blended quick-drying fabric; wherein, the preparation method of the first yarn is: first processing mulberry silk into mulberry silk drawing, and then mixing wool fiber and water-soluble vinylon fiber Blending is processed into wool-water-soluble vinylon blended raw sliver, and then th...

Embodiment 3

[0063] A preparation method of mulberry silk blended quick-drying fabric, in parts by weight, 10 parts of mulberry silk, 8 parts of wool fiber and 2.5 parts of water-soluble vinylon fiber are blended into the first yarn, and the inner surface layer and the outer surface layer are formed by machine weaving. 3.5 parts of cotton fiber and 7 parts of bamboo fiber are blended into the second yarn, and the middle layer is formed by upper machine weaving, so as to obtain the fabric blank, and the finishing liquid is used for ultrasonic heating and finishing, and soaked in clear water for 8 minutes after being pulled out (removing unreacted borax etc.), drying to obtain the described a kind of mulberry silk blended quick-drying fabric; wherein, the preparation method of the first yarn is: first processing mulberry silk into mulberry silk drawing, and then mixing wool fiber and water-soluble vinylon fiber Blending is processed into wool-water-soluble vinylon blended raw sliver, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com