Micro-foaming hole plugging resin for PCB as well as preparation method and application of micro-foaming hole plugging resin

A technology of micro-foaming and plugging, which is applied in the PCB field, can solve the problems of resin plugging process and resin cracks, etc., and achieve the effects of ensuring glass transition temperature, reducing curing stress, and reducing volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

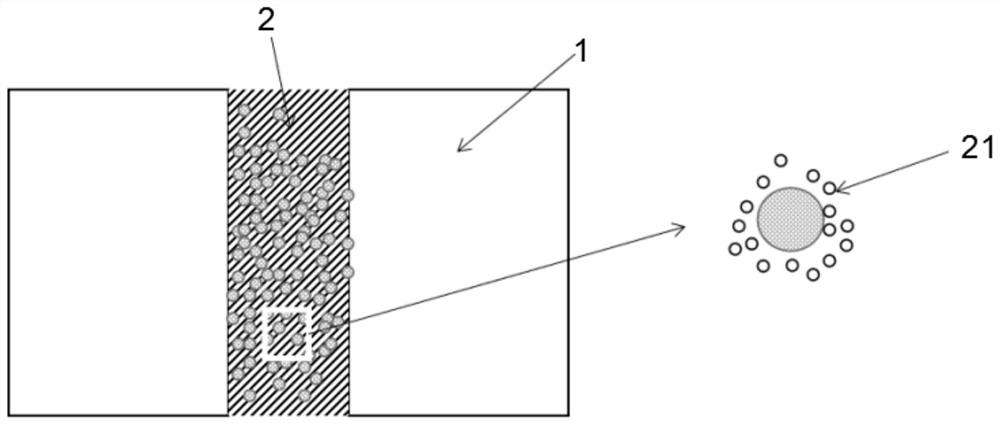

Image

Examples

preparation example Construction

[0048] The second aspect of the embodiment of the present application provides a method for preparing PCB microfoam plugging resin, comprising the following steps:

[0049] S01. Provide various components according to PCB micro-foaming plugging resin;

[0050] S02. The epoxy resin, curing agent, inorganic filler, and auxiliary agent are subjected to a first mixing treatment to obtain a first mixture;

[0051] S03. The foaming agent and the first mixture are subjected to a second mixing treatment, and are subjected to grinding and defoaming treatment to obtain a PCB microfoam plugging resin.

[0052] The preparation method of PCB micro-foaming plugging resin provided in the second aspect of the application is simple and convenient. It only needs to simply mix the components, and perform conventional grinding and defoaming treatment to obtain PCB micro-foaming resin. The foam plug hole resin, the preparation method is simple to operate, does not require large instruments and eq...

Embodiment 1

[0077] PCB microfoam plugging resin and its preparation method and application

[0078] PCB Microfoaming Plugging Resin

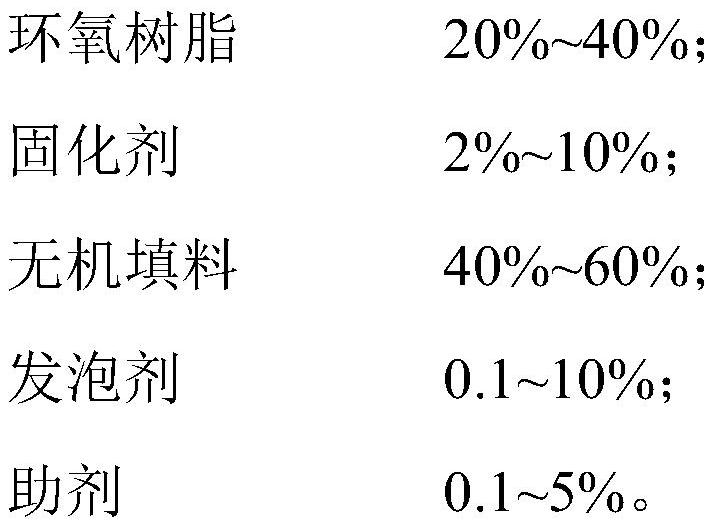

[0079] Based on the total weight of PCB micro-foaming plugging resin as 100%, it includes the following components in weight percentage:

[0080]

[0081] Wherein, epoxy resin is selected from dicyclopentadiene phenol type epoxy resin;

[0082] The curing agent is selected from 1-cyanoethyl-2-ethyl-4-methylimidazole;

[0083] The inorganic filler is selected from barium sulfate;

[0084] The foaming agent is selected from N,N-dinitrosopentamethylenetetramine;

[0085] The auxiliary agent is selected from the mixture of wetting and dispersing agent and defoaming agent, the wetting and dispersing agent is selected from BYK-110 of Germany BYK, and the defoaming agent is selected from BYK-A550.

[0086] Preparation method of PCB microfoaming plugging resin

[0087] According to the PCB micro-foam plugging resin provided in Example 1, each component ...

Embodiment 2

[0095] PCB microfoam plugging resin and its preparation method and application

[0096] PCB Microfoaming Plugging Resin

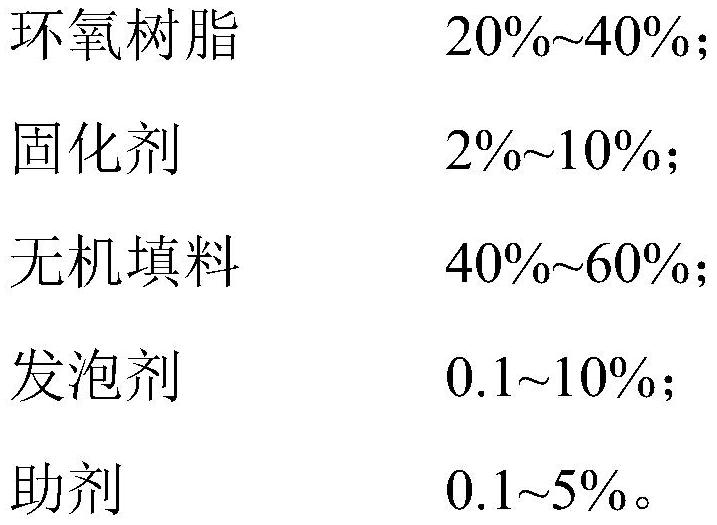

[0097] Based on the total weight of PCB micro-foaming plugging resin as 100%, it includes the following components in weight percentage:

[0098]

[0099] Wherein, epoxy resin is selected from biphenyl phenol type epoxy resin;

[0100] The curing agent is selected from phthalic anhydride;

[0101] Inorganic filler is selected from talcum powder;

[0102] Foaming agent is selected from azodicarbonamide;

[0103] The auxiliary agent is selected from the mixture of wetting and dispersing agent and defoaming agent, the wetting and dispersing agent is selected from BYK-110 of Germany BYK, and the defoaming agent is selected from BYK-A515.

[0104] Preparation method of PCB microfoaming plugging resin

[0105] According to the PCB micro-foam plugging resin provided in Example 2, each component is provided;

[0106] performing the first mixing treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com