Hydrophilic oleophobic sponge as well as preparation method and application thereof

A hydrophilic and oleophobic sponge technology is applied in the field of hydrophilic and oleophobic sponges and their preparation, and can solve the problems of reducing the oil-water separation ability of lipophilic and hydrophobic sponges, blocking pores with organic pollutants, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of hydrophilic oleophobic sponge, comprises the following steps:

[0028] The nanoparticle suspension is mixed with the modifying agent solution to obtain a modified solution; the nanoparticle suspension includes a nanometer ferric oxide suspension and / or an ethanol suspension of nanometer silicon dioxide coated with silicon dioxide on the surface; Described modifying agent solution is chitosan acetic acid aqueous solution and polyvinyl alcohol aqueous solution;

[0029] After the sponge is immersed in the modification solution, it is mixed with glutaraldehyde aqueous solution to carry out cross-linking reaction to obtain the hydrophilic and oleophobic sponge.

[0030] The nanoparticle suspension is mixed with the modifying agent solution to obtain a modified solution; the nanoparticle suspension includes a nanometer ferric oxide suspension and / or an ethanol suspension of nanometer silicon dioxide coated with silicon d...

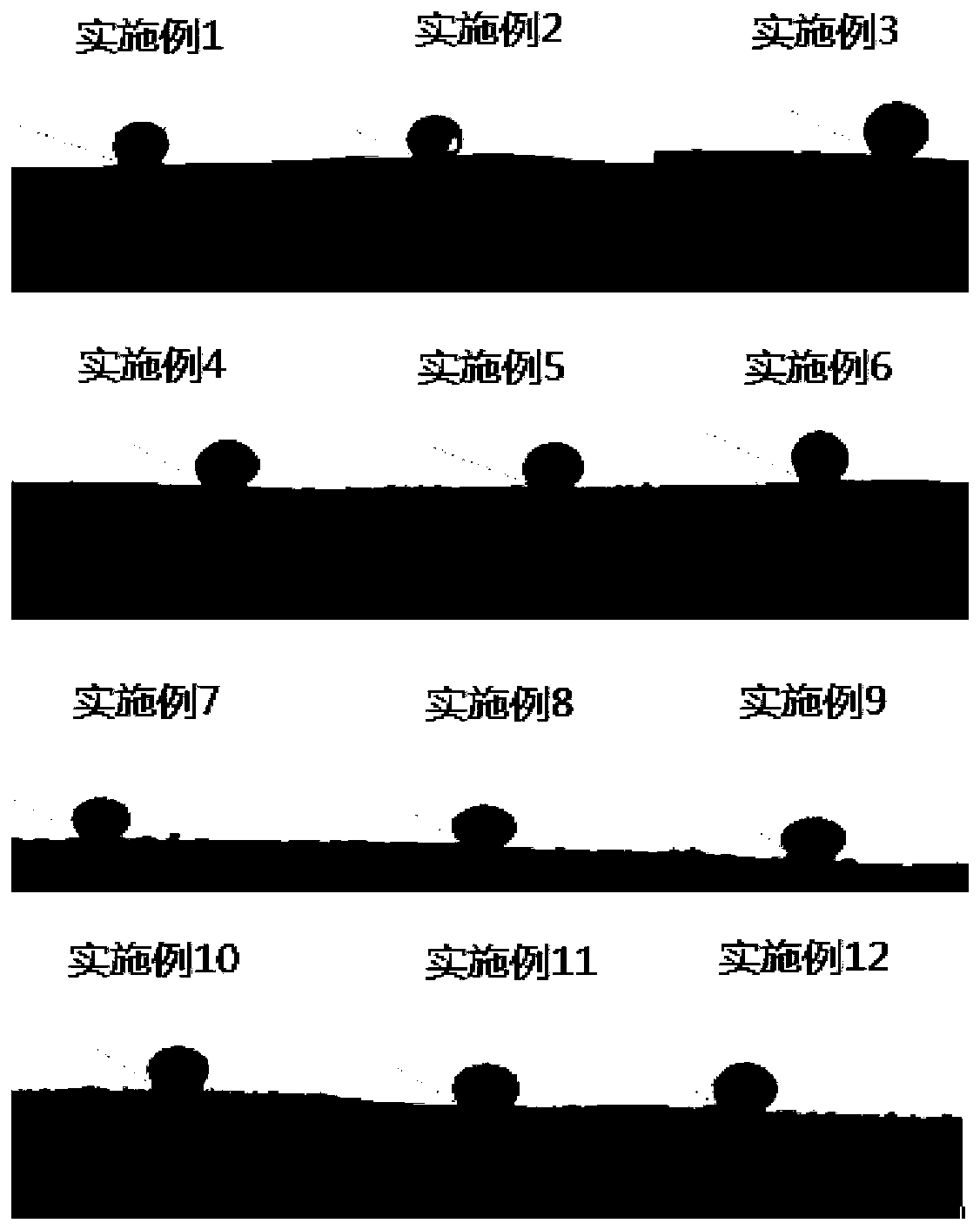

Embodiment 1

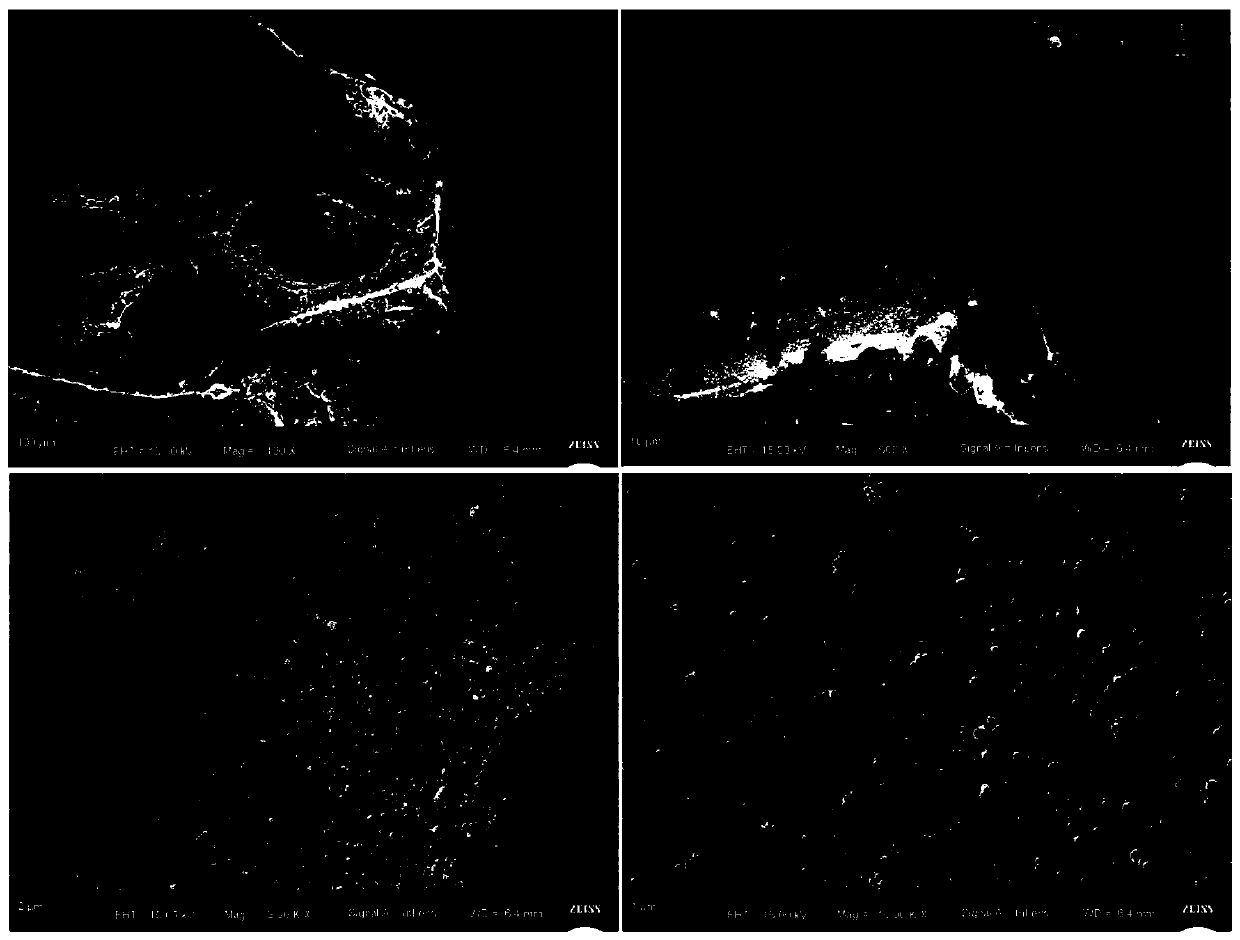

[0072] (1) 1.623g FeCl 3 ·6H 2 O with 0.597g FeCl 2 4H 2 Dissolve O in 30mL of deionized water, and stir for 30min at 60°C under nitrogen protection; then add 26g of sodium hydroxide aqueous solution (sodium hydroxide 1g, water 25g), then add 0.125g of trisodium citrate, and the temperature rises to 80°C , stirred and reacted for 1 hour; after the reaction was completed, cool to room temperature to obtain hydrophilic ferric iron tetroxide particles, perform magnetic separation and wash 6 times with deionized water, and then add 50 mL of deionized water to prepare hydrophilic triferrous oxide particles Iron particle suspension; add 4mL ammonia water (concentration: 25wt%) to the above suspension, stir for 5min, then add 0.25mL tetraethoxysilane, and then react for 12h under nitrogen protection at room temperature; the reaction is completed to obtain surface-coated silicon dioxide The ferric oxide particles were magnetically separated and washed 6 times with deionized water, ...

Embodiment 2

[0078] (1) Same as Step 1 of Embodiment 1.

[0079] (2) Weigh 0.4 g of chitosan and dissolve it in 1 wt % acetic acid solution, stir at room temperature for 4 h to obtain 40 mL of chitosan acetic acid aqueous solution.

[0080] (3) Weigh 0.4 g of polyvinyl alcohol and add it into deionized water, and stir at 50° C. for 2 hours to obtain 12 mL of polyvinyl alcohol aqueous solution.

[0081] (4) Add 45mL ferric oxide suspension coated with silica on the surface and 40mL chitosan acetic acid aqueous solution into a round bottom flask, stir for 3 minutes, then add 12mL polyvinyl alcohol aqueous solution, stir for 5 minutes, and then put 6 pieces of dense Soak the amine sponge (4cm×2.5cm×0.7cm) in the above mixed solution, stir for 15min, add 0.075mL glutaraldehyde aqueous solution, stir for 12h, finally take out the sponge from the mixed solution and directly dry it in vacuum at 60°C for 24h, A hydrophilic and oleophobic sponge is obtained. Gained modified sponge is 154 degree t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com