Double-color electroplating process

A two-color electroplating and process technology, applied in the field of electroplating, can solve problems such as poor adhesion between the palladium particle layer and the surface of the workpiece to be electroplated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

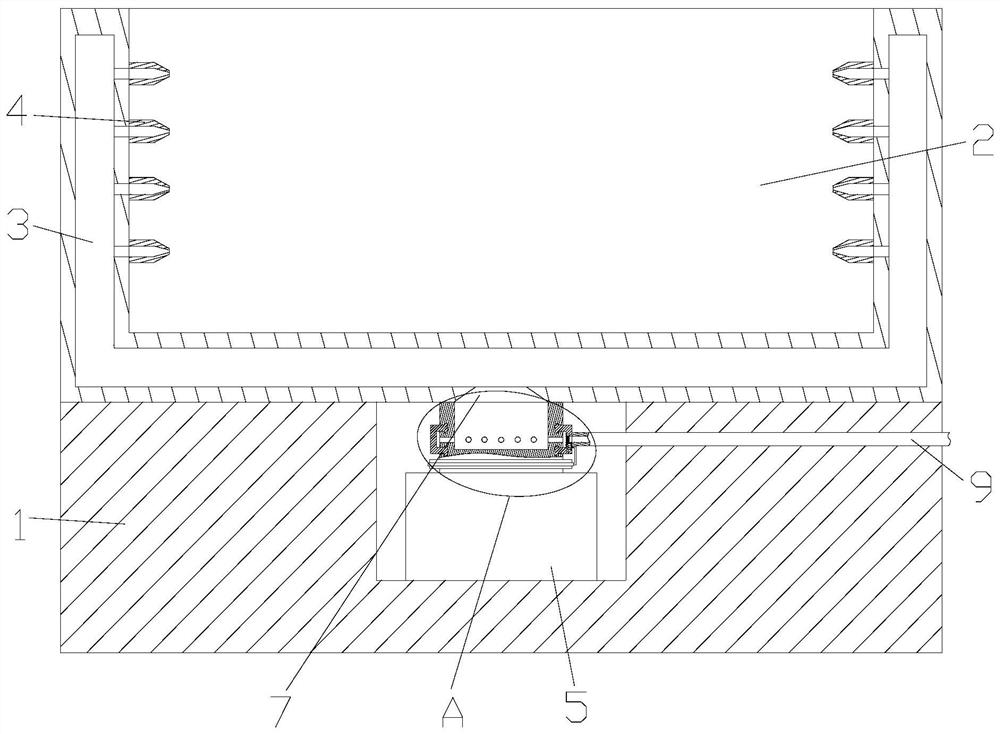

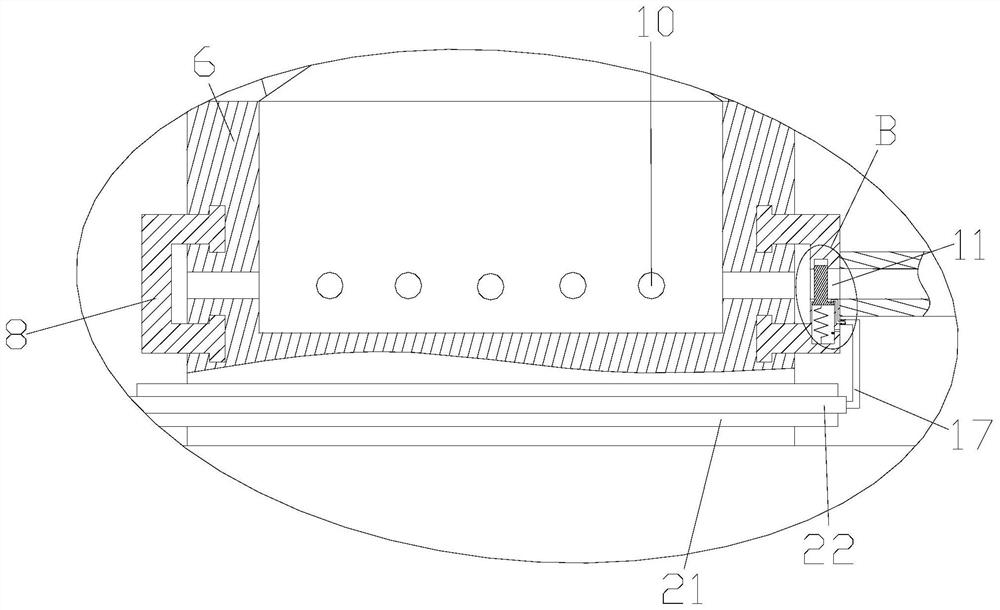

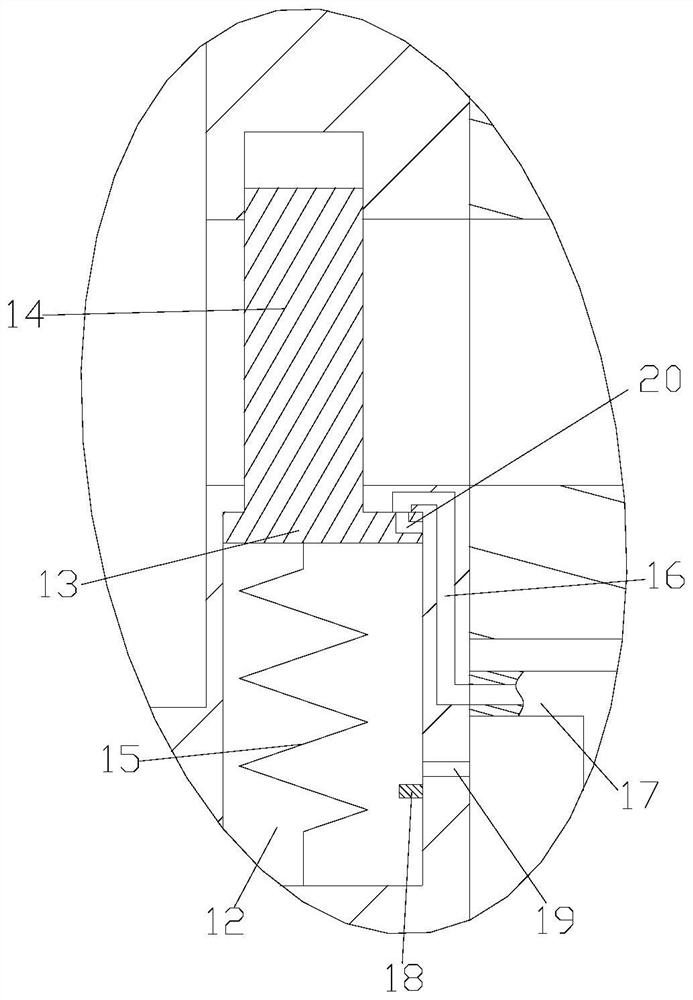

[0028] The reference signs in the drawings of the description include: base 1, spray tank 2, liquid guide cavity 3, nozzle 4, motor 5, liquid guide tube 6, liquid guide hole 7, sealed liquid guide sleeve 8, liquid inlet pipe 9 , Liquid inlet hole 10, communication hole 11, first positioning groove 12, limit block 13, stopper 14, support spring 15, air guide hole 16, air guide tube 17, positioning block 18, pressure relief hole 19, adjustable conduction Hole 20, shell 21, wind guide sleeve 22.

[0029] A two-color electroplating process, comprising the following steps:

[0030] Step 1, hot water washing, place the workpiece to be electroplated in a hot water washing tank, and wash with hot water at 35°C for 1.5 minutes; it is used to wash away impurities such as dust adhered to the surface of the workpiece to be electroplated.

[0031] Step 2. Ultrasonic degreasing. Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com