A kind of low surface energy material with micro-nano groove structure and preparation method thereof

A low surface energy, micro-nano technology, used in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems of expensive organic fluorine resins, poor salt resistance, and long curing time, Achieve the effect of increasing micro-roughness, improving anti-corrosion performance and high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

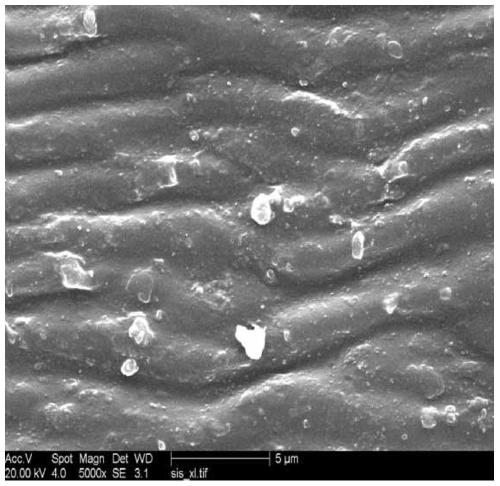

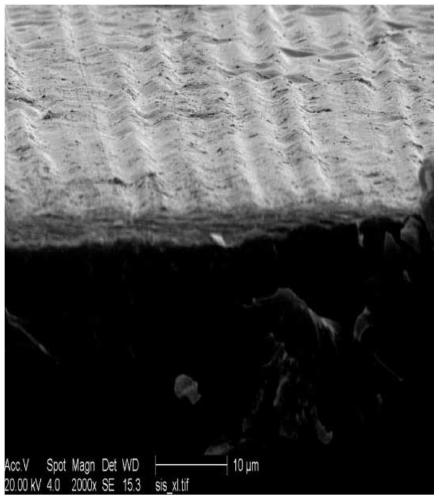

Image

Examples

Embodiment 1

[0032] Embodiment 1: The preparation method of the low surface energy material with the micro-nano groove structure of the present embodiment is carried out according to the following steps:

[0033] 1. Preparation of epoxidized hydroxyl-terminated polybutadiene polyurethane:

[0034] a. Raw material preparation: Weigh 56.8% of hydroxyl-terminated polybutadiene HTPB, 24.9% of tetramethylxylylene diisocyanate TMXDI, and 18.3% of epoxy resin E-51 by mass percentage; wherein hydroxyl-terminated polybutadiene Diene HTPB has a hydroxyl value of 1.36 and a low-viscosity liquid rubber with a number average molecular weight of 1700;

[0035] b. Synthesis of hydroxyl-terminated polybutadiene polyurethane: Add TMXDI into a three-necked flask, stir and heat up to 60°C, add pre-vacuumized to no-foam hydroxyl-terminated polybutadiene into the three-necked flask, keep stirring for 40 minutes, and heat up React at 100°C for 3 hours, take samples to measure -NCO content, when -NCO% = 7.0%, c...

Embodiment 2

[0048] Embodiment 2: The preparation method of the low surface energy material with the micro-nano groove structure of the present embodiment is carried out according to the following steps:

[0049] 1. Preparation of epoxidized hydroxyl-terminated polybutadiene polyurethane:

[0050] a. Raw material preparation: Weigh 56.8% of hydroxyl-terminated polybutadiene HTPB, 24.9% of tetramethylxylylene diisocyanate TMXDI, and 18.3% of epoxy resin E-51 by mass percentage; wherein hydroxyl-terminated polybutadiene Diene HTPB is a low-viscosity liquid rubber with a hydroxyl value of 1.05 and a number average molecular weight of 2300;

[0051] b. Synthesis of hydroxyl-terminated polybutadiene-type polyurethane: Add TMXDI into a three-necked flask, stir and heat up to 60°C, add pre-vacuumized to no-foam hydroxyl-terminated polybutadiene into the three-necked flask, keep stirring for 40min, and heat up React at 100°C for 3 hours, take a sample to measure the -NCO content, cool down to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com