Magnesium alloy surface treatment process

A surface treatment, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of high temperature strength, low creep performance, high price, poor corrosion resistance, etc., achieve grain structure refinement, and increase film forming speed , the effect of inhibiting microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

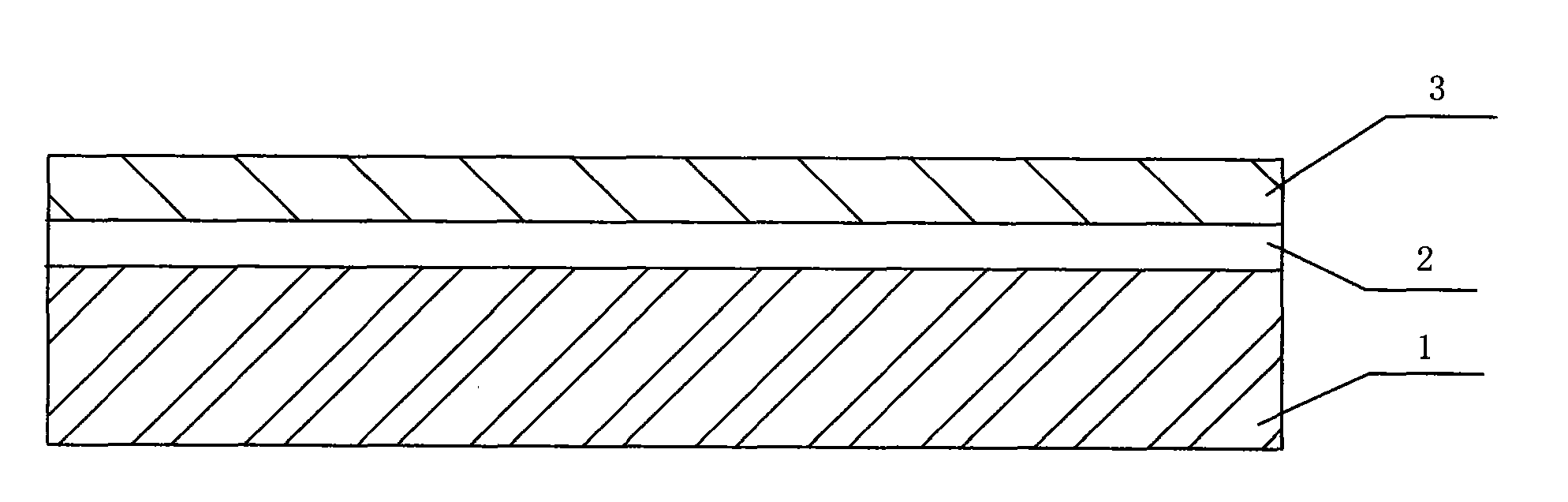

[0040] A surface treatment process for a magnesium alloy, the surface treatment process comprising (1) first dipping a magnesium alloy substrate surface 1 into a phosphate film-forming solution, then washing and drying to form a layer of transition film 2; (2) external coating Chromium-free Dacromet functional coatings to obtain protective coatings 3;

[0041] Described phosphate film-forming solution is the aqueous solution that is made up of the component of following concentration:

[0042] Phosphoric acid 30g / L

[0045] Amine fluoride 1.5g / L

[0046] Crystallization control agent 2g / L

[0047] Reaction Accelerator 1.5g / L

[0048] Anionic surfactant 1.5g / L;

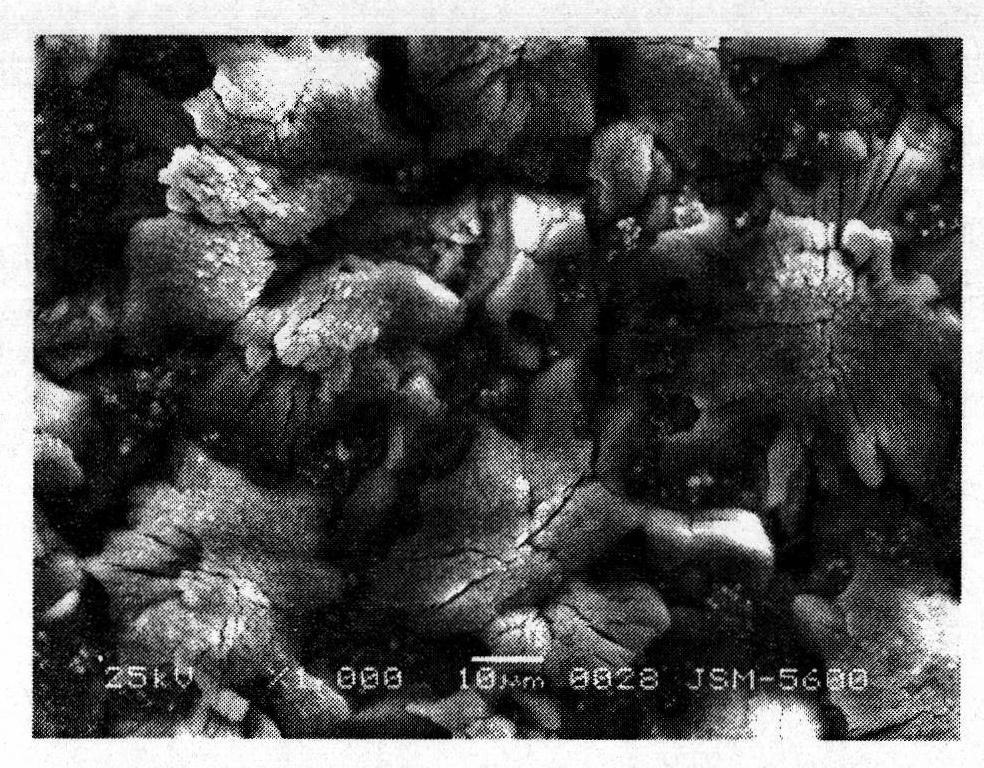

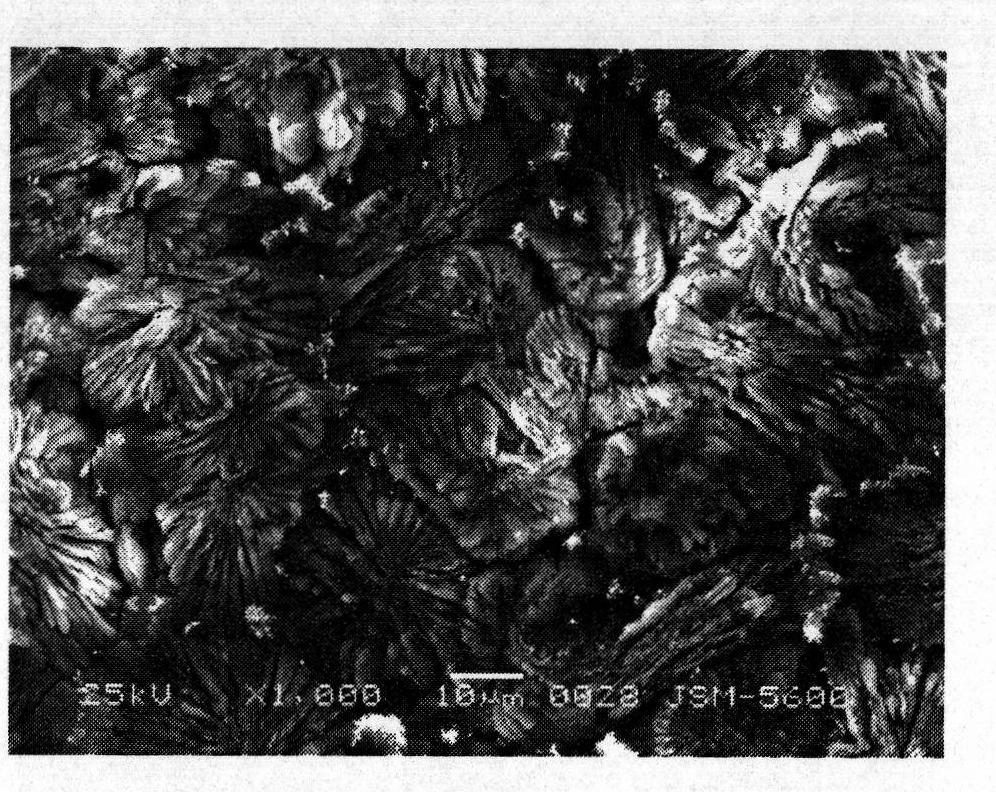

[0049] The microstructure obtained by the magnesium alloy of the present invention after the surface treatment process is as follows: figure 1 shown. The surface morphology of the transition film prepared by the surface treatment process of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com