Production method for B-containing steel

A production method and technology for steel slabs, applied in the direction of metal rolling, etc., can solve problems such as affecting the working environment of workers, damage to molds, and falling off of iron oxide sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

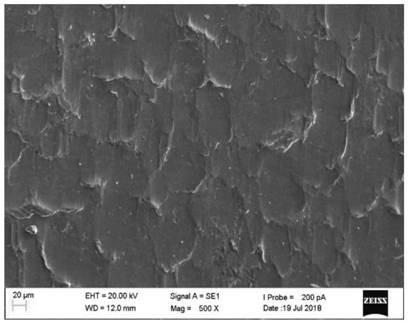

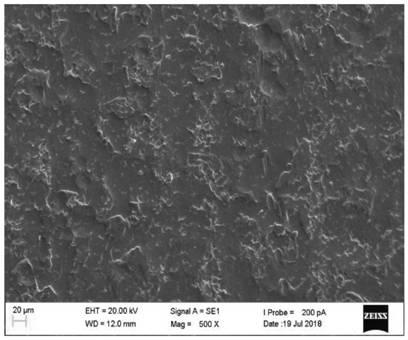

Image

Examples

Embodiment

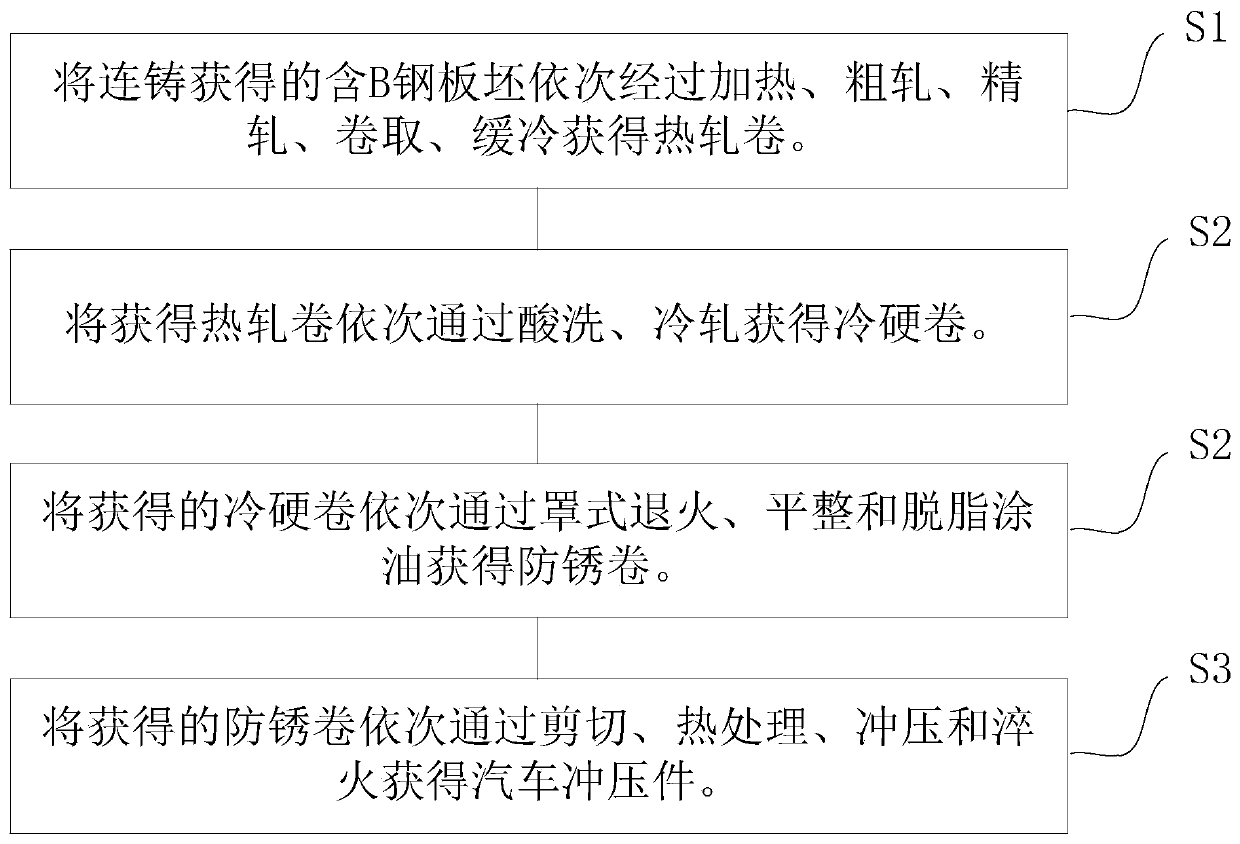

[0052] The implementation method of this embodiment is as follows:

[0053] S1: For the B-containing steel slab, the B-containing steel slab obtained by continuous casting is sequentially heated, rough rolled, finished rolled, coiled, and slowly cooled to obtain a hot rolled coil.

[0054] S2, the hot-rolled coils are sequentially pickled and cold-rolled to obtain chilled coils.

[0055] S3, the chilled coil is sequentially subjected to cover annealing, flattening, and degreasing and oiling to obtain an anti-rust coil.

[0056] S4, the anti-corrosion coil is subjected to shearing, heat treatment, stamping and quenching in sequence to obtain automobile stamping parts, wherein the heat treatment adopts N 2 As a protective gas.

[0057] In this embodiment, the coiling temperature and slow cooling process are optimized first, and the process parameter control is shown in Table 1.

[0058] Table 1

[0059] Serial number Curling temperature, ℃ Slow cooling time in slow cooling pit, h Tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com