A method for dyeing polyimide fiber with disperse dyes

A technology of polyimide fiber and disperse dye, applied in the direction of dyeing method, textile and papermaking, etc., can solve the problems of difficulty in dyeing polyimide fiber, achieve good industrial application value, excellent fastness and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put the polyimide fiber in absolute ethanol with a bath ratio of 1:100, and treat it at 60°C for 60 minutes. After cleaning, put it into a 30g / L sodium hydroxide solution with a bath ratio of 1:100. Treat at 80°C for 10 minutes, then wash and dry.

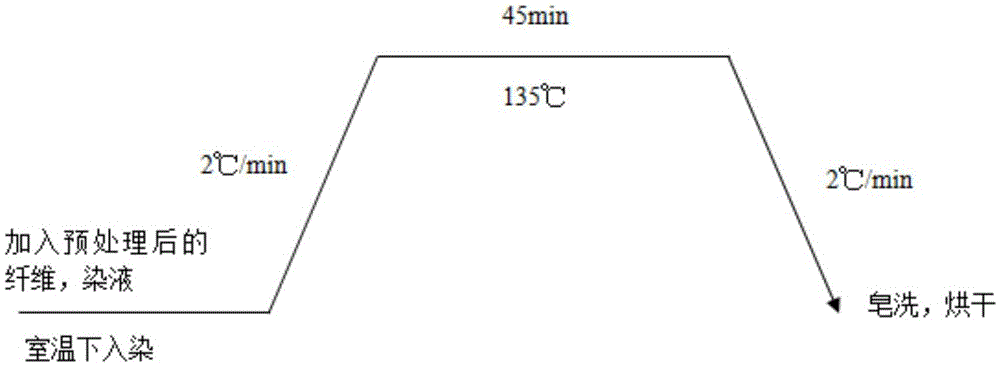

[0026] (2) under room temperature, the polyimide fiber that step (1) obtains is put into by the disperse blue SE-2R dyestuff that is 5% by fabric weight, the sodium nitrate that concentration is 4g / L and concentration is 40g / L In the working liquid composed of benzyl alcohol, the working liquid bath ratio is 1:100, the temperature is raised to 135°C at 2°C / min, kept for 45min, then cooled to 60°C at a rate of 2°C / min, and washed with water.

[0027] In this embodiment, the blue disperse dye used, plus the yellow color of the fiber itself, does not require multiple dyes to match colors,

[0028] The direct color is green and can be used for military field protective clothing. After dyeing, the K / S value, washing fastnes...

Embodiment 2

[0034] (1) Put the polyimide fiber in absolute ethanol with a bath ratio of 1:100, and treat it at 60°C for 60 minutes. After cleaning, put it into a 20g / L sodium hydroxide solution with a bath ratio of 1:100. Treat at 80°C for 10 minutes, then wash and dry.

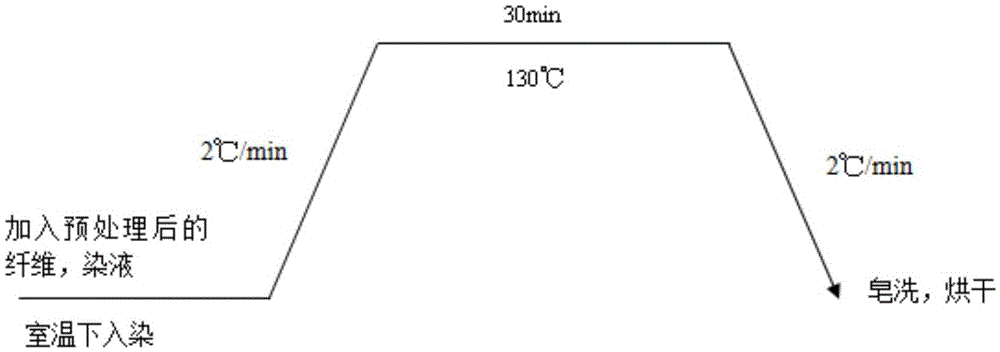

[0035] (2) under room temperature, the polyimide fiber that step (1) obtains is put into by the disperse red C.I.Disperse Red 227 dyestuff of 5% by fabric weight, the sodium nitrate that concentration is 4g / L and concentration is 40g / In the working liquid composed of L benzyl alcohol, the working liquid bath ratio is 1:100, the temperature is raised to 130°C at 2°C / min, kept for 30min, then cooled to 60°C at a rate of 2°C / min, and washed with water.

[0036] In this embodiment, the red disperse dye used, together with the yellow color of the fiber itself, does not require color matching of multiple dyes, and the color is directly orange-red, which can be used for fire protection clothing. After dyeing, the K / S value, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com