Super-hydrophilic agent, preparation method thereof and super-hydrophilic vehicle window glass

A hydrophilic agent and super-hydrophilic technology, applied in the coating and other directions, can solve the problems of increasing the driving risk, obstructing the driver's sight, and high light transmittance, so as to improve the micro-roughness of the coating and the high visible light transmittance. The effect of high efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of above-mentioned superhydrophilic agent simultaneously, it is characterized in that, comprises the steps:

[0040] Step 1: preparing tin dioxide nanoparticles;

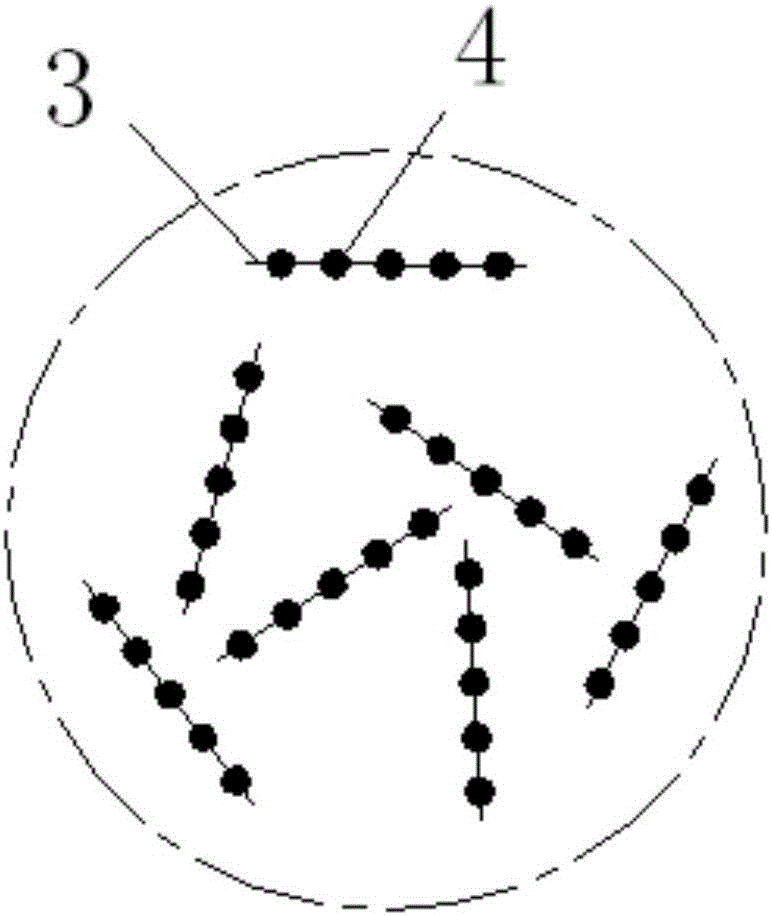

[0041] Step 2: Mix a dispersant with a volume ratio of 4 to 7:1 and a dilute acid solution to form a dispersion, then add 2 to 5 wt% carbon nanotube powder to make the pH of the solution 3 to 5, and then Stir at ~30°C for 1-3 hours, and mix evenly to obtain a carbon nanotube dispersion;

[0042] Step 3: Add 0.08-0.33 wt% tin dioxide nanoparticles to the carbon nanotube dispersion, then add 0.2-0.8 wt% polyvinyl alcohol, and stir for 1-2 hours to obtain superhydrophilic agent. Wherein, wt% is weight percentage, h is hour, and the weight percentage of each component mentioned above refers to its weight ratio that accounts for the superhydrophilic agent that finally makes.

[0043] Further, the preparation method of the tin dioxide nanoparticles...

Embodiment 1

[0050] Embodiment one: the preparation of superhydrophilic agent

[0051] (1) Preparation of tin dioxide nanoparticles. Add 3g of cetyltrimethylammonium chloride to 10ml of n-pentane, then add 5ml of n-pentanol, stir and heat to 60°C to completely dissolve cetyltrimethylammonium chloride, then add 6wt% of Add 0.3ml of polyvinyl alcohol aqueous solution and cool down to 30°C. Then 0.5ml of 8wt% tin tert-butoxide / tert-butanol solution was added dropwise, reacted at 30°C for 2h, added 12ml of ethanol to break the emulsion, ultrasonicated for 2min, and centrifuged at 5000rpm for 10min. After centrifugation, the solid was washed with 6.5ml of carbon tetrachloride, centrifuged, and freeze-dried at -45°C for 6 hours to obtain the product.

[0052] For the above-mentioned process of preparing tin dioxide nanoparticles, please refer to the "preparation method of tin dioxide nanoparticles" disclosed in Chinese patent CN105819497A for the specific preparation method. In order to meet ...

Embodiment 2

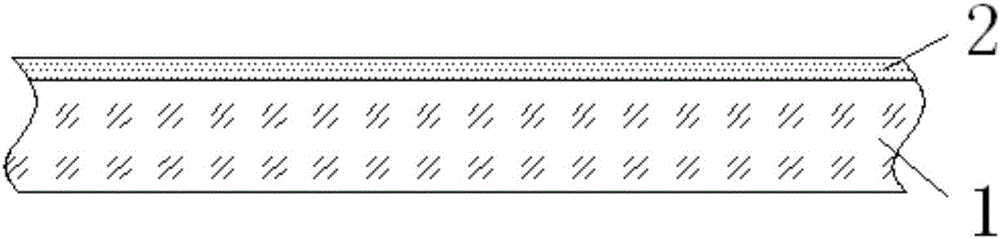

[0055] Embodiment two: the making of super hydrophilic glass

[0056] (1) cleaning. Take a glass substrate, clean it with detergent and deionized water, then wash it with acetone, ethanol, and water for 10 minutes, then wash it with deionized water, and dry it to obtain a clean glass substrate.

[0057] (2) Spin-coat the super-hydrophilic coating prepared in Example 1 on the surface of the glass substrate. Take 0.3ml of superhydrophilic agent and add it dropwise to the center of the glass, spin-coat at 2000rpm for 2min, place it in an oven at 60°C for 5min, and then cool it naturally. Then put the glass substrate in a heating furnace, raise the temperature to 120°C at 2°C / min, keep it for 1h, then raise the temperature to 500°C at 4°C / min, keep it for 2h, and then cool it down to room temperature naturally to obtain superhydrophilic Glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com