Preparation method of hydrophobic catalyst for hydrogen-water isotope exchange

An isotope exchange and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of high utilization rate of active metal, diversified shapes and specifications, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of 2mm×2mm θ rings with a loading capacity of 0.8~1% hydrophobic catalyst on regular shaped metal fiber mats

[0050] The specific steps of preparation are as follows.

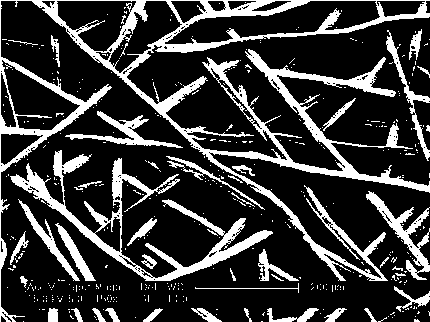

[0051] 1. The supporting carrier is a square metal fiber felt of 100mm×100mm, such as figure 1 shown. Weigh metal fiber felt (specific surface area 235m 2 g -1 , porosity 88%, thickness 2mm) initial weight.

[0052] 2. Weigh 200mg of Pt / C catalyst, 500mg of polytetrafluoroethylene and 200mg of polymethyl methacrylate respectively, add these three components into a grinding bowl for grinding, then add about 100ml of deionized water, and disperse with ultrasonic stirring A homogeneously mixed aqueous solution.

[0053] 3. Take out 1.2ml of the emulsifier with a liquid extractor, put it into a beaker, and add a small amount of deionized water to disperse it, then slowly add it to the aqueous solution prepared in step 2, and use ultrasonic stirring throughout the process. Continue ultrason...

Embodiment 2

[0059] Preparation of Corrugated Hydrophobic Catalyst Using Corrugated Metal Fiber Mat as Support

[0060]1. The support carrier is a square metal fiber mat of 100mm×100mm, and the metal fiber felt is processed into a corrugated shape. Weigh metal fiber felt (specific surface area 235m 2 g -1 , porosity 88%, thickness 2mm) initial weight.

[0061] 2. Weigh 200mg of Pt / C catalyst, 500mg of polytetrafluoroethylene and 200mg of polymethyl methacrylate respectively, add these three components into a grinding bowl for grinding, then add about 100ml of deionized water, and ultrasonically stir and disperse A homogeneously mixed aqueous solution.

[0062] 3. Take out 1.2ml of the emulsifier with a liquid extractor, put it into a beaker, and add a small amount of deionized water to disperse it, then slowly add it to the aqueous solution prepared in step 2, and use ultrasonic stirring throughout the process. Continue ultrasonic stirring until the solution becomes a suspension to mak...

Embodiment 3

[0066] Weigh 200mg of Pt / C catalyst, 550mg of polytetrafluoroethylene and 220mg of polymethyl methacrylate respectively, put these three components into a grinding bowl for grinding, then add about 120ml of deionized water, ultrasonically stir and disperse until uniform mixing of aqueous solution. Take out 1.3ml of the emulsifier with a liquid extractor, put it into a beaker, and add a small amount of deionized water to disperse it, then slowly add it to the aqueous solution, and use ultrasonic stirring throughout the process. Continue ultrasonic stirring until the solution becomes a suspension to make a suspension. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com