Purification device for industrial waste gases

A technology for purifying equipment and industrial waste gas, which is applied in the directions of gas treatment, air quality improvement, chemical instruments and methods, etc. It can solve problems such as difficult treatment of volatile organic compound equipment, achieve simple structure, save water resources, and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

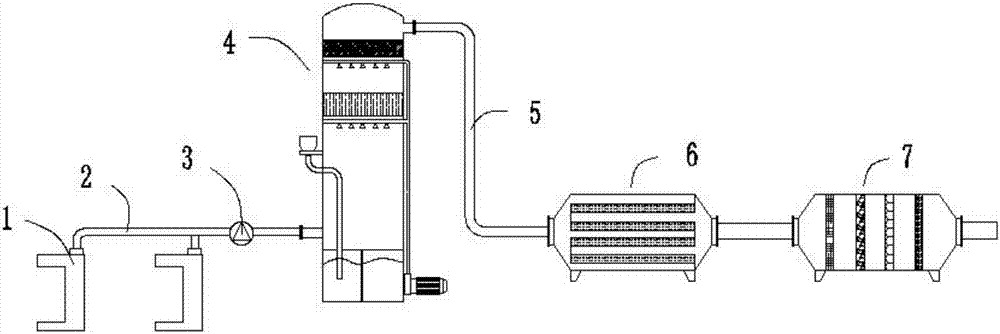

[0023] Such as Figures 1 to 4 As shown, the present embodiment provides a purification device for industrial waste gas, including a main exhaust gas pipeline 2, and an exhaust fan 3 is arranged on the main exhaust gas pipeline 2, and it is characterized in that one end of the main exhaust gas pipeline 2 is connected with a water tank located in a spraying workshop. The curtain cabinet 1, the other end of the waste gas main pipeline 2 is connected with a circulation absorption tower 4, and the circulation absorption tower 4 is connected with an activated carbon adsorber 6 and a strengthened absorber 7 in turn through a pipeline A5, and the strengthened absorber 7 includes a shell 7- 6. The two ends of the housing 7-6 are respectively provided with an air inlet 7-1 and an air outlet 7-7, and the housing 7-6 is detachably provided with a coarse filter cotton layer 7-2 and a HEPA filter layer 7- 3. The photocatalytic filter plate 7-4 and nano photocatalytic filter plate 7-5, the ...

Embodiment 2

[0027] This embodiment is further optimized on the basis of embodiment 1, specifically:

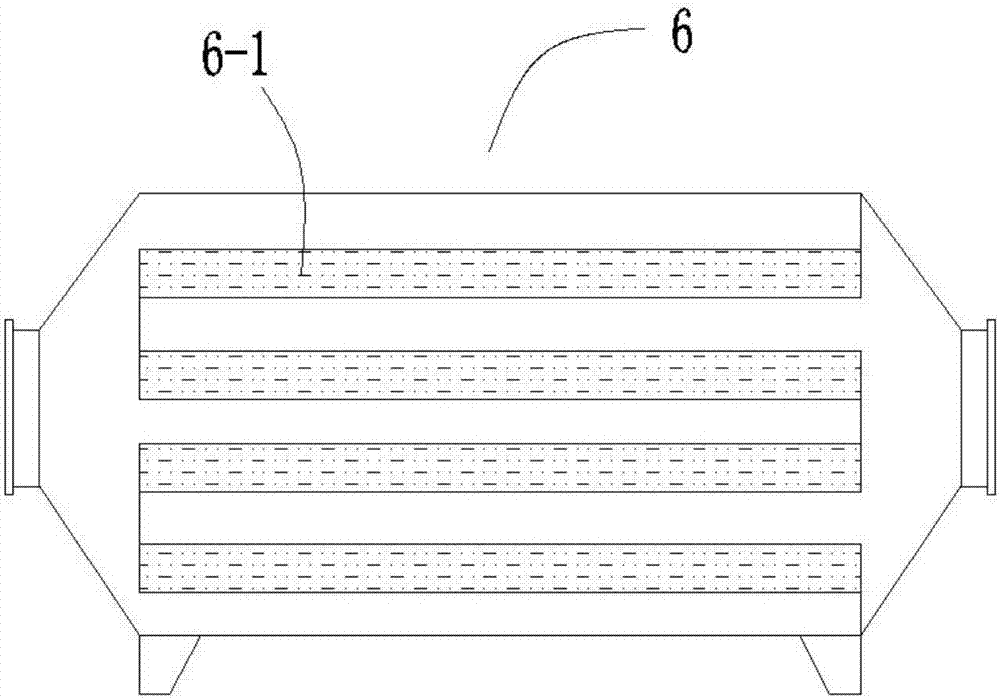

[0028] The activated carbon adsorber 6 is provided with a plurality of activated carbon adsorption layers 6-1, and the distance between two adjacent activated carbon adsorption layers 6-1 is equal.

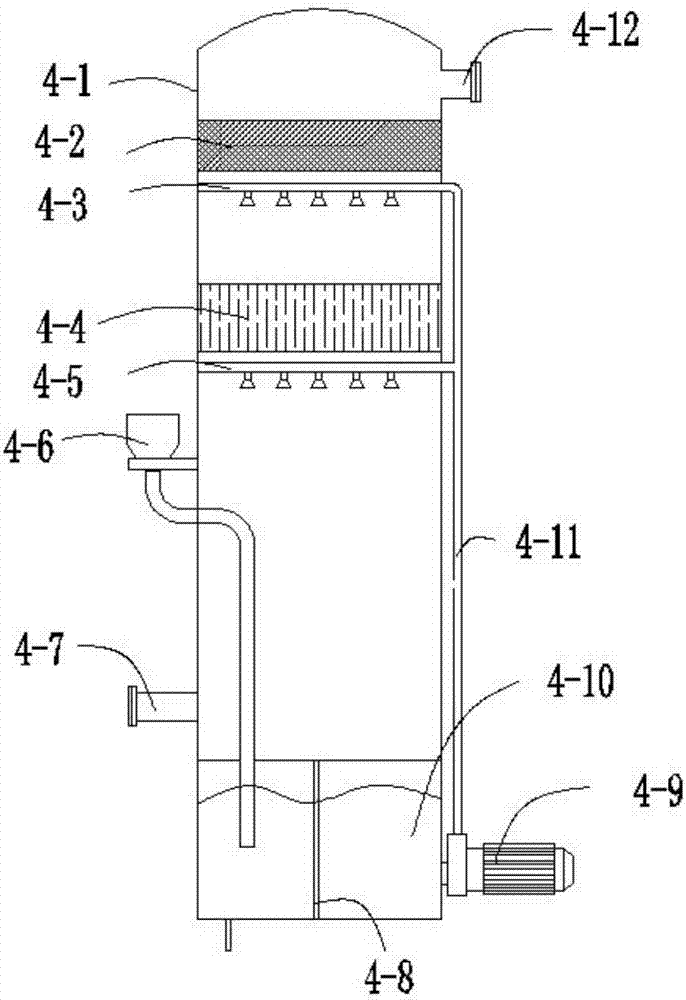

[0029] The circulation absorption tower 4 comprises a tower body 4-1, an air inlet pipe 4-7 and an outlet pipe 4-12 communicated with the inside of the tower body 4-1, and the tower body 4-1 is sequentially provided with dewatering pipes from top to bottom. The mist device 4-2, the packing layer 4-4, and the tower body 4-1 are also equipped with a circulating spraying system.

[0030] The circulating spray system includes a water tank 4-10 arranged at the inner bottom of the tower body 4-1 and a main spray pipe 4-11 arranged on the outer wall of the tower body 4-1, and the main spray pipe 4-11 passes through the water pump 4-9 Connected with the water tank 4-10, the circulating spray system ...

Embodiment 3

[0032] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0033] One side of the tower body 4-1 is provided with a water inlet 4-6 communicating with the water tank 4-10, a liquid level sensor 4-8 is provided in the water tank 4-10, and a sewage outlet is provided at the bottom of the water tank 4-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com