Zirconium based alloys having excellent creep resistance

A technology of zirconium-based alloys and zirconium alloys, applied in the field of zirconium-based alloy composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

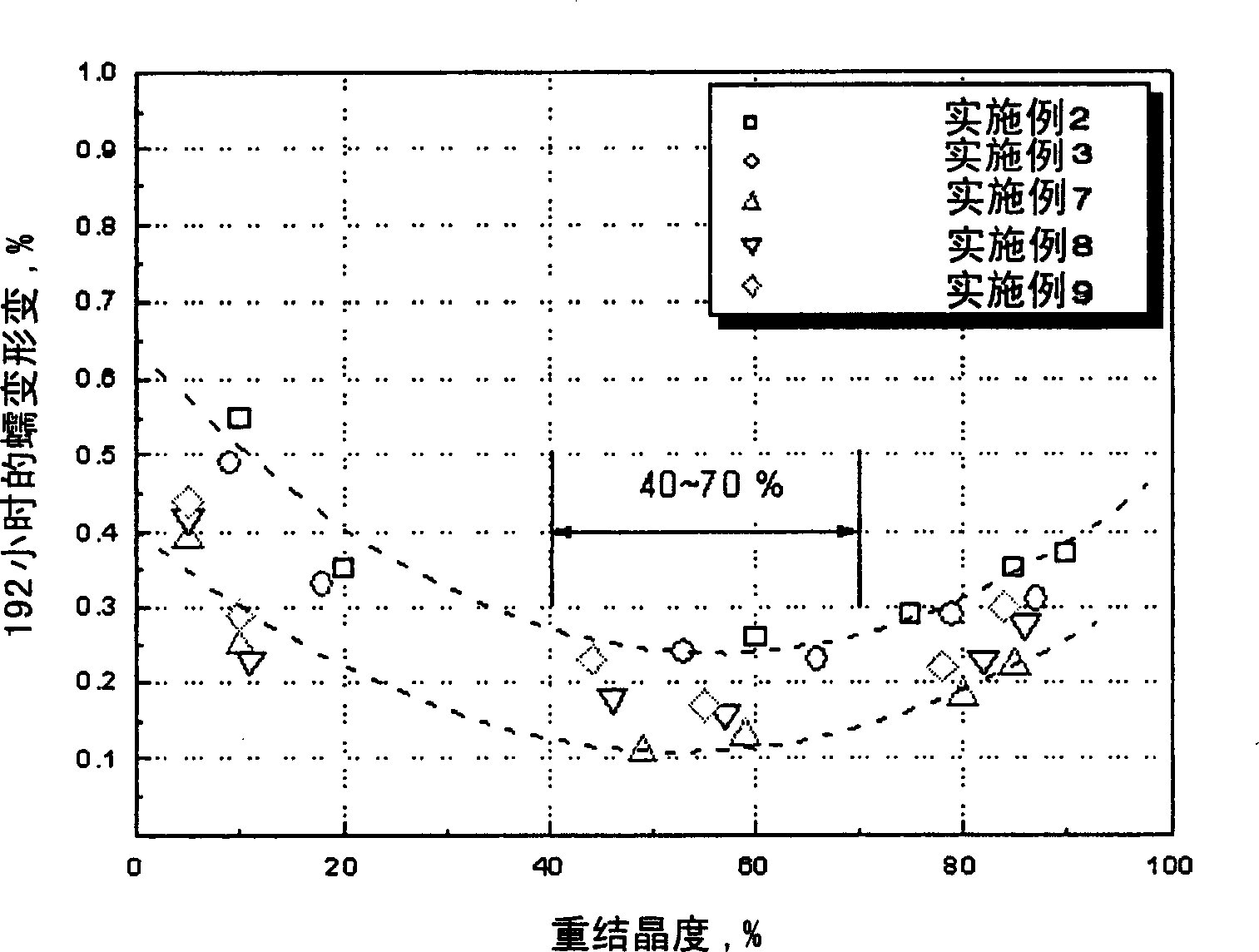

[0053] Embodiment 1~13: the preparation method of zirconium alloy

[0054] Examples of 4 alloys with a niobium content of 0.8% to 1.8%:

[0055] (1) Zr-0.8%Nb-0.07%Cu-0.14%O-0.008%C-0.008%Si-0.002%S;

[0056] (2) Zr-1.1%Nb-0.07%Cu-0.14%O-0.008%C-0.008%Si-0.002%S;

[0057] (3) Zr-1.5%Nb-0.07%Cu-0.14%O-0.008%C-0.008%Si-0.002%S; and

[0058] (4) Alloy of Zr-1.8%Nb-0.07%Cu-0.14%O-0.008%C-0.008%Si-0.002%SZr-1.5%Nb-0.4%Sn:

[0059] (5) Zr-1.5%Nb-0.4%Sn-0.14%O-0.008%C-0.008%Si-0.002%S

[0060] Four alloy examples prepared by adding one or more elements selected from Cu, Fe and Cr to the above alloy comprising Zr-1.5%Nb-0.4%Sn:

[0061] (6) Zr-1.5%Nb-0.4%Sn-0.1%Cu-0.14%O-0.008%C-0.008%Si-0.002%S;

[0062] (7) Zr-1.5%Nb-0.4%Sn-0.1%Fe-0.14%O-0.008%C-0.008%Si-0.002%S;

[0063] (8) Zr-1.5%Nb-0.4%Sn-0.1%Cu-0.1%Fe-0.14%O-0.008%C-0.008%Si-0.002%S;

[0064] and

[0065] (9) Zr-1.5%Nb-0.4%Sn-0.2%Fe-0.1%Cr-0.14%O-0.008%C-0.008%Si-0.002%S

[0066] Examples of 4 alloys with an S conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com