Method for improving ultra-fast cooling uniformity of medium and heavy plate after rolling

An ultra-fast cooling and uniform technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve problems such as water system stability impact and cooling system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Taking the pipeline steel with furnace number 0313400000 produced by a domestic steel factory as an example, its specific specification is 17.2mm×3403mm×39750mm, and the target process parameters of the cooling process are shown in Table 1.

[0044]

[0045] Table 1

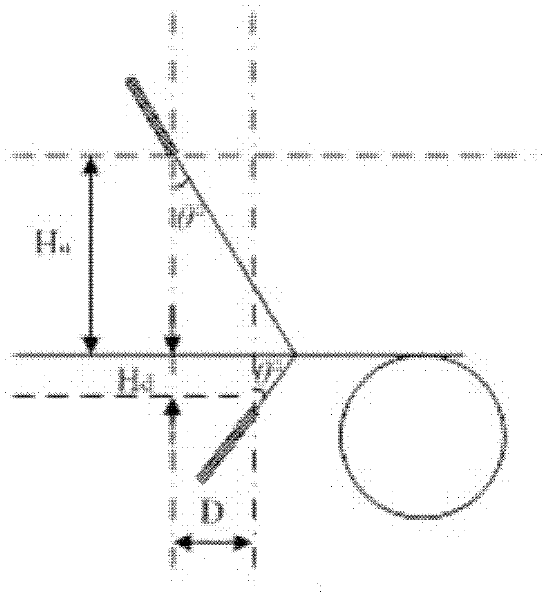

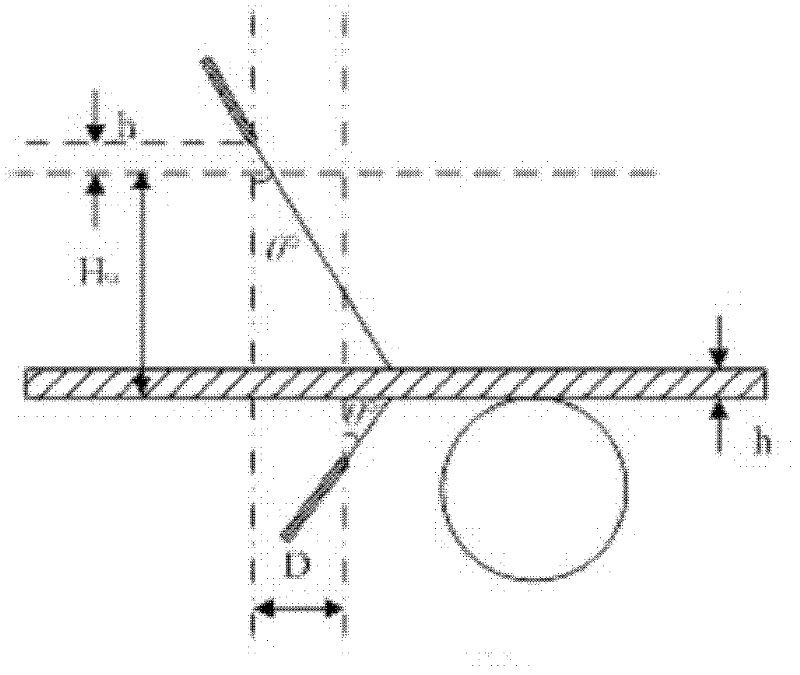

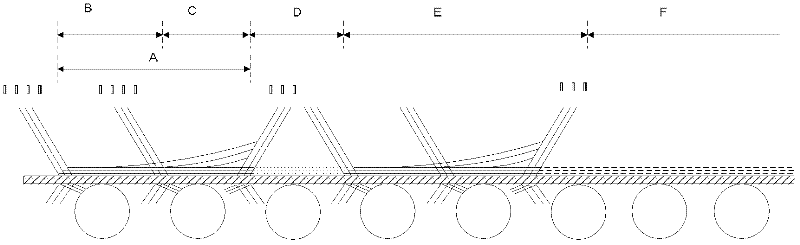

[0046] According to the cooling process requirements, the control model should set the height of the upper header frame as H 0 +h=348.5+17.5=366mm, and its corresponding cooling regulation setting is shown in Table 2. In order to achieve uniform longitudinal temperature of the steel plate, the set value of the running speed of the steel plate is as follows: Image 6 shown.

[0047]

[0048] Table 2

[0049] The above cooling procedure is executed by the basic automatic control system, and the actual flatness of the steel plate is far less than the target requirement of 8mm / m. Such as Figure 7 As shown, more than 95% of the temperature in the longitudinal direction is controlled within the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com