Zirconium-base alloy used for light-water reactor

A zirconium-based alloy and reactor technology, which is applied in the field of zirconium alloy materials, can solve problems such as the alloy’s anti-buncle corrosion behavior, and achieve improved uniform corrosion resistance, high creep and fatigue resistance, excellent resistance to uniformity and corrosion resistance. Effect of furuncle corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in more detail through specific embodiments.

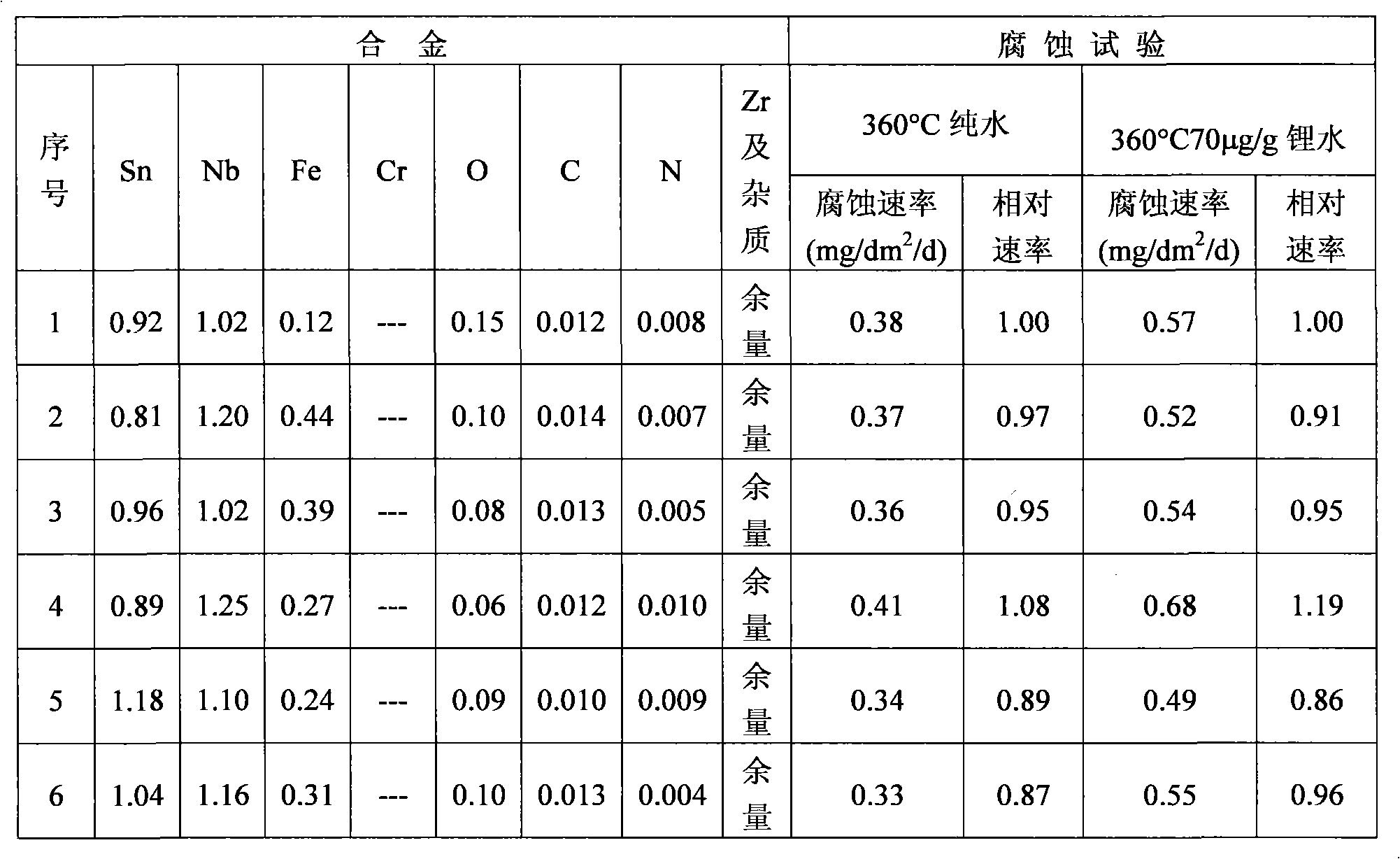

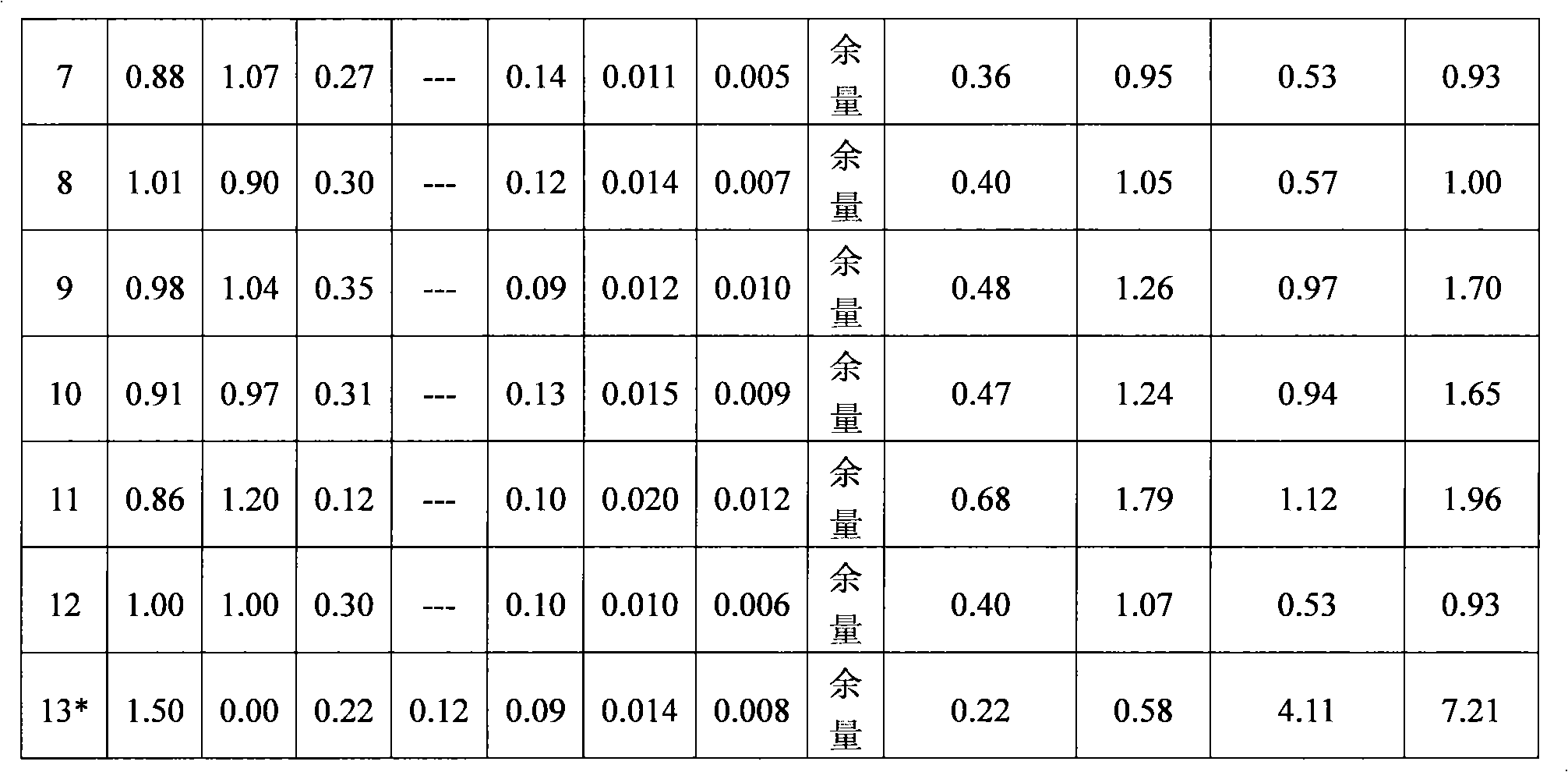

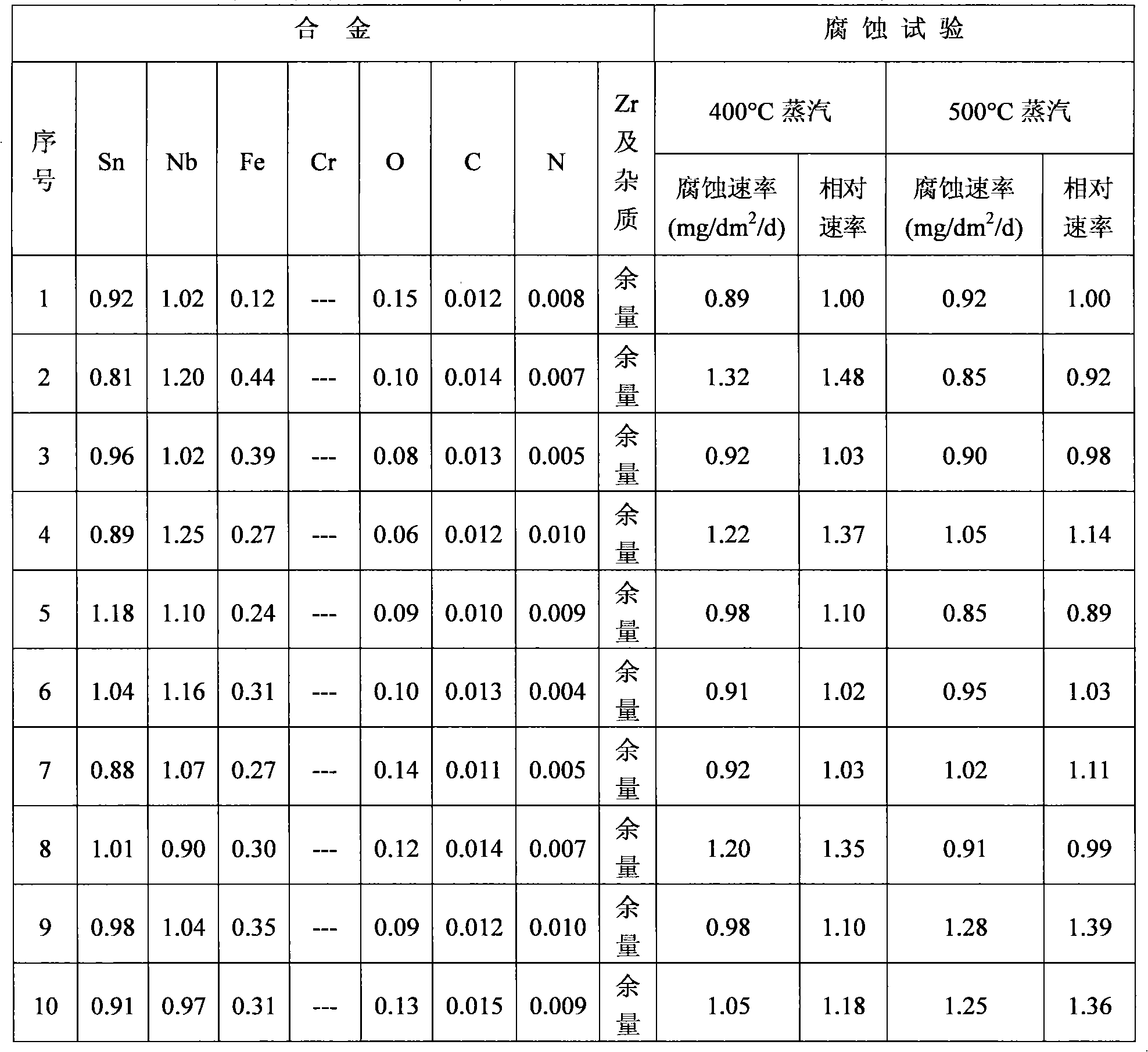

[0025]Table 1 is the composition of the alloy provided by the present invention, in Table 13 * The Zr-4 alloy composition and the corresponding test results, each content in Table 1 is the weight percentage of the corresponding component in the alloy.

[0026] Table 1 Alloy composition provided by the present invention

[0027] Alloy

Serial number

Sn

Nb

Fe

Cr

O

C

N

Zr and

Impurities

1

0.92

1.02

0.12

---

0.15

0.012

0.008

Margin

2

0.81

1.20

0.44

---

0.10

0.014

0.007

Margin

3

0.96

1.02

0.39

---

0.08

0.013

0.005

Margin

4

0.89

1.25

0.27

---

0.06

0.012

0.010

Margin

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com