Zirconium alloy compositions having excellent corrosion resistance by the control of various metal-oxide and precipitate and preparation method thereof

a technology of zinc alloy and control of various metal-oxides, applied in the field of zinc alloy compositions, can solve the problems of deterioration of mechanical properties, serious corrosion phenomenon of nuclear fuel, and deterioration of corrosion resistance of metal-oxides, and achieve excellent corrosion resistance and excellent corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

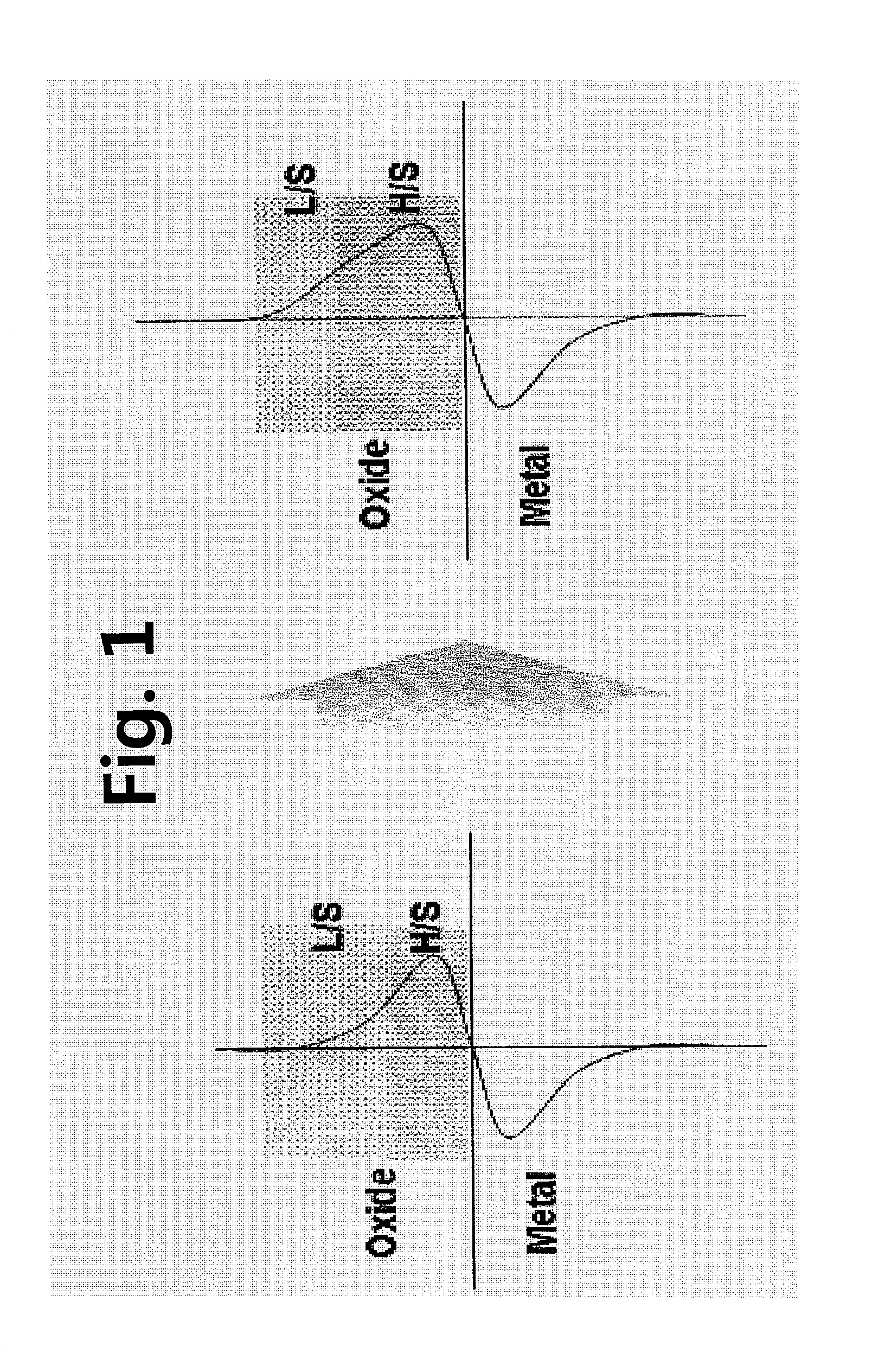

Image

Examples

example 1

Preparation of a Zirconium Alloy Composition

[0059](1) Ingot Formation

[0060]1.2 wt % of niobium, 0.2 wt % of iron and residual zirconium were formed into an ingot through a vacuum arc remelting (VAR) process. Reactor-grade sponge zirconium defined clearly in the ASTM B349 was used as the zirconium, and other alloy elements had a purity of 99.99%. In order to prevent the segregation of impurities and the nonuniform distribution of a zirconium alloy composition, the vacuum arc remelting process was repeatedly conducted four times. Subsequently, the zirconium alloy composition was formed into the ingot in a water-cooled copper crucible having a cooling water pressure of 1 kgf / cm2 and a diameter of 60 mm by applying an electric current of 500 Å thereto in a state in which the vacuum in a chamber was maintained at a pressure of 1×10−5 torr and then high-purity argon gas (99.99%) was charged in the chamber in order to prevent the oxidization of the zirconium alloy composition.

[0061](2) β-F...

examples 2 to 18

[0073]The zirconium alloy compositions having excellent corrosion resistance of Examples 2 to 18 were prepared using the same method as in Example 1, except that chemical compositions constituting the zirconium alloy compositions and stepwise heat treatment conditions were changed. The chemical compositions constituting the zirconium alloy compositions and stepwise heat treatment conditions are shown in Table 1.

experimental example 1

Manufacturability of a Zirconium Alloy Composition

[0075]The manufacturability of the zirconium alloy composition according to the present invention was evaluated by the zirconium alloy composition preparation processes of Examples 1 to 18 and Comparative Examples 1 to 6.

[0076]In Examples 1 to 18 and Comparative Examples 3 to 6, the zirconium alloy compositions were smoothly prepared without damage, but, in Comparative Examples 1 and 2, the zirconium alloy compositions were seriously damaged during their preparation processes. From this phenomenon, it can be seen that, when 0.85 wt % or more of Fe or 0.75 wt % or more of Cr is added to a zirconium alloy composition including 1.2 wt % of Nb, it is difficult to impart excellent manufacturability to the zirconium alloy composition, and thus it is not preferred that the amount of iron or chromium be excessively increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com