Germanium-containing Zr-Sn-Nb alloy for fuel cladding of nuclear power station

A technology for fuel cladding and nuclear power plants, applied in the field of zirconium-tin-niobium alloys, which can solve problems such as the inability to judge the corrosion resistance of new zirconium alloys, and achieve the effects of good processing performance, improved corrosion resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

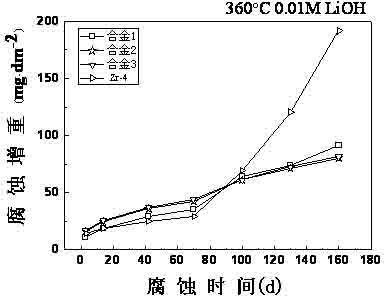

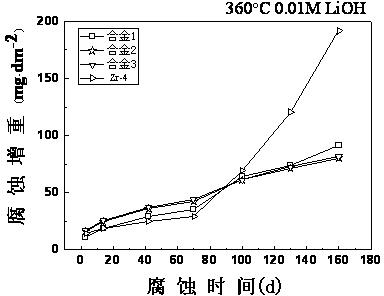

[0021] See Table 1, which shows the composition of three typical germanium-containing zirconium-tin-niobium alloy materials according to the present invention.

[0022] Table 1 Composition of germanium-zirconium-tin-niobium alloys 1 to 3 and comparative examples

[0023]

[0024] The alloy materials with the composition in Table 1 were prepared according to the following steps:

[0025] (1) According to the above formula and ingredients, use a vacuum non-consumable electric arc furnace to melt into an alloy ingot with a weight of about 65g, fill it with high-purity argon for protection during melting, and turn the alloy over and smelt it 6 times to make an alloy ingot with a uniform composition;

[0026] (2) The above-mentioned alloy ingot is hot-pressed at 700°C for several times, and processed into a billet, the purpose is to break the coarse as-cast grain structure;

[0027] (3) After the billet has been descaled and pickled, it is subjected to β-phase homogeni...

Embodiment 2

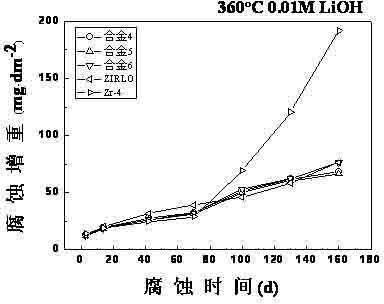

[0031]See Table 2, which shows the composition of three typical germanium-containing zirconium-tin-niobium alloy materials according to the present invention.

[0032] Table 2 Composition of germanium-zirconium-tin-niobium alloys 4 to 6 and comparative examples

[0033]

[0034] The alloy materials with the composition in Table 2 are prepared according to the following steps:

[0035] (1) According to the above formula and ingredients, use a vacuum non-consumable electric arc furnace to melt into an alloy ingot with a weight of about 65g, fill it with high-purity argon for protection during melting, and turn the alloy over and smelt it 6 times to make an alloy ingot with a uniform composition;

[0036] (2) The above-mentioned alloy ingot is hot-pressed at 700°C for several times, and processed into a billet, the purpose is to break the coarse as-cast grain structure;

[0037] (3) After the billet has been descaled and pickled, it is subjected to β-phase homogeniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com