Preparation method for light-heat dual-cured woodware UV varnish coating

A dual-curing, varnish coating technology, used in epoxy resin coatings, coatings, etc., can solve problems such as difficult curing, inability to cure, and conversion rate limitations, and achieve high adhesion, chemical corrosion resistance, and coating film hardness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

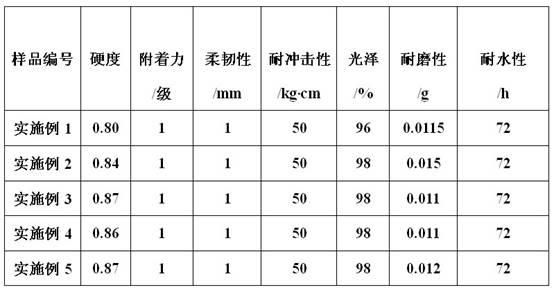

Examples

Embodiment 1

[0025] (1) Calculated in parts by weight, every 1g is 1 part, take 100g of industrial grade epoxy resin E51, add it to the reaction kettle, heat it in an oil bath, and raise the temperature to 110°C; then add 25g of industrial grade methacrylic acid, After mixing 1g of industrial grade N,N-dimethylbenzylamine and 0.05g of hydroquinone evenly, add it into epoxy resin E51 evenly within 4 hours, keep the temperature of epoxy resin E51 at 110°C during the dropping process , Measure the acid value immediately after the dropwise addition, and then measure the acid value every half an hour. After the acid value drops below 5mg / g, cool the reaction system to 30°C, and then add 32g of trimethylolpropane triacrylate (TMPTA ), after stirring evenly, the material is cooled and discharged to obtain epoxy acrylate;

[0026] (2) Add 3.5g of photoinitiator Darocure1173 provided by Shanghai Chuangxin Chemical Co., Ltd., 3.5g of photoinitiator 184 provided by Wuhan Dinghui Chemical Co., Ltd. an...

Embodiment 2

[0028] (1) Calculated in parts by weight, each 1g is 1 part, take 50g of industrial grade epoxy resin E44 and 50g of industrial grade epoxy resin E51, add them to the reaction kettle, heat them in an oil bath, and raise the temperature to 110°C; then After mixing 25g industrial grade methacrylic acid, 1g industrial grade tetrabutylammonium bromide and 0.1g hydroquinone evenly, they were evenly added to the epoxy resin within 3 hours, and the temperature of the epoxy resin was kept at 110°C, measure the acid value immediately after the dropwise addition, then measure the acid value every half an hour, wait until the acid value drops below 5mg / g, cool the reaction system to 30°C, and then add 32g of trimethylolpropane triacrylate (TMPTA), cooling discharge after stirring, obtain epoxy acrylate;

[0029] (2) Add 3.5g of Darocure1173 provided by Shanghai Chuangxin Chemical Co., Ltd., 3.5g of photoinitiator 184 provided by Wuhan Dinghui Chemical Co., Ltd. and 4.92g of thermal initi...

Embodiment 3

[0031](1) Calculated in parts by weight, each 1g is 1 part, take 25g of industrial grade epoxy resin E44 and 75g of industrial grade epoxy resin E51, add them to the reaction kettle, heat them in an oil bath, and raise the temperature to 90°C; then Mix 25g of industrial-grade acrylic acid, 1g of industrial-grade N,N-dimethylbenzylamine and 0.15g of hydroquinone evenly and add them to the epoxy resin within 2 hours. During the dropping process, keep the temperature of the epoxy resin at 90°C, measure the acid value immediately after the titration is completed, then measure the acid value every half an hour, until the acid value drops below 5mg / g, cool the reaction system to 30°C, then add 32g trimethylolpropane triacrylate ( TMPTA), after stirring evenly, cooling discharge, obtain epoxy acrylate;

[0032] (2) 3.5g of Darocure1173 provided by Shanghai Chuangxin Chemical Co., Ltd., 3.5g of photoinitiator 184 provided by Wuhan Dinghui Chemical Co., Ltd., 2.5g of azobisisobutyronit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com