Dual-cured coating composition and method for preparation thereof

A dual curing and composition technology, applied in the direction of coating, etc., can solve the problems of poor flexibility and scratch resistance of the paint film, and achieve the effect of good adhesion, good scratch resistance and smooth paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

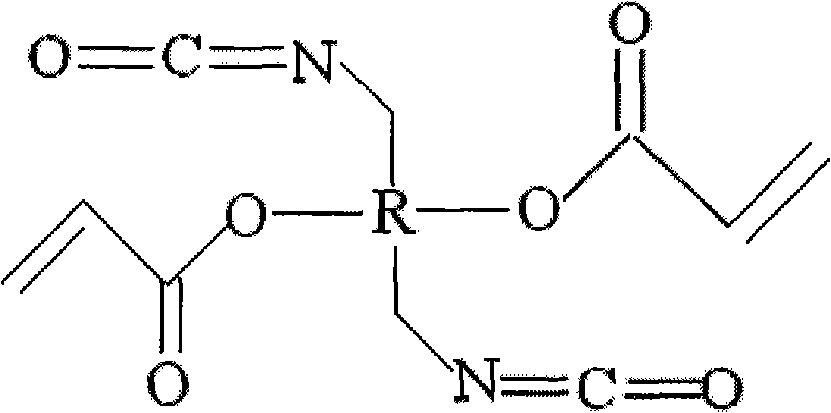

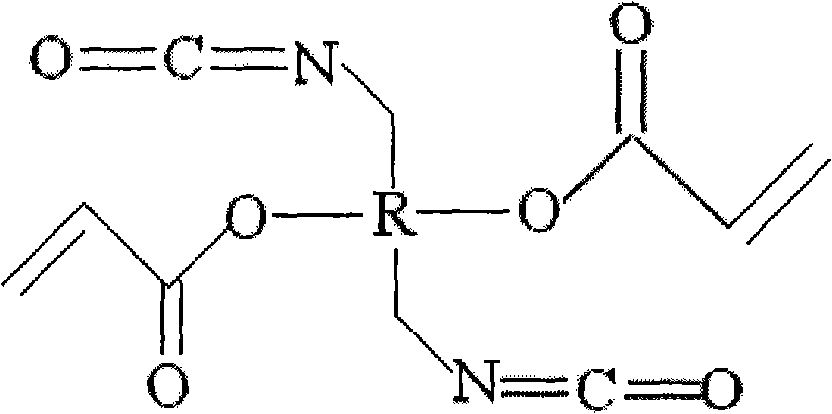

Image

Examples

preparation example Construction

[0022] According to the preparation method of the composition provided by the present invention, it can be prepared by directly mixing the components forming the composition of the present invention evenly.

[0023] The use method of the composition provided by the invention is simple. The above mixture is directly dissolved in a solvent to form a uniform solution and then coated on a release film to obtain the desired polyurethane film. Described solvent can be acetone, toluene, ethyl acetate, butyl acetate, isopropanol, n-butanol, cyclohexanone, xylene, methyl isobutyl ketone, ethylene glycol butyl ether, ethylene glycol ethyl ether acetate one or more of them. There is no particular limitation on the amount of the solvent, as long as it can effectively dissolve the components of the above composition, obtain a uniform solution and facilitate coating. For example, the amount of the solvent is generally 60-80 parts by weight relative to 100 parts by weight of the above compo...

Embodiment 1

[0028] This embodiment is used to illustrate the dual-cure coating composition provided by the present invention and its preparation method.

[0029] Get 60.0 grams of hydroxyl polyester resin (DSM company in the Netherlands, Uralac AN822) and 40 milliliters of butyl acetate and stir in the first mixing bucket to obtain a uniformly dispersed mixed solution, then 5.0 grams of ultraviolet photoinitiator Irgacure184, 20.0 Add the solution of 1 gram diluent (domestic HDDA), 0.8 gram leveling agent (Germany Cognis, F41), 1.0 gram wetting and dispersing agent (Dispers 710) and 10 milliliters of butyl acetate in the above-mentioned first stirring barrel, and rotate at 1200 rpm Minute speed stirring for 90 minutes, to obtain the uniformly dispersed first slurry. The slurry does not delaminate or agglomerate within 72 hours at room temperature.

[0030] 20 grams of isocyanate acrylate (Germany BASF company, Laromer LR9000), 0.2 gram of leveling agent (Germany Cognis, F41) and 10 milli...

Embodiment 2

[0033] This embodiment is used to illustrate the dual-cure coating composition provided by the present invention and its preparation method.

[0034] Get 60.0 grams of hydroxyl polyester resin (Netherlands DSM company, Uralac AN822), 5.0 grams of UV photoinitiator Irgacure184, 20.0 grams of diluent (domestic HDDA), 1.0 grams of leveling agent (Germany Cognis, F41), 1.0 grams of wetting and dispersing Agent (Dispers 710), 20 grams of isocyanate acrylate (German BASF company, Laromer LR9000) and 0.2 grams of leveling agent (German Cognis, F41) were mixed evenly to obtain the dual curing coating composition S2 provided by the present invention.

[0035] Mix the above composition with 30 ml of toluene, 10 ml of ethyl acetate, 15 ml of butyl acetate, 10 ml of n-butanol and 5 ml of cyclohexanone to obtain the slurry of dual curing coating composition S2 provided by the present invention. The slurry was fully caked and cured within 12 hours at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com