Low-volatilization photocoagulation dipping insulating paint

A technology of impregnating insulation and insulating varnish, applied in the field of insulating varnish, which can solve the problems of prolonging the curing time of impregnating varnish, difficult motor technology, and reducing work efficiency, and achieve the effects of shortening curing time, fast curing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

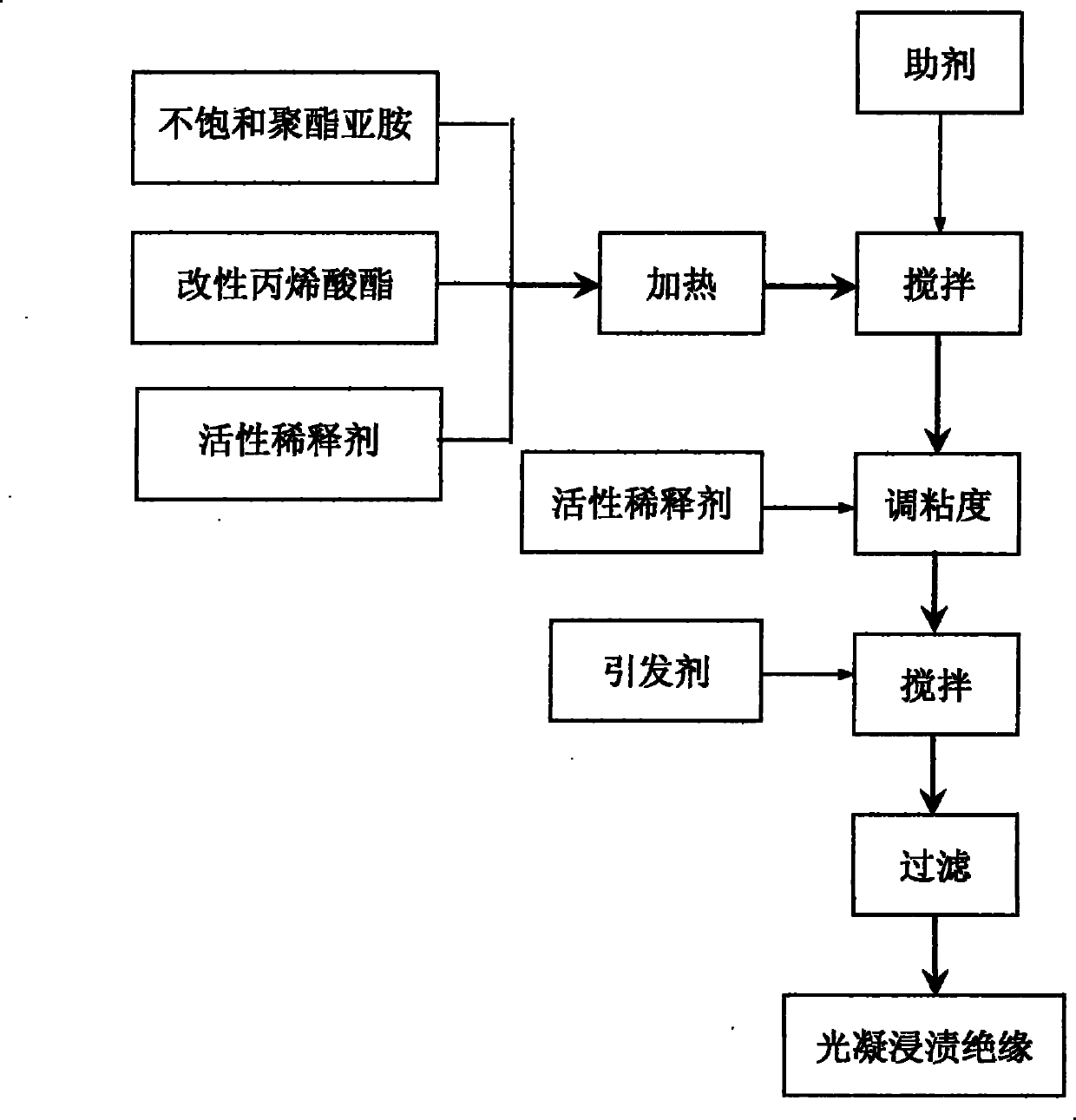

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (by weight percentage):

[0032] Imine modified unsaturated polyester resin: 60%

[0033] Urethane acrylate prepolymer: 10%

[0034] Diphenylene diperoxide: 2%

[0035] 1-Hydroxycyclohexyl phenyl ketone: 2%

[0036] 1,6-Hexanediol diacrylate: 25.5%

[0037] o-Toluene Hydroquinone 0.05%

[0038] TEGO Wet 505 0.15%

[0039] BYK 307 0.1%

[0040] TEGO Rad 2500 0.2%

Embodiment 2

[0041] Embodiment 2 (by weight percentage):

[0042] Unsaturated polyester resin: 46%

[0043] Epoxy acrylate prepolymer: 14%

[0044] tert-butyl perbenzoate: 1%

[0045] 1-Hydroxycyclohexyl phenyl ketone: 1%

[0046] BP: 0.5%

[0047] Neopentyl glycol dimethacrylate: 22%

[0048] Pentaerythritol tetraacrylate: 15%

[0049] o-Toluene Hydroquinone: 0.05%

[0050]TEGO Wet 505: 0.25%

[0051] Levaslip 435: 0.1%

[0052] TEGO Rad 2500: 0.1%

Embodiment 3

[0053] Embodiment 3 (by weight percentage):

[0054] Unsaturated polyester resin: 30%

[0055] Polyimide acrylate prepolymer: 20%

[0056] Polyester acrylate prepolymer: 10%

[0057] Di-tert-butyl perphthalate: 1%

[0058] Benzoin Dimethyl Ether: 3%

[0059] Propoxylated Trimethylolpropane Triacrylate: 35.2%

[0060] Tert-Butylcatechol: 0.05%

[0061] TEGO Wet 505: 0.3%

[0062] TEGO Flow ZFS 460: 0.15%

[0063] TEGO Rad 2500: 0.3%

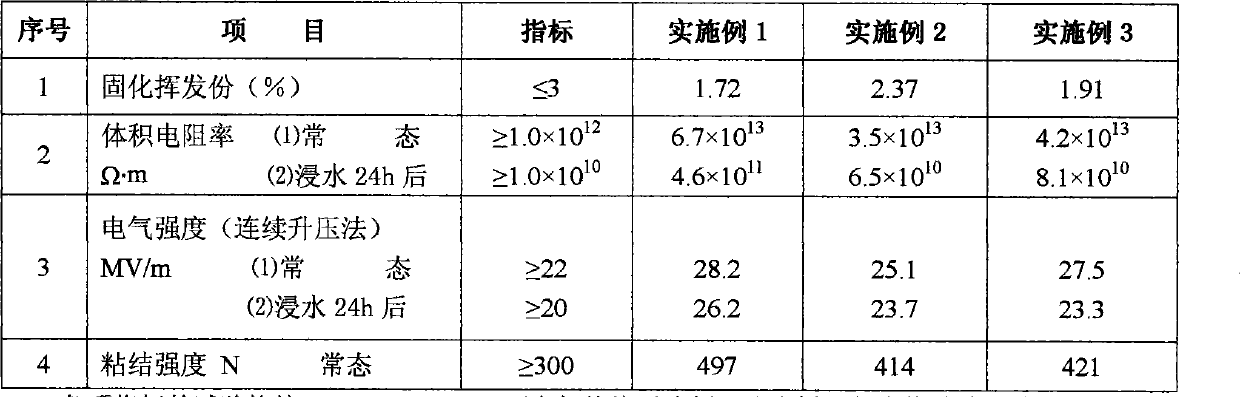

[0064] Example effect

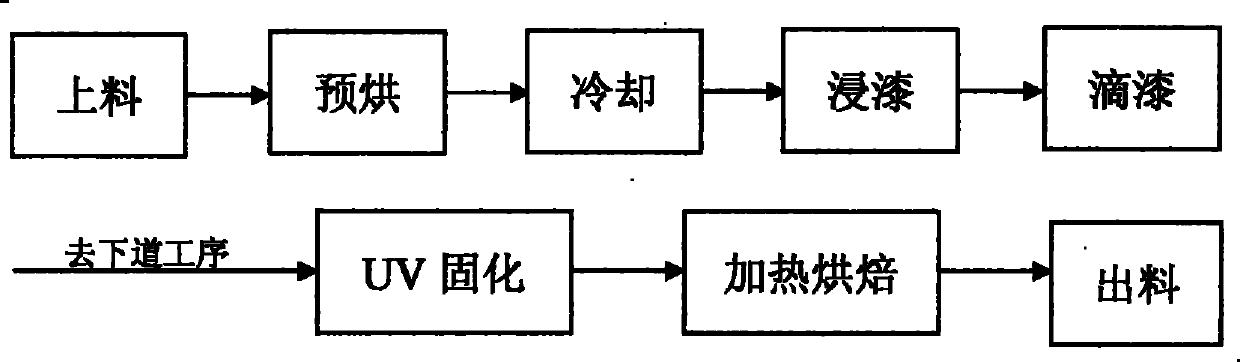

[0065] The above-mentioned photocoagulation insulating varnish is firstly cured by ultraviolet light for 5 minutes, and then heated and cured at 150°C / 5h. The various properties are shown in Table 1:

[0066] Table 1. Properties of low-volatile photocondensation impregnating varnishes

[0067]

[0068] The tests of various indicators are carried out according to the provisions of GB / T 15023-1994 "Test Methods for Electrical Insulation Solvent-free Polymerizable Resin Compounds".

[0069] Cured volatile matter:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com