Dual-curing adhesive composition and application thereof and method for bonding substrates

A technology of composition and adhesive, which is applied in the field of bonding substrates and dual-curing adhesive compositions, can solve the problems of adhesive 5 that cannot be cured, aging deformation hardness, substrate cracking, etc., and can improve the light curing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

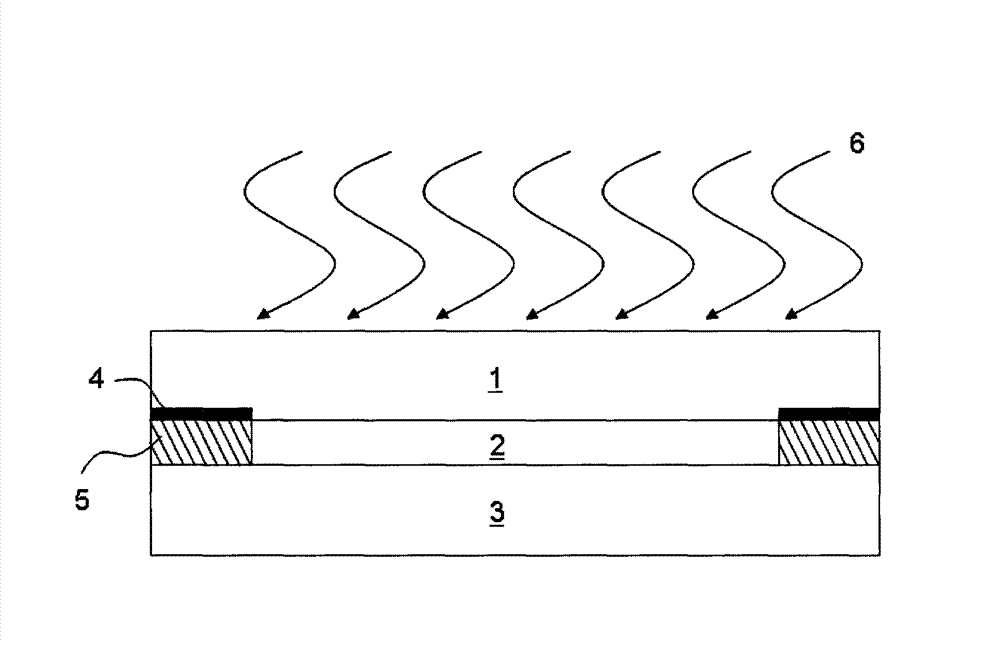

Image

Examples

preparation example Construction

[0143] [Preparation of dual-cure adhesive composition]

[0144] Epoxy resin, (meth)acrylate monomer and / or oligomer having (meth)acryloyloxy group, thermal polymerization catalyst, photopolymerization initiator and optionally other components used in the present invention Mixing can be done by any suitable method, in any suitable order. Mixing can be performed continuously or batchwise. Stirring may be performed during mixing as required. In different stages of mixing, the stirring speed can be set to be the same or different, for example, the preceding stirring speed can be set to about 50-80 rpm, and the subsequent stirring speed can be set to about 80-120 rpm.

[0145] Mixing and subsequent storage should be performed under reduced lighting conditions, preferably dark conditions, at the time of and after addition of the photopolymerization initiator. It is advantageous to complete the mixing with other components before mixing the photopolymerizable component with the ph...

Embodiment 1

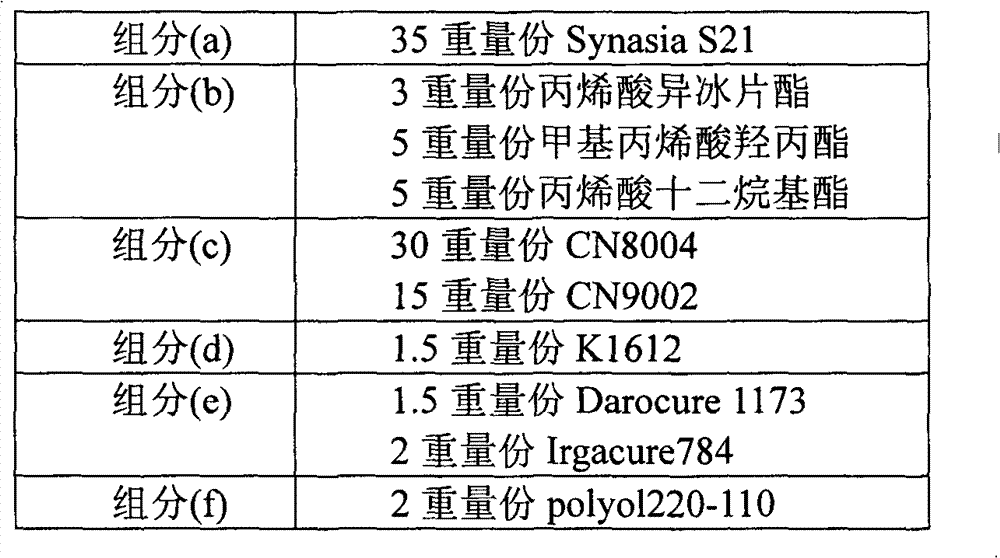

[0182] First, at room temperature, weigh 35 parts by weight of Synasia S21, 3 parts by weight of isobornyl acrylate, 5 parts by weight of hydroxypropyl methacrylate, 5 parts by weight of dodecyl acrylate, 30 parts by weight of CN8004, 15 The parts by weight of CN9002 and 2 parts by weight of polyol220-110 are put into a stirring tank for stirring, the speed is set at about 60 rpm, and the stirring time is about 60 min. Subsequently, weigh 1.5 parts by weight of K1612, 1.5 parts by weight of Darocure 1173 and 2 parts by weight of Irgacure784, put them into the mixer, set the speed at about 100 rpm, and continue stirring for about 60 minutes. After mixing evenly, the obtained mixture can be filtered. During the entire feeding and stirring process, keep away from light and keep constant temperature.

[0183] The specific formulation of the dual curing adhesive composition of embodiment 1 is shown in the following table:

[0184]

Embodiment 2

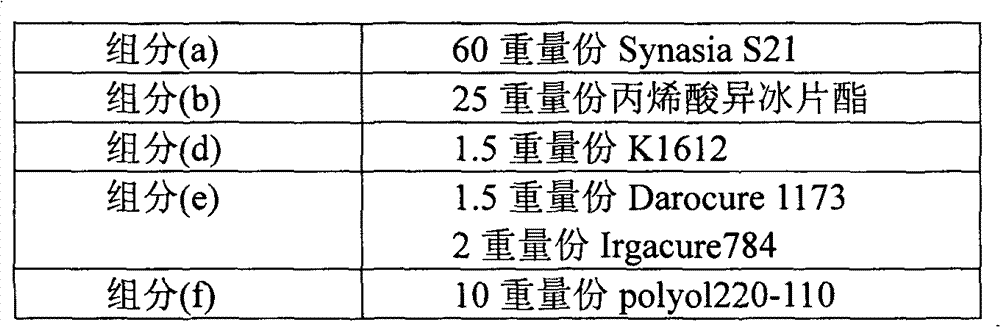

[0186] The dual-cure adhesive composition of Example 2 was prepared in the same manner as in Example 1, except that the formulation of the dual-cure adhesive composition was changed as shown in the table below.

[0187] The specific formulation of the dual curing adhesive composition of embodiment 2 is shown in the table below:

[0188]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com