Polyacrylic resin with side-chain modification of hybrid epoxy acrylate and synthesis method

A technology of epoxy acrylate and polyacrylic resin, which is applied in the field of photocuring hybrid epoxy acrylate side chain modified polyacrylic resin and its synthesis, can solve the problem of obtaining high hardness and mechanical strength resin, gel, Problems such as limiting the amount of modified epoxy resin added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

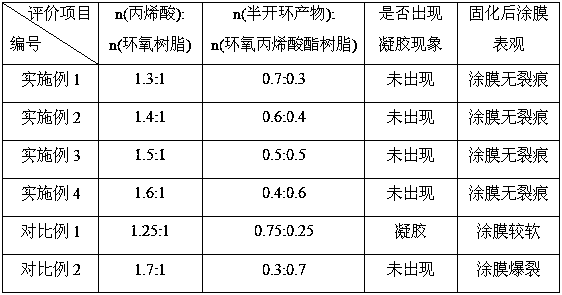

[0101] Hybrid epoxy acrylate side chain modified polyacrylic resin Examples 1-4 Raw material components and ratios are shown in Table 3:

[0102] Table 3 Raw material components and ratios of hybrid epoxy acrylate side chain modified polyacrylic resin Examples 1-4

[0103]

[0104] Note: "-" in the table means not added.

Embodiment 1

[0106] According to the parts by weight of the raw materials described in Table 3 Hybrid Epoxy Acrylate Side Chain Modified Polyacrylic Resin Example 1, carboxylated polyacrylate 1 and hybrid epoxy acrylate 1 were mixed, and added during heating Basic catalyst and polymerization inhibitor, at 100°C, keep warm for 4 hours until the acid value is 4mgKOH / g, then cool to obtain hybrid epoxy acrylate side chain modified polyacrylic resin 1.

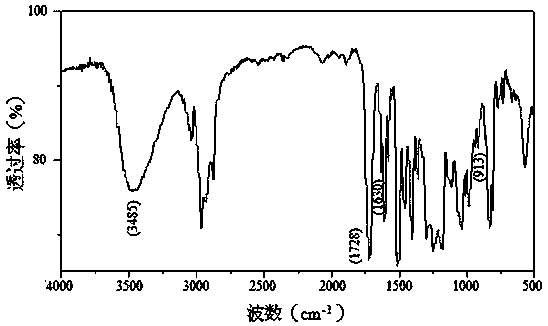

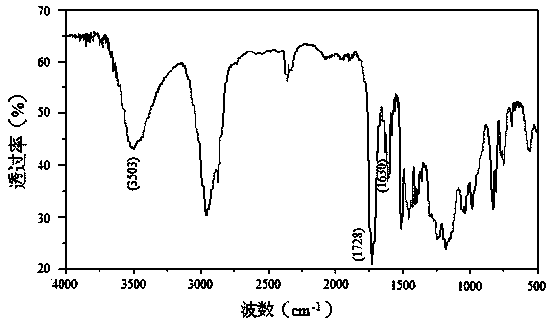

[0107] Such as figure 2 As shown, in the infrared spectrogram of the hybrid type epoxy acrylate side chain modified polyacrylic resin of the embodiment of the present invention, at 1728cm -1 There is also a strong conjugated carbon-oxygen double bond stretching vibration peak at 1630cm -1 The carbon-carbon double bond stretching vibration peak appears at 913cm -1 The characteristic absorption peak of the epoxy group at the place basically disappears, which shows that the side chain of the carboxylated polyacrylate has been successfully graf...

Embodiment 2

[0109] According to the parts by weight of the raw materials described in Table 3 Hybrid Epoxy Acrylate Side Chain Modified Polyacrylic Resin Example 2, carboxylated polyacrylate 2 and hybrid epoxy acrylate 2 were mixed, and added during heating Basic catalyst and polymerization inhibitor, heat preservation reaction at 95°C for 5 hours until the acid value is 5 mgKOH / g, and cooling to obtain hybrid epoxy acrylate side chain modified polyacrylic resin 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com