Double-curing varnish paint

A dual-curing varnish and coating technology, applied in coatings and other directions, can solve the problems of insufficient weather resistance of UV-cured coatings, application limitations of UV-cured coatings, and contradiction between coating hardness and toughness, and achieve gloss and color retention properties. Good, improved weather resistance, good fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

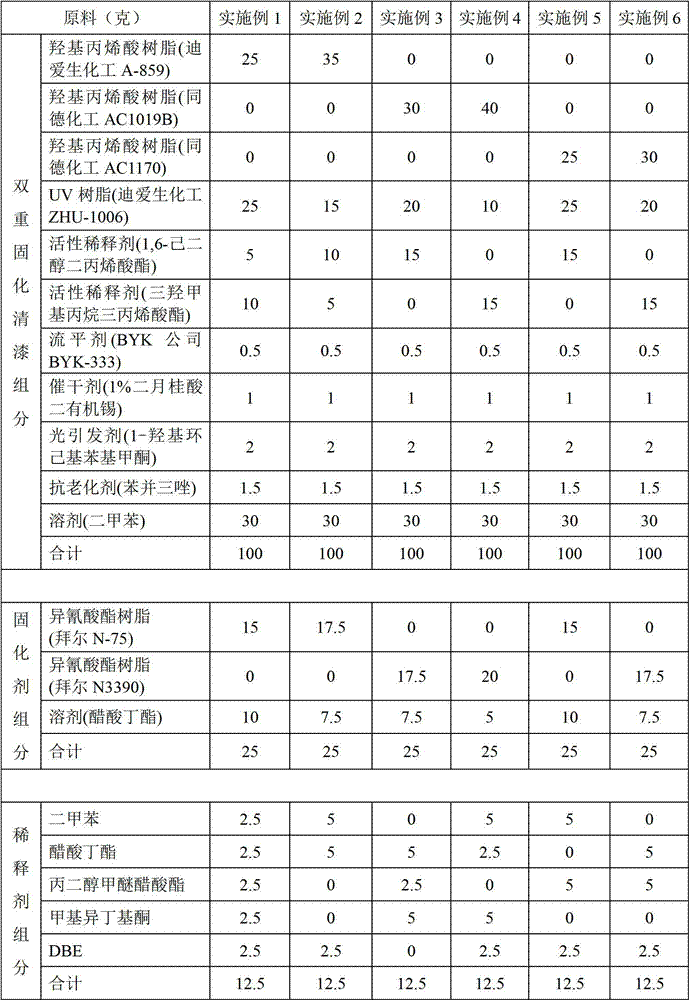

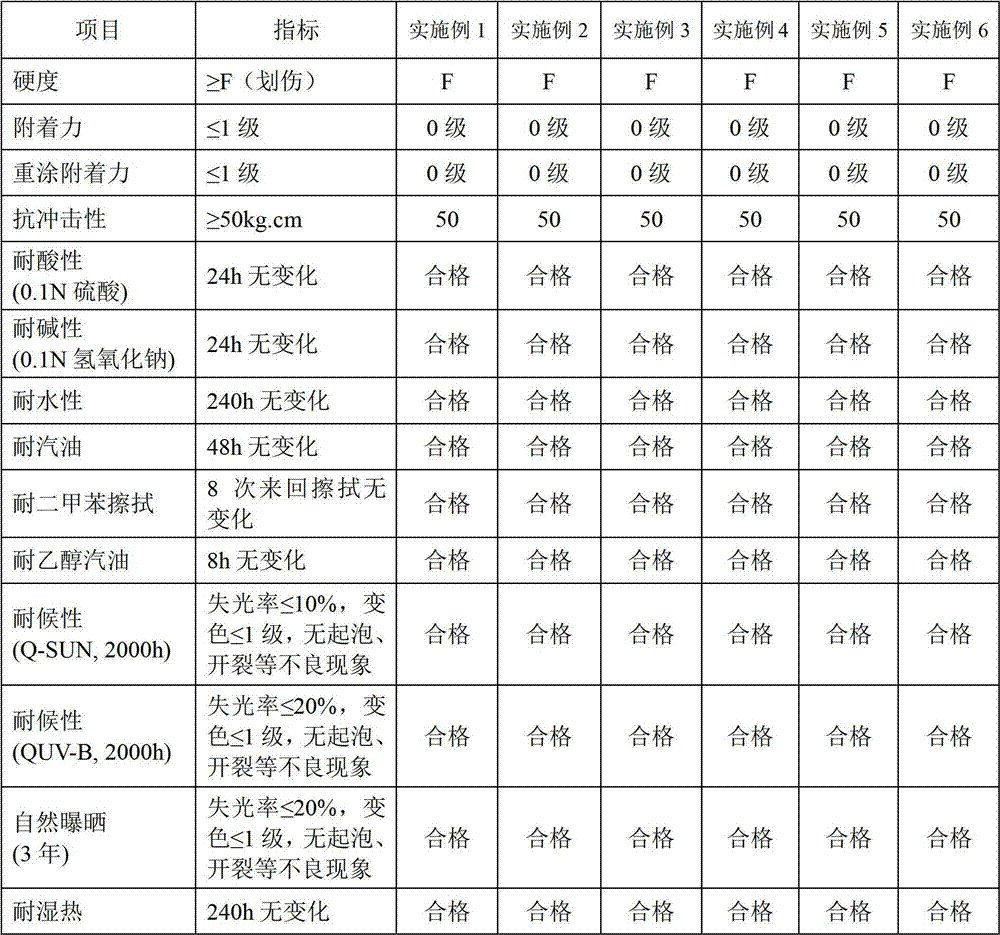

[0030] The technical solutions and effects of the present invention will be further described below through examples, but the present invention is not limited to the following examples.

[0031] According to the formula listed in Table 1, prepare the dual curing varnish coating of the present invention.

[0032] Table I

[0033]

[0034] According to the formula listed in Table 1, the described dual-curing varnish, curing agent and diluent are prepared respectively, and the specific preparation process is as follows: first, the dual-curing varnish components are mixed and stirred evenly, and filtered with a filter cloth of 5 to 10 microns; Mix and stir the curing agent components evenly, and filter with a filter cloth of 5-10 microns; mix and stir the diluent components evenly, and filter with a filter cloth of 5-10 microns. Then, mix and stir the dual-curing varnish, curing agent and thinner according to the mass ratio of 4:1:0.5, and use an air spray gun under the condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com