Application of quaternary ammonium salt with hydroxyethyl group in polyvinyl alcohol processing

A technology of polyvinyl alcohol and hydroxyethyl, which is applied in the chemical industry and can solve the problems of easy shrinkage of hydroxyl, easy yellowing, and easy yellowing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

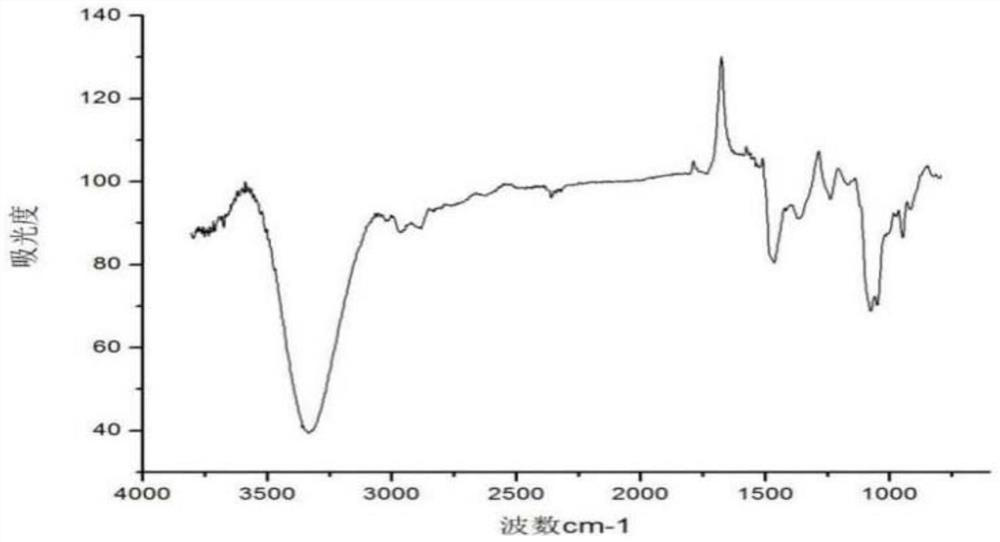

[0048]The present invention also provides a terephthalate quaternary ammonium salt used as a nucleating agent for polyester PET or a polymer electrolyte material and a preparation method thereof in one embodiment. This preparation method comprises the steps:

[0049] Condensation reaction of any one of the above quaternary ammonium salts with hydroxyethyl group and phthaloyl chloride to obtain quaternary ammonium terephthalate.

[0050] The preparation method of the above-mentioned terephthalate quaternary ammonium salt is simple, and the prepared terephthalate quaternary ammonium salt has certain ion conductivity, which can be used for the solid electrolyte component of the battery and can also be used for PET nucleating agent.

[0051] Preferably, the amount of the quaternary ammonium salt with hydroxyethyl group and phthaloyl chloride is 1:(1.1˜1.2).

[0052] In one embodiment, when the number of hydroxyethyl groups in the quaternary ammonium salt with hydroxyethyl groups...

Embodiment 1

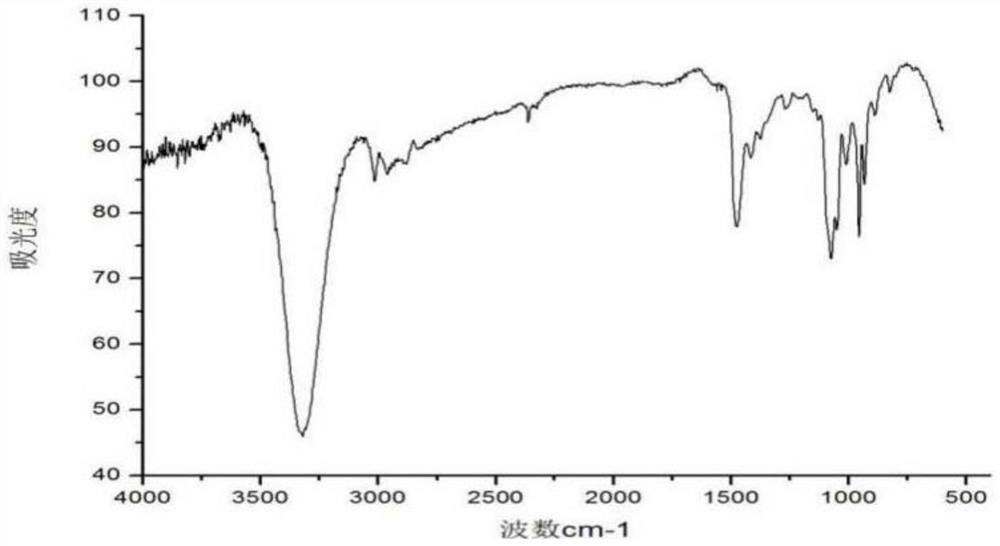

[0081] Example 1N, N-dimethylethanolamine (DMEA) and 2-bromoethanol synthesize two (hydroxyethyl) dimethyl quaternary ammonium bromide

[0082]

[0083] Add DMEA and 2-bromoethanol according to the ratio of the amount of substances at 1:1.2, dehydrate toluene (boiling point 110.6°C) as solvent, and use diethyl ether as precipitant.

[0084] When the reaction condition was 86°C for 5 hours, the product was a white powder with a yield of 62.2%.

[0085] When the reaction condition was 88°C for 2.5h, the product was a white powder with a yield of 96.26%.

[0086] When the reaction condition was 88°C for 9 hours, the product was a white powder with a yield of 40.6%.

[0087] Based on the above experiments, the more suitable reaction temperature for the synthesis of quaternary ammonium salts from N,N-dimethylethanolamine and 2-bromoethanol is 88°C, and the reaction time is about 2.5h.

Embodiment 2 3

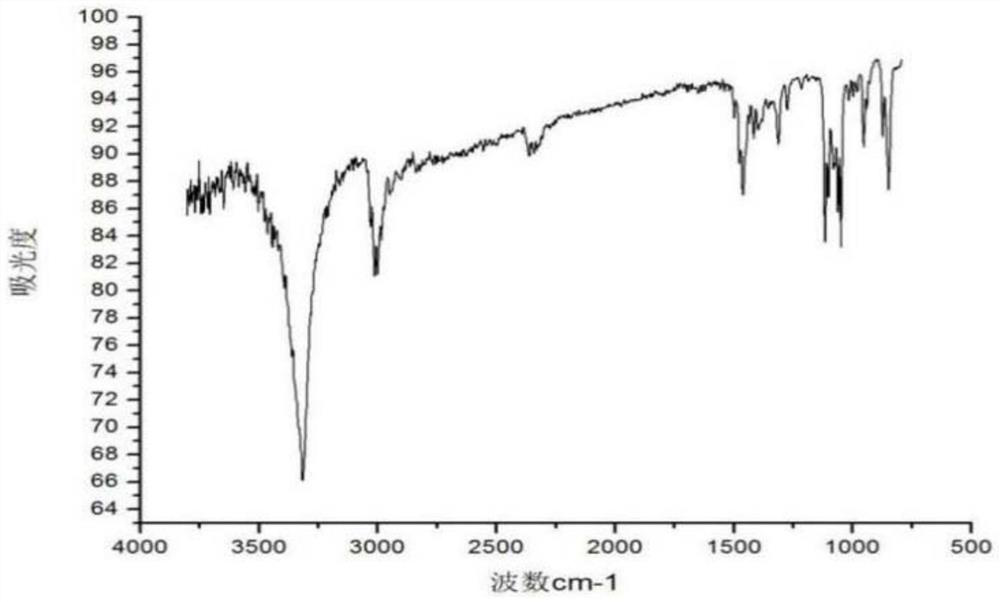

[0088] Example 2 Triethylenediamine (TEDA) and 2-bromoethanol synthesize brominated N, N'-diethanoltriethylenediamine quaternary ammonium salt

[0089]

[0090] In a 100mL three-necked flask, put 50nL of dry toluene, then add 0.1 mole of triethylenediamine and 0.21 mole of 2-bromoethanol, heat up to 95°C under stirring, react for 12h, cool to room temperature, add ether, and obtain a white precipitate. The crude product was isolated. The crude product was dissolved in ethanol and then precipitated with ether to isolate the product with a yield of 36.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com