Fluorine-containing silicone oil and preparation method thereof

A technology of fluorine-containing silicone oil and amino silicone oil, which is applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of high cost and high production cost, and achieve the effects of overcoming yellowing, increasing added value, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

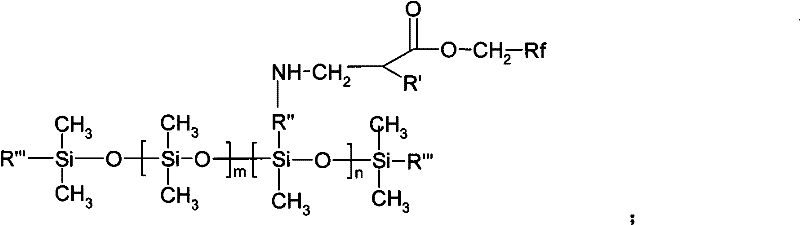

[0029] Synthesis of fluorine-containing silicone oil: Add 81.8g of hexafluorobutyl methacrylate, 100g of aminopropyl silicone oil and 80g of tetrahydrofuran into a 2L three-necked flask equipped with mechanical stirring and nitrogen protection device, pass through nitrogen protection, stir and heat up to 50°C for reaction 4 hours, its reaction formula is:

[0030]

[0031] Among them, m is 15, n is 8;

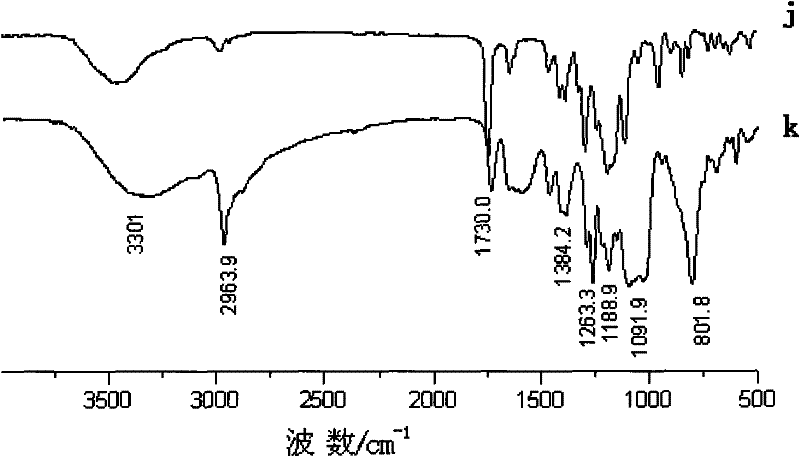

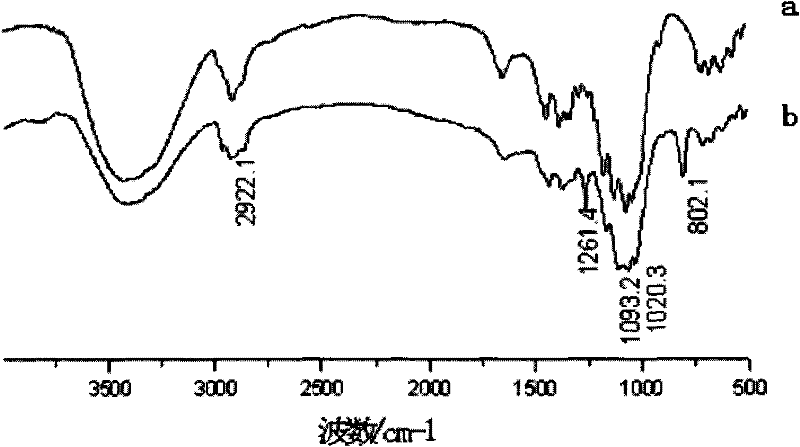

[0032] After the reaction was completed, the solvent was distilled off to obtain hexafluorobutyric acid isopropylamino-modified amino silicone oil with a yield of 91%. The fluorine content of the product was 25%. FT-IR (v, cm -1 ): 3301.1cm -1 (-NH 2 ), 2963.9 (-CH 3 ), 1730.0 (C=0), 1384.2, 1188.9 (C-F), 1063.3, 1091.9 (Si-C-Si), 1260.0, 801.8 (Si-CH 3 ).

[0033] See attached figure 1, it is the infrared spectrogram of the hexafluorobutoxyamidoisopropylamine-modified amino silicone oil prepared according to the technical scheme of this embodiment, and is compared w...

Embodiment 2

[0038] Synthesis steps: Add 8.26g of dodecafluoroheptyl methacrylate, 50g of aminoethyl silicone oil and 80g of tetrahydrofuran into a 2L three-necked flask equipped with mechanical stirring and nitrogen protection device, pass through nitrogen protection, stir and heat up to 40°C for 5 hours , whose reaction is:

[0039]

[0040] Among them, m is 12, n is 6;

[0041] After the reaction, the solvent was distilled off to obtain dodecafluoroheptyloxyisopropylamino-modified amino silicone oil with a yield of 85%. The fluorine content of the product was 12%. FT-IR (v, cm -1 ): 3309cm -1 (-NH 2 ), 2975.1 (-CH 3 ), 1738.0 (C=0), 1386.6, 1191.3 (C-F), 1065.2, 1093.2 (Si-C-Si), 1265.2, 802.8 (Si-CH 3 ).

[0042] Preparation of finishing working solution: In a 500mL tall beaker, add 200g of water, 2g of polyethylene glycol, 6g of sodium lauryl sulfate and 4g of Tween80, and stir to dissolve. Under high-speed stirring, 40 g of the above-prepared dodecafluoroheptyloxyisopropyl...

Embodiment 3

[0047] Synthesis steps: Add 10.32g of dodecafluoroheptyl acrylate, 50g of aminopropyl silicone oil and 80g of toluene into a 2L three-necked flask equipped with mechanical stirring and nitrogen protection device, pass through nitrogen protection, stir and heat up to 60°C for 4 hours, and the reaction The formula is:

[0048]

[0049] Among them, m is 8, n is 9;

[0050] After the reaction was completed, the solvent was distilled off to obtain dodecafluoroheptyloxyacylamide-modified amino silicone oil with a yield of 88%. The fluorine content of the product was 15%. FT-IR (v, cm -1 ): 3311.1cm -1 (-NH 2 ), 2975.4 (-CH 3 ), 1738.5 (C=0), 1388.1, 1194.2 (C-F), 1065.5, 1093.8 (Si-C-Si), 1265.5, 805.8 (Si-CH 3 ).

[0051] Preparation of finishing working solution: In a 500mL tall beaker, add 200g of water, 2g of polyethylene glycol, 8g of sodium lauryl sulfate and 8g of Tween80, and stir to dissolve. Under high-speed stirring, 40 g of the above-prepared dodecafluorohepty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com