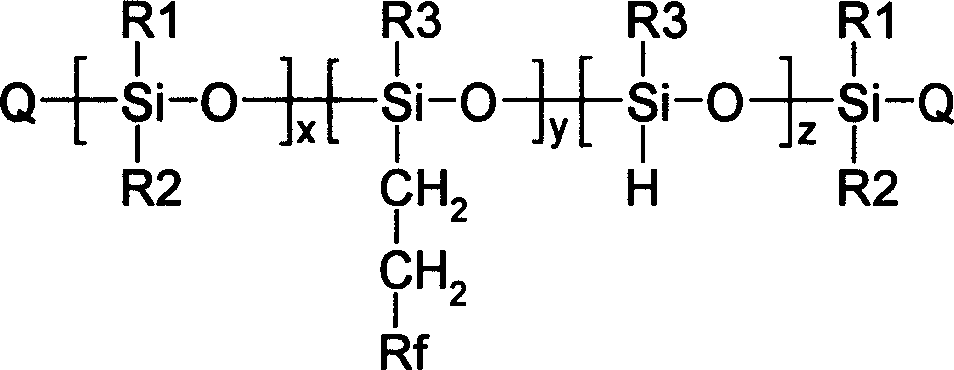

Fluoro organosilicon polymer preparation and application

A polymer and silicone technology, applied in the direction of water repellent addition, etc., can solve the problems of non-oil repellency, complicated preparation process, and influence, and achieve the effect of mild reaction conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

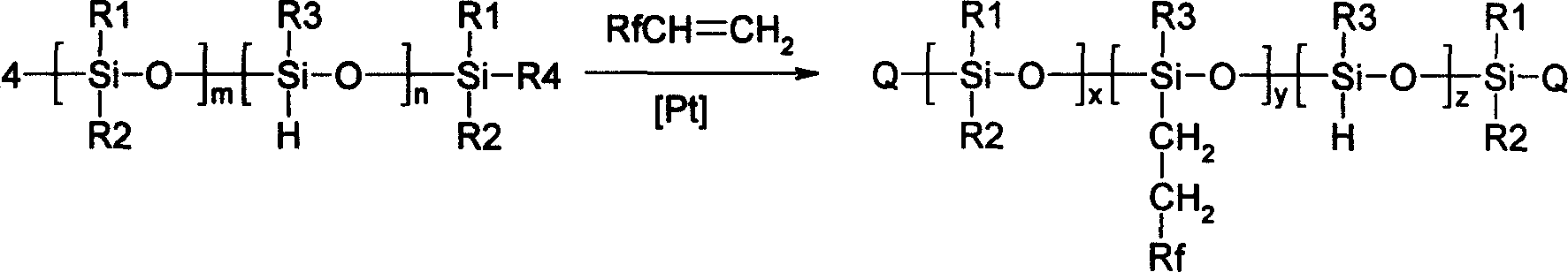

Method used

Image

Examples

Embodiment 1

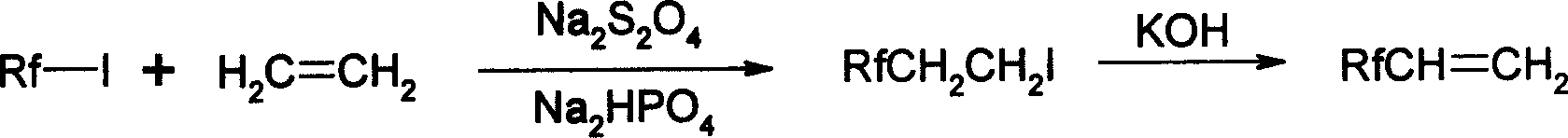

[0024] Example 1: Using 1-iodoperfluorooctane as a starting material to synthesize hydrofluorosiloxane polymers

[0025] In a 5-liter stainless steel reaction flask, add 1900 grams (3.48 moles) of 1-iodoperfluorooctane, 62.70 grams (0.36 moles) of sodium dithionite, 64.50 grams (0.45 moles) of sodium hydrogen phosphate, and 2.7 liters of acetonitrile , 0.9 liters of water. Ethylene gas at 100 atmospheres is introduced into the steel tank containing this mixture. The mixture was warmed to 40-45°C and maintained for 5 hours. Excess ethylene gas was released, and the organic layer was separated, washed with water and saturated brine, and dried over anhydrous sodium sulfate. Then, the fraction collected at 125-127° C. under reduced pressure with a pressure of 45 mm of mercury was 1-iodo-1H, 1H, 2H-perfluorodecane, and 1898 grams of the product were obtained (yield 95%).

[0026] Dissolve 574.02 grams (1 mole) of the compound 1-iodo-1H, 1H, 2H-perfluorodecane obtained in the pre...

Embodiment 2

[0028] Example 2: Synthesis of Hydrofluorosiloxane Polymer Using 1-Iodoperfluorohexane as Starting Material

[0029] In a 1-liter stainless steel reaction flask, add 345 grams (0.77 moles) of 1-iodoperfluorohexane, 13.93 grams (0.08 moles) of sodium dithionite, 14.3 grams (0.30 moles) of sodium hydrogen phosphate, and 600 milliliters of acetonitrile , 200 ml of water. Ethylene gas at 30 atmospheres is introduced into the steel tank containing this mixture. The mixture was warmed to 40-45°C and maintained for 5 hours. Excess ethylene gas was released, and the organic layer was separated, washed with water and saturated brine, and dried over anhydrous sodium sulfate. Then by vacuum distillation 45mm Hg, the fraction at 90-92°C was collected, which was 1-iodo-1H, 1H, 2H-perfluorooctane, and 348 grams of product were obtained (yield 95%).

[0030] Dissolve 94.8 grams (0.2 moles) of the compound 1-iodo-1H, 1H, 2H-perfluorooctane obtained in the previous step reaction in 200 mill...

Embodiment 3

[0032] Example 3: Synthesis of Hydrofluorosiloxane Polymer Using 1-Iodoperfluorobutane as Starting Material

[0033] In a 3-liter stainless steel reaction flask, add 802.58 grams (2.32 moles) of perfluorooctyl iodide, 41.80 grams (0.24 moles) sodium dithionite, 43 grams (0.30 moles) sodium hydrogen phosphate, 1.8 liters of acetonitrile, 0.6 liters of water. Ethylene gas at a pressure of 60 atmospheres is introduced into the steel tank containing this mixture. The mixture was warmed to 40-45°C for 4 hours. Excess ethylene gas was released, and the organic layer was separated, washed with water and saturated brine, and dried over anhydrous sodium sulfate. Then, by distillation, the fraction at 142-145° C. was collected, which was 1-iodo-1H, 1H, 2H-perfluorohexane, and 820 grams of the product were obtained (yield 94%).

[0034] Dissolve 188 grams (0.5 moles) of the compound 1-iodo-1H, 1H, 2H-perfluorohexane obtained in the previous step reaction in 0.5 liters of ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com