Preparation method of polyester monofilament for woven mesh cloth

A technology of monofilament and polyester, which is applied in the field of preparation of polyester monofilament for woven mesh, which can solve the problems of promoting bacterial reproduction and growth, affecting appearance, and reducing the surface free energy of monofilament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

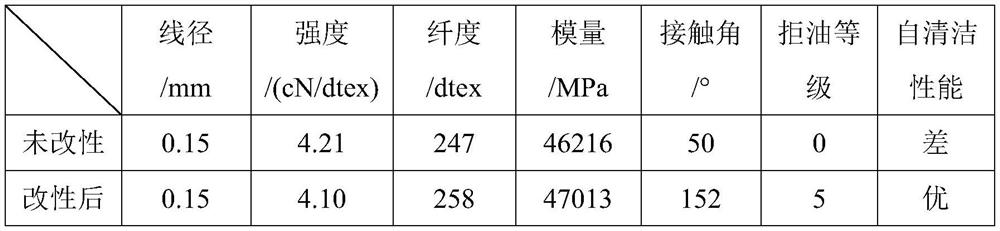

[0024] A kind of preparation method of polyester monofilament for weaving net cloth is characterized in that: comprise the following steps:

[0025] (1) Preparation of nanometer mesoporous silica: ① mix absolute ethanol and 1% ammonia solution at room temperature, add cationic surfactant cetyltrimethylammonium bromide and nanometer silicon dioxide (nano The specific surface area of silicon oxide is greater than 180g / m 2 , the mass ratio of surfactant to silicon dioxide is 0.2:25), stirred in a constant temperature water bath at 40°C at a speed of 350r / min for 10min to obtain a mixed solution, and ultrasonically dispersed for 1h. ② Slowly add tetraethyl orthosilicate to the mixed solution at a rate of 22ml / min under stirring, and stir at a speed of 230r / min in a water bath at 50°C for 2 hours to obtain a mixed reaction solution.

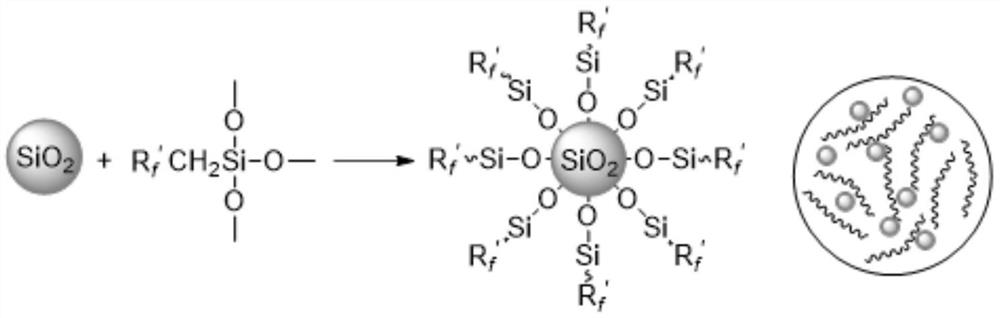

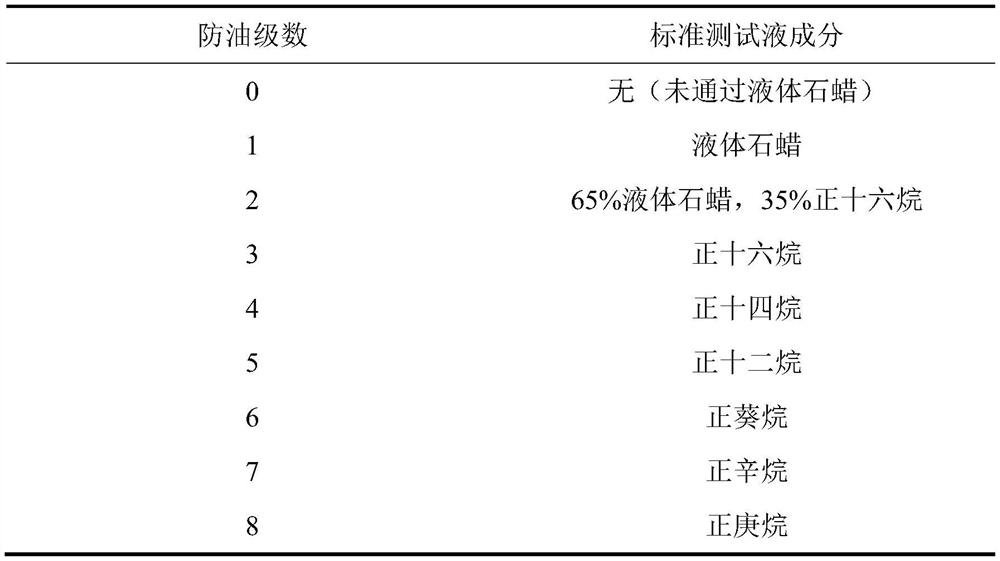

[0026] (2) Surface modification of nano-silica with fluorine-containing silyl compounds: ①Add 3,3,3-trifluoropropylmethoxysilane to the above mixe...

Embodiment 2

[0043] Only change the cationic surfactant used in embodiment 1 step (1), described cationic surfactant is alkyl trimethyl ammonium chloride, cetyl trimethyl ammonium bromide, lauryl pyridinium chloride Onium, Stearyl Trimethyl Ammonium Chloride, Fluorohexyl Trimethyl Ammonium Chloride, Dimethyl Monococoyl Ammonium Acetate, Octadecyl Dimethyl Vinyl Phenyl Ammonium Chloride, Didodecane One of the base amine polyoxyethylene ether ammonium chloride. The rest are the same as implementation case 1.

Embodiment 3

[0044] Embodiment 3: Only replace the mesoporous silica in embodiment 1 with other inorganic nanoparticles, and the inorganic nanoparticles are one of nano-TiO2 and nano-ZnO. Nano-zinc oxide and nano-titanium dioxide are direct wide-bandgap semiconductors, which can be effectively excited by ultraviolet light, have photocatalytic properties, have a certain self-cleaning ability, and can form protrusions on the surface of monofilaments. watery. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com