Manufacturing method of multi-layer colored glass plate

A manufacturing method and glass plate technology, which are applied in the glass plate manufacturing, glass coating layer brush screen printing composite technology and manufacturing fields, can solve the problems of easy yellowing of adhesives, less application and high glass plate manufacturing cost, and achieve Unique function, simple production process and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples.

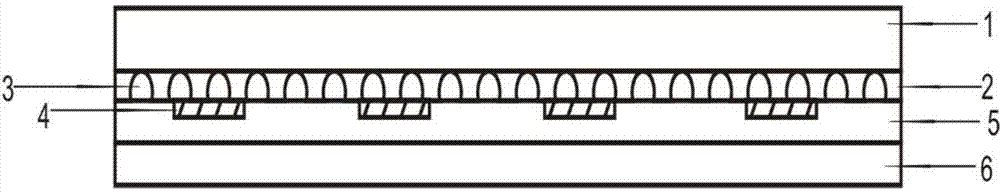

[0023] as attached figure 1 Shown, the multi-layer colored glass plate of the present invention comprises glass substrate 1, and glass substrate 1 is tempered flat plate or curved glass, and coating translucent layer 2 is arranged on glass substrate 1, and on coating translucent layer 2, pass through reducing The silk-making layer 3 formed by the method of dividing concave lines and brushing patterns is printed with a metallic screen printing color surface layer 5 on the silk-making layer 3 , and a back cover protection layer 6 is screen-printed or rolled on the metallic color screen printing color surface layer 5 .

[0024] Between the silk-making layer 3 and the metallic color screen printing color surface layer 5, a partial pattern layer 4 can also be printed by screen printing according to the needs of customers.

[0025] The glass substrate 1 is 2-6m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com