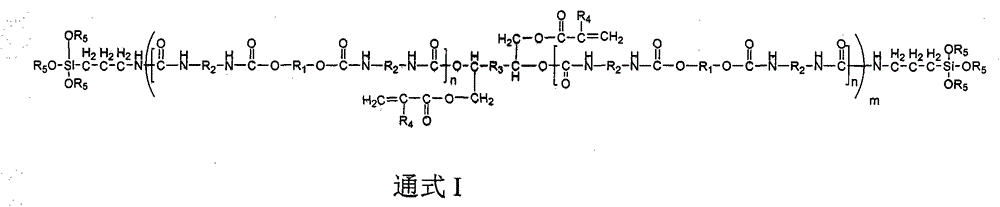

Ultraviolet ray and moisture dual-cured modified polyurethane and preparation method thereof

A dual-curing, ultraviolet technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of cured object shape, thickness, color restrictions, shadow curing and other difficult problems. Achieve the effect of solving the problem of curing depth, reducing curing energy and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

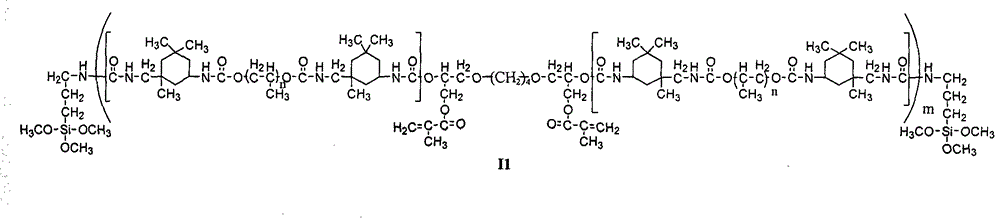

[0032] Embodiment 1 modified polyurethane (I1) is synthesized

[0033] Step 1: Add 1,4-butanediol diglycidyl ether and methacrylic acid to a 2L reactor equipped with a stirrer, thermometer and condenser, then heat to 120°C, react for 3 hours, and cool to room temperature , to obtain the chain extender epoxy acrylate, the second step polypropylene glycol and isophorone diisocyanate into the reactor, then add the catalyst diisobutyltin laurate, the mol ratio of hydroxyl and isocyanate group is 1: (1.1 ~1.3), under nitrogen protection, react at 60-80°C for 4-6h to obtain NCO-terminated polyurethane prepolymer, then add the chain extender epoxy acrylate into the reaction kettle, under nitrogen protection, 60-80°C, continue the reaction for 4 -6h to obtain the synthesis of a polyurethane prepolymer containing NCO groups, then cool the temperature to 40°C, add aminopropyltrimethoxysilane, and react for 2h to obtain a modified polyurethane (I1).

[0034]

Embodiment 2

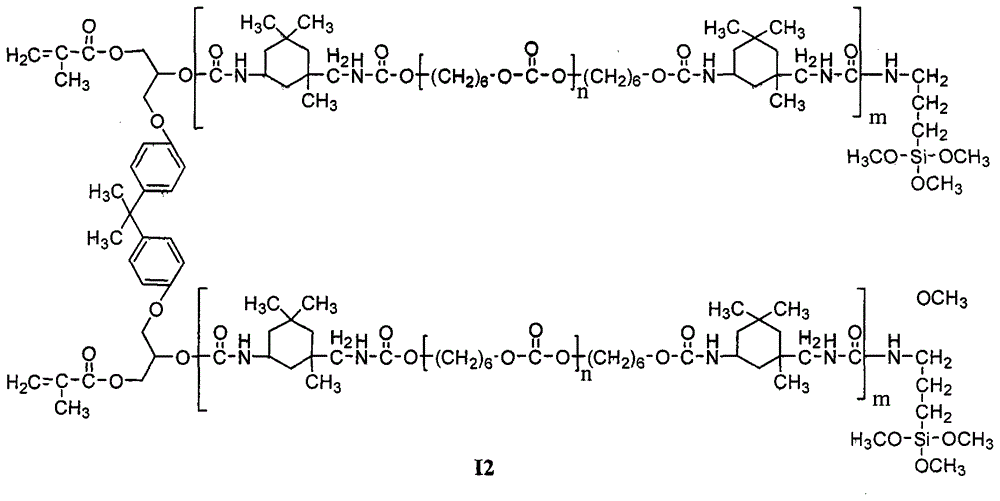

[0035] Embodiment 2 modified polyurethane (I2) is synthesized

[0036] Step 1: Add bisphenol A diglycidyl ether and methacrylic acid to a 2L reactor equipped with a stirrer, a thermometer and a condenser, then heat to 120°C, react for 3 hours, and cool to room temperature to obtain chain extension In the second step, polycarbonate diol and isophorone diisocyanate are put into the reaction kettle, and then the catalyst diisobutyltin dilaurate is added, and the molar ratio of hydroxyl group to isocyanate group is 1: (1.1~1.3 ), under nitrogen protection, react at 60-80°C for 4-6h to obtain NCO-terminated polyurethane prepolymer, then add the chain extender epoxy acrylate into the reaction kettle, under nitrogen protection, at 60-80°C, continue to react for 4-6h , to obtain the synthesis of a polyurethane prepolymer containing NCO groups, then cool the temperature to 40°C, add aminopropyltrimethoxysilane, and react for 2h to obtain a modified polyurethane (I2).

[0037]

Embodiment 3

[0039] According to parts by weight, mix 76.63 parts of modified polyurethane (I1) and 6.39 parts of methyltrimethoxysilane at room temperature and under vacuum for 20 to 30 minutes; then add 3.83 parts of 1-hydroxycyclohexyl phenyl ketone, acrylic acid monomer 12.77 parts, 0.38 parts of isopropyl orthotitanate, mixed at room temperature and protected from light for 20 to 30 minutes to make it uniform, and made a UV and moisture dual curing composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com