Fluorescent material coating apparatus and method of coating fluorescent substance using the same

A technology of fluorescent substance and coating device, which is applied in the application of luminescent paint, tube/light screen manufacturing, building structure, etc., can solve the problems of complicated operation process, difficulty in mass production of fluorescent lamps, and large temperature difference of glass tubes, etc. The effect of ensuring coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

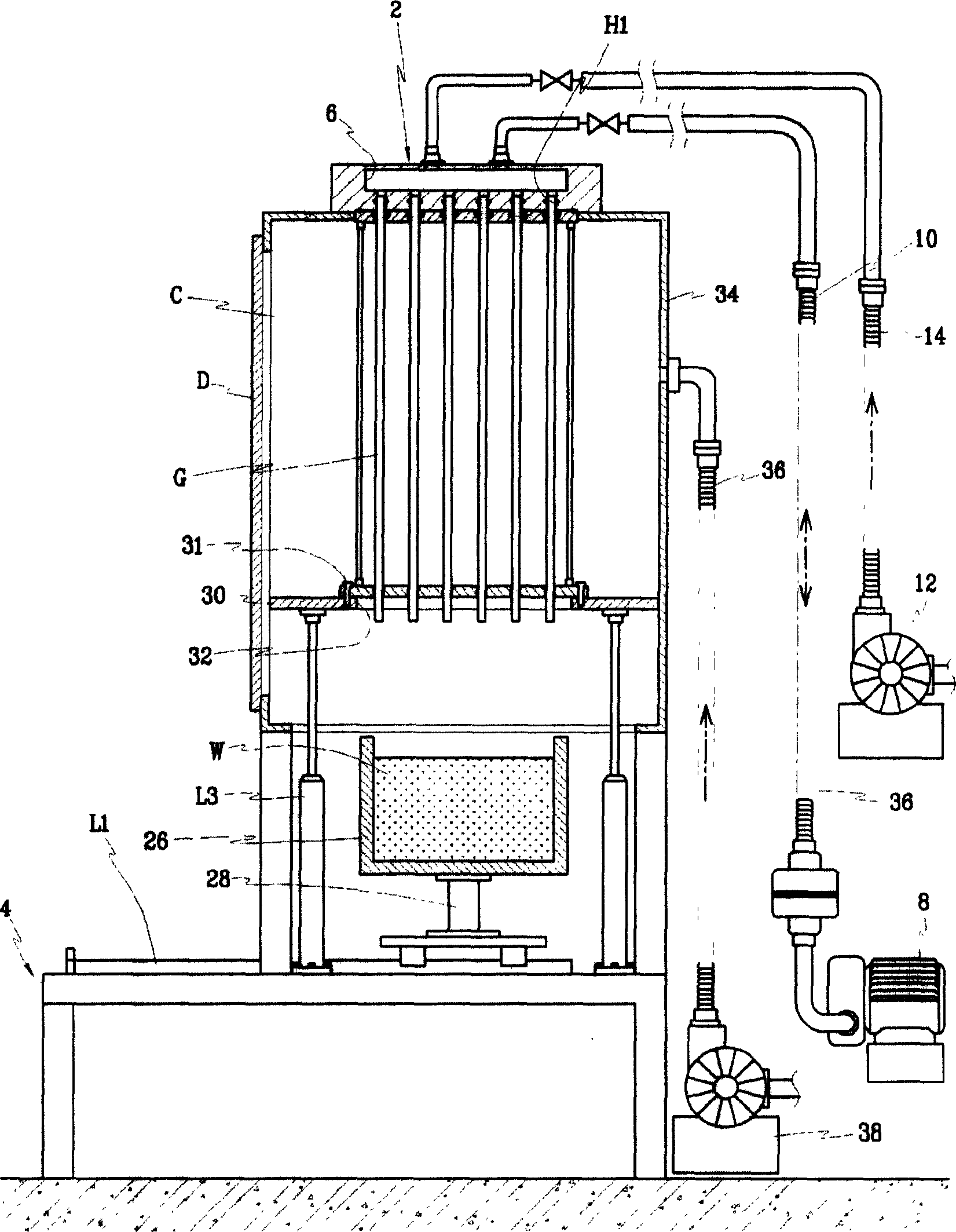

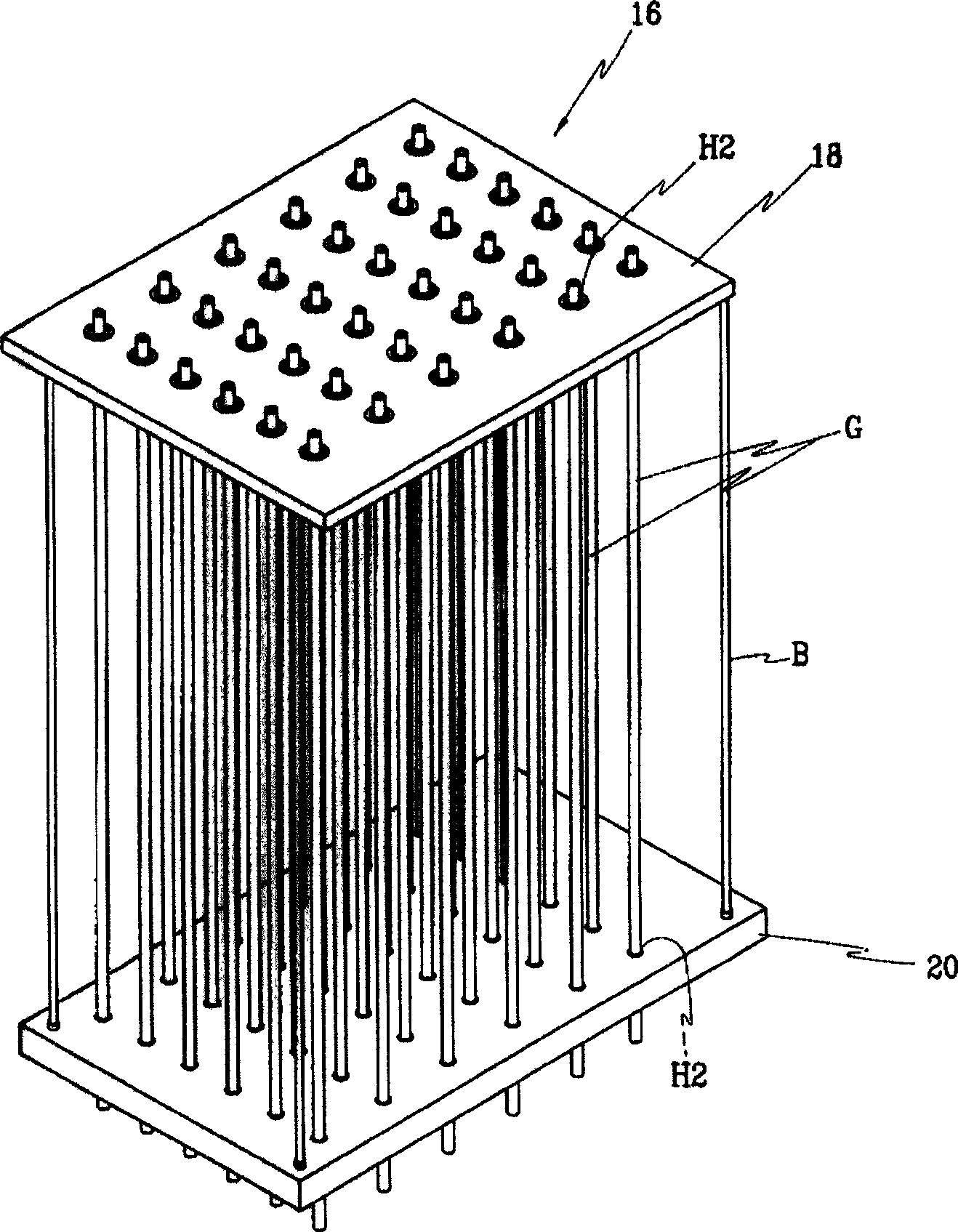

[0035] figure 1 It is a structural schematic diagram of a fluorescent substance coating device for manufacturing fluorescent lamps according to the present invention, and the number 2 in the figure represents a distributing device. The distribution device 2 is fixed on the upper part of the bracket 4 , and the distribution device 2 is provided with a distribution chamber 6 .

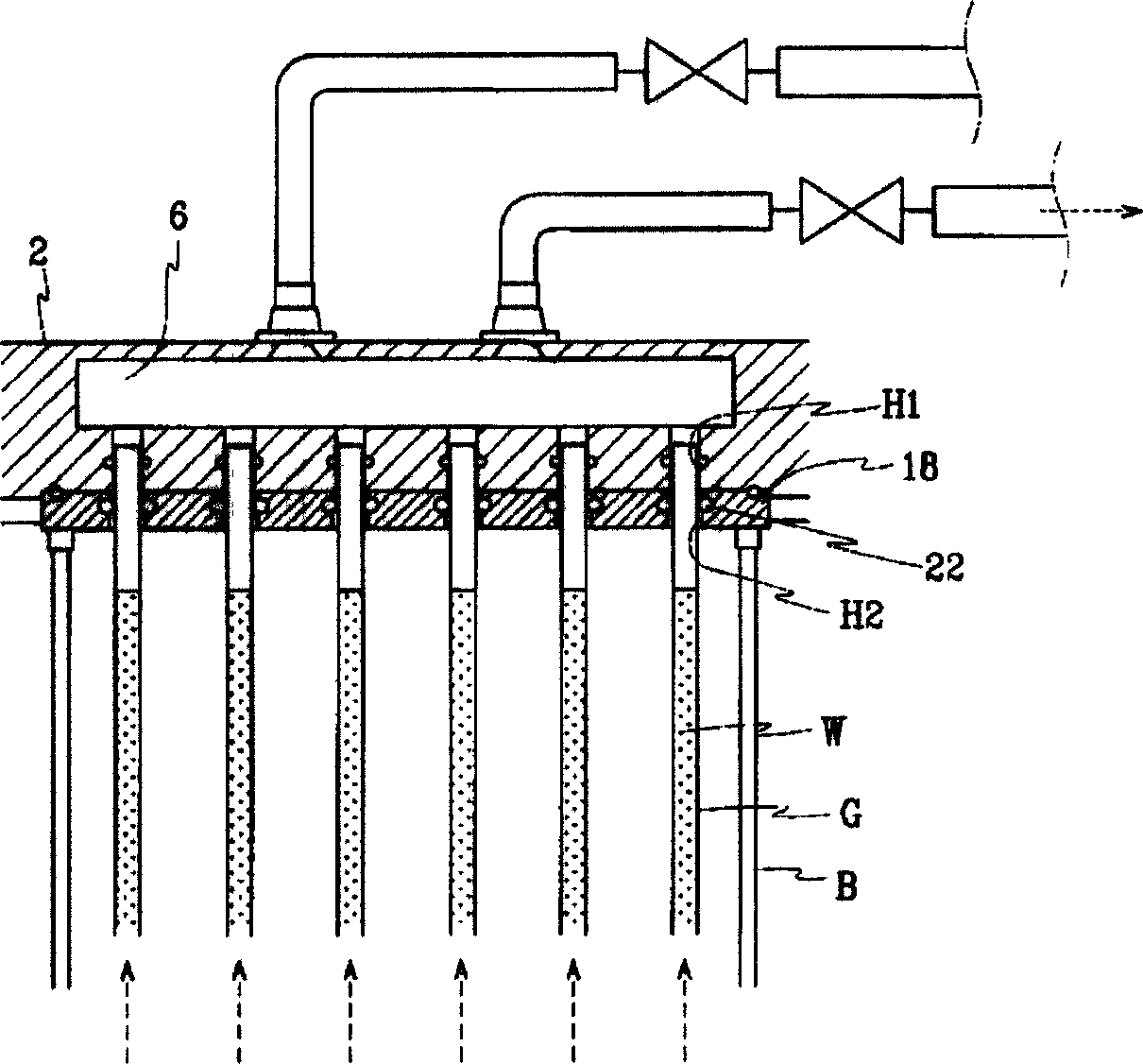

[0036] The distribution chamber 6 communicates with the vacuum pump 8 through a flexible hose (flexible hose) 10, so that a negative pressure can be generated in the distribution chamber 6, and the distribution chamber 6 is connected with a heating device through a flexible hose 14. A first blower 12 of a device (not shown) is connected to draw hot air.

[0037] The distribution chamber 6 is perforated with at least two communication holes H1, the communication holes H1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com