Patents

Literature

41 results about "Thiodiethylene Glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2,2'-Thiodiethanol, β,β'-dihydroxydiethyl sulfide, β-thiodiglycol, thiodiethylene glycol, β-hydroxyethyl sulfide, 2-hydroxyethyl sulfide, bis(β-hydroxyethyl)sulfide, Glyecine A, Kromfax Solvent, Tedegyl. ... It is structurally similar to diethylene glycol. Thiodiglycol has both polar and nonpolar solvent properties.

Silver and silver alloy plating bath

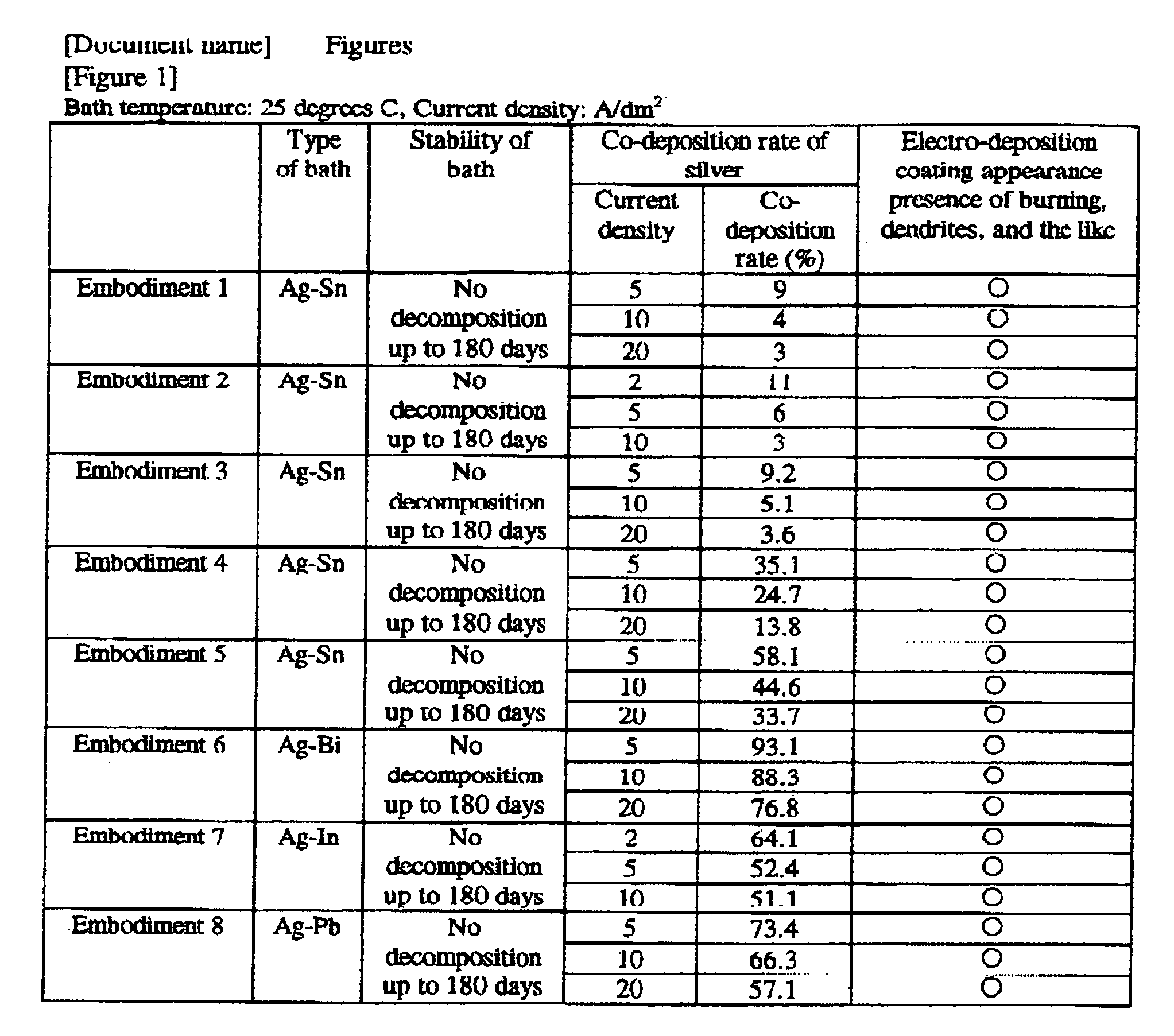

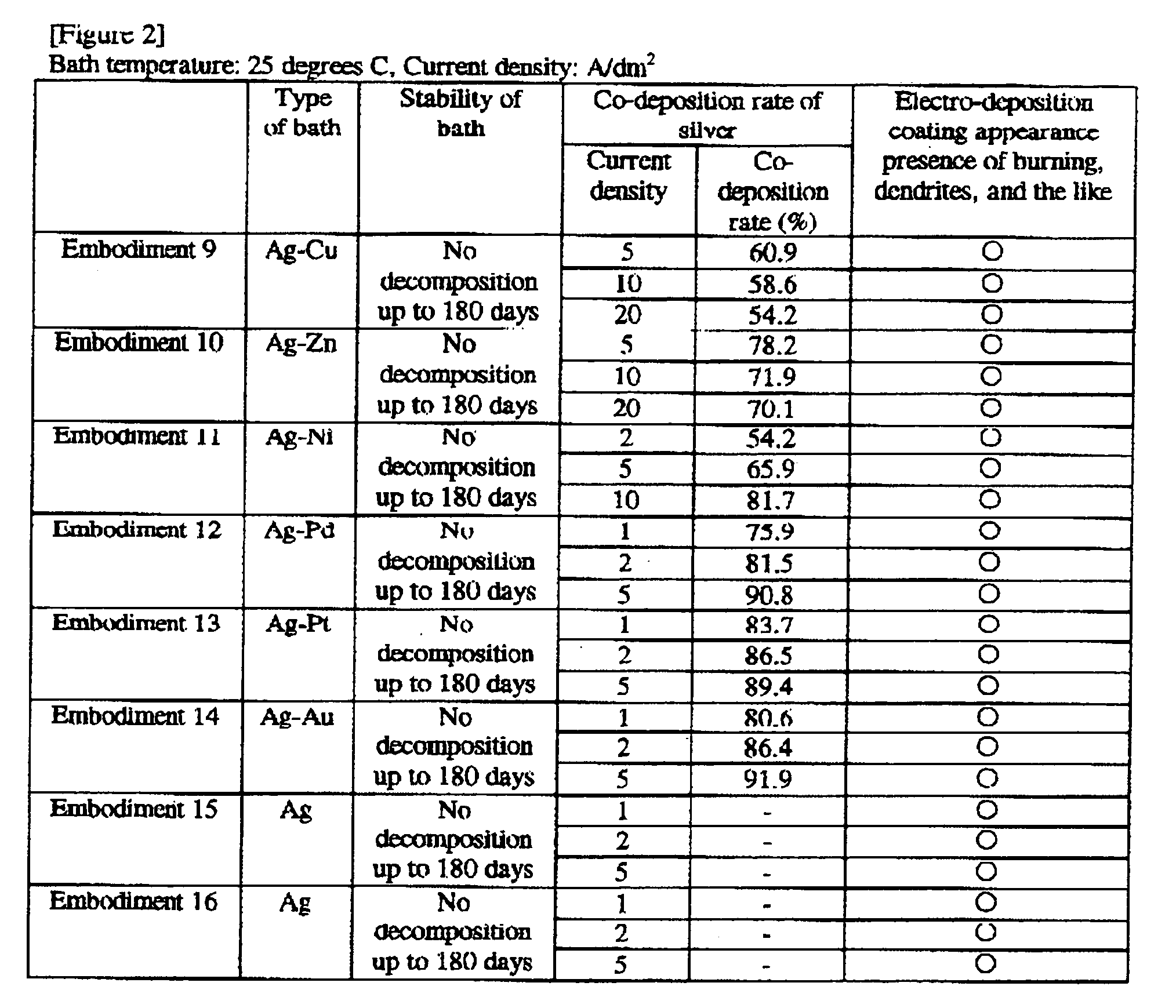

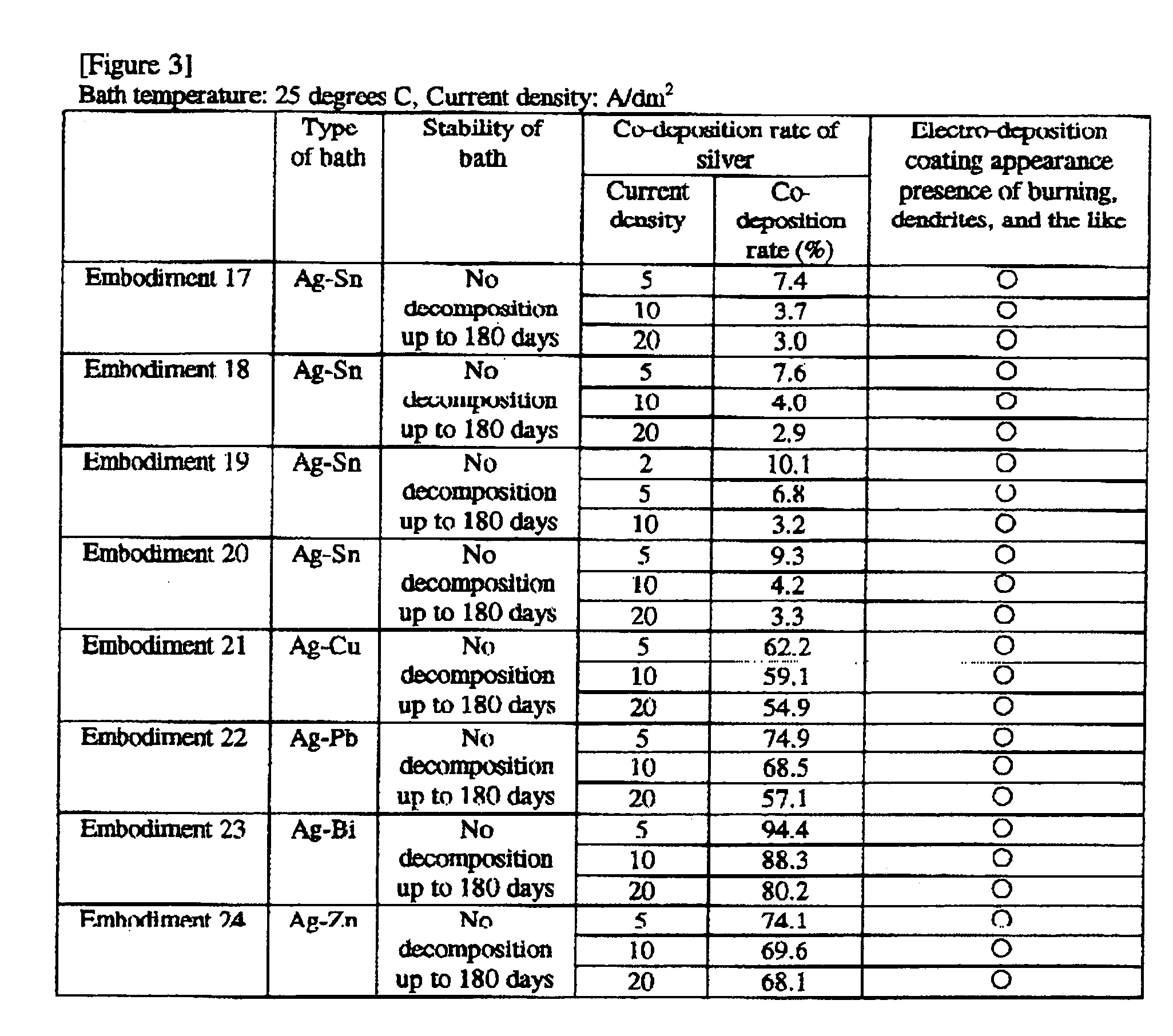

InactiveUS7628903B1Extension of timeImprove stabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingIndiumThiodiethylene Glycol

A silver and silver alloy plating bath, includes (A) a soluble salt, having a silver salt or a mixture of a silver salt and a salt of a metal such as tin, bismuth, indium, lead, and the like; and (B) a particular aliphatic sulfide compound, such as thiobis(diethyleneglycol), dithiobis(triglycerol), 3,3′-thiodipropanol, thiodiglycerin, 3,6-dithiooctane-1,8-diol, and the like, which contain at least one or more of an ether oxygen atom, a 1-hydroxypropyl group, a hydroxypropylene group, or two or more of a sulfide bond in the molecule, and not containing a basic nitrogen atom. Compared to baths containing aliphatic monosulfide compounds, such as thiodiglycol or beta-thiodiglycol, which do not contain an ether oxygen atom, 1-hydroxypropyl group, a hydroxypropylene group, or two or more of a sulfide bond in the molecule, by having these particular compounds, the plating bath of the present invention has excellent stability over extended time, excellent co-deposition of silver and various metals, and excellent appearance of the electrodeposition coating.

Owner:ISHIHARA CHEM +1

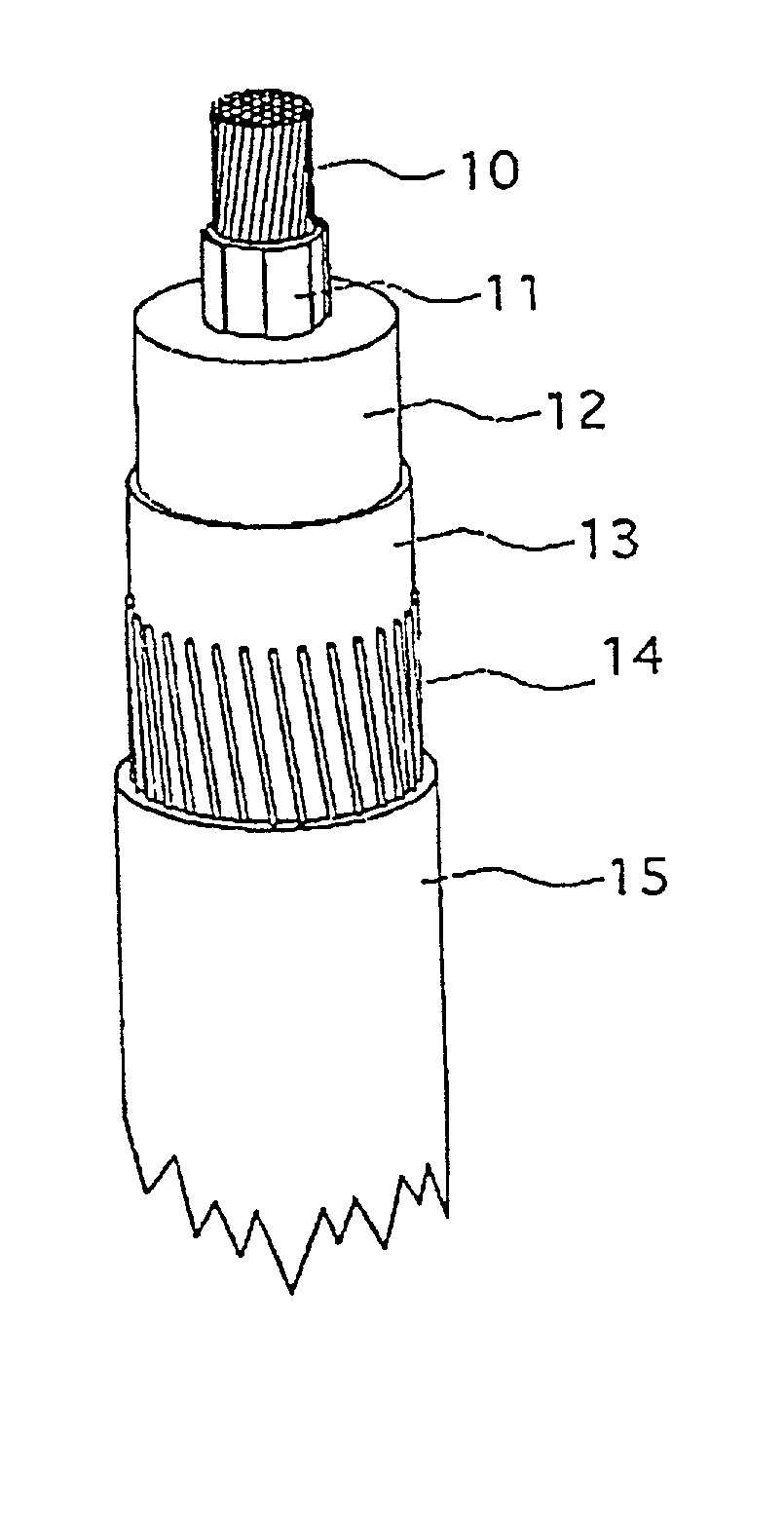

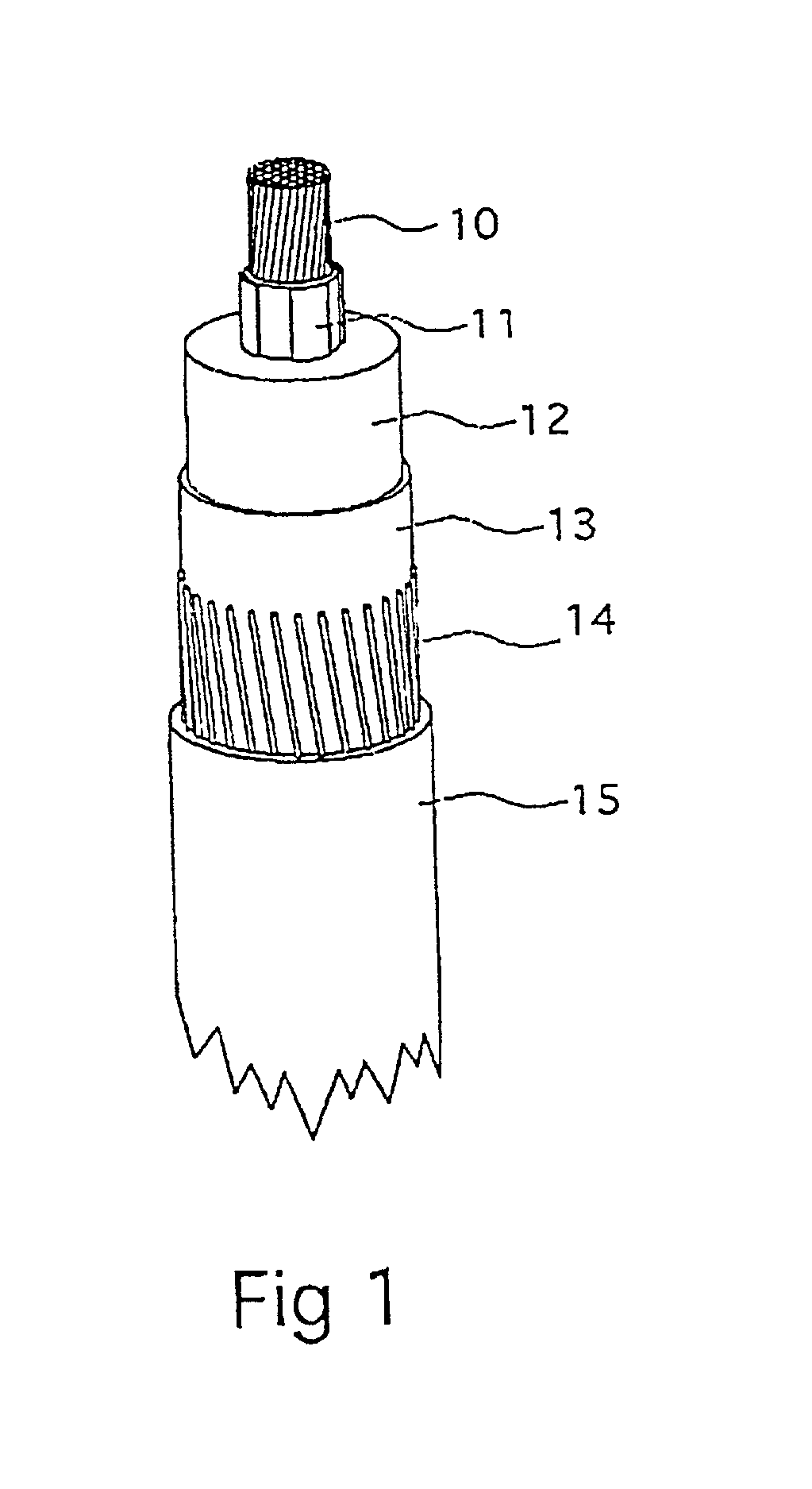

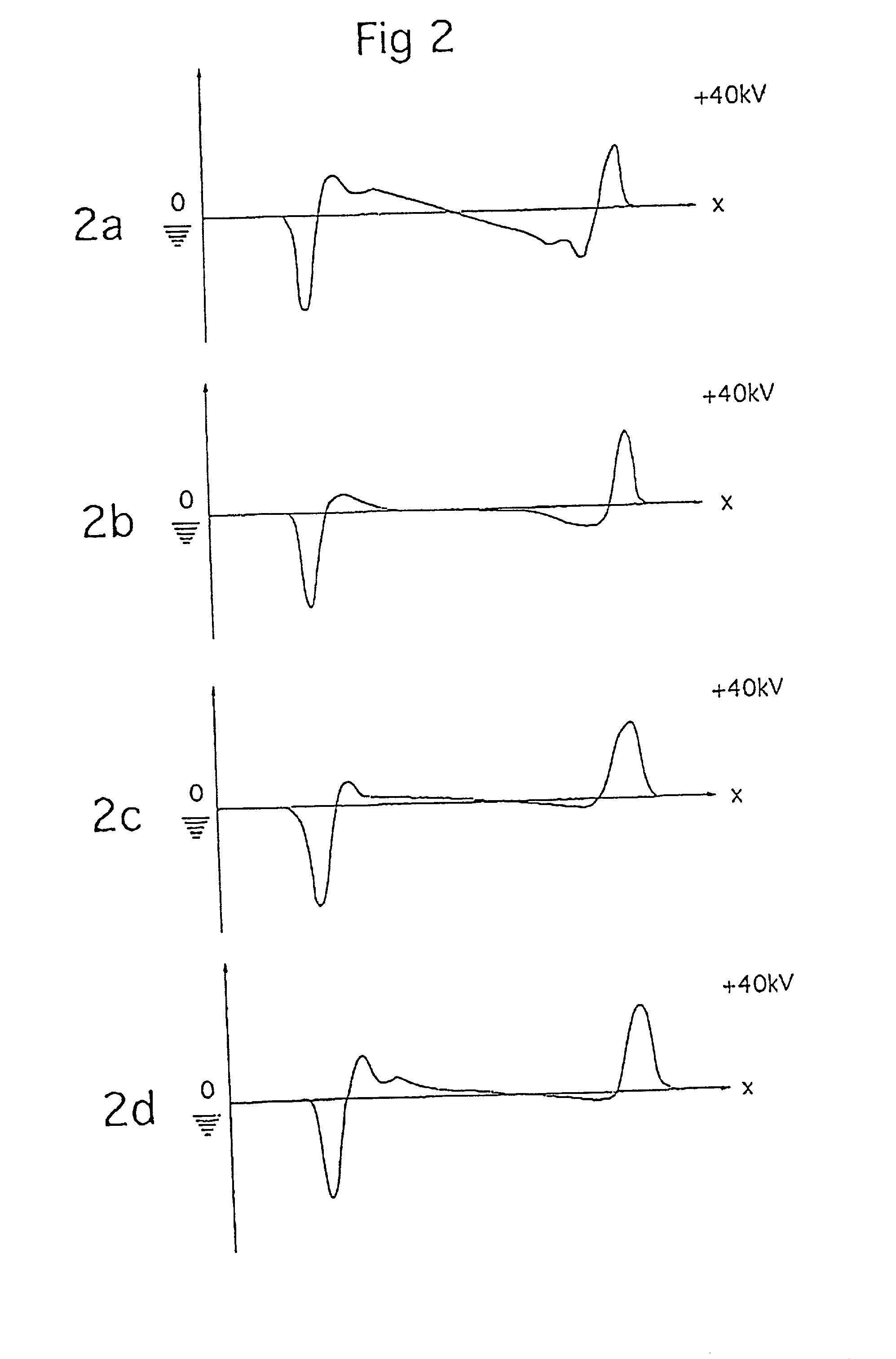

Electric DC-cable with an insulation system

InactiveUS20020039654A1Shorten production timeLow production costPlastic/resin/waxes insulatorsYarnCross-linkElectrical conductor

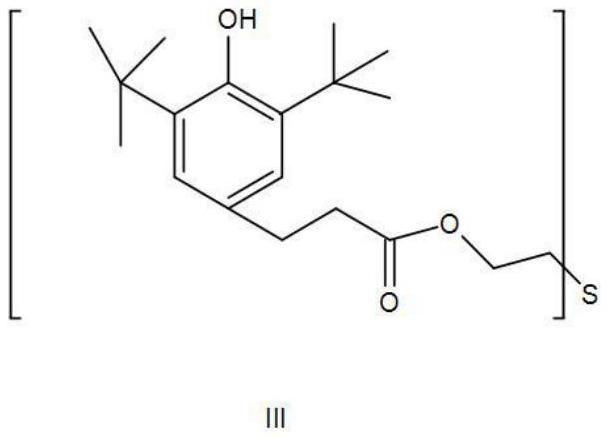

An insulated DC-cable and method for production of an insulated DC-cable with an insulating system comprising an extruded cross-linked polyethylene based insulation disposed around the conductor. The extruded polyethylene based compound comprises additives such as cross-linking agent, scorch retarding agent and antioxidant. The scorch retarding agent comprises a compound (D), 2,4-diphenyl-4-methyl-pentene-1 and the antioxidant comprises a compound (C), a diester of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionicacid and thiodiglycol. The compounded polyethylene based resin composition is extruded and cross-linked at a temperature and for a period of time sufficient enough to cross link the insulation. The temperature and the period of time upon extrusion and cross-linking are limited so as to substantially suppress or essentially avoid undesired polar by-products being formed in the cross-linked composition.

Owner:GUSTAFSSON BILL +7

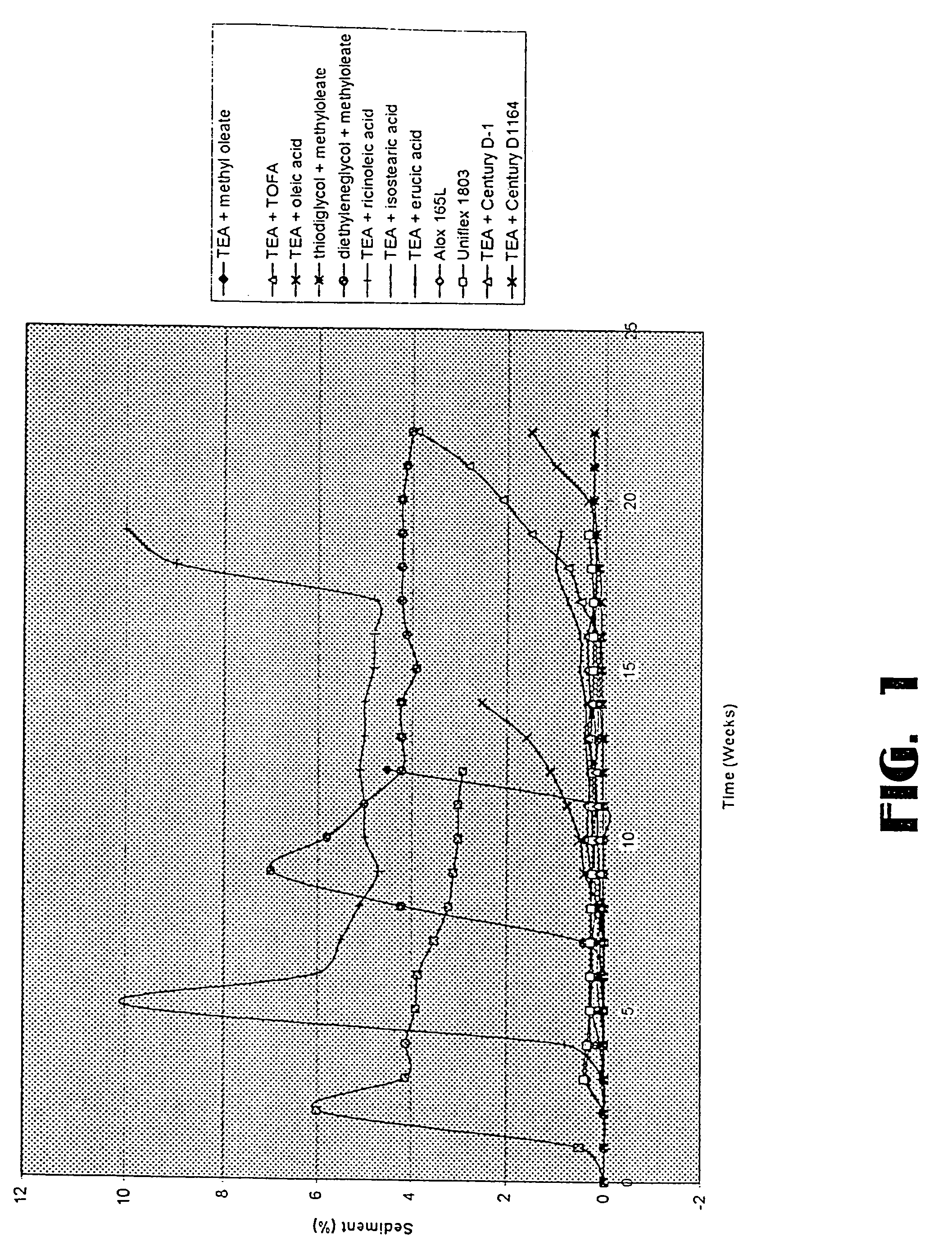

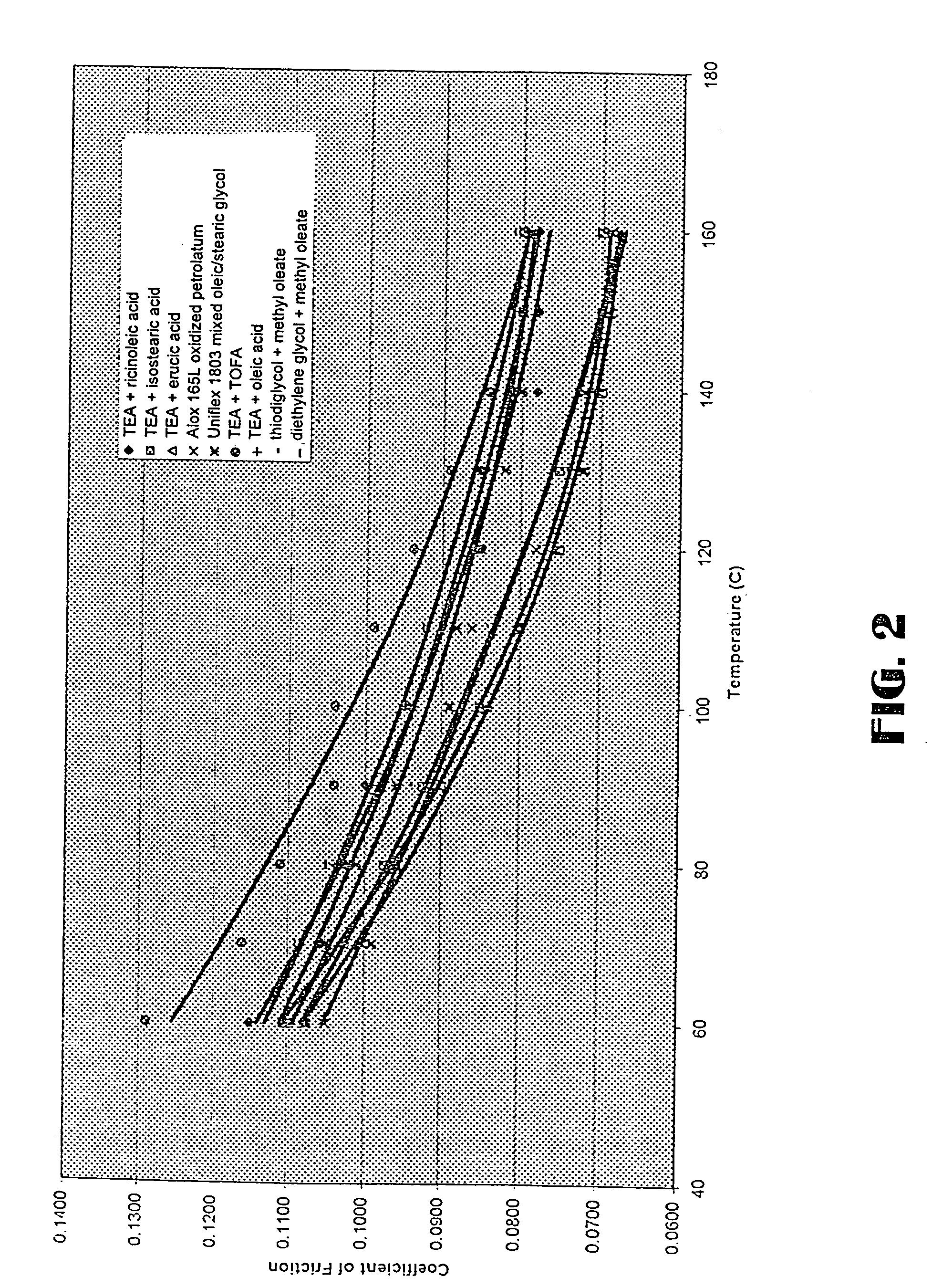

Low sediment friction modifiers

InactiveUS20050124510A1Improve the lubrication effectAvoid excessive sedimentationLiquid carbonaceous fuelsAdditivesSulfonateAlkaline earth metal

An additive mixture for lubricant oils includes an overbased alkaline earth metal sulfonate, and at least one friction modifier selected from the group consisting of an overbased alkaline earth carboxylate, the reaction product of an alkanolamine with a fatty acid or a fatty acid ester and the reaction product of thiodiglycol or a dialkylene glycol with a fatty acid or a fatty acid ester. The additive mixture, when combined with a lubricant stock, provides a lubricant composition characterized by less sedimentation during storage.

Owner:CHEMTURA CORP

Low-silver-bearing printed circuit board silver paste and preparation method thereof

ActiveCN104078098AReduce dosageImprove yieldNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseThiodiethylene Glycol

A low-silver-bearing printed circuit board silver paste comprises, by weight, 1 part to 2 parts of glucose, 20 parts to 30 parts of nanoscale sheet cooper powder, 30 parts to 40 parts of 1-micrometer to 20-micrometer sheet silver powder, 13 parts to 16 parts of glass powder, 5 parts to 7 parts of hyperbranched polyester resin, 5 parts to 8 parts of terpilenol, 2 parts to 5 parts of sulfo-diglycol, 2 parts to 4 parts of bisphenol A epoxy resin, 6 parts to 8 parts of butyl carbitol, 7 parts to 9 parts of acetic ether, 1 part to 2 parts of nanometer titania, 1 part to 2 parts of nanometer crystalline cellulose, 3 parts to 5 parts of nanometer tantalum carbide powder and 3 parts to 5 parts of nanometer niobium carbide powder. According to the low-silver-bearing printed circuit board silver paste, the nanoscale sheet copper powder, the nanometer tantalum carbide powder and the nanometer niobium carbide powder are added, so that the good conductive performance is kept, and the use amount of the silver powder is saved; the glass powder does not contain lead and is environmentally friendly and good in caking property, and a circuit is firm; the organic vehicle solvents are sequentially volatilized, the high temperature resistance is good, the printing performance is good, and the circuit yield is high.

Owner:乐凯特科技铜陵有限公司

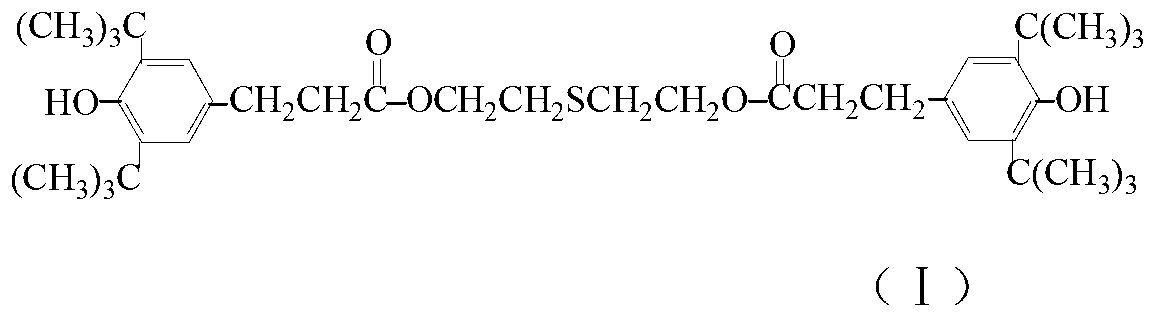

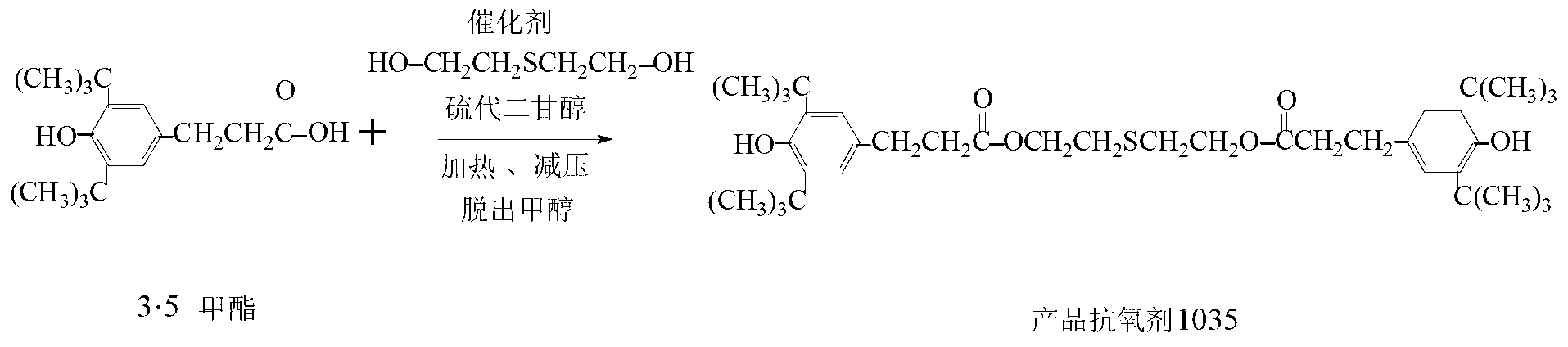

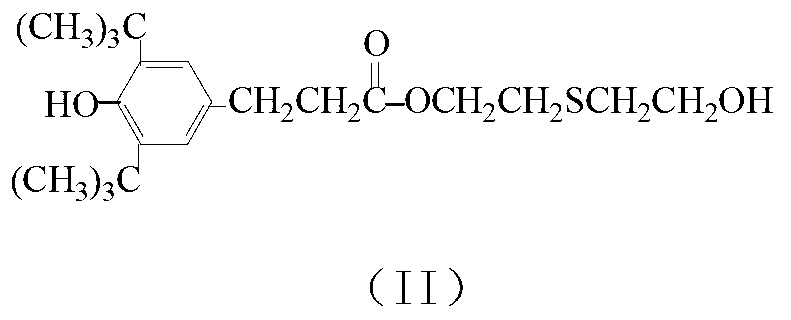

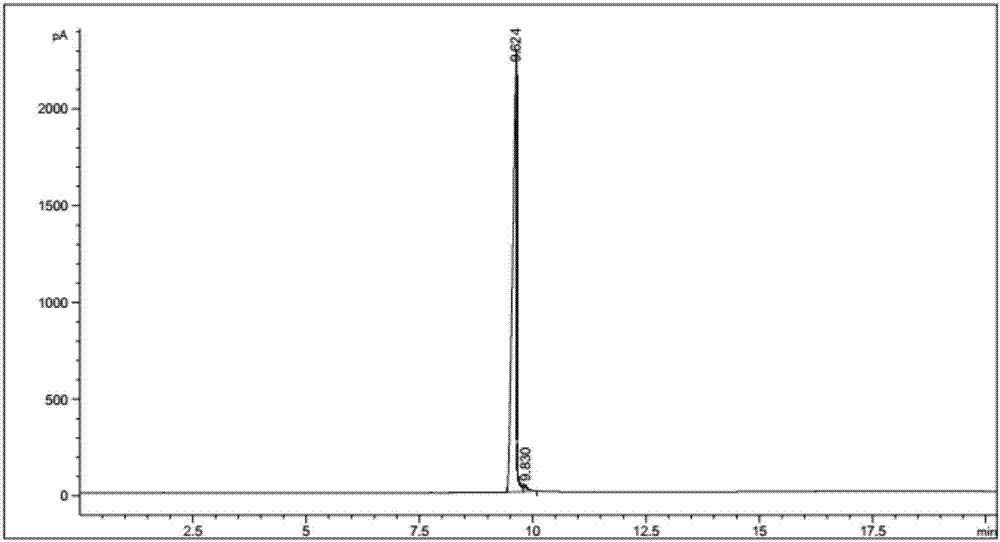

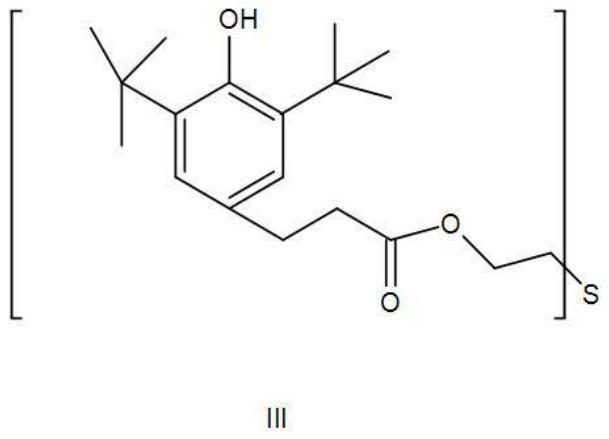

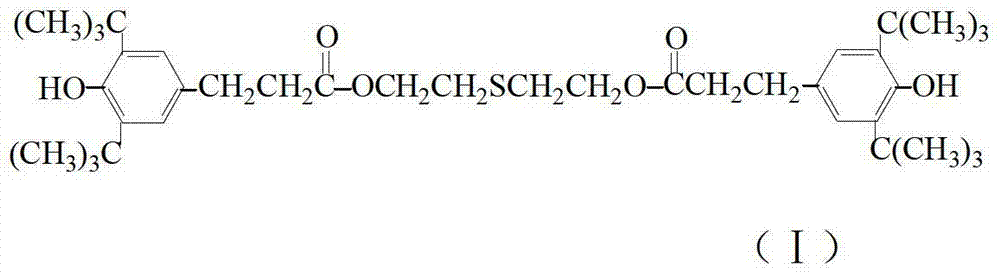

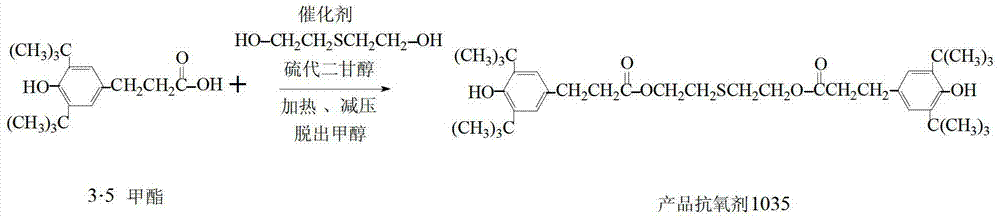

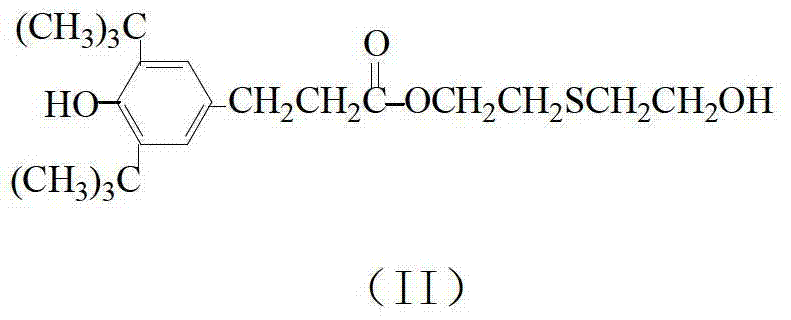

Preparation method of thiophenol compound antioxidant product

ActiveCN103319387AGood synergyReduce dissolution lossSulfide preparationPropionateThiodiethylene Glycol

The invention relates to a preparation method of a thiophenol compound antioxidant product, relating to the technical field of preparation of antioxidant products. A process technical method of the thiophenol compound antioxidant product comprises the following steps of: taking 3, 5-methyl ester and thiodiglycol as raw materials, performing ester exchange reaction under the actions of a catalyst and a color blocking agent, and generating a reaction product mixed solution containing 2, 2'-thiodiethyl bis(3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate by continuously removing a byproduct, namely methanol during the reaction process; adding an appropriate amount of phosphite ester-like compound into the reaction product mixed solution, and generating a new phosphite ester-like compound by secondary ester exchange reaction; and selecting a recrystallization solvent, performing recrystallization and refining on the reaction product mixed solution, and performing solid-liquid separation to obtain a while granular crystal product.

Owner:宁波福天新材料科技有限公司

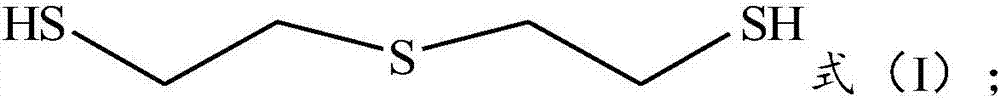

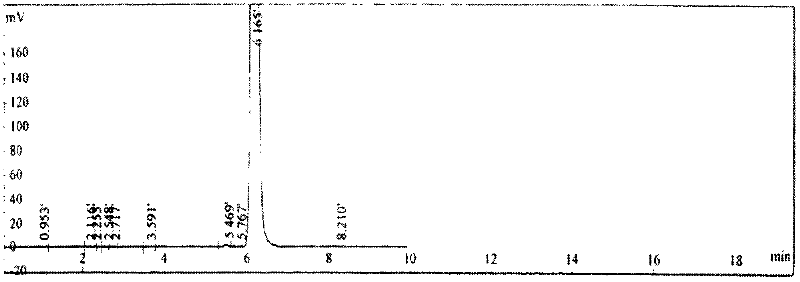

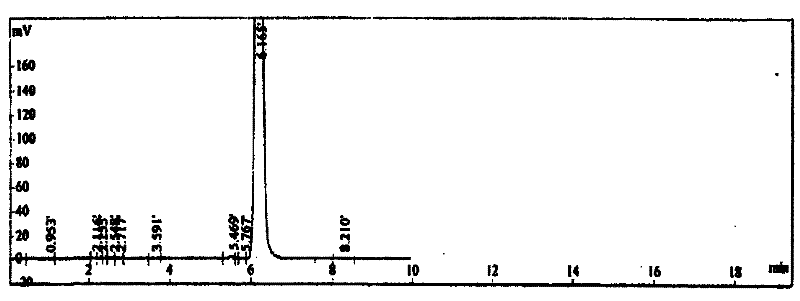

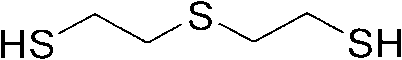

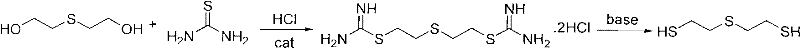

Preparation method of thiodiethanethiol

The invention provides a preparation method of thiodiethanethiol. The preparation method comprises the following steps: a) mixing thiodiglycol, thiourea and hydrochloric acid to carry out a salt forming reaction and then adding an alkaline solution for hydrolysis reaction to obtain a reaction mixture; b) skimming the reaction mixture obtained in the step a) to separately obtain a thiodiethanethiolcoarse product and reaction wastewater; and then washing the thiodiethanethiol coarse product to separately obtain thiodiethanethiol and washing waste water; and c) separately flocculating the reaction waste water and the washing waste water obtained in the step b) to obtain circulating water. Compared with the prior art, the preparation method provided by the invention has relatively high product quality and yield, and can achieve circular use of waste water. Experimental results verify that the content of thiodiethanethiol prepared by the preparation method is stabilized at over 99%, and the yield is over 98%, and zero discharge of the waste water is achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

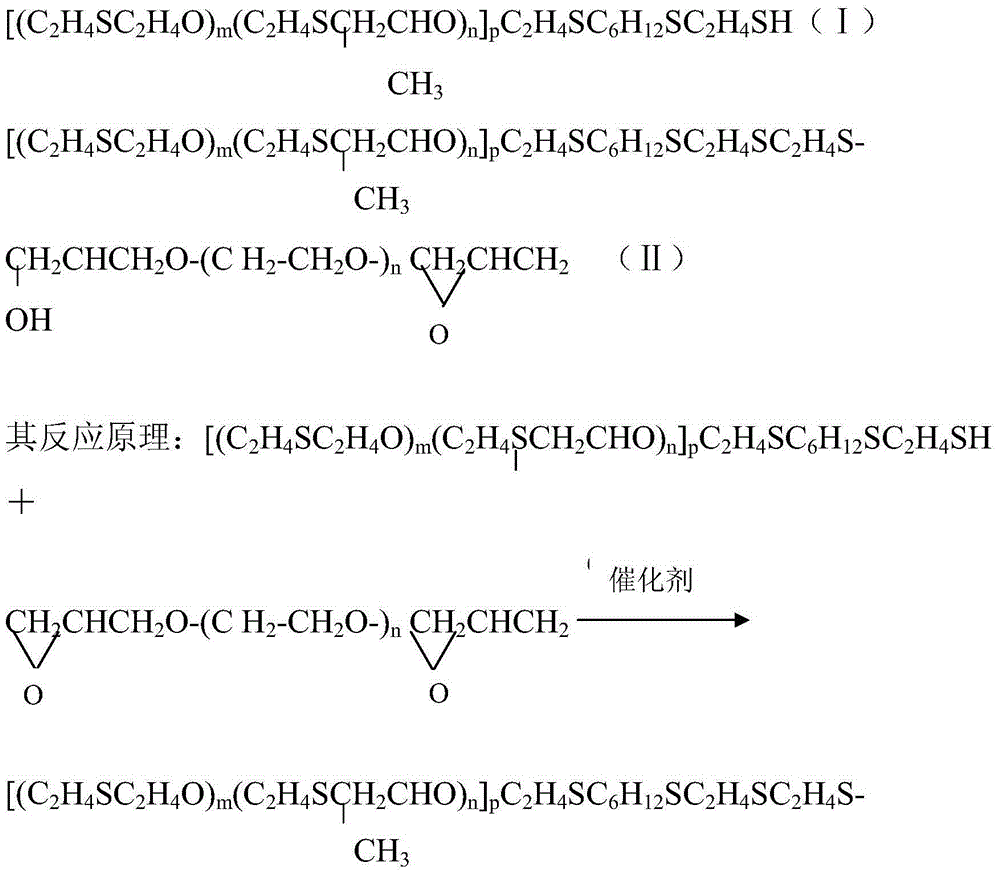

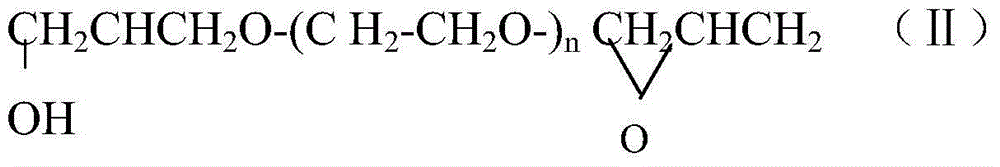

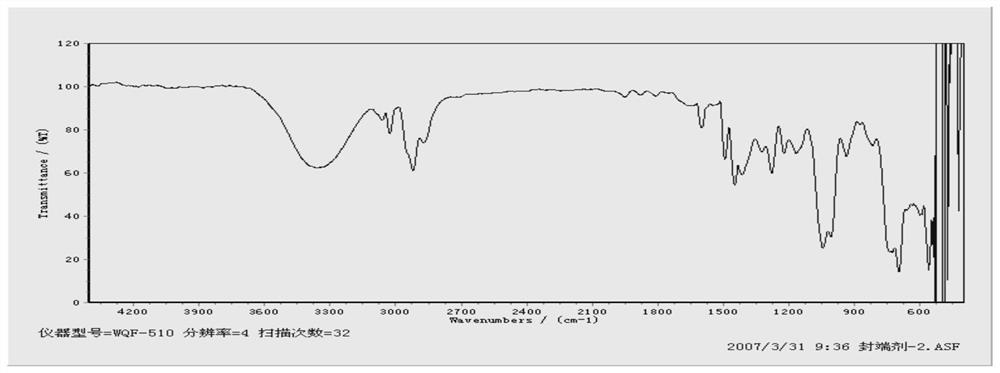

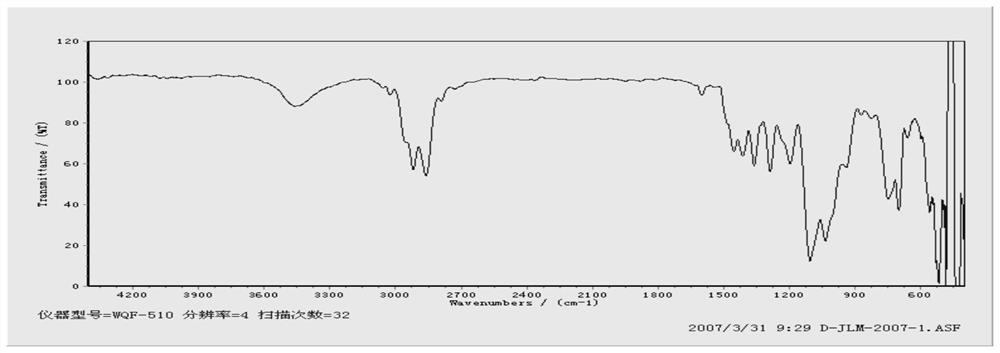

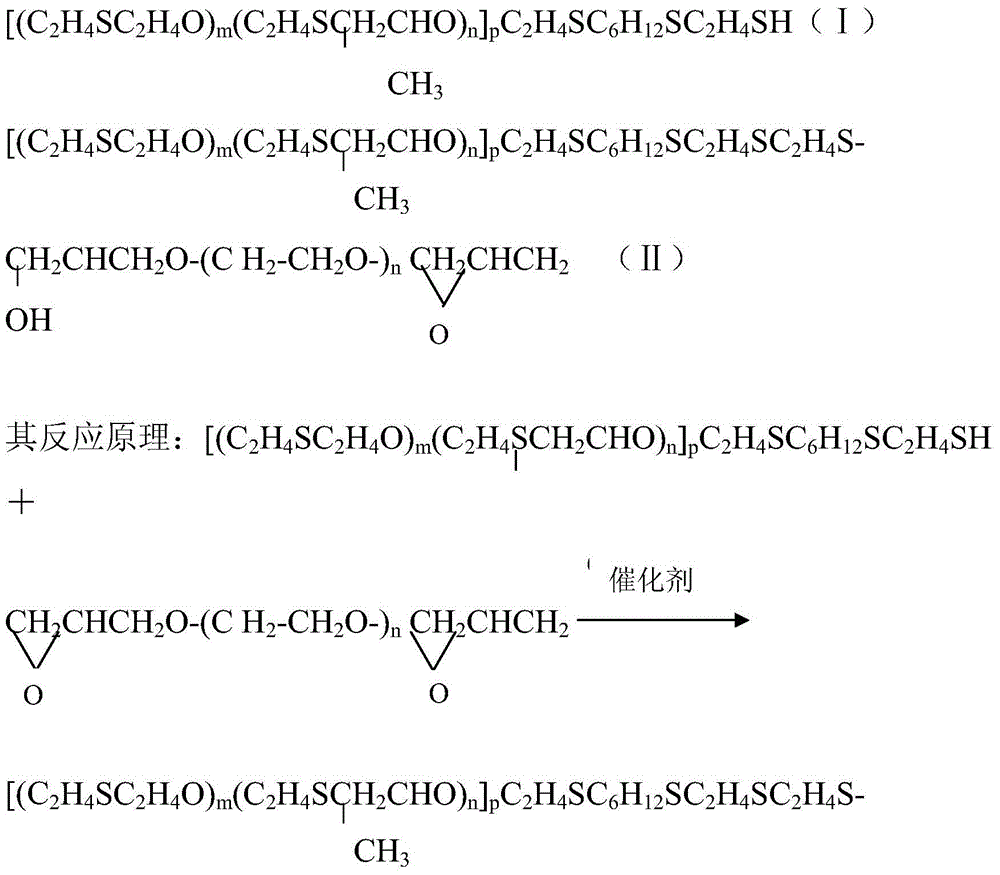

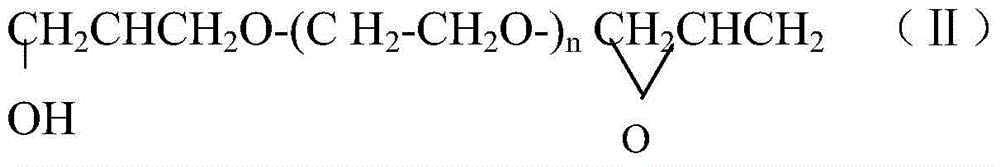

Synthetic method for epoxy end group polythioether liquid rubber

ActiveCN104558584AModerate viscosityGood adhesionPoly(ethylene glycol) diglycidyl etherHeat resistance

The invention discloses a synthetic method for epoxy end group polythioether liquid rubber. The method comprises the following steps: synthesizing sulphydryl end group polythioether liquid rubber by using thiodiglycol, hydroxyethyl-2-hydroxypropyl thioether and the like as main monomers; then using polyethylene glycol diglycidyl ether resin as a transforming agent so as to transform a sulphydryl end group into an epoxy end group so as to finally generate the end group polythioether liquid rubber. The technology has the advantages that the polyethylene glycol diglycidyl ether resin is adopted as the transforming agent of the end group, the defects that the viscosity of a sulphydryl in traditional epoxy modification technology is high, solvents of toluene, butanone and the like are needed to perform dilution, the reaction exotherm is violent, and a side effect is easy to generate are overcome; reactions are smooth, the product quality is easy to control, the viscosity of the generated epoxy end group polythioether liquid rubber is moderate, and the stability is good; the strength of epoxy resin and the toughness and the heat resistance of polythioether rubber are reserved after the end group is transformed, so that the brittleness of the epoxy resin is improved, and the adhesive property of materials is improved.

Owner:锦西化工研究院有限公司

Anti-corrosion PE water supply pipe and preparation method thereof

The invention discloses an anti-corrosion PE water supply pipe and a preparation method thereof. The pipe is prepared from the following raw materials by weight part: 46-62 of ultra-high molecular weight polyethylene, 22-36 of polyphenylene sulfide, 12-24 of a liquid crystal polymer, 10-15 of terpene resin, 16-22 of precipitated barium sulphate, 10-15 of magnesia, 8-14 of nano-calcium titanate, 2-3 of dibasic lead phthalate, 1.5-2.5 of zinc ricinate, 1-2 of barium ricinate, 2-3 of trimethylolpropane, 1-2 of thiodiethylene glycol bis(beta-aminocrotonic acid)ester, 1.5-2.5 of stearoylbenzoylmethane, 2-4 of docosanamide, 3-5 of glycerol triacetylricinoleate, 4-8 of solid paraffin, 22-28 of filling masterbatch, 10-15 of liquid nitrile rubber, 1-2 of 1, 4-cyclohexanedimethanol dibenzoate, and 1-2 of N, N'-bis[beta-(3, 5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine. The PE pipe provided by the invention has excellent resistance to chemical corrosion, can resist erosion of a variety of chemical mediums, especially acid, alkali, salt and oil, and is free of electrochemical corrosion, has strong adaptability to the environment, does not rot or corrode after long-term use, and is durable in use.

Owner:ANHUI DINGYUAN ZHENYUN PLASTIC

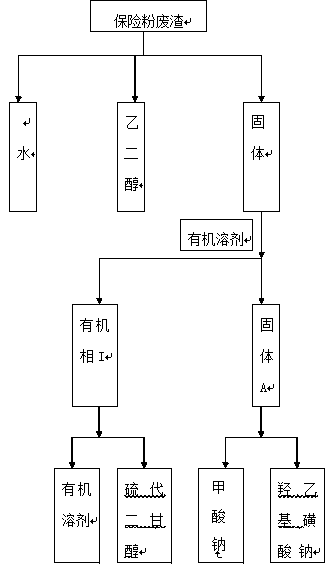

Comprehensive utilization method of sodium hydrosulfite waste residue

ActiveCN103694101AOrganic compound preparationHydroxy compound preparationSolubilityThiodiethylene Glycol

The present invention discloses a comprehensive utilization method of sodium hydrosulfite waste residue. The comprehensive utilization method comprises that: (1) a vacuum distillation method is adopted to remove water in sodium hydrosulfite waste residue and concurrently obtain ethylene glycol; (2) the remaining waste residue obtained from vacuum distillation is washed by using an organic solvent to obtain an organic phase I and a solid A; (3) according to different solubilities of the solid in the solvent, sodium isethionate and sodium formate can be obtained; and (4) the organic phase I is subjected to vacuum distillation to recover the solvent and concurrently obtain thiodiglycol. According to the invention, the waste residue produced in the sodium hydrosulfite production process is subjected to comprehensive utilization and is purified to obtain four organic products, such that enterprise waste emission is reduced while economic benefits and social benefits are brought to enterprises.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

Synthesis method of thioether phenolic antioxidant

PendingCN112279792AEasy to separate and recycleReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPropanoic acidPtru catalyst

The invention relates to a synthesis method of a thioether phenolic antioxidant, which comprises the steps of synthesizing 2,2'-thiodiethyl bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] by taking 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate and thiodiglycol as raw materials and using a supported ester exchange catalyst. The supported transesterification catalyst provided by theinvention is low in dosage, cheap, easy to obtain, efficient and easy to separate, and can be recycled for multiple times, and meanwhile, the problem that the product quality is influenced by catalystresidues in the reaction is solved.

Owner:利安隆(天津)新材料科技有限公司

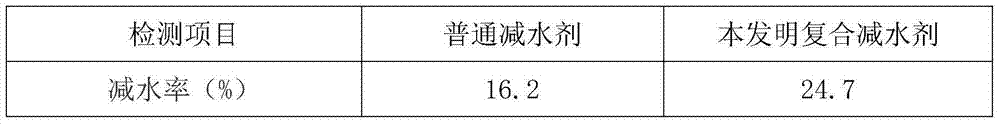

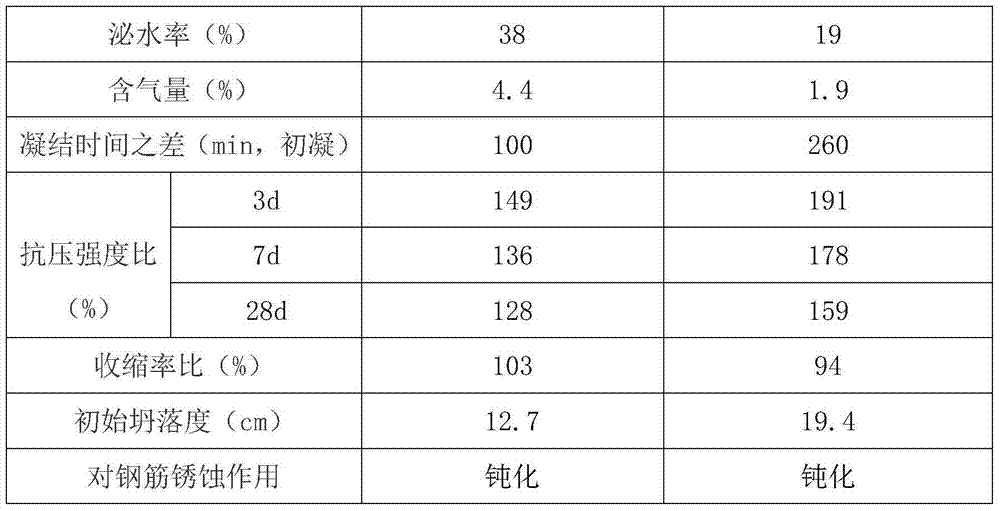

Retarding water-reducing crack arresting agent

The invention discloses a retarding water-reducing crack arresting agent. The retarding water-reducing crack arresting agent is prepared from the raw materials in parts by weight: 24-36 parts of sodium lignosulfonate, 14-26 parts of calcium propionate, 15-25 parts of bischofite powder, 48-54 parts of UNF-5 type efficient water-reducing agent, 35-45 parts of FDN-II type efficient water-reducing retarder, 10-15 parts of poly(methacrylate hyroxyehthyl ester), 10-15 parts of nano-carbon fiber, 7-11 parts of potassium dihydrogen phosphate, 4-8 parts of wormwood seed powder, 6-9 parts of sodium meta-aluminate, 10-15 parts of manganese slag, 3-6 parts of p-toluene sulfonic acid, 4-7 parts of benzotriazole, 4.5-6.5 parts of dithiodiglycolic acid, 2-4 parts of hydroxyethyl oil acid imidazoline betaine and 4-6 parts of promoter. The retarding water-reducing crack arresting agent has the characteristics of high shrinkage rate, strong crack resistance, strong toughness and strong freezing resistance, can be used for effectively reducing the shrinkage of concrete and preventing dry-shrinkage cracks, and also has the effect of efficient water reduction, and the water-reducing rate can be 15-25%. With the adoption of the retarding water-reducing crack arresting agent, the workability and the fluidity of fresh concrete are obviously improved, the bleeding and segregation phenomena do not occur after the concrete is mixed, the retarding effect is good, the slump loss is little, and the long-distance transportation is facilitated.

Owner:山东晟瑞新材料有限公司

Aqueous ink for mimeograph printing and method for mimeograph printing

A water-based ink for stencil printing, which comprises an unsaturated carboxylic acid-based water-soluble polymer and triethylene glycol. The ink preferably further comprises β-thiodiglycol as an optional component.

Owner:RISO KAGAKU CORP

Sound-absorbing cotton material and preparation method thereof

InactiveCN107778655AAchieve stableImprove antioxidant capacityPhenolic antioxidantThiodiethylene Glycol

The invention discloses a sound-absorbing cotton material and a preparation method thereof. The cotton material comprises the following components in parts by weight: 100-120 parts of polypropylene, 0.05-1 part of a hindered phenolic antioxidant, 0.05-1 part of a phosphite antioxidant, 0.02-0.5 part of an acid absorbing agent, and 0.05-1 part of a combination synergist. According to the invention,combined action of the hindered phenolic antioxidant and the phosphite antioxidant in the components can realize higher stability and oxidation resistance of the component material; and the combination synergist selects thiodiglycol distearate and / or distearyl thiodipropionate, so that synergistic effects produced between the combination synergist and the hindered phenolic antioxidant enhance theoxidation resistance of the material, and enhances the yellowing resistance of the material.

Owner:杭州宸达新材料有限公司

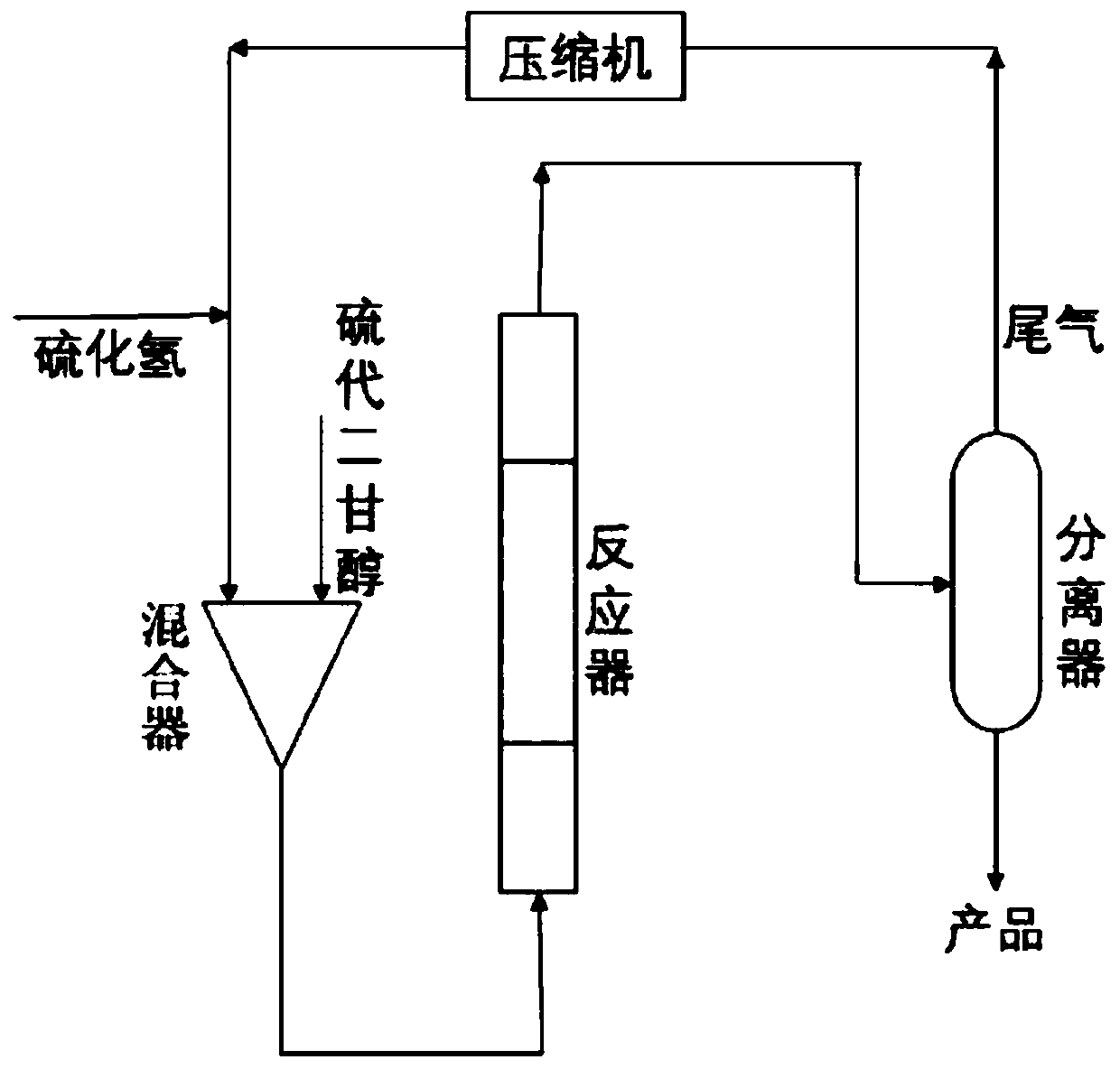

Preparation method of thiodiethanethiol

The invention belongs to the technical field of organic synthesis, and particularly relates to a preparation method of thiodiethanethiol, wherein the preparation method particularly comprises the steps: introducing thiodiethylene glycol and hydrogen sulfide into a mixer, sufficiently mixing, carrying out pressurized introduction of the thiodiethylene glycol by a pump, and introducing the hydrogensulfide under the reduced pressure by a steel cylinder; enabling the uniformly mixed raw materials to pass through a fixed bed reactor filled with a catalyst from bottom to top, and carrying out a reaction of thiodiethylene glycol with hydrogen sulfide to generate thiodiethanethiol; and enabling the reacted product and unreacted hydrogen sulfide to enter a separator, pressurizing the hydrogen sulfide from the upper part of the separator for recycling, and producing the product from the lower part of the separator. The hydrogen sulfide is adopted to replace thiourea, hydrochloric acid, alkali and other chemicals in the original process, the cost is reduced, no three wastes are generated, the fixed bed reactor is adopted, the device is a continuous reaction device, the operation is simple, the reaction is sufficient, and side reactions are reduced.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

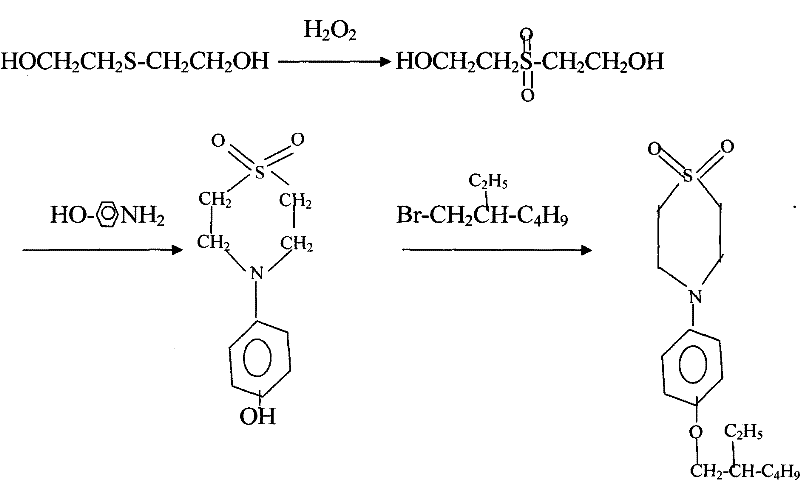

Preparation method of N-(4-(2-ethylhexyloxy) phenyl)-1, 1-dioxothiomorpholino

The invention relates to a preparation method of N-(4-(2-ethylhexyloxy) phenyl)-1, 1-dioxothiomorpholino. The method is characterized by comprising the following steps of: adding 10 parts by weight of thiodiglycol and 10 parts by weight of water to a reaction kettle, then adding 1-2 parts by weight of quaternary ammonium salt as a catalyst, adding 65-75 parts by weight of hydrogen peroxide dropwisely into the reaction kettle, after dropping, preserving the heat of the mixture and allowing it to stand for one hour so as to generate bishydroxyethylsulfone, adding p-aminophenol to conduct a condensation reaction for 3 hours, then adding bromoisooctane for a further condensation reaction for 3 hours, pouring n-heptane into a product stock solution, stirring the solution and allowing it to stand, taking out the extraction phase and evaporating the solvent to dryness, thus obtaining a finished product. Application of the method provided in the invention can prepare products with an overall yield of over 86% and effective content of more than 98%, so the method is completely applicable to large scale industrial production. With substantial economic benefit, social benefit and ecological benefit, the method provided in the invention fully meets the requirements of safety, environmental protection and high efficiency that are advocated by the nation in developing low carbon economy.

Owner:XIANTAO WYLSON CHEM

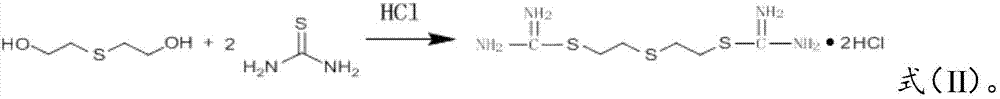

Synthesis method for bis (2-mercaptoethyl) sulfide

The invention relates to a synthesis method and production technology for bis (2-mercaptoethyl) sulfide. The method uses thiodiglycol and thiourea as raw materials to synthesize target products after two reacting steps of substitute salifying and alkaline hydrolysis, product purity is larger than 99%, total yield of the two steps is improved to more than 98% on the basis of 80% in the existing technology. The synthesis method has the advantages of being free of rigor conditions in production, smooth and safe in operation, less in three wastes, high in product purity, low in production cost and the like and is suitable for being applied to industrial production.

Owner:INSIGHT FINECHEM +1

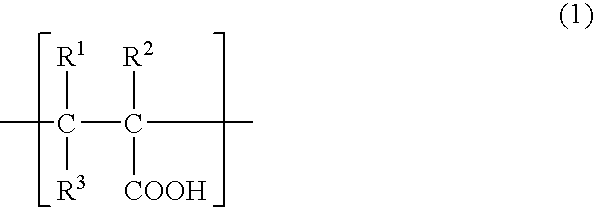

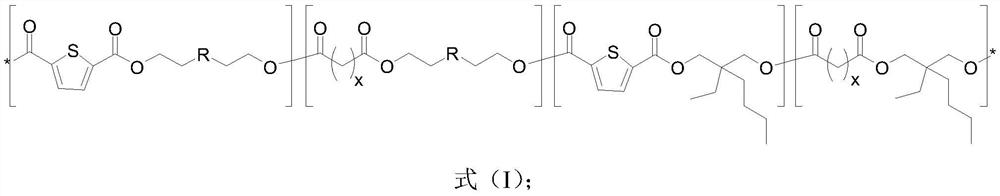

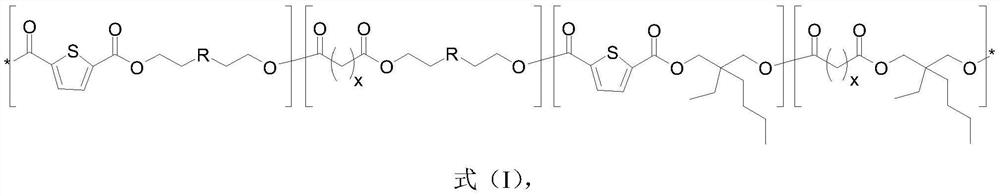

Heteroatom-containing high-barrier biodegradable copolyester and preparation method and application thereof

ActiveCN112375214APromote degradationImprove barrier propertiesBio-packagingMonocomponent copolyesters artificial filamentTextile fiberPolymer science

The invention discloses a heteroatom-containing high-barrier biodegradable copolyester and a preparation method and application thereof. The copolyester is mainly prepared by esterification and polycondensation of aliphatic diol and aliphatic dibasic acid, in the polyester synthesis process, aromatic dibasic acid, 2, 2 '-thiodiethylene glycol and a monomer 2-ethyl-2-butyl-propylene glycol containing a side chain group are introduced into a molecular chain of the polyester, the barrier property of the polymer is improved by utilizing the polarity of heteroatoms and the steric hindrance of the side chain group, meanwhile, the hydrophilic property of the copolyester is improved by introducing sulfur atoms; the obtained copolyester has excellent mechanical properties, high barrier property andbiodegradability, and can be widely applied to the fields of food preservation, agricultural film water retention, barrier bottles, textile fibers and the like.

Owner:RACHEM CHINA CO LTD +1

Synthesis method of inert end group polythioether polymer

PendingCN112430325AImprove temperature resistanceFix compatibility issuesPolymer sciencePtru catalyst

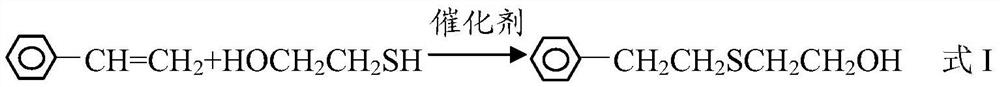

The invention discloses a synthesis method of an inert end group polythioether polymer, which comprises the following steps of: (1) mixing raw materials styrene and mercaptoethanol according to a molar ratio of 1: (1-1.3), adding a catalyst A, reacting under heating conditions to generate a 1-hydroxy-3-thia-5-phenyl pentane crude product, and rectifying the crude product to obtain 1-hydroxy- 3-thia-5-phenyl pentane; (2) mixing the 1-hydroxy-3-thia-5-phenyl pentane obtained by rectification with thiodiethylene glycol according to a molar ratio of 1: (3.0-4.5), adding a catalyst B, and then heating to carry out a hydroxyl dehydration polycondensation reaction; and (3) after solvent extraction, removing low-boiling-point substances under a vacuum heating condition to obtain the inert end group polythioether polymer. The problem that an existing plasticizer for a polythioether sealant is poor in temperature resistance, poor in compatibility and the like is solved, the comprehensive performance of the sealant is improved, and the used raw materials are cheap, easy to obtain and stable in reaction.

Owner:锦西化工研究院有限公司

A kind of anti-corrosion coating and preparation method thereof

ActiveCN107955539BImprove corrosion resistanceImprove impact resistanceAnti-corrosive paintsLignin material coatingsPhosphoric Acid EstersThiodiethylene Glycol

The invention discloses zinc-aluminum coating anti-corrosion paint. The paint is composed of two-components of A and B in a mass ratio of 3:1, wherein a component A comprises the following raw materials: zinc aluminum alloy powder, nano-silica, sodium lignosulphonate, benzotriazole, thiodiethylene glycol, amino trimethylene phosphonic acid, sodium carboxymethylcellulose and deionized water; a component B comprises the following raw materials: zircinium fluoride, gamma-aptes, inositol hexaphosphate, cellaburate, ethanol and the deionized water, wherein the zinc aluminum alloy powder is composedof Zn, Al, Ti, Ni, Mg and Mn. According to the zinc-aluminum coating anti-corrosion paint and the preparation method thereof, excellent corrosion resistance and impact resistance are acquired and a deficiency that the production process of triphenylphosphine in the prior art has potential dangers on environmental safety and operators is compensated by means of adjusting mass ratio of each component of the zinc aluminum alloy powder on the basis of replacing the triphenylphosphine with the amino trimethylene phosphonic acid and the sodium carboxymethylcellulose.

Owner:WUXI YIBO COATING

Zinc-aluminum coating anti-corrosion paint and preparation method thereof

ActiveCN107955539AImprove corrosion resistanceImprove impact resistanceAnti-corrosive paintsLignin material coatingsAlloyThiodiethylene Glycol

The invention discloses zinc-aluminum coating anti-corrosion paint. The paint is composed of two-components of A and B in a mass ratio of 3:1, wherein a component A comprises the following raw materials: zinc aluminum alloy powder, nano-silica, sodium lignosulphonate, benzotriazole, thiodiethylene glycol, amino trimethylene phosphonic acid, sodium carboxymethylcellulose and deionized water; a component B comprises the following raw materials: zircinium fluoride, gamma-aptes, inositol hexaphosphate, cellaburate, ethanol and the deionized water, wherein the zinc aluminum alloy powder is composedof Zn, Al, Ti, Ni, Mg and Mn. According to the zinc-aluminum coating anti-corrosion paint and the preparation method thereof, excellent corrosion resistance and impact resistance are acquired and a deficiency that the production process of triphenylphosphine in the prior art has potential dangers on environmental safety and operators is compensated by means of adjusting mass ratio of each component of the zinc aluminum alloy powder on the basis of replacing the triphenylphosphine with the amino trimethylene phosphonic acid and the sodium carboxymethylcellulose.

Owner:湖州达立智能设备制造有限公司

Method for continuously synthesizing thiodiglycol

ActiveCN105399651AGuaranteed gas phase mixingEasy to removeSulfide preparationThiodiethylene GlycolPhotochemistry

The invention discloses a method for continuously synthesizing thiodiglycol. The method is based on a tubular reactor, ethylene oxide and sulfureted hydrogen serve as raw materials, the reaction is performed at 0-40 DEG C, and thiodiglycol is synthesized by liquid phase catalysis at normal temperature and normal pressure. The operation is simple, the conditions are mild, the method is green, environmentally friendly and free of three wastes, and a catalyst can be reused; the reaction standing time is short, no back-mixing occurs, no by-product is generated, slightly excessive ethylene oxide can be recycled, the production cycle is shortened, and the production cost is reduced. The tubular reactor can react continuously, the product purity can reach 98-99.5%, and the yield of thiodiglycol can reach 92-99% according to hydrogen sulfide.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Physiologically active agents containing vicinal dithioglycols and use thereof in various branches of economy

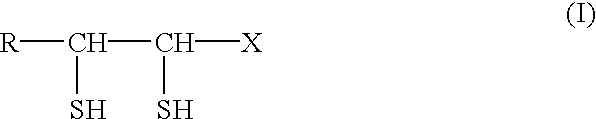

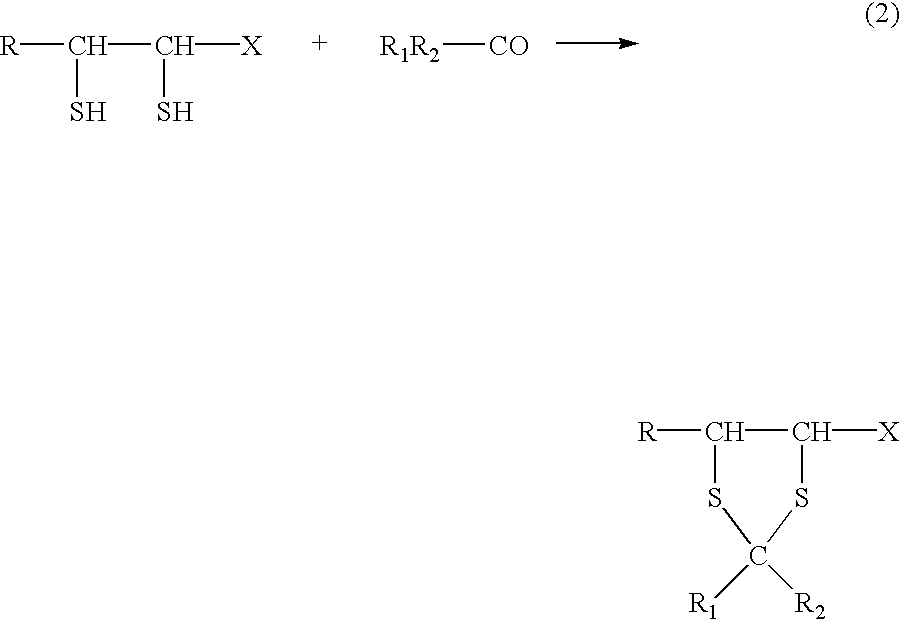

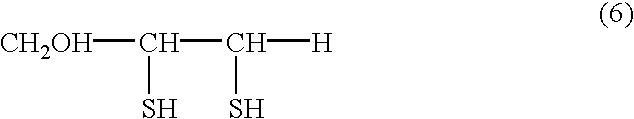

InactiveUS7229637B2Extended shelf lifeImprove immunityCosmetic preparationsOrganic active ingredientsFood additiveActive agent

The invention relates to the food and medical industries, medical cosmetics, dermatology, agriculture and the mixed feed industry. According to the invention vicinal dithioglycole (common formula RCH(SH)CH(SH)R−1 (I)) is used as a food additive, a food product, physiologically-active substances and active ingredients of forage additives and of forage, in cosmetic and / or dermatological and skin-therapeutic remedies. The invention comprises methods for producing such additives, products and remedies. The substance of formula (I) stimulates physiological processes, increases human and animal immunity, inhibits undesirable process in organisms and food products, produces curative and preventive action of skin, hair and nails and after vicinal dithioglycole is administered the intoxication effect of alcohol consumption known as hang-over is completely remored.

Owner:ZENOVICH SERGEI MIKHAILOVICH +1

Oxidation resistance reinforcing strip metallic aluminum pigment

InactiveCN106084293AGood dispersionImprove corrosion resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsMetallic aluminumPlastic materials

The invention discloses an oxidation resistance reinforcing strip metallic aluminum pigment. The pigment is prepared from the following raw materials in parts by weight: 70-75 parts of flaky aluminum powder, 14-15 parts of methacryloxy propyl trimethoxyl silane, proper amount of absolute ethyl alcohol, 28-30 parts of trimethylolpropane triacrylate, 1-1.2 parts of acrylic acid, 0.09-0.1 part of azodiisobutyronitrile, 1.75-1.9 parts of polyvinylpyrrolidone, 2.5-3 parts of N,N-ethylidene bisricinoleamide, 17-19 parts of polypropylene, 1.5-2 parts of antioxidant 1010, 3-3.5 parts of thiodiglycol, 2-2.5 parts of lauric acid and 0.05-0.06 part of p-toluenesulfonic acid. The pigment can obviously reinforce the oxidation resistance of the products, can be uniformly dispersed in plastic materials and has high storage stability by preparing an antioxidant through reaction between thiodiglycol and lauric acid, mixing the antioxidant with the antioxidant 1010, then internally mixing the mixture with polypropylene and then adding the mixture to the products.

Owner:HEFEI SUNRISE PIGMENTS

A kind of synthetic method of epoxy-terminated polythioether liquid rubber

The invention discloses a synthetic method for epoxy end group polythioether liquid rubber. The method comprises the following steps: synthesizing sulphydryl end group polythioether liquid rubber by using thiodiglycol, hydroxyethyl-2-hydroxypropyl thioether and the like as main monomers; then using polyethylene glycol diglycidyl ether resin as a transforming agent so as to transform a sulphydryl end group into an epoxy end group so as to finally generate the end group polythioether liquid rubber. The technology has the advantages that the polyethylene glycol diglycidyl ether resin is adopted as the transforming agent of the end group, the defects that the viscosity of a sulphydryl in traditional epoxy modification technology is high, solvents of toluene, butanone and the like are needed to perform dilution, the reaction exotherm is violent, and a side effect is easy to generate are overcome; reactions are smooth, the product quality is easy to control, the viscosity of the generated epoxy end group polythioether liquid rubber is moderate, and the stability is good; the strength of epoxy resin and the toughness and the heat resistance of polythioether rubber are reserved after the end group is transformed, so that the brittleness of the epoxy resin is improved, and the adhesive property of materials is improved.

Owner:锦西化工研究院有限公司

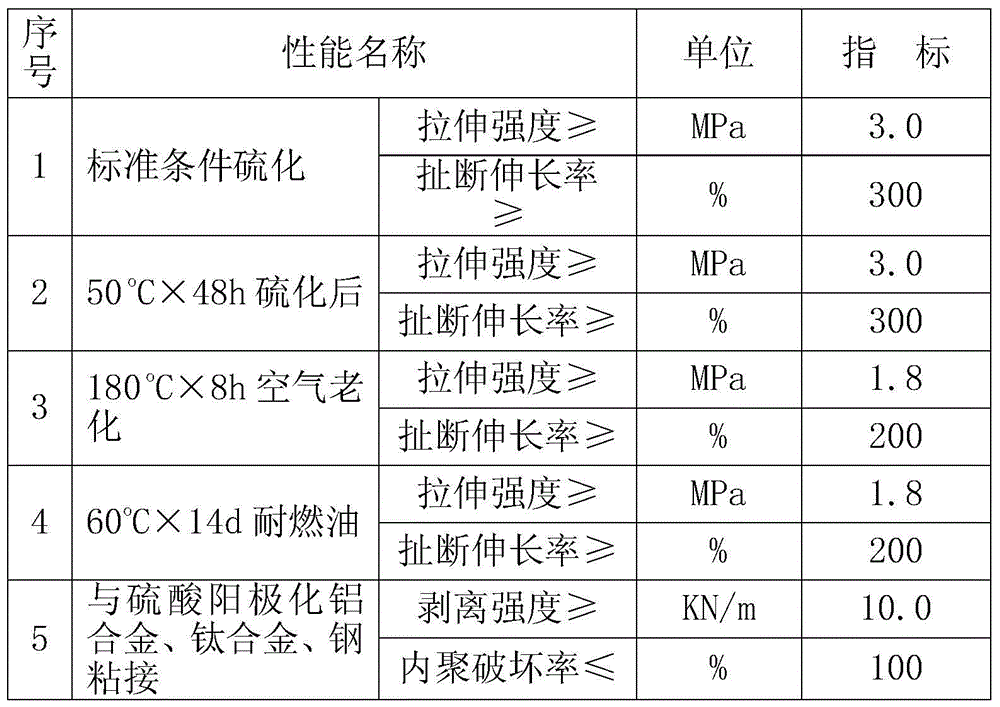

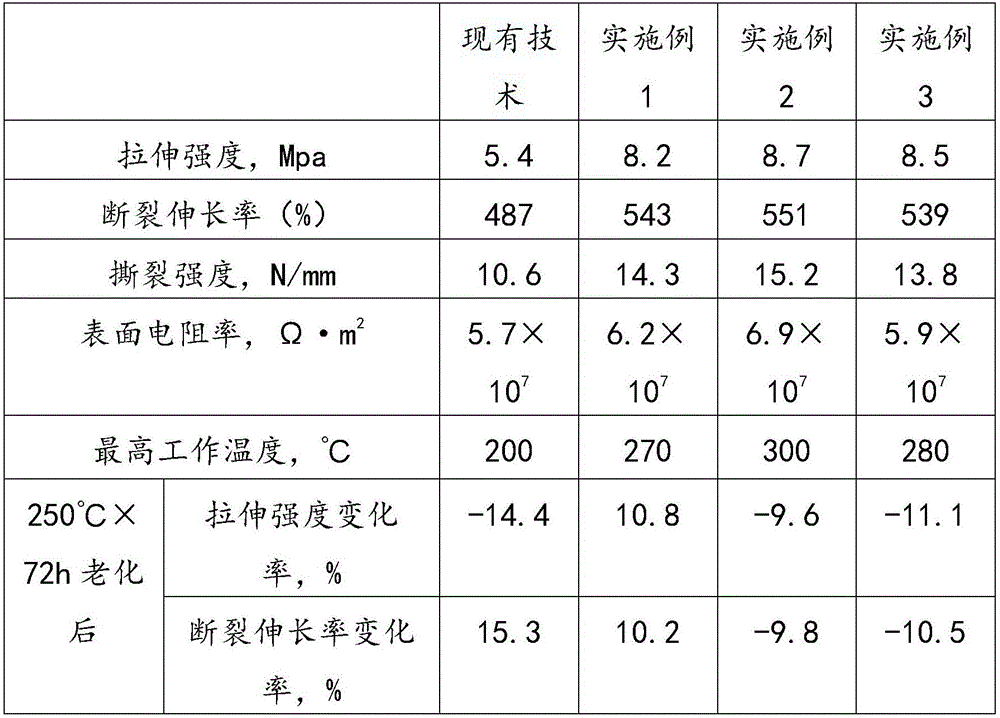

High temperature and aging resistant silicone rubber material for battery heat insulation film frame and preparation method thereof

ActiveCN106589948BLow thermal conductivityIncrease high temperature use temperaturePolymer sciencePicrite basalt

The invention discloses a high-temperature-resistant and ageing-resistant silicone rubber material for a battery heat isolation film frame and a preparing method of the high-temperature-resistant and ageing-resistant silicone rubber material. The high-temperature-resistant and ageing-resistant silicone rubber material is prepared by following raw materials including, by weight, 44-57 parts of phenylene silicone rubber, 13-19 parts of pentaerythritol ester of hydrogenated rosin, 2-4 parts of methyl 2-benzoylbenzoate, 14-22 parts of hollow nano silicon dioxide microspheres, 4-6 parts of iron oxide, 3-5 parts of tungsten oxide, 10-15 parts of glass wool waste, 12-18 parts of tetra-(2-ethylhexyl)pyromellitate, 2-3 parts of 2,4-DCBP, 5-9 parts of hydroxyl-fluoro silicone oil, 4-6 parts of zinc carbonate, 11-17 parts of picrite basalt, 1-3 parts of dithiodiglycol dimyristictate, 1-2 parts of an accelerant DPTT and 1-2 parts of an anti-aging agent KY-405. The hollow nano silicon dioxide microspheres and the like are adopted as filler so that the material heat conduction coefficient can be reduced and meanwhile the materials are reinforced. The iron oxide, the tungsten oxide and the like serve as an oxidizing agent to be matched with pentaerythritol ester of hydrogenated rosin to be used, the high-temperature using temperature of the materials can be increased, the long-term using temperature can reach 250-300 DEG C, the ageing resistance of the materials can be improved as well, and the service life of the materials is greatly prolonged.

Owner:DONGGUAN GUI XIANG INSULATION MATERIAL CO LTD

A method for synthesizing 9-hydroxyl-4-oxa-7-thianonene

ActiveCN106631938BRaw materials are cheap and easy to getSuitable for industrial productionSulfide preparationThiodiethylene GlycolChemistry

The invention relates to a method for synthesizing 9-hydroxy-4-oxa-7-thianonene. The method is characterized by comprising the following steps: A, adding solid caustic soda and thiodiglyco into a reaction kettle, slowly raising the temperature to 30 to 50DEG C, and reacting for 1 to 3 hours to generate thiodiglycolic sodium; B, adding chloropropene into a metering tank, then charging materials into the reaction kettle, and dropwise adding the chloropropene at the temperature of 30 to 50DEG C for 1 to 4 hours; after adding, raising the temperature to 80 to 130DEG C, reacting for 1 to 3 hours, and cooling a reaction solution; C, carrying out acidizing, filtering and desalting treatment on the cooled reaction solution to obtain a crude product of 9-hydroxy-4-oxa-7-thianonene; then rectifying, and collecting fractions to obtain colorless or pale yellow transparent 9-hydroxy-4-oxa-7-thianonene. The method disclosed by the invention has the advantages that the raw materials are low in price and easily obtained, and the yield of a product is high; the method is suitable for industrially producing the 9-hydroxy-4-oxa-7-thianonene.

Owner:锦西化工研究院有限公司

Strong anti-aging cable sheathing material and preparation method thereof

The invention provides a strong anti-aging cable sheathing material and a preparation method thereof, and relates to the technical field of cable sheath production. The cable sheathing material is prepared from the following raw materials, in parts by weight: 45-55 parts of silicone rubber, 20-25 parts of cis-polybutadiene, 10-15 parts of acrylate rubber, 8-12 parts of distearyl pentaerythrityl diphosphite, 2-3 parts of nano cerium dioxide, 0.6-1.0 part of a cross-linking agent, 6-8 parts of 2,6-tert-butyl-4-methylphenol, 3-5 parts of dithiodinglycol distearictate, 5-7 parts of diaryl p-phenylenediamine, 2-4 parts of diallyl phthalate, 2-4 parts of a vulcanizing agent, and 2-4 parts of a dispersing agent. The method provided by the invention overcomes the deficiencies in the prior art, andcan effectively improve the aging resistance of the sheathing material and prevent a cable from being aged under influence of external light, heat and oxygen, and the cable sheath has excellent overall performance, high safety and a long service life, and is suitable for promotion.

Owner:安徽上华电缆有限公司

A kind of preparation method of thiophenol compound antioxidant product

The invention relates to a preparation method of a thiophenol compound antioxidant product, relating to the technical field of preparation of antioxidant products. A process technical method of the thiophenol compound antioxidant product comprises the following steps of: taking 3, 5-methyl ester and thiodiglycol as raw materials, performing ester exchange reaction under the actions of a catalyst and a color blocking agent, and generating a reaction product mixed solution containing 2, 2'-thiodiethyl bis(3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate by continuously removing a byproduct, namely methanol during the reaction process; adding an appropriate amount of phosphite ester-like compound into the reaction product mixed solution, and generating a new phosphite ester-like compound by secondary ester exchange reaction; and selecting a recrystallization solvent, performing recrystallization and refining on the reaction product mixed solution, and performing solid-liquid separation to obtain a while granular crystal product.

Owner:宁波福天新材料科技有限公司

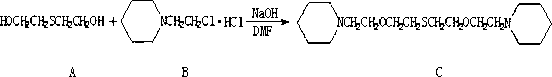

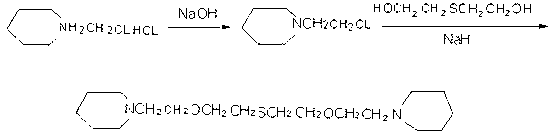

Preparation method of 1,11-di(1-bispiperdine)-3,9-dioxo-6-thia-hendecane

ActiveCN103288778AThe process steps are simpleThe post-processing process is simpleOrganic chemistryN dimethylformamideDistillation

The invention provides a preparation method of 1,11-di(1-bispiperdine)-3,9-dioxo-6-thia-hendecane. The preparation method comprises the following steps of: (1) adding N,N-dimethylformamide and sodium hydroxide to a reaction container, adding thiodiglycol under stirring at a room temperature, wherein the mol ratio of the thiodiglycol to the sodium hydroxide is 1: (4-12); adding N-chloroethyl piperidine hydrochloride in batches in 0.5-1 hour, wherein the mol ratio of the thiodiglycol to the N-chloroethyl piperidine hydrochloride is 1: (2-4); and reacting for 3-8 hours at a reaction temperature in the range from 40 to 90 DEG C; (2) cooling after the reaction is completed until the temperature reaches the room temperature, adding water and stirring, extracting by using a solvent, washing with water, drying and concentrating, and then performing reduced pressure distillation, thereby obtaining the 1,11-di(1-bispiperdine)-3,9-dioxo-6-thia-hendecane. The preparation method provided by the invention is simple in steps, short in reaction time, simple in after-treatment process, high in yield, low in cost, and convenient for industrial production.

Owner:沈阳感光化工研究院有限公司

A kind of method for continuously synthesizing thiodiglycol

The invention discloses a method for continuously synthesizing thiodiglycol. The method is based on a tubular reactor, ethylene oxide and sulfureted hydrogen serve as raw materials, the reaction is performed at 0-40 DEG C, and thiodiglycol is synthesized by liquid phase catalysis at normal temperature and normal pressure. The operation is simple, the conditions are mild, the method is green, environmentally friendly and free of three wastes, and a catalyst can be reused; the reaction standing time is short, no back-mixing occurs, no by-product is generated, slightly excessive ethylene oxide can be recycled, the production cycle is shortened, and the production cost is reduced. The tubular reactor can react continuously, the product purity can reach 98-99.5%, and the yield of thiodiglycol can reach 92-99% according to hydrogen sulfide.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com