High temperature and aging resistant silicone rubber material for battery heat insulation film frame and preparation method thereof

A technology of heat insulation film and high temperature resistance, which is applied in the field of silicone rubber materials and its preparation, can solve the problems of high temperature resistance and aging resistance that cannot meet the market demand, achieve excellent high temperature resistance, reduce thermal conductivity, and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

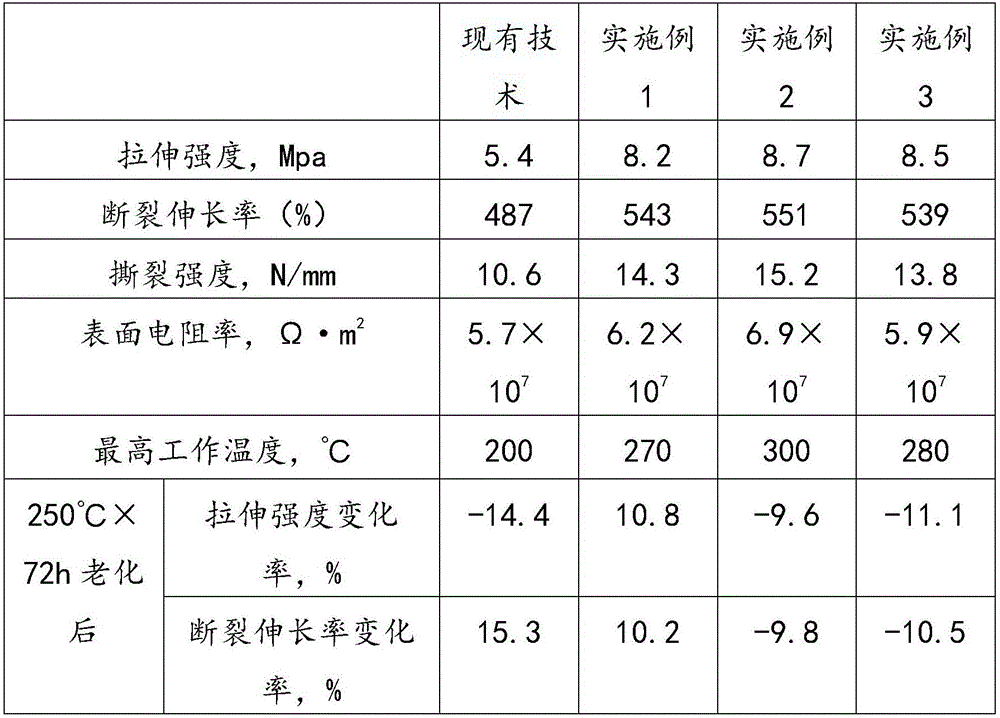

Examples

Embodiment 1

[0015] A high-temperature-resistant and aging-resistant silicone rubber material for a frame of a battery insulating film, which is made of the following raw materials in weight (kg): phenylene silicone rubber 44, hydrogenated rosin pentaerythritol ester 13, methyl o-benzoyl benzoate 2, hollow Nano silica microspheres 14, iron oxide 4, tungsten oxide 3, glass wool waste 10, tetraisooctyl pyromellitic acid 12, 2,4-dichlorobenzoyl peroxide 2, hydroxyfluorosilicone oil 5, carbonic acid Zinc 4, Kulanyan 11, thiodiglycol dimyristate 1, accelerator DPTT 1, antioxidant KY-405 1.

[0016] A method for preparing a high temperature resistant and aging resistant silicone rubber material for a frame of a battery heat insulating film, comprising the following steps:

[0017] (1) Mix the glass wool waste and the bitter rock evenly, pulverize, pass through a 200-mesh sieve, and set aside for use;

[0018] (2) adding phenylene silicone rubber, hydrogenated rosin pentaerythritol ester, and te...

Embodiment 2

[0021] A high-temperature-resistant and aging-resistant silicone rubber material for a frame of a battery insulating film, which is made of the following raw materials in weight (kg): 50 phenylene silicone rubber, 15 hydrogenated rosin pentaerythritol ester, 3 methyl o-benzoyl benzoate, 3 hollow Nano silica microspheres 18, iron oxide 5, tungsten oxide 4, glass wool waste 12, tetraisooctyl pyromellitic acid 15, 2,4-dichlorobenzoyl peroxide 2.5, hydroxyfluorosilicone oil 7, carbonic acid Zinc 5, Kulanyan 14, thiodiglycol dimyristate 2, accelerator DPTT 1.5, antioxidant KY-4051.5.

[0022] A method for preparing a high temperature resistant and aging resistant silicone rubber material for a frame of a battery heat insulating film, comprising the following steps:

[0023] (1) Mix the glass wool waste and the bitter rock evenly, pulverize, pass through a 220-mesh sieve, and set aside for use;

[0024] (2) adding phenylene silicone rubber, hydrogenated rosin pentaerythritol ester,...

Embodiment 3

[0027] A high-temperature-resistant and aging-resistant silicone rubber material for a frame of a battery insulation film, which is made of the following raw materials in weight (kg): phenylene silicone rubber 57, hydrogenated rosin pentaerythritol ester 19, methyl o-benzoyl benzoate 4, hollow Nano-silica microspheres 22, iron oxide 6, tungsten oxide 5, glass wool waste 15, tetraisooctyl pyromellitic acid 18, 2,4-dichlorobenzoyl peroxide 3, hydroxyfluorosilicone oil 9, carbonic acid Zinc 6, Kulanyan 17, Thiodiglycol Dimyristate 3, Accelerator DPTT 2, Anti-aging agent KY-405 2.

[0028] A method for preparing a high temperature resistant and aging resistant silicone rubber material for a frame of a battery heat insulating film, comprising the following steps:

[0029] (1) Mix the glass wool waste and the bitter rock evenly, pulverize, pass through a 250-mesh sieve, and set aside for use;

[0030] (2) adding phenylene silicone rubber, hydrogenated rosin pentaerythritol ester, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com