Synthesis method for bis (2-mercaptoethyl) sulfide

A technology of dimercaptoethyl sulfide and its synthetic method, which is applied in the fields of sulfide preparation and organic chemistry, can solve the problems of low product purity, high processing cost, and large amount of three wastes, and achieve high product purity and environmental protection. The effect of being friendly and reducing the amount of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

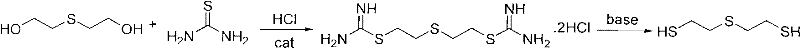

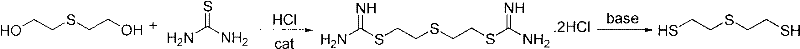

Method used

Image

Examples

Embodiment 1

[0022] Synthesis of isosulfuronium salts

[0023] In a 2L four-necked flask, add 334.4g (4.4mol) thiourea and 573.6g (4.4mol, 28%) industrial hydrochloric acid, when the temperature rises to 32 DEG C, the solid dissolves completely, and the heating is stopped, and 244.0g (2.0 mol) of thiodiethylene glycol, after the dropwise addition, add 25g of zinc chloride to the system, slowly raise the temperature to 90-100°C (about 40min), keep the temperature for 4 hours, stop heating, and cool the reaction solution to 30- 35°C, directly used in subsequent reactions.

[0024] Synthesis of Bismercaptosulfide

[0025] Add 17.3g of tetrabutylammonium bromide to the above-mentioned isosulfuronium salt solution, stir and mix well, add 740g of diammonium hydrogen phosphate / ammonium phosphate buffer solution (pH=11.0) dropwise, and finish dropping in about 30 minutes, pay attention to control the reaction The pH value of the system is ~10, and the temperature is raised to 60-65°C, and the re...

Embodiment 2

[0027] Synthesis of isosulfuronium salts

[0028] Add 334.4g (4.4mol) thiourea and 573.6g (4.4mol, 28%) industrial hydrochloric acid in a 2L four-necked flask, when the temperature rises to 32°C, the solid dissolves completely, stop heating, and add 244.0g (2.0mol) dropwise within 20min ) of thiodiethylene glycol, after the dropwise addition, 30g of ferric chloride was added to the system, the temperature was slowly raised to 90-100°C (about 40min), and the temperature was kept for 7.5 hours, then the heating was stopped, and the temperature of the reaction solution was lowered to 30-35 °C, used directly in subsequent reactions.

[0029] Synthesis of Dimercaptosulfide (DMDS)

[0030] Add 17.3g of tetrabutylammonium bromide to the above-mentioned isosulfuronium salt solution, stir and mix well, add 740g of diammonium hydrogen phosphate / ammonium phosphate buffer solution (pH=11.0) dropwise, and finish dropping in about 30 minutes, pay attention to control the reaction The pH o...

Embodiment 3

[0032] Synthesis of isosulfuronium salts

[0033] Add 334.4g (4.4mol) thiourea and 573.6g (4.4mol, 28%) industrial hydrochloric acid in a 2L four-necked flask, when the temperature rises to 32°C, the solid dissolves completely, stop heating, and add 244.0g (2.0mol) dropwise within 20min ) of thiodiethylene glycol, after the dropwise addition, add 30g of zinc chloride to the system, slowly raise the temperature to 70-80°C (about 25min), keep the temperature for 8h, stop heating, and cool the reaction solution to 30-35°C , used directly in subsequent reactions.

[0034] Synthesis of Dimercaptosulfide (DMDS)

[0035] Add 17.3g tetrabutylammonium bromide to the solution of above-mentioned isosulfuronium salt, stir and mix, dropwise add 712g ammonium carbonate aqueous solution (wt 50%), drip in about 30min, pay attention to controlling the exhaust rate in the early stage of reaction, control The pH of the reaction system is ~10, and the temperature is raised to 60-65°C, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com