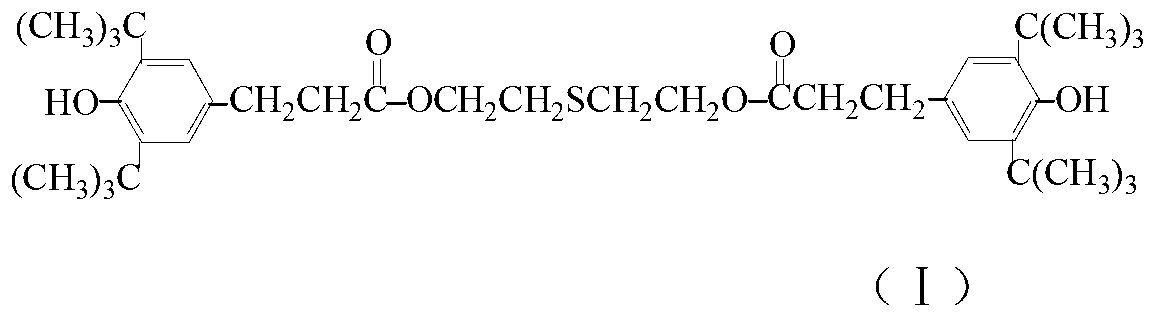

Preparation method of thiophenol compound antioxidant product

A compound and antioxidant technology, applied in the field of preparation of thiophenol compound antioxidant products, can solve problems such as low yield, non-universal problems, low product yield, etc., achieve high yield, reduce dissolution loss, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

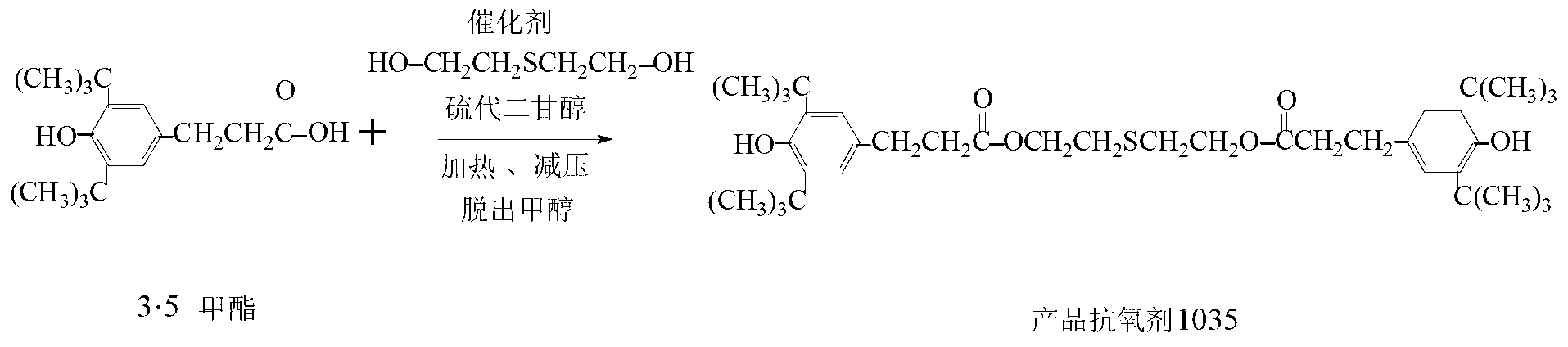

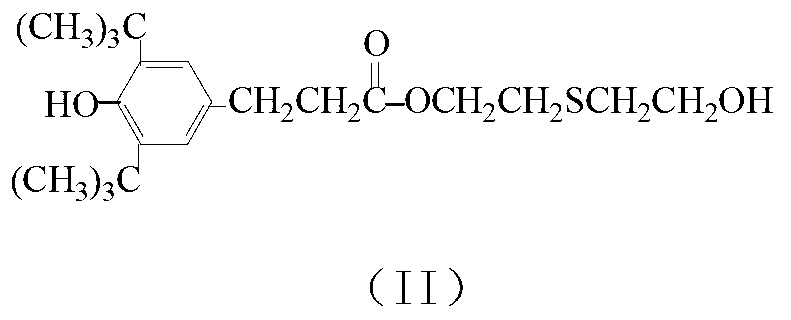

Method used

Image

Examples

Embodiment 1

[0038] Add 120g of 3,5-methyl ester, 29g of thiodiethylene glycol, 1.2g of dibutyltin oxide, 0.4g of 2-[1- (2-Hydroxy-3,5-di-t-pentylphenyl)-ethyl]-4,6-dit-pentyl phenyl acrylate; under nitrogen protection, heat up to 70-85°C and start stirring; heat up to 130-135°C, heat preservation reaction for 0.5h, intensify stirring to fully mix the reaction materials, depressurize until the pressure in the kettle is -0.04Mpa to -0.06Mpa, heat preservation reaction at 130-135°C for 2.5h; heat up to 160°C, the pressure in the kettle -0.05Mpa to -0.06Mpa, heat preservation reaction for 1.0h; heat up to 170°C, pressure inside the kettle is -0.085Mpa to -0.095Mpa, heat preservation reaction for 1.5h; cool down the temperature in the reaction kettle to 125-130°C, and use nitrogen Restore the pressure in the kettle to 0.0Mpa, press 1.0g of triethyl phosphite into the reaction kettle, keep the temperature at 140-145°C for 1.0h, cool down to 50-60°C, and obtain the antioxidant 1035 reaction pro...

Embodiment 2

[0040] Add 120g of 3,5-methyl ester, 25g of thiodiethylene glycol, 0.6g of dibutyltin oxide, 0.5g of 2-tert-butyl -6-(3-tert-butyl-2-hydroxy-5-methylphenyl)-4-methylphenol acrylate; under nitrogen protection, heat up to 70-85°C and start stirring; heat up to 130-135°C , heat preservation reaction for 0.5h, intensify stirring to fully mix the reaction materials, depressurize until the pressure in the kettle is -0.04Mpa to -0.06Mpa, heat preservation reaction at 130-135°C for 1.5h; heat up to 150°C, and the pressure in the kettle is -0.05Mpa to -0.06Mpa, keep warm for 2.0h; heat up to 170°C, the pressure inside the kettle is -0.085Mpa to -0.095Mpa, keep warm for 2.0h; Return to 0.0Mpa, press 1.2g of trimethyl phosphite into the reaction kettle, keep warm at 140-145°C for 1.0h, cool down to 50-60°C to obtain the reaction product containing antioxidant 1035 liquid. Add 300g (including: 245g ethanol, 18g ethylene glycol, 37g water) recrystallization solvent into the reaction kett...

Embodiment 3

[0042]Add 120g of 3,5-methyl ester, 28g of thiodiethylene glycol, 1.0g of dibutyltin oxide, 0.4g of 2-[1- (2-Hydroxy-3,5-di-tert-butylphenyl)-methyl]-4,6-di-tert-butylphenyl acrylate; under nitrogen protection, heat up to 70-85°C and start stirring; heat up to 130-135°C, heat preservation reaction for 2.0h, strengthen stirring to mix the reaction materials fully, reduce pressure until the pressure in the kettle is -0.04Mpa to -0.06Mpa, heat preservation reaction at 130-135°C for 2.0h; heat up to 155°C, the pressure in the kettle -0.05Mpa to -0.06Mpa, heat preservation reaction for 1.5h; heat up to 170°C, pressure inside the kettle is -0.085Mpa to -0.095Mpa, heat preservation reaction for 1.0h; cool down the temperature inside the reaction kettle to 125-130°C, while using nitrogen Restore the pressure in the kettle to 0.0Mpa, press 0.4g of triethyl phosphite into the reaction kettle, keep the temperature at 140-145°C for 0.5h, and cool down to 50-60°C to obtain the antioxidant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com