Synthesis method of inert end group polythioether polymer

A technology of terminal polythioether and synthesis method, which is applied in the field of synthesis of inert terminal polythioether polymers, can solve the problems of poor temperature resistance, poor compatibility and easy precipitation, etc., to improve comprehensive performance, reaction Stable and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

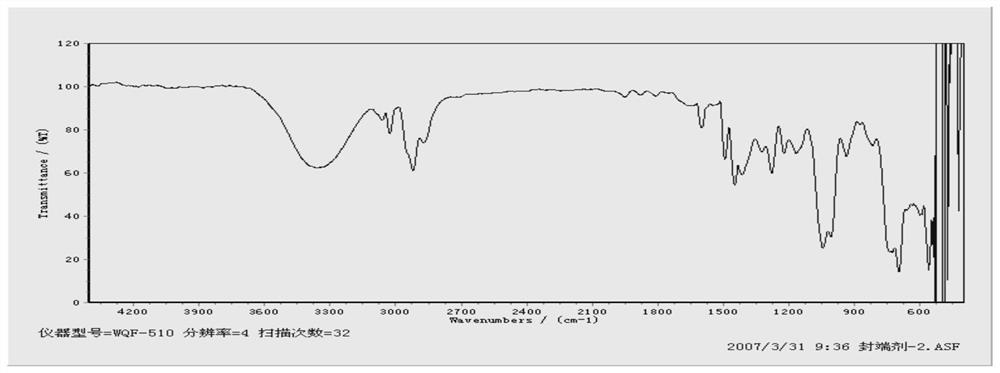

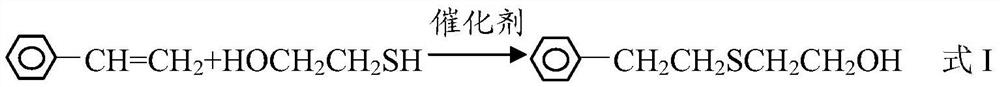

[0025] In a 500ml three-necked flask equipped with a stirrer and a thermometer, add 150 g of mercaptoethanol (industrial product, purity 99%), 2.25 g of tert-butyl peroxybenzoate, 0.23 g of tetramethylguanidine, and dropwise add styrene (industrial product , purity 99%) 174g, heat up to 80°C ± 2°C, react for 7 hours, control the crude product kettle temperature at 130°C ~ 160°C, and rectify below the residual pressure of 2.66kPa to obtain 1-hydroxyl-3-thia-5 -Phenylpentane, yellowish in color and 98% pure, figure 1 It is the infrared spectrum of 1-hydroxy-3-thia-5-phenylpentane.

[0026] In a 500ml three-necked flask equipped with a stirrer and a thermometer, add thiodiglycol (industrial product, purity 98%) 150g, 1-hydroxyl-3-thia-5-phenylpentane (purity 98%) 63.8 g, triphenyl phosphite 2.25, heat up to 160°C ± 2°C, after 8 hours of reaction, the reaction product needs to be extracted by solvent to remove unreacted small molecules, and the residual pressure is below 2.66kPa ...

Embodiment 2

[0028] 1-Hydroxy-3-thia-5-phenylpentane was synthesized by the method in Example 1.

[0029] In a 500ml three-necked flask equipped with a stirrer and a thermometer, add thiodiglycol (industrial product, purity 98%) 150g, 1-hydroxy-3-thia-5-phenylpentane (purity 98%) 54.7 g, triphenyl phosphite 2.25, heat up to 125°C ± 2°C, after 9 hours of reaction, the reaction product needs to be extracted by solvent to remove unreacted small molecules, and the residual pressure is below 2.66kPa to carry out vacuum reaction for 2h to obtain the inert end Polythioether-based polymer, light yellow in color, 0.1% moisture, 0.15 mg acid value, 1.17 g / cm3 relative density, and 660 (25°C) mPa·s viscosity.

Embodiment 3

[0031] 1-Hydroxy-3-thia-5-phenylpentane was synthesized by the method in Example 1.

[0032] In a 500ml three-necked flask equipped with a stirrer and a thermometer, add thiodiglycol (industrial product, purity 98%) 150g, 1-hydroxyl-3-thia-5-phenylpentane (purity 98%) 74.1 g, triphenyl phosphite 2.25, heat up to 180°C±2°C, after 6 hours of reaction, the reaction product needs to be extracted by solvent to remove unreacted small molecules, and the residual pressure is below 2.66kPa for vacuum reaction for 2h to obtain the inert end based polythioether polymers. The color is light yellow, the water content is 0.1%, the acid value is 0.15 mg, the relative density is 1.17 g / cm3, and the viscosity is 350 (25°C) mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com