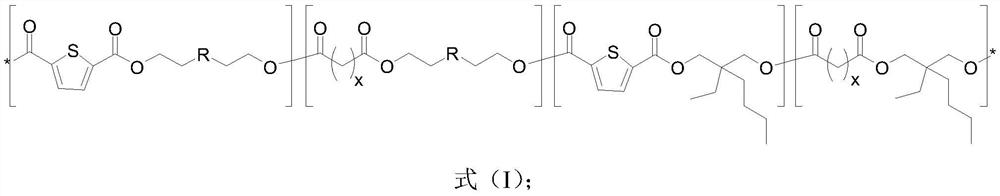

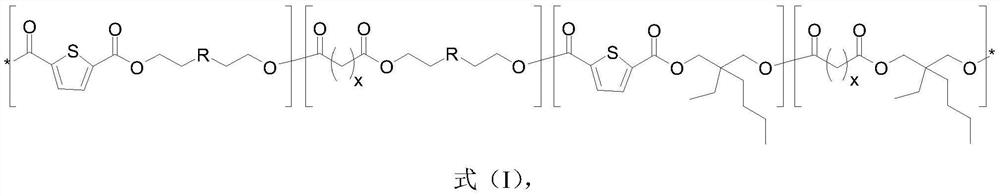

Heteroatom-containing high-barrier biodegradable copolyester and preparation method and application thereof

A biodegradable, high-barrier technology, applied in the direction of single-component copolyester artificial filaments, etc., can solve the problems of no degradation performance, poor water vapor barrier property, and large environmental hazards, and achieve good biodegradability and degradation rate Accelerates and blocks the effect with remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]0.7mol thiophenedicarboxylic acid, 0.3mol adipic acid, 1mol butanediol, 0.4mol 2,2'-thiodiglycol, 0.1mol 2-ethyl-2-butyl-propanediol, 0.15mmol n-butyl titanate The ester was added into the reaction kettle under nitrogen protection, the temperature was raised to 220°C with stirring, and the reaction was carried out for 4 hours. Then the temperature was raised to 230° C., pre-condensed under low vacuum for 1 hour, and then 0.2 mmol of n-butyl titanate was added. The temperature was raised to 245° C., the vacuum was gradually evacuated to 50 Pa, and the polycondensation was carried out for 3 hours to obtain the product. The intrinsic viscosity of product is 1.32dL / g, and terminal carboxyl group is 24mol / t, and the breaking strength of sample after processing is 29MPa, and elongation at break is 480%, and the water vapor transmission rate of the prepared thickness 25 μm film is 80g / ( m 2 day), the oxygen transmission rate is 35mL / (m 2 ·day·atm), the degradation rate of th...

Embodiment 2

[0037] 0.3mol thiophenedicarboxylic acid, 0.7mol sebacic acid, 0.1mol butanediol, 0.5mol 2,2'-thiodiglycol, 0.9mol 2-ethyl-2-butyl-propanediol, 0.15mmol titanate Butyl ester was added into the reaction kettle, under nitrogen protection, the temperature was raised to 210°C with stirring, and the reaction was carried out for 3 hours. Then the temperature was raised to 230° C., pre-condensed under low vacuum for 1 hour, and then 0.2 mmol of n-butyl titanate was added. The temperature was raised to 245° C., the vacuum was gradually evacuated to 50 Pa, and the polycondensation was carried out for 3 hours to obtain the product. The intrinsic viscosity of product is 1.28dL / g, and terminal carboxyl group is 15mol / t, and the breaking strength of sample after processing is 18MPa, and elongation at break is 680%, and the water vapor transmission rate of the thickness 25 μm film of preparation is 70g / ( m 2 ·day), the oxygen transmission rate is 25mL / (m 2 ·day·atm), the degradation rate...

Embodiment 3

[0039] Add 1 mol of succinic acid, 0.8 mol of butanediol, 0.2 mol of 2,2'-thiodiglycol, 0.5 mol of 2-ethyl-2-butyl-propylene glycol, and 0.15 mmol of n-butyl titanate into the reaction kettle, Under nitrogen protection, the temperature was raised to 190° C. with stirring, and the reaction was carried out for 3 hours. Then the temperature was raised to 230° C., pre-condensed under low vacuum for 1 hour, and then 0.2 mmol of n-butyl titanate was added. The temperature was raised to 245° C., the vacuum was gradually evacuated to 50 Pa, and the polycondensation was carried out for 3 hours to obtain the product. The intrinsic viscosity of product is 1.21dL / g, and terminal carboxyl group is 18mol / t, and the breaking strength of sample after processing is 17MPa, and elongation at break is 760%, and the water vapor transmission rate of the thickness 25 μm film of preparation is 91g / ( m 2 ·day), the oxygen transmission rate is 45mL / (m 2 ·day·atm), the degradation rate of the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com