Preparation method of thiodiethanethiol

A technology of thiodiglycol thiol and thiodiglycol, which is applied in the preparation of thioether, organic chemistry, etc., can solve the problems of high waste water treatment cost, large amount of waste water generation, low atom utilization rate, etc., and achieve easy operation , sufficient reaction and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

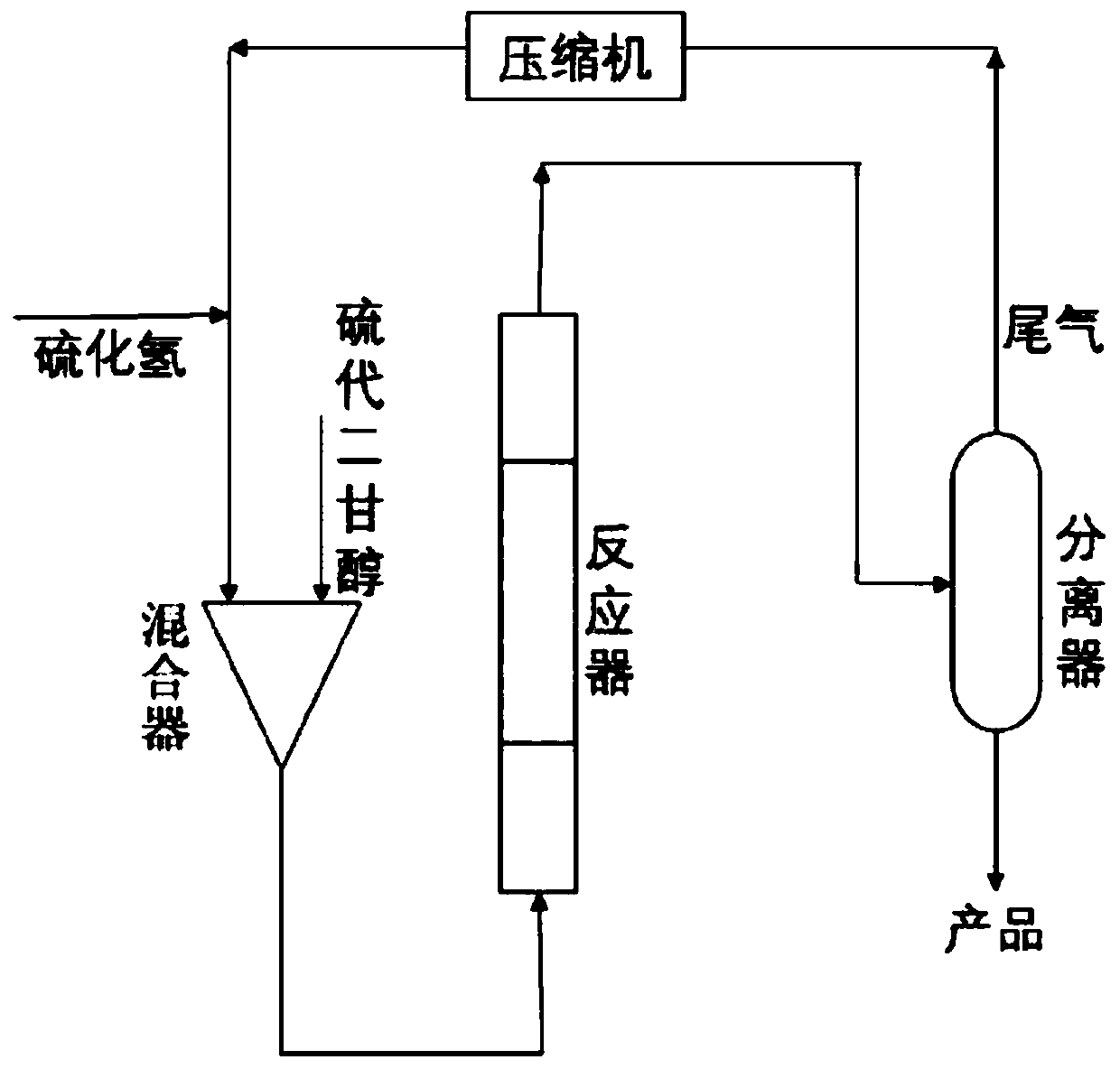

Method used

Image

Examples

Embodiment 1

[0020] Fill the fixed bed reactor with 20ml of prepared cobalt catalyst, fill evenly, connect the pipeline, open the hydrogen sulfide cylinder, control the pressure to 0.6MPa through the pressure reducing valve, and control the flow rate to 20L / h (the space velocity is 1000h -1 ), replaced for 10 minutes, opened the thiodiglycol feed pump, and the flow control was 21.8g / hour (the mol ratio of hydrogen sulfide to thiodiglycol was 5), and the reaction temperature was controlled by the reactor jacket to be 120°C. Sampling was started after 60 minutes of reaction, and the detected product content was 99.6%, and the product yield from the first hour to the second hour was 98.6%.

Embodiment 2

[0022] Fill the fixed-bed reactor with 20ml of prepared molybdenum catalyst, fill evenly, connect the pipeline, open the hydrogen sulfide cylinder, control the pressure to 0.2MPa through the pressure reducing valve, and control the flow rate to 20L / h (the space velocity is 1000h -1 ), replaced for 10 minutes, opened the thiodiglycol feed pump, and the flow control was 21.8g / hour (the mol ratio of hydrogen sulfide to thiodiglycol was 4), and the reaction temperature was controlled by the reactor jacket to be 120°C. Sampling was started after 60 minutes of reaction, the detected product content was 99.0%, and the product yield from the first hour to the second hour was 97.2%.

Embodiment 3

[0024] Fill the cobalt and molybdenum catalyst prepared by 20ml in the fixed-bed reactor, fill evenly, connect the pipeline, open the hydrogen sulfide cylinder, control the pressure to be 0.6MPa through the pressure reducing valve, flow control 40L / h (space velocity is 2000h -1 ), replacement for 10 minutes, open the thiodiglycol feed pump, flow control is 43.6g / hour (hydrogen sulfide and thiodiglycol mol ratio is 5), the reaction temperature is 120 ℃ by reactor jacket control, Sampling began after 60 minutes of reaction, and the detected product content was 98.7%, and the product yield from the first hour to the second hour was 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com