Sound-absorbing cotton material and preparation method thereof

A technology of sound-absorbing cotton and acid-absorbing agent, applied in the field of automobile sound-absorbing materials, can solve the problems of insoluble, difficult to achieve the degree of blending, poor anti-oxidation performance, etc. The effect of yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

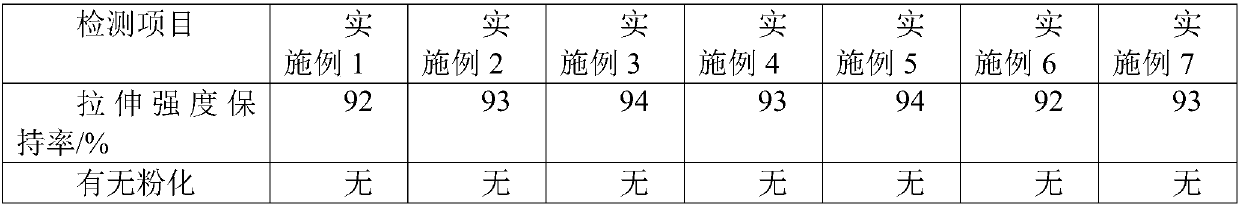

Examples

Embodiment 1

[0032] A sound-absorbing cotton material, comprising the following components in parts by weight: 100 parts of polypropylene, 0.05 part of α-tocopherol, 0.05 part of bis(2,4-di-p-isopropylphenyl) pentaerythritol bisphosphite, hard 0.02 parts of calcium stearate, 0.05 parts of thiodiethylene glycol distearate.

Embodiment 2

[0034] A sound-absorbing cotton material, comprising the following components in parts by weight, 100 parts of polypropylene, 0.05 part of α-tocopherol, 0.5 part of bis(2,4-di-p-isopropylphenyl) pentaerythritol bisphosphite, hard Zinc fatty acid 0.03 part, sodium metaaluminate 0.1 part, thiodiethylene glycol distearate 0.05 part.

Embodiment 3

[0036]A sound-absorbing cotton material, comprising the following components in parts by weight, 100 parts of polypropylene, 0.5 parts of triethylene glycol bis[3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate] Parts, 1 part of (2,4,6-tri-tert-butylphenyl-2-butyl-2-ethyl)-1,3-propanediol phosphite, 0.04 parts of zinc stearate, 0.2 parts of sodium metaaluminate part, 0.1 part of dioctadecyl thiodipropionate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com