Bearing used for automobile oil-free air compressor

A technology of oil-free air compressors and bearings, applied in bearings, bearing components, shafts and bearings, etc., can solve problems such as bearing failure, low equipment compression efficiency, noise, etc., achieve strong working performance, reduce noise, and achieve reliability and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

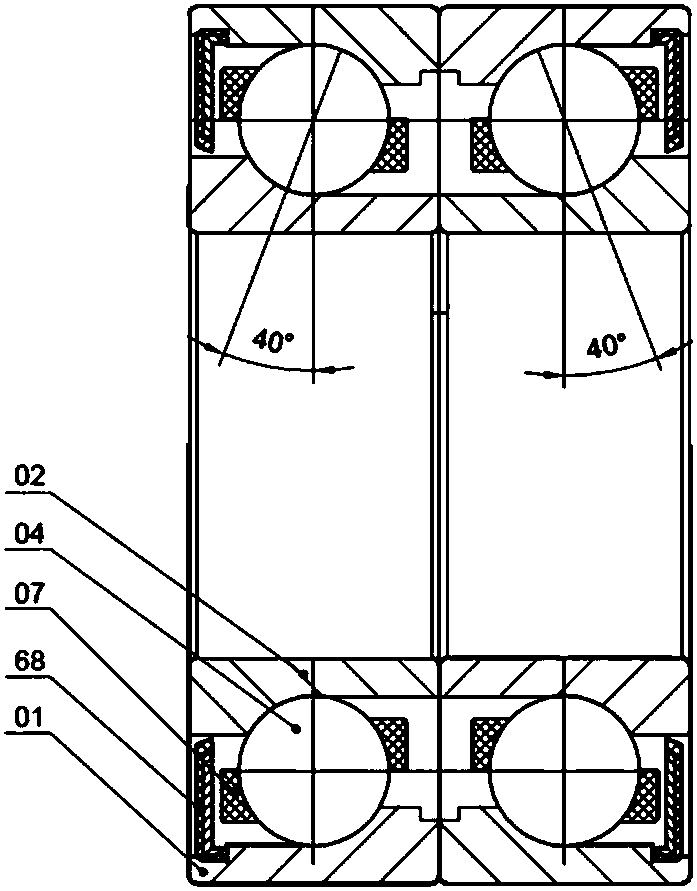

[0028] Such as figure 1 As shown, a bearing for an automobile oil-free air compressor includes two sets of angular contact ball bearing bodies, the two sets of angular contact ball bearing bodies are arranged back to back, sealing rings are provided on both sides of the bearing, and lubricants are filled inside.

[0029] The bearing includes two outer rings 01, two inner rings 02, several steel balls 04, a cage 07, a sealing ring 68, and a certain amount of grease. 07 Divide it evenly on the entire channel. The inner ring is set on the inner side of the steel ball circumference. After configuration, there are sealing rings on both sides of the outer ring. The sealing ring is relatively fixed to the outer ring and rotates relative to the inner ring. The inside of the bearing is filled with grease.

[0030] The sealing ring is arranged on both sides of the outer ring. The angular contact ball bearing body adopts a contact angle of 40 degrees. Ribs are provided on the outer rin...

Embodiment 2

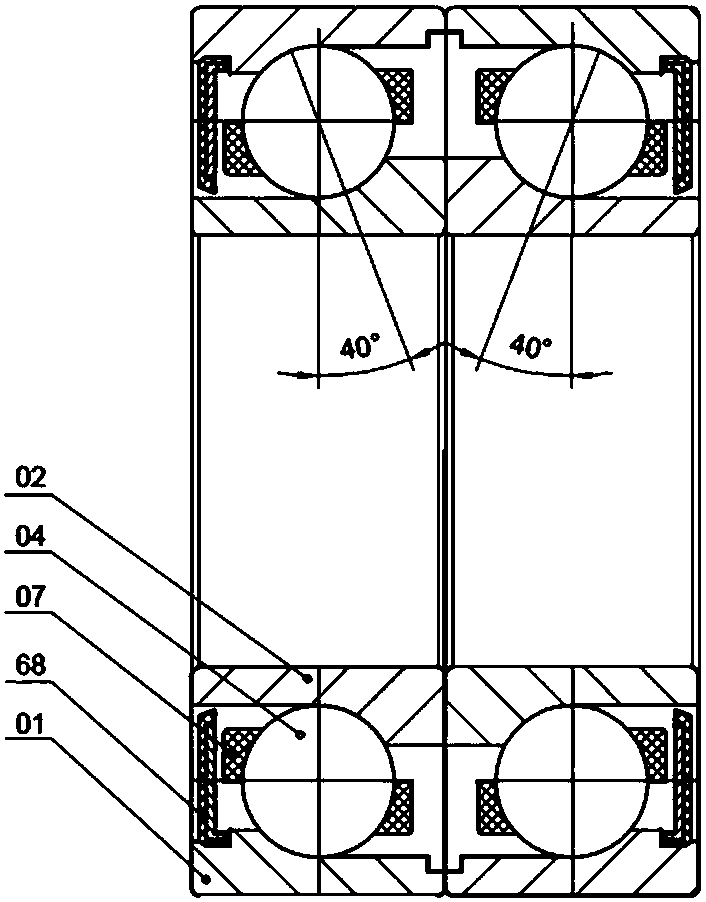

[0033] Such as figure 2 As shown, a bearing for an automobile oil-free air compressor includes two sets of angular contact ball bearing bodies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com