Low-expansion-coefficient insulating medium slurry and preparation method thereof

A low expansion coefficient, insulating medium technology, applied in the field of electronic materials, can solve the problems of rapid decline in glass comprehensive performance, difficulty in achieving low sintering temperature, and high processing temperature, and achieve excellent adhesion fastness and good acid and alkali corrosion resistance , the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

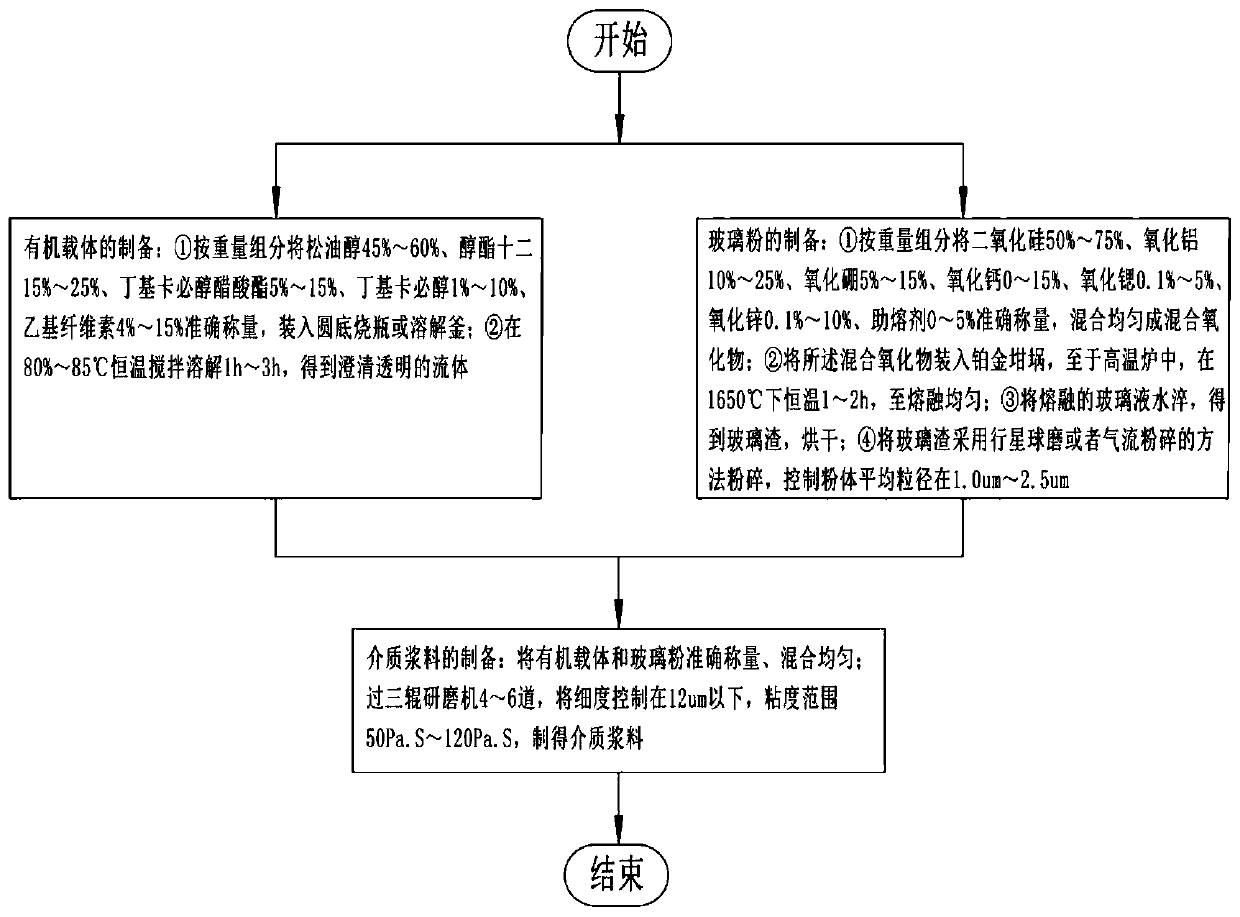

Method used

Image

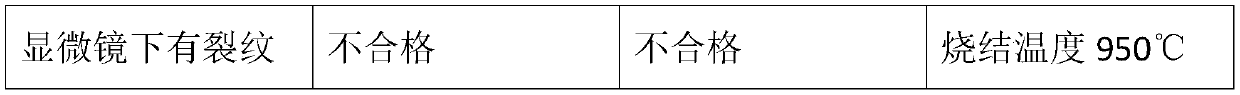

Examples

Embodiment 1

[0046] A low expansion coefficient insulating medium slurry and a preparation method thereof, the preparation steps are as follows:

[0047]a. Preparation of organic carrier: 1. by weight components, terpineol 60%, alcohol ester twelve 15%, butyl carbitol acetate 10%, butyl carbitol 7%, ethyl cellulose 8% Accurately weigh and put into a round bottom flask or dissolution kettle; ② Stir and dissolve at a constant temperature of 80-85°C for 3 hours to obtain a clear and transparent fluid;

[0048] b. Preparation of glass powder: ① mix silicon dioxide (SiO2) by weight component 2 )63%, alumina (Al 2 o 3 )18%, boron oxide (B 2 o 3 ) 9%, Calcium Oxide (CaO) 7%, Strontium Oxide (SrO) 1.5%, Zinc Oxide (ZnO) 1.5%, accurately weighed, and mixed evenly to form a mixed oxide; ②Put the mixed oxide into a platinum crucible , as for the high-temperature furnace, keep the temperature at 1650°C for 1 hour until the melting is uniform; ③ water quench the molten glass to obtain glass slag, ...

Embodiment 2

[0056] A low expansion coefficient insulating medium slurry and a preparation method thereof, the preparation steps are as follows:

[0057] a. Preparation of organic carrier: 1. by weight components, terpineol 55%, alcohol ester twelve 15%, butyl carbitol acetate 15%, butyl carbitol 7%, ethyl cellulose 8% Accurately weigh and put into a round bottom flask or dissolution kettle; ② Stir and dissolve at a constant temperature of 80-85°C for 3 hours to obtain a clear and transparent fluid;

[0058] b. Preparation of glass powder: ① mix silicon dioxide (SiO2) by weight component 2 )62%, alumina (Al 2 o 3 )17%, boron oxide (B 2 o 3 ) 10%, Calcium Oxide (CaO) 9%, Strontium Oxide (SrO) 0.5%, Zinc Oxide (ZnO) 1.5%, accurately weighed, and mixed evenly to form a mixed oxide; ②Put the mixed oxide into a platinum crucible , as for the high-temperature furnace, keep the temperature at 1650°C for 1 hour until the melting is uniform; ③quench the molten glass liquid with water to obtain...

Embodiment 3

[0065] A low expansion coefficient insulating medium slurry and a preparation method thereof, the preparation steps are as follows:

[0066] a. Preparation of organic carrier: 1. by weight components, terpineol 55%, alcohol ester twelve 15%, butyl carbitol acetate 16%, butyl carbitol 2%, ethyl cellulose 12% Accurately weigh and put into a round bottom flask or dissolution kettle; ② Stir and dissolve at a constant temperature of 80-85°C for 3 hours to obtain a clear and transparent fluid;

[0067] b. Preparation of glass powder: ① mix silicon dioxide (SiO2) by weight component 2 )74%, alumina (Al 2 o 3 )3%, boron oxide (B 2 o 3 ) 10%, calcium oxide (CaO) 9%, strontium oxide (SrO) 1%, flux 3%, accurately weighed, mixed evenly to form a mixed oxide; ② put the mixed oxide into a platinum crucible, and In the furnace, keep the temperature at 1650°C for 1 hour until the melting is uniform; ③quench the molten glass with water to obtain glass slag, and dry it; ④use the planetary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com