Bonding agent and electro-optic assembly and electrophoretic medium thereof

An electro-optical and adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, film/sheet adhesives, etc., can solve the mechanical and electrical properties of polyester-based urethane emulsions. Medium, change the electrical properties of urethane emulsion, the electrical properties are not suitable for electro-optical displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

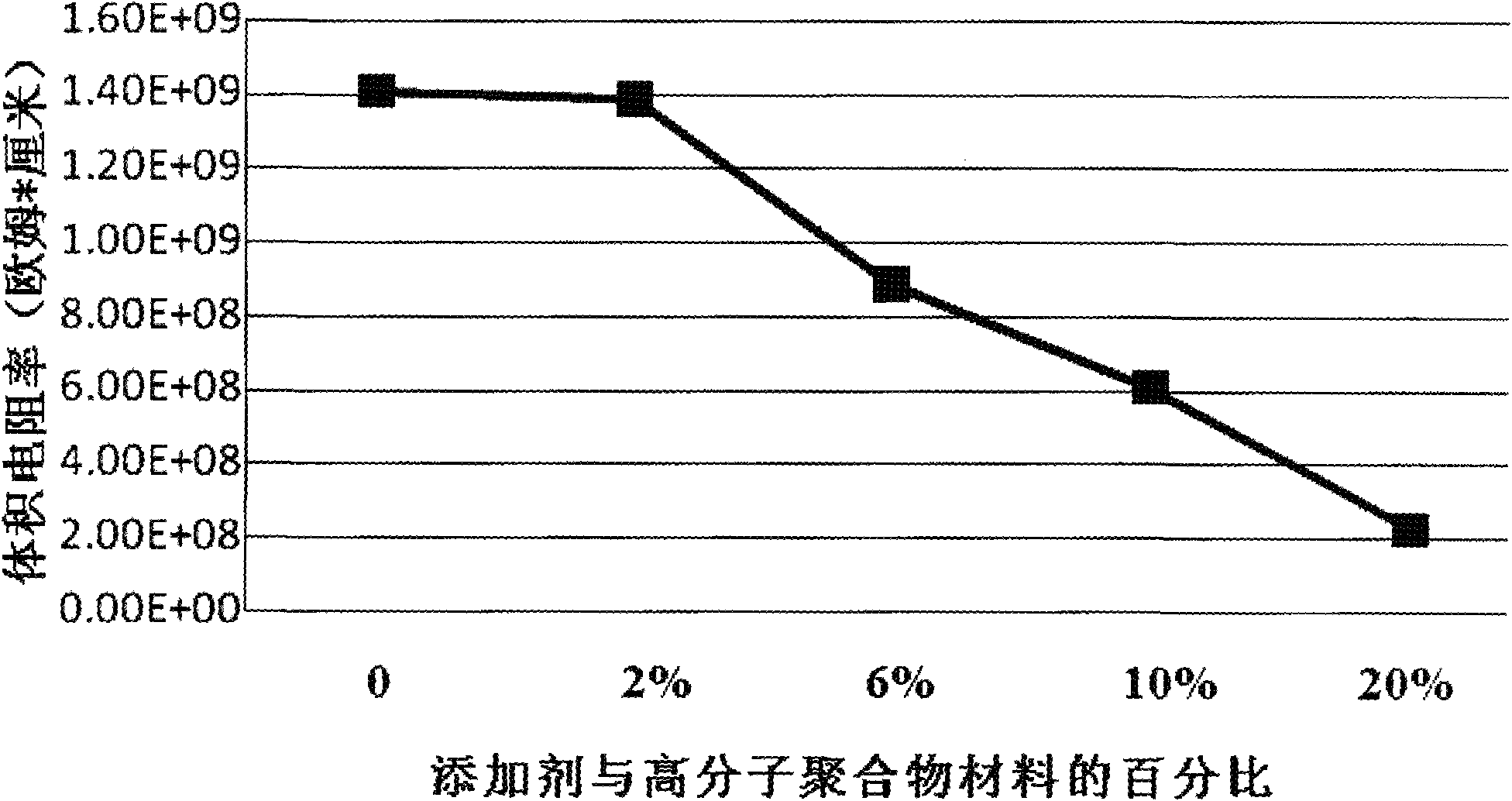

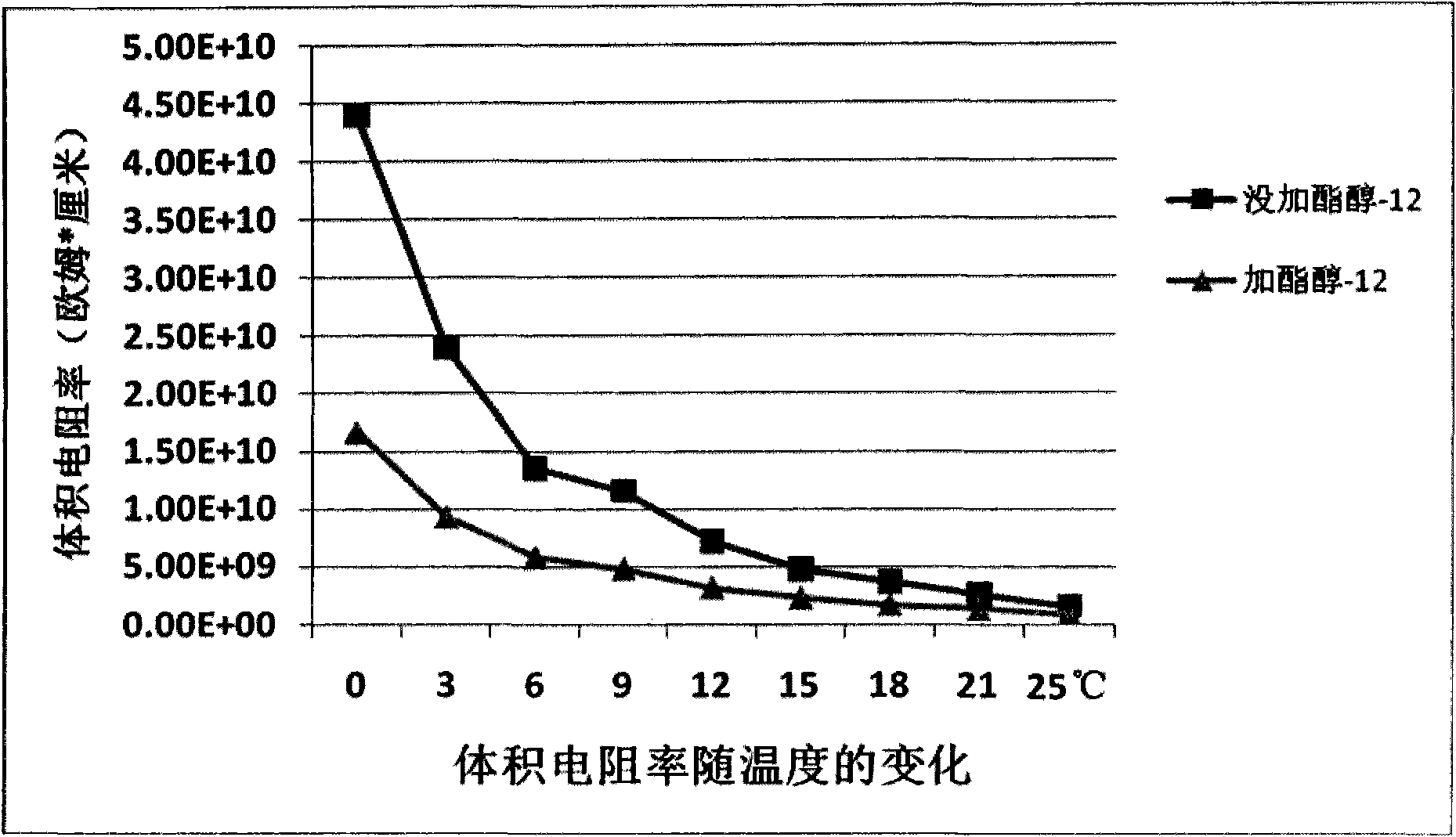

[0150] Example 1: Mixtures and performance tests comprising polymeric binder materials and additives

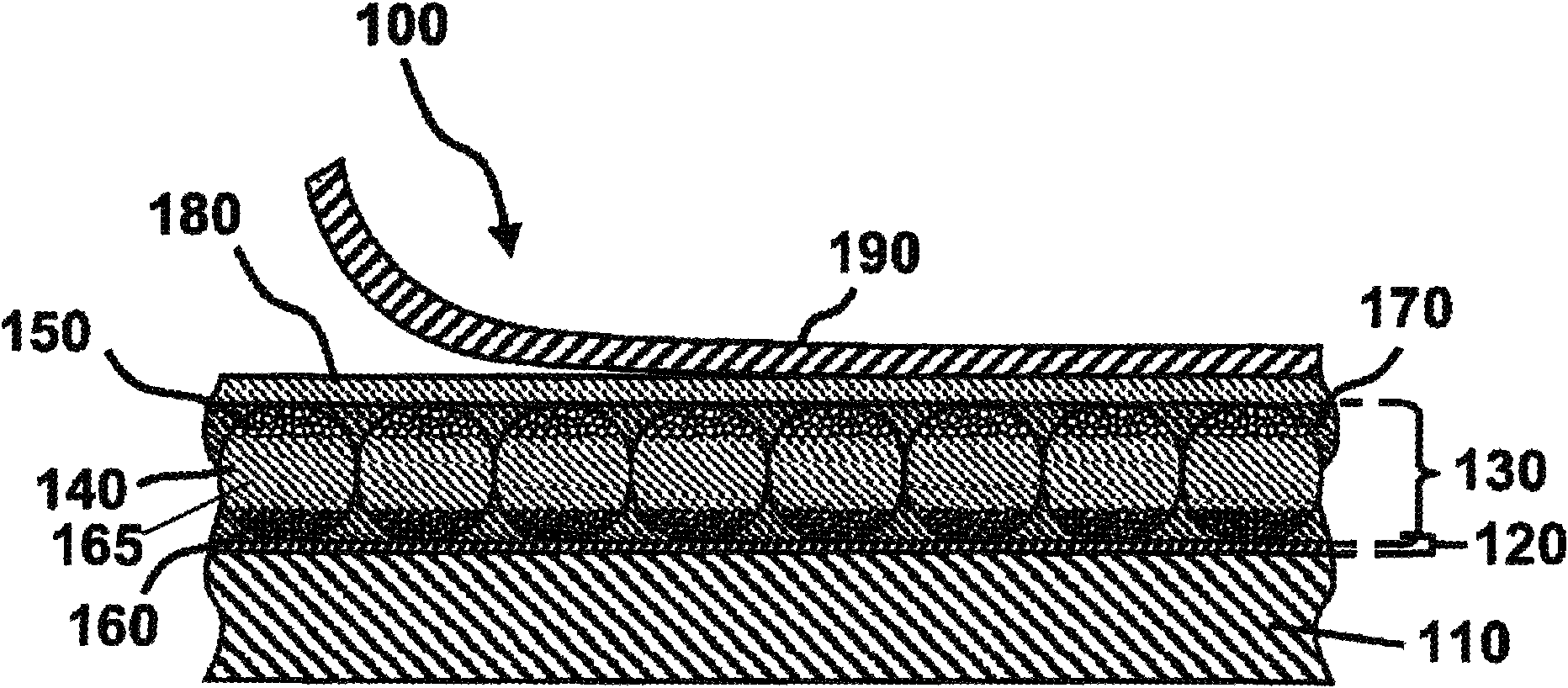

[0151] Weigh 100g of pre-prepared water-based polyurethane emulsion (polyurethane content is 50% (w / v)), add 3g of alcohol ester-12 into the water-based polyurethane emulsion, mix at a stirring speed of 250rpm, and mix for 1h. The mixture can be used for electronic Adhesive material for paper assembly, ie, material for lamination adhesive layer 180 (6 weight percent alcohol ester-12 to polyurethane). Tests were similarly performed with other amounts of alcohol ester-12.

[0152] After the mixture is prepared through the above method steps, the mixture (as the material for the lamination adhesive layer 180) can be accurately coated or printed on the electrophoretic ink layer (that is, the optical layer 130) by using a coating machine, and then heated and cured to obtain Electrophoretic display material layers. Then, the electrophoretic display material layer and the ITO cond...

Embodiment 2

[0160] Example 2: Mixtures and performance tests comprising polymeric binder materials and additives

[0161] Weigh 100g of pre-prepared water-based polyurethane emulsion (polyurethane content is 50% (w / v)), add 3g of propylene glycol into the water-based polyurethane emulsion, mix at a stirring speed of 250rpm, and mix for 1h. The mixture can be used for electronic paper assembly Adhesive material, that is, the material for the lamination adhesive layer 180 (the weight percentage of propylene glycol to polyurethane is 6%). Tests were similarly performed with other amounts of propylene glycol.

[0162] After the mixture is prepared through the above method steps, the mixture (as the material for the lamination adhesive layer 180) can be accurately coated or printed on the electrophoretic ink layer (that is, the optical layer 130) by using a coating machine, and then heated and cured to obtain Electrophoretic display material layers. Then, the electrophoretic display material...

Embodiment 3

[0170] Example 3: Mixtures and performance tests comprising polymeric binder materials and additives

[0171] Take by weighing 100g pre-prepared aqueous polyurethane emulsion (polyurethane content is 50% (w / v)), 5g alcohol ester-12 and 0.5g polystyrene copolymerized maleic anhydride sodium salt are added in aqueous polyurethane emulsion, the stirring speed of 250rpm Mixing is carried out, and the mixture after mixing for 1 hour can be used as an adhesive material for electronic paper assembly, that is, as a material for the lamination adhesive layer 180 (the weight percentage of propylene glycol to polyurethane is 6%). Tests were similarly performed with other amounts of propylene glycol.

[0172] After the mixture is prepared through the above method steps, the mixture (as the material for the lamination adhesive layer 180) can be accurately coated or printed on the electrophoretic ink layer (that is, the optical layer 130) by using a coating machine, and then heated and cure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com