Solar energy reflecting heat-insulation coating and preparation method thereof

A heat-reflecting heat-insulating coating and solar energy technology, applied in the field of coatings, can solve the problems of unsatisfactory heat-insulating effect and decline in comprehensive performance such as acid and alkali resistance and salt spray resistance, and achieve good acid and alkali resistance and good heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

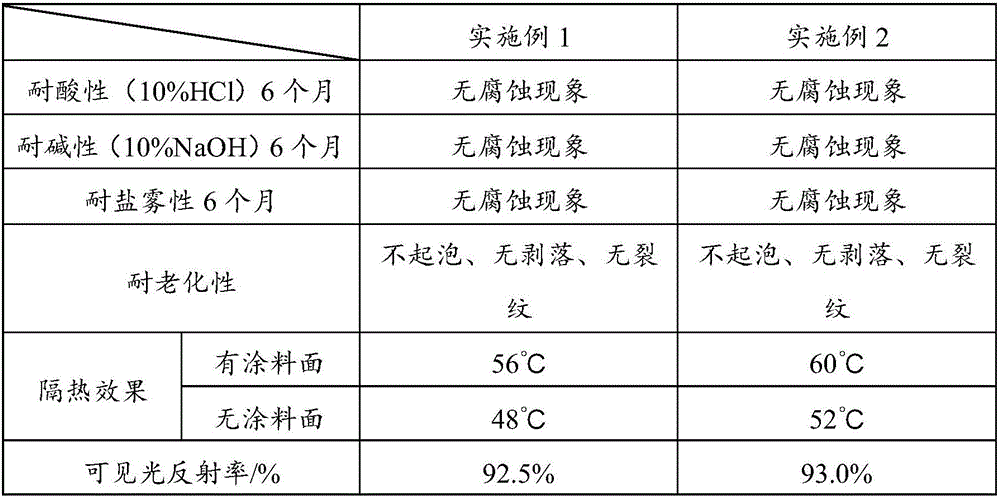

Examples

Embodiment 1

[0020] Recipe: 3 parts of Aladdin's mesoporous silica powder MCM-41; 1 part of nanoscale titanium dioxide; 16 parts of Dow solid epoxy resin DER671; 12 parts of steralnium chloride hectorite: 3 parts of zinc stearate ; 3 parts calcium stearate; 1 part hydroxypropyl guar gum; 2 parts hydroxypropyl methylcellulose; 4 parts potassium tripolyphosphate; 7 parts butyl carbitol; 8 parts calcium silicate; 6 parts silicon aluminum acid; 11 parts of melamine formaldehyde resin powder; 1 part of 2-aminobenzenethiol; 0.3 parts of γ-aminopropyltriethoxysilane; 14 parts of methyl isobutyl ketone; 15 parts of toluene; 8 parts of xylene.

[0021] Preparation:

[0022] 1) taking each raw material for subsequent use;

[0023] 2) Disperse mesoporous silica powder MCM-41, nano-scale titanium dioxide, and Dow solid epoxy resin DER671 using high-speed mixing and shearing machine A;

[0024] 3) Add methyl isobutyl ketone, toluene, and xylene to the high-speed mixing shear machine A and heat up to ...

Embodiment 2

[0029] 2 parts Aladdin's mesoporous silica powder MCM-41; 2 parts nanoscale titanium dioxide; 17 parts Dow solid epoxy resin DER671; Parts calcium stearate; 2 parts hydroxypropyl guar gum; 3 parts hydroxypropyl methylcellulose; 5 parts potassium tripolyphosphate; 8 parts butyl carbitol; 9 parts calcium silicate; 7 parts aluminum silicate ; 12 parts of melamine formaldehyde resin powder; 2 parts of 2-aminobenzenethiol; 0.5 parts of γ-aminopropyltriethoxysilane; 15 parts of methyl isobutyl ketone; 16 parts of toluene; 9 parts of xylene.

[0030] Preparation method is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com