Water-based circuit board cleaning agent and preparation method thereof

A circuit board cleaning agent, water-based technology, applied in the field of washing, can solve problems such as difficulty in controlling costs, potential safety hazards, loss of effect, etc., and achieve the effects of convenient and simple use, long cleaning cycle, and large chelation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

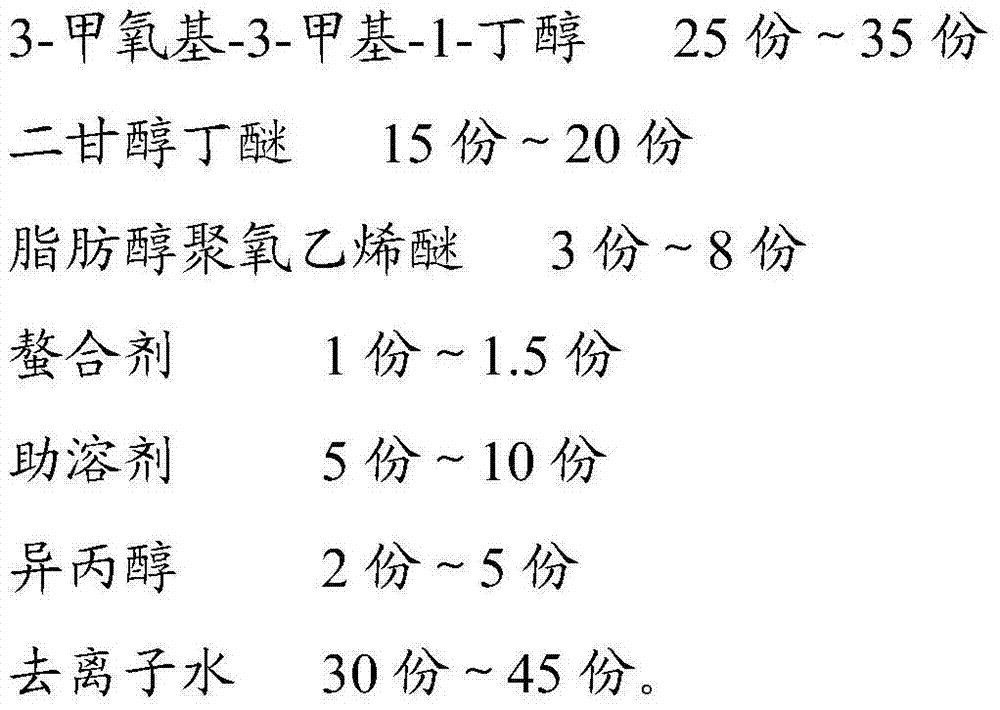

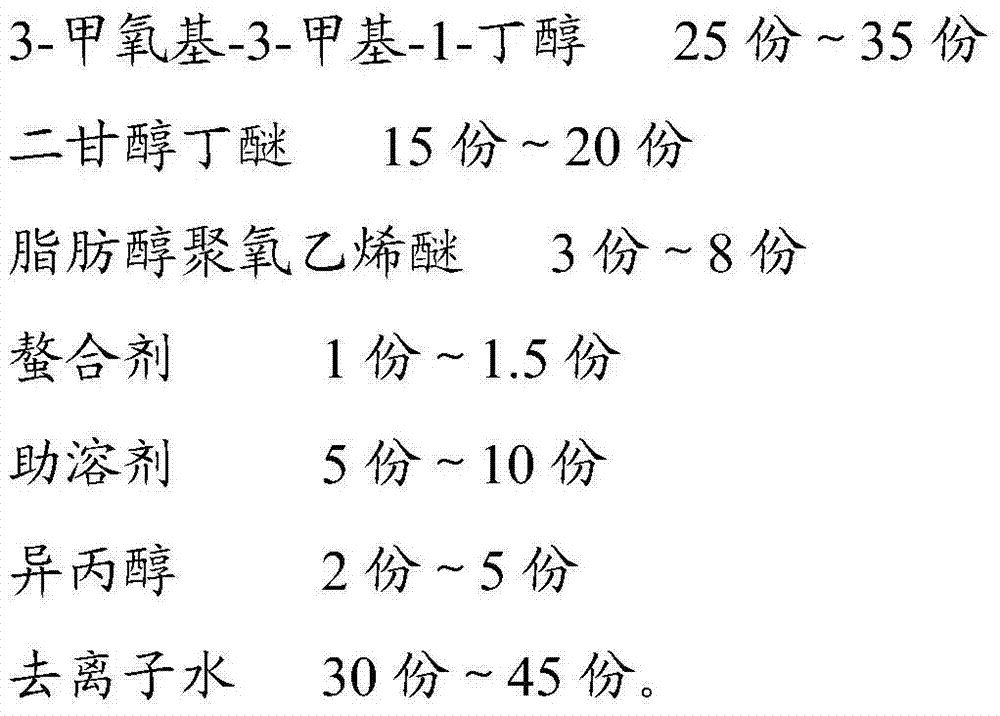

[0044] A preparation method of an aqueous circuit board cleaning agent, in parts by weight, the preparation method comprises the steps of:

[0045] (1) Mix 1-1.5 parts of chelating agent with 30-45 parts of deionized water, heat to 40°C-45°C, and stir for 6-12 minutes;

[0046] (2), cooling to 28 ℃ ~ 31 ℃;

[0047] (3) Add 3 to 8 parts of fatty alcohol polyoxyethylene ether, control the addition speed of fatty alcohol polyoxyethylene ether to 0.05 parts / min, and keep stirring;

[0048] (4) Add 3-7 parts of co-solvent, and then add 25-35 parts of 3-methoxy-3-methyl-1-butanol;

[0049] (5), continue to add 15 to 20 parts of diethylene glycol butyl ether, and then add 2 to 3 parts of co-solvent;

[0050] (6) Add 2 to 5 parts of isopropanol, continue stirring for 1 hour, and let stand for 10 to 15 minutes to obtain a transparent solution.

[0051] The pH value of the transparent solution obtained in the above step (6) is pH 7-7.5. Keep the pH of the product neutral, mild in na...

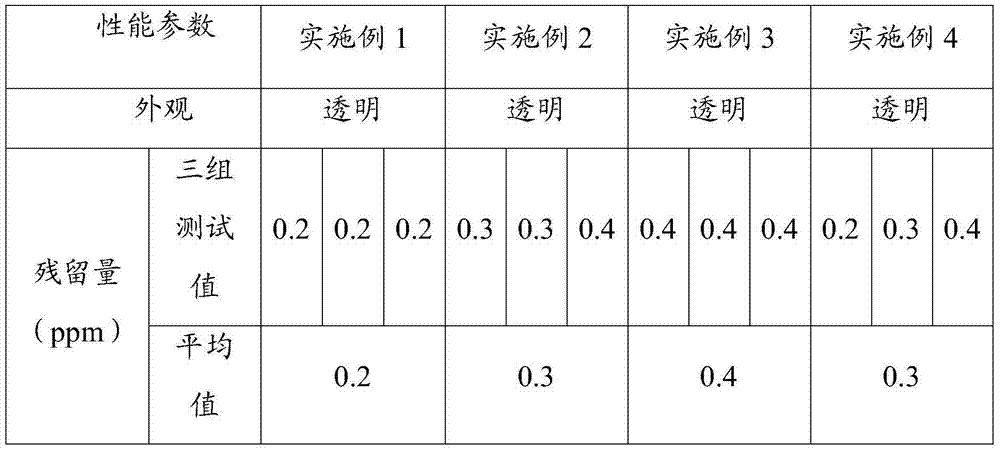

Embodiment 1

[0054] This preparation method comprises the steps:

[0055] (1) Take 1kg of sodium gluconate as a chelating agent, mix it with 45kg of deionized water, heat to 40°C, and stir for 6 minutes;

[0056] (2) Cool to 29°C;

[0057] (3) Add 3kg fatty alcohol polyoxyethylene ether, control the addition speed of fatty alcohol polyoxyethylene ether to 50g / min, and keep stirring;

[0058] (4) Add 3kg of triethanolamine as co-solvent, then add 25kg of 3-methoxy-3-methyl-1-butanol;

[0059] (5), continue to add 19kg of diethylene glycol butyl ether, and then add 2kg of co-solvent triethanolamine;

[0060] (6) Add 2kg of isopropanol, continue stirring for 1 hour, and let stand for 10 minutes to obtain a transparent solution.

[0061] Test the pH value of the transparent solution obtained in the above step (6), and adjust its final pH value to pH 7.0. Moreover, in step (3) to step (6), the reaction temperature is always controlled at 28° C. to 30° C., and the whole process is carried ou...

Embodiment 2

[0063] This preparation method comprises the steps:

[0064] (1) Take 1.5kg of ethylenediaminetetraacetic acid as a chelating agent, then mix it with 30kg of deionized water, heat to 45°C, and stir for 12 minutes;

[0065] (2) Cool to 31°C;

[0066] (3) Add 8kg fatty alcohol polyoxyethylene ether, control the addition speed of fatty alcohol polyoxyethylene ether to 50g / min, and keep stirring;

[0067] (4) Add 7kg of acetamide as co-solvent, then add 30.5kg of 3-methoxy-3-methyl-1-butanol;

[0068] (5), continue to add 15kg of diethylene glycol butyl ether, and then add 3kg of co-solvent acetamide;

[0069] (6) Add 5kg of isopropanol, continue stirring for 1 hour, and let stand for 15 minutes to obtain a transparent solution.

[0070] Test the pH value of the transparent solution obtained in the above step (6), and adjust its final pH value to pH 7.5. Moreover, in step (3) to step (6), the reaction temperature is always controlled at 30° C. to 31° C., and the whole process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com