Inkjet printing method, inkjet ink, ink cartridge, and colored fabric

An inkjet printing and inkjet ink technology, which is applied to ink cartridges and colored cloth, inkjet printing methods, and inkjet ink fields, can solve the problems of thickening of pigment ink, hardening of colored cloth, and poor operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

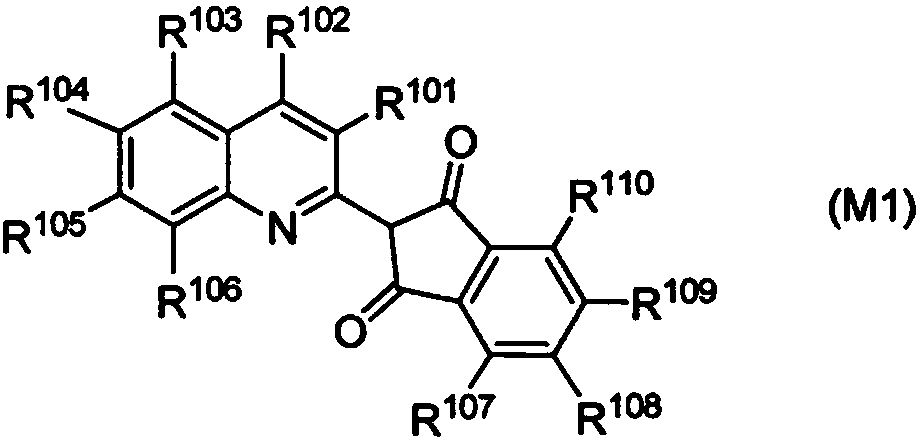

[0561] [Synthesis of Dye Polymer (Y-1-1)]

[0562] Exemplary compound (Y-1-1) was synthesized by the following scheme.

[0563] [chemical formula 65]

[0564]

[0565] 10 mL of N-methylpyrrolidone (NMP) was added to a 100 mL three-necked flask, and the internal temperature was raised to 85°C. To the above NMP, 9.0 g of the polymerizable monomer YM-1 (synthesized by the method described in Japanese Patent No. 5315267 ), 1.0 g of the polymerizable monomer MOI-BP ( Manufactured by Showa Denko K.K., trade name: Karenz MOI-BP), 0.98 g of V-601 (manufactured by Wako Pure Chemical Industries, Ltd., trade name) and 0.35 g of 1-dodecanethiol were dissolved in 13.24 g of NMP The resulting solution. After completion|finish of dripping, it was made to react at 85 degreeC for 1 hour, and the reaction liquid A was obtained. Then, V-601 (0.098g) was added to the reaction liquid A, and it was made to react at 85 degreeC for 2 hours, and the reaction liquid B was obtained. The reaction s...

Synthetic example 2

[0567] [Synthesis of Dye Polymer (Y-2-1)]

[0568] Exemplary compound (Y-2-1) was synthesized by the following scheme.

[0569] [chemical formula 66]

[0570]

[0571] Regarding the exemplary compound (Y-2-1), the MOI-BP (manufactured by Showa Denko K.K., trade name: Karenz MOI-BP) used in the synthesis of the exemplary compound (Y-1-1) of the above synthesis example 1 Change to methacrylic acid (MAA), and change the amount of V-601 (manufactured by Wako Pure Chemical Industries, Ltd., trade name) in the solution dropwise with the polymerizable monomer from 0.98 g to 0.126 g, and It synthesized in the same manner except having changed the quantity of 1-dodecanethiol from 0.35 g to 0.443 g. The maximum absorption wavelength of the ultraviolet-visible absorption spectrum of the exemplary compound (Y-2-1) in tetrahydrofuran (THF) dilute solution is 441 nm. And, the weight average molecular weight (Mw) by GPC measurement was 10,500 (polystyrene conversion). The Tg of the po...

Synthetic example 3

[0573] [Synthesis of Dye Polymer (R-2-1)]

[0574] Exemplary compound (R-2-1) was synthesized by the following scheme.

[0575] [chemical formula 67]

[0576]

[0577] Regarding the exemplary compound (R-2-1), YM-1 used in the synthesis of the exemplary compound (Y-1-1) in Synthesis Example 1 above was changed to RDW R-13 (Wako Pure Chemical Industries, Ltd. manufactured, trade name), and MOI-BP (manufactured by Showa Denko K.K., trade name: Karenz MOI-BP) was changed to 2-ethylhexyl methacrylate (EHMA), and the polymerizable monomer was added dropwise The amount of V-601 (manufactured by Wako Pure Chemical Industries, Ltd., trade name) in the solution was changed from 0.98 g to 0.057 g, and the amount of 1-dodecanethiol was changed from 0.35 g to 0.200 g, and It synthesized in the same manner except having changed NMP into propylene glycol-1-monomethyl ether-2-acetate (PGMEA). The maximum absorption wavelength of the ultraviolet-visible absorption spectrum of the exempl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com