Drum-type hydraulic double-reinforcement shoe anchor pin type brake

A brake and hydraulic technology, applied in the direction of hydraulic drum brakes, brake parts, slack adjusters, etc., can solve the problems of unguaranteed safety, bulky, easy to deform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

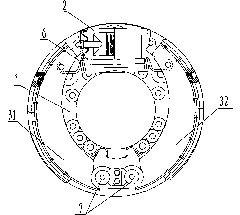

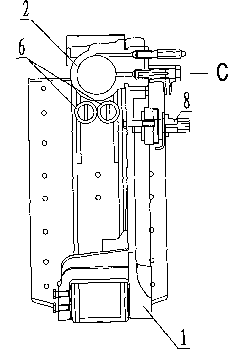

[0020] Such as figure 1 figure 2 A drum-type hydraulic double tendon shoe pin-type brake is shown, including a bracket 1, a hydraulic cylinder 2 fixed on the bracket 1, and left and right brake shoes 31, 32 symmetrically arranged on the bracket 1 , The left and right brake shoes 31,32 are double rib type brake shoes, and the slave cylinder 2 is covered with a slave cylinder dust cover.

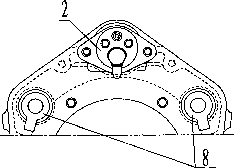

[0021] Such as Figure 4 Figure 5 As shown, the left and right brake shoes 31, 32 have brake shoe skeletons, and the brake shoe skeletons are fixed by spot welding of two parallel steel rib plates 4 and steel curved panels 5 respectively, and the two rib plates 4 is also fixed with a side plate respectively, and the outer side of the curved panel 5 is fixed with a friction plate with a rivet. Therefore, the manufactured brake shoe has high rigidity and fastness, the manufacturing process is simplified, and the production cost is reduced.

[0022] Such as figure 1 figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com